One of the most important aspects of safety, reliability, correct operation of electrical power lines, installations, devices, etc., is high-quality insulation. Many people who are far from electrical engineering issues take it for granted. That is, there is insulation - and it’s nice, it means everything is normal, and you can use electricity without fear. Meanwhile, this is a serious misconception.

Firstly, ideal dielectrics simply do not exist. Secondly, even the most reliable insulation can lose its qualities over time - burn out, melt, crack, begin to crumble, and suffer mechanical damage. Thirdly, its dielectric qualities are also affected by external factors - dampness, air humidity, surface contamination and others.

How to use a megohmmeter

So monitoring the state of insulation is no less important than all other components of electrical installations. No facility can be put into operation until the insulation resistance has been verified to comply with existing standards. And for such control measurements, special devices called megohmmeters (or megohmmeters) are used. In everyday life, owners of houses and apartments rarely encounter them. And many do not even suspect the existence of such control and measuring devices. Meanwhile, one way or another, it is necessary to monitor the condition of your electrical network. Therefore, it seems that information on how to use a megohmmeter will be useful to everyone.

Measuring insulation resistance with a megohmmeter

Despite the fact that the megohmmeter is considered a professional measuring device, in some cases it can also be in demand at home. For example, when you need to check the condition of electrical wiring. Using a multimeter for this purpose will not allow you to obtain the necessary data; at most, it can detect the problem, but not determine its scale. That is why measuring insulation resistance with a megohmmeter remains the most effective test method; this is described in detail in our article.

Types of megohmmeters

Today there are two types of megohmmeters on the market: analog and digital:

- Analog (pointer megohmmeter). The main feature of the device is the built-in generator (dynamo), launched by rotating the handle. Analog instruments are equipped with a scale with an arrow. Insulation resistance is measured through magnetoelectric action. The pointer is attached to an axis with a frame coil, which is influenced by the field of a permanent magnet. When current moves through the frame coil, the needle deviates by an angle, the magnitude of which depends on the force and voltage. This type of measurement is possible thanks to the laws of electromagnetic induction. The advantages of analog devices include their simplicity and reliability, the disadvantages are their heavy weight and significant size.

- Digital (electronic megohmmeter). The most common type of meters. Equipped with a powerful pulse generator operating using field-effect transistors. Such devices convert alternating current into direct current; the current source can be a battery or a network. The measurements themselves are carried out by comparing the voltage drop in the circuit with the resistance of the standard using an amplifier. The measurement results are displayed on the device screen. Modern models provide a function for storing results in memory for further comparison of data. Unlike an analog megohmmeter, an electronic one has compact dimensions and light weight.

SELECTION OF MEGA OHMMETER - COMPARISON TABLE

Currently, on the market of measuring instruments, there are many different megohmmeters , or, as they are also called, insulation resistance meters. They all differ in their parameters, as well as in their price category. We have prepared this table for you to make choosing a megohmmeter a little easier. The table is compiled from the main technical characteristics. Let's look at each of them.

The test voltage generated by the device can vary from 50 to 10,000 volts. The only megohmmeter that covers the entire range of test voltages is MI 3200 . Other devices generate a certain voltage range.

The principle of generating test voltage : megohmmeters : - With a built-in mechanical generator

— Battery powered

-Battery power supply.

All types have both their pros and cons. Let's look at them:

Megaohmmeters with a built-in generator have a big advantage, such as operation at very low temperatures and for any amount of time, because voltage is generated manually. The disadvantage of this type of power supply is the accuracy of the measurement; rotating the generator handle at the same speed will make it difficult to maintain a stable voltage. When using battery-powered megohmmeter, The disadvantage of this power supply is the constant need for batteries (AA batteries can be replaced) and poor performance at negative temperatures. Battery power supply – high-capacity batteries supplied with the megohmmeter are used. One of the advantages is that it can work in autonomous mode for quite a long time; there is no need to constantly buy additional AA batteries. Cons: poor performance at sub-zero temperatures, need to be charged from an industrial network from time to time. Measuring range of megohmmeters: The measuring range depends on the voltage. The higher the voltage that the megohmmeter , the greater the resistance the device can measure. Measurements range from 0 ohm to 10 tom.

Information output: There are two types of information output. Analog (A) and Digital (D).

Additional functions of the megohmmeter: There are several of them, but in our table we included only two functions - Measurement of absorption coefficient (DAR) and polymerization coefficient (PI), as well as communication with a PC

Megaohmmeter price: The price of the device depends on the parameters of the device itself. The higher the parameters, the higher the price.

Inclusion of a megohmmeter in the state register: Many devices from our table are included in a single state register, therefore they can have “Verification.” Some megohmmeters have “Primary verification,” which is carried out at the manufacturer’s plant.

order megaohmmeters by calling or sending us a request by email: Email address is being protected from spambots. Javascript must be enabled in your browser to view the address. You can also find out more about placing an order on our website.

Cable insulation resistance measurement

It is often necessary to measure the insulation resistance of a cable or wire. If you know how to use a megohmmeter, when checking a single-core cable it will take no more than a minute; with multi-core cables you will have to tinker longer. The exact time depends on the number of wires - you will have to check each one.

Select the test voltage depending on the network voltage with which the wire will operate. If you plan to use it for 250 or 380 V wiring, you can set it to 1000 V (see table).

Checking a three-core cable - you don’t have to twist it, but try on all pairs

To check the insulation resistance of a single-core cable, we attach one probe to the core, the second to the armor, and apply voltage. If there is no armor, attach the second probe to the “ground” terminal and also apply test voltage. Let's look at the readings. If the arrow shows more than 0.5 MOhm, everything is normal and the wire can be used. If it is less, the insulation is broken and it cannot be used.

You can check the multi-core cable. Testing is carried out for each core separately. In this case, all other conductors are twisted into one bundle. If at the same time it is necessary to check the ground fault, a wire connected to the corresponding bus is added to the common harness.

If the cable has a screen, metal sheath or armor, these are also added to the bundle. When forming a tourniquet, it is important to ensure good contact.

The insulation resistance of socket groups is measured in approximately the same way. All devices are turned off from the sockets and the power to the panel is turned off. One probe is installed on the ground terminal, the second - in one of the phases. Test voltage - 1000 V (according to the table). Turn it on and check it. If the measured resistance is greater than 0.5 MΩ, the wiring is normal. We repeat with the second core.

If the wiring is old - there is only phase and zero, testing is carried out between two conductors. The parameters are similar.

How not to make a mistake when choosing a MEGAOHMETER

To protect people from electric shock when the insulation in consumer electrical installations is damaged, periodic monitoring of the insulation condition of electrical wiring, cables, electrical installations, etc. is necessary.

Insulation resistance and absorption coefficient are measured using a megohmmeter (megger).

A megohmmeter is a device that measures the direct current resistance of insulation. Until recently, the source of direct current was a generator with permanent magnets built into the megohmmeter, rotated by hand or by an electric drive. With the development of technology, digital megohmmeters began to be equipped with electronic converters, powered by an adapter or battery (for example, TsS0202, etc.), which led to a reduction in the size of the device.

Which megaohmmeter should you choose? The choice of megohmmeter type can be divided into several criteria.

APPLICATION

The choice of megohmmeter type is made depending on the nominal resistance of the object (power cables 1-1000, switching equipment 1000-5000, power transformers 10-20,000, electrical machines 0.1-1000, porcelain insulators 100-10,000 MOhm), its parameters and rated voltage. As a rule, to measure the insulation resistance of equipment with a rated voltage of up to 1000 V (secondary switching circuits, motors, etc.), megohmmeters for rated voltages of 100, 250, 500 and 1000 V (ES0202/1G, TsS0202) are used, and in electrical installations with a rated voltage of more than 1000 V, megohmmeters of 1000 and 2500 V are used (ES0202/2G, ES0210, TsS0202).

EASY TO USE

What type of display: pointer dial (ES0202, ES0210, M419, F4106), digital liquid crystal (TSS0202) or LED display, auxiliary devices: backlight, equipment (all megohmmeters from the Uman Megohmmeter plant).

OPERATING MODE

What are the climatic operating conditions (TSS0202-2 for the north)?

Should this device always be at hand?

Power source: magnetic-electric generator (available only in megohmmeters produced by the Uman Megohmmeter plant), rechargeable battery, battery?

What other measurements will need to be performed: current, voltage, absorption coefficient (TsS0202 measures)?

We recommend:

One of the main types of protection is the use of various types of insulation of live parts. The simplest, but very effective method of monitoring its condition is to measure the insulation resistance using a megohmmeter.

With this method of assessing the quality of insulation, the reliability of the readings comes to the fore, which consists of the basic error of the device, its resolution and additional error due to ambient temperature, humidity, etc., and for devices with dial indication also the parallax error vision.

Digital megohmmeters TsS0202-1 and TsS0202-2 developed and produced by Umansky measure the voltage at the facility, insulation resistance, and calculate the absorption coefficient. Megaohmmeters TsS0202-1 and TsS0202-2 automatically remember the last 10 values of RХ, R60 and R15, and also calculate the absorption coefficient.

All these parameters in the TsS0202-1 and TsS0202-2 megohmmeters can be displayed on the display by pressing one button. A wide operating temperature range (-30°C to +55°C) is achieved through the use of a vacuum-illuminescent display. All this will allow you to obtain reliable readings in almost any operating conditions.

The TsS0202-1 and TsS0202-2 devices are powered from a rechargeable battery, or from an alternating current network through an adapter, which also serves to charge the battery. Megohm meters TsS0202-1 and TsS0202-2 are equipped with a battery condition monitoring system. The built-in stabilizer protects the battery from overcharging. Also, the TsS0202-1 and TsS0202-2 megaohmmeters automatically switch to energy-saving mode 1 minute after the end of measurements (inactivity).

The climatic design of the TsS0202-1 and TsS0202-2 devices allows its use at ambient temperatures from -30 to +50°C and relative air humidity of 90% (at tair.+30°C). The degree of protection of the device housing TsS0202-1 and TsS0202-2 is IP42. The delivery set includes test leads up to 2.5 kV, a standard charger and battery.

TsS0202 megohmmeters have better performance in most parameters compared to the E6-24 and E6-24/1 megohmmeters that appeared on the Russian market.

Comparative table of technical characteristics of TsS0202-2 and E6-24/1, E6-24:

| Parameter name | TsS0202 | E6-24 |

| Measuring range, MOhm | 100 000 | Up to 10,000 |

| Basic accuracy | 2,5% | 3%±3e.m.r. |

| Test voltages, V | 100-2,500 in increments of 50 | 500; 1 000; 2 500 |

| Voltage measurement at the object, V | 1-500 | 1-400 |

| Absorption coefficient calculations | Eat | Eat |

| Memory | 10 last measurements | 1 last measurement |

| Resistance indication for 15 and 60 seconds | Eat | Eat |

| Operating temperature range, °C | -30…+50 | -30…+50 |

| Indication | Digital with interactive mode | Digital |

| Nutrition | Battery, network 220 V/50 Hz | Battery, network 220 V/50 Hz |

| Dimensions, mm | 220x156x61 | 80x120x250 |

| Weight, kg | 1 | 1,2 |

| Working position | Any | Any |

| Average service life, years | 10 | 10 |

| Calibration interval | 1 year | 1 year |

Operating rules

A megaohmmeter is a dangerous device due to high voltage. Only a person who has knowledge and experience can work with it.

Only trained people who know safety precautions can start working with a megohmmeter. Work in electrical installations where the voltage is more than 1000 volts is carried out with permits, that is, a work permit. However, issuing a document for several works is not permitted. Also, working at a similar mains voltage is allowed for people who have the third and fourth electrical safety groups.

Megaohmmeter - how to choose?

Measuring insulation with a megohmmeter is a necessary procedure. For this reason, almost all industries should take care of purchasing a megohmmeter. Especially those who have a full-time electrician and use voltages over 500V for equipment.

Of course, you can buy any megaohmmeter in an online store. But before purchasing, it is better to familiarize yourself with several principles for choosing a device. When choosing, you should consider:

- Nominal resistance of the measured dielectric;

- Rated voltage generated by the device;

Insulating materials can have different resistances. However, there is a nominal resistance that certain insulating materials must meet. For example:

- electrical machines 0.1–1000 MOhm;

- power cables 1-1000 MOhm;

- switching equipment 1000-5000 MOhm;

- porcelain insulators 100 - 10,000 MOhm;

- power transformers 10-20,000 MOhm.

The device should be selected according to the specified parameters. As a rule, work with a megohmmeter should be carried out by a specialist. However, once a year the megohmmeter must be verified. In particular, to identify errors and the possibility of further operation of the device.

Read: Buying an apartment in a new building

Share link:

- Click to share on Twitter (Opens in new window)

- Click here to share content on Facebook. (Opens in a new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share posts on Tumblr (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to share posts on Pocket (Opens in new window)

- Click to share on Telegram (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to share on Skype (Opens in new window)

Megaohmmeter

Insulation, like any other material, is influenced by various external factors: weather, mechanical wear and others. For timely detection of insulation defects, there is a device, the so-called megohmmeter. It measures insulation resistance.

Operating principle of the device

What the device is intended for can be understood from its name, which is formed from three words: “mega” - the dimension of the number 10 6; “ohm” - a unit of resistance and “meter” - to measure. To measure electrical resistance in the megohm range, a megohmmeter is used. The principle of operation of the device is based on the application of Ohm's law, from which it follows that the resistance (R) is equal to the voltage (U) divided by the current (I) flowing through this resistance. Therefore, in order to implement this law in a device, you need:

- DC generator;

- measuring head:

- terminals for connecting the measured resistance;

- a set of resistors for operation of the measuring head within the working area;

- a switch that switches these resistors;

Implementation of a megohmmeter according to this scheme requires a minimum of elements. It is simple and reliable. Such devices have been working properly for half a century. The voltage in such devices is supplied by a direct current generator, the value of which varies in different models. Usually it is equal to 100, 250, 500, 700, 1000, 2500 volts. Different models of devices may use one or more voltages from this series. Generators differ in power and, accordingly, in size. Such generators are operated manually. To operate, you need to twist the handle of a dynamo, which produces direct current.

Currently, electromechanical devices are being replaced by digital ones. In such devices, either galvanic cells or batteries are used as direct current sources. There are also new models with a built-in power supply.

Working with a megohmmeter

Working on any equipment with this device is a high-risk job due to the fact that the device generates high voltage and there is a possibility of electrical injury. Work with this device is permitted to be carried out by personnel who have studied the instructions for working with the device, in accordance with the rules of labor protection and safety precautions when working in electrical installations. The employee must have the appropriate access group and periodically undergo tests on knowledge of the rules of work in electrical installations, know the instructions on labor protection, including the use of a megohmmeter.

Typically, this device measures the insulation resistance of cable lines, electrical wiring and electric motors. Devices must undergo periodic inspection by the metrological service and have the appropriate documents. It is prohibited to carry out measurements with an untested device; it must be taken out of service and sent for inspection.

Before starting work using a megohmmeter, you need to ensure the integrity of the device by visual inspection. There should be a verification stamp on it, there should be no chips on the device body, the indicator glass should be intact. Test leads are checked for insulation damage.

The device needs to be tested. To do this, it is necessary, if a pointer instrument is used, to install it on a horizontal surface in order to avoid measurement errors and carry out measurements with open and closed probes. On older models of megohmmeters, measurements are carried out by rotating the generator handle at a constant frequency of 120–140 rpm. On other models, measurements are made by pressing the corresponding button on the device. The megohmmeter should show infinity and zero megohms, respectively. After this, you can begin work on measuring insulation resistance.

Megaohmmeter - attachment to a multimeter

This easy-to-use attachment, together with the 83x series multimeter, which has a maximum active resistance measurement limit of 2 MΩ, allows you to directly measure the resistance of resistors and high-resistance circuits up to 20 MΩ. No additional power source is required for the set-top box.

It is known that inexpensive and popular among radio amateurs, multimeters of the 83x series do not allow measuring active resistance of more than 2 MOhm without additional components or calculations. The proposed attachment expands the measurement limits to 20 MOhm. The value of the measured resistance is displayed on the multimeter display. As in other set-top boxes developed by the author, power (+3 V) is supplied to it from the internal stabilizer of the multimeter ADC chip.

The attachment diagram is shown in Fig. 1. A current source (IT) is assembled using op-amp DA1.1 and resistors R3-R6 according to a circuit known in the radio engineering literature as Howland IT. The author has already used such a node in his earlier development [1]. Its output current is calculated based on the following conditions: R3 = R5, R4 = R6 for the convenience of their subsequent selection; the current through resistor R6 is equal to the algebraic sum of the currents through resistor R3 and the measured resistor Rx; input currents of op-amp DA1 are negligible. The op-amp is covered by deep OOS for direct current through the divider R4R5, therefore, equal voltages are set at both its inputs (inverting and non-inverting) if the output voltage is less than the maximum at a given supply voltage. In this case, the IT output current (Iout) will be equal to: Iout = UR2/3, where UR2 is the voltage at the output of the resistive divider R1R2 (i.e., across the resistor R2). This voltage serves as a reference voltage for IT, since the resistance of resistor R2 is significantly less than the resistance of resistor RЗ.

Rice. 1

The IT output current is chosen to be 0.1 μA, and it is quite enough to measure the resistance of resistors up to 20 MOhm, since the voltage drop across it will not exceed 2 V, which is less than the supply voltage of the set-top box (3 V). With the resistances of resistors R3-R6 indicated in the diagram, the DA1.1 op-amp is guaranteed to operate in linear mode, providing high stability and constancy of the IT output current flowing through the measured resistor Rx, and therefore a high linearity of the dependence of the voltage drop across the measured resistor or circuit. This voltage is supplied to the input of a buffer amplifier, made using op-amp DA1.2 (input resistance - at least 1 GOhm) with unity voltage gain. To interface with the multimeter, use a resistive voltage divider R7R8, which reduces the voltage at the output of op-amp DA1.2 tenfold. From the output of the divider it goes to the “VΩmA” input of the multimeter for subsequent measurement.

The current consumption of the set-top box is almost equal to the current consumption of the DA1 microcircuit. The error in measuring resistance in the range from 2 to 19.99 MOhm is no more than 3%.

The attachment is assembled on a board made of fiberglass foil on one side; its drawing is shown in Fig. 2, the location of the elements on it is shown in Fig. 3. The MCP602 op amp can be replaced with the domestic KR1446UD4A op amp (in DIP8 housing) [2]. When replacing with another Rail-to-Rail op-amp, it should be taken into account that its inputs must be made of field-effect transistors (input resistance - at least 1 GOhm), the minimum supply voltage - no more than 3 V and current consumption (per case) - no more 3 mA. To reduce the error when measuring resistances less than 2 MOhm, the zero offset voltage should not exceed 1...2 mV. Blocking capacitor C1 - tantalum K53-1, resistors - MLT, S2-33, high-resistance - KIM. Pairs of resistors R3 and R5, R4 and R6 should be selected using a multimeter with a resistance deviation of no more than 1% in each pair. In this case, the deviation of the resistance from the nominal does not affect the measurement accuracy - their equality is important. The resistances in each pair can be reduced to 1.5 MOhm and 300 kOhm, respectively. In this case, the voltage on resistor R2 must be reduced based on the equality UR2(V) = 0.1xRZ (MΩ). For example, if RЗ = R5 = 1.6 MOhm, R4 = R6 = 330 kOhm, then R1 = 27 kOhm, R2 - 1.6 kOhm. Pin XP1 - suitable from the connector or a piece of tinned wire of a suitable diameter. The hole for it in the board is drilled “in place” after installing the XP2, XP3 pins. Pins ХР2 and ХРЗ are from multimeter probes. Input jacks XS1, XS2 - screw terminal block ED350V-02P from DINKLE or similar.

Rice. 2

Rice. 3

When working with the attachment, the switch for the type of operation of the multimeter is set to the position of measuring direct voltage at the “200mV” limit. Before calibration, in order to avoid failure of the internal +3 V ADC stabilizer, the set-top box is first connected to an autonomous power source with a voltage of 3 V (two 1.5 V galvanic elements connected in series can be used) and the current consumption is measured, which should not exceed 3 mA, and then connect to a multimeter. Next, calibration is carried out by connecting a resistor with a resistance of several megaohms with a known resistance or an accuracy class of no worse than 1% to the XS1, XS2 “Rx” sockets. By selecting resistor R7, the desired readings on the indicator are achieved. The readings, taking into account the comma, are divided by ten. Please note that to facilitate calibration, resistor R7 on the board is made up of two resistors connected in series. In Fig. 3 they are designated as R7′ and R7“.

The photograph (Fig. 4) shows an attachment connected to a multimeter when measuring a KIM-0.125 resistor with a nominal resistance of 15 MOhm and a permissible deviation from the nominal value of ±10%.

Rice. 4

LITERATURE

- Glibin S. LC-meter - an attachment to a multimeter. - Radio, 2014, No. 8, p. 21-24.

- KR(KF)1446UDxx operational amplifiers. - URL: https://www.qrz.ru/reference/tісго/сіаіазьеІ/1446ud.pdf

Author: S. GLIBIN, Moscow Source: Radio No. 5, 2015

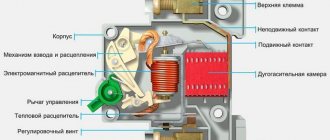

Pointer megohmmeter and its design

A simplified electrical circuit, typical for analog devices, is equipped with the following components:

- DC generator;

- a measuring head, which consists of two interacting frames (working and counteracting);

- a toggle switch between measurement limits, which allows you to regulate the operation of various resistor chains designed to correct the output voltage and operating modes of the head;

- current limiting resistor.

In turn, the dielectric sealed durable housing of this unit is equipped with:

- handle for ease of transportation;

- a folding portable generator handle, rotating which generates voltage;

- a lever used to switch measurement modes;

- output terminals designed for the operation of the entire circuit (connecting wires are connected to the terminals).

Most megohmmeter models have three output terminals for connection. Each of them has a name: ground (G), line (L) and screen (E).

Z and L are intended for measuring insulation resistance. E - in order to eliminate the influence of current losses in the case of measuring in the area of two parallel cable cores.

What safety measures should be observed when working with a megger?

Everything seems to be extremely simple. But it turns out that such devices belong exclusively to the professional category. And not all workers can be allowed to operate them - certain training and obtaining the appropriate permit are required - not lower than the third electrical safety group.

In this case, the author of the article in no way recommends, as is usually customary on construction sites, to take measurements with your own hands. But if any owner of a house or apartment takes upon himself the courage and responsibility for performing independent measurements, he must at least comply with the safety requirements for performing work as much as possible.

- The device itself should not have any mechanical damage to the housing. Particular attention is paid to the integrity of the insulation of the measuring leads, the serviceability of the probes, alligator clips, and pin contacts for connecting to the megger.

- Any tested object or line must be de-energized. All circuit breakers are switched to the “off” position or, in old switchboards, the fuses - plugs - are unscrewed. In some cases, it is necessary to temporarily disconnect the wires from the output terminals of the circuit breakers.

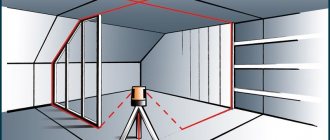

Before testing the insulation resistance, the object is completely de-energized

It is advisable to focus attention on the intentionally disabled state of the network by installing a sign, for example, “Do not turn on! Work is underway." So that none of the household or assistants accidentally turn on the machines during testing.

- All devices are disconnected from the network. The plugs are removed from the sockets. Light bulbs are unscrewed from lamp sockets. Particular attention is paid to devices with precision electronics. The high voltage supplied to the line can easily “kill” them.

Plugs are pulled out of all sockets. The lamps are unscrewed (removed) from the lamps (don’t forget about spotlights).

- The so-called portable grounding is being prepared for work. Craftsmen use a factory-made device, but it is quite possible to make a completely working device yourself.

Factory-produced portable grounding.

Something similar can be done with your own hands. It can be a piece of copper stranded wire of the required length, with a cross-section of at least 1.5 mm². One end of it is stripped and can be equipped with a terminal or alligator clip for connection to a grounding bus. The second end, also stripped, must be secured to a dielectric rod. It’s good if you can find a plastic rod of the required length. If not, then a dry wooden strip will do, on the edge of which the stripped end of the wire is attached, for example, with several turns of electrical tape. The place on the bar that you have to grasp with your hands can also be “dressed” in a couple of layers of electrical tape. And the length of the rod is chosen such that it is convenient to touch the ends of the tested wires from a safe distance.

After each measurement, it is recommended to remove the residual voltage in the conductors being tested by touching this portable ground. By the way, when testing lines of considerable length, a serious charge may remain in them, capable of causing severe electrical injury.

- It is advisable to carry out work on measuring insulation resistance while wearing dielectric gloves. Many people ignore this, and probably in vain. During measurements, especially due to inexperience, it is okay to touch the probe or live part, say, with the back of your hand. And you have to work with voltages that sometimes reach 2500 volts! Not a joke!

- The probes must be handled correctly. If you pay attention, each of them has a side on the handle, a kind of guard. This is not so much for convenience as for safety. This sets the boundary of the finger-safe zone, which is prohibited from crossing when taking measurements.

Guards on the probe handles clearly limit the position of the operator's fingers. Closer to the exposed part it becomes dangerous.

- After each measurement, the residual voltage in the megger probes must also be removed. To do this, their bare ends are simply closed together. It must be said that modern devices are often equipped with an automatic discharge function after each reading is taken. But it’s better to be on the safe side, and for many electricians, this type of contact closure after each measurement has simply become a habit.

Partners

- Civil Defense and Emergency (15) Regulations (2)

- Orders (3)

- OT (4)

- Job descriptions (34)

- Fire safety instructions (6)

- License Registration of public benefit organizations (1)