Every owner who purchases a country plot for construction tries to build a house that will be warm and comfortable to live in.

And without high-quality insulated walls, this is very difficult to achieve. Relatively recently, insulation material from the company Isoplaat appeared in our country, developed specifically for the conditions of the northern humid climate. Nowadays, isoplat insulation boards are increasingly used in the construction industry, as evidenced by user reviews. Isoplat is represented by a special plate used for both thermal insulation and sound insulation purposes. This material is environmentally friendly, made from softwood fiber without the use of chemical additives and artificial impurities.

Peculiarities

Produced from wood and coniferous pulp with the addition of paraffin. After drying in the drying chamber, the mixture loses excess moisture and acquires moisture protection characteristics. Does not contain chemical additives. Environmentally safe, harmless to humans.

Structure

Important! Isoplat contains no glue. Reliable adhesion is provided by wood resins.

A short video describing the material and its scope of use in construction:

Manufacturing technology

The production of ISOPLAAT material consists of several stages:

- Selected softwood raw materials are crushed to produce wood chips.

- The chips are treated with water steam and completely saturated with moisture under a pressure of 0.8 - 1.0 MPa.

- There are types of products that go through another stage of additional grinding.

- Wood fiber is diluted with water up to 98% and, using special equipment, a fiber carpet is formed.

- The compressed slab is cut into separate pieces of the required size.

- The sheets are dehydrated in the dryer at temperatures up to 160°C.

- After drying, the panels can be cut to the size required by the consumer, they are assembled and packaged.

Specifications

Produced in thicknesses of 4-50 mm. Depends on the purpose of the slabs. For interior decoration sheets up to 7 mm. For the floor - squares 850x590 mm. Standard size – 2700x1200 mm.

The thermal efficiency of isoplat is similar to mineral wool. Inferior in thickness. It is not used as the main insulation. Only as an addition to the existing thermal insulation.

The coniferous-fiber structure provides good vapor permeability. This is important when working with a wooden surface. There is no need to lay a vapor barrier layer.

It has a high degree of sound insulation. Wall decoration reduces noise by 20-25 dB.

The paraffin coating of the plates ensures high moisture resistance. Do not leave outside for more than 2 weeks. They will become saturated with moisture and change their geometry. Indoors such changes are noticeable. This is the reason for additionally gluing the joints with reinforcing tape.

Isoplat is made from sawdust and is fire resistant due to the fire retardants in its composition. As the temperature rises, the top ball becomes charred. Ash prevents the fire from spreading to other building materials.

Environmentally friendly, harmless to humans and the environment. The fastening ingredient is natural polymers.

Important! Since the material is made of wood, without chemical additives, it is equal to natural wood. The slabs are used to decorate the walls of a children's room.

Use in children's room

Does windproof isoplat provide rigidity to the frame?

One of the popular questions on the forums is whether isoplat gives rigidity to the frame and whether it can be used without jibs. There are different opinions.

I will express my opinion - yes, you can use it without jibs. But - 12mm only for a 1-storey building, if for a 2-storey building, then 24mm. In general, the question of the need for jibs together with an isoplat is quite specific and largely depends on the specific design of the wall.

Why do I think this? Firstly, while I was making the roof, and the frame was standing with temporary jibs, some “staggering” was felt. After sheathing with a 12mm slab and removing the temporary jibs, it’s gone.

Moreover, the box, without internal walls , under a roof and only covered with 12mm isoplaat, stood completely calm from the fall until the next summer. Although there was enough snow in winter, and a couple of times there was even a stormy wind.

You must also understand that isoplat is not the only element that gives rigidity to the frame. In the future, interior decoration, exterior decoration, etc. will be added. I call this the “bun of arrows” principle. One arrow is easy to break, but a bunch is not.

So it is with the rigidity of the frame. Perhaps just a 12mm isoplate will not be enough. But in general, in combination with other layers of the wall, each of which makes its own contribution, the rigidity will be sufficient.

In addition, in my opinion, as paradoxical as it sounds, the softness of the windproof Isoplaat gives rigidity to the structure.

The fact is that due to its softness, the windproof plate is pressed very tightly against the racks

Stiffer boards (OSB, DSP, etc.) will not press in this way precisely because they are rigid. Thus, it turns out that MDVP has a contact area with the frame and “adhesion” to it that is much better and denser than that of more rigid slabs.

Therefore, my conclusion is that in terms of rigidity, it is quite possible to use 12-24mm isoplats without jibs. But this will depend on the number of floors of the house, the windiness of the area and other layers of the wall.

Scope of application

The functionality of the material is extensive. There are types for external and internal use as thermal insulation. Place it on the floor like a rough underlay for a parquet or laminated board. The material for finishing the walls on the outside has an additional paraffin layer. It ensures the moisture resistance of the skin.

Important! Direct purpose - heat protection, wind insulation of walls and roofs of houses.

Purpose of building material:

- In the construction of frame houses, they are used for external and internal cladding of walls and roofs.

- Acts as insulation for wooden, stone, and aerated concrete buildings.

- Windproof slabs are the base for roofing buildings. Basis for tiled and tin roofs.

Wind protection of the roof

- The use of slabs is recommended when repairing old or laying new floor coverings. Provide floor levelness, heat and sound insulation.

- The sheets are used for their intended purpose, for decorative purposes.

- Strengthens basic thermal insulation.

Important! Material for internal use without paraffin coating. Even, smooth, a good basis for finishing (decorating).

Decorating walls with isoplate

Advantages

Isoplat is an ideal option for soundproofing premises for various purposes; having a porous structure, the product is capable of not only protecting against the penetration of sounds, but also absorbing outgoing ones. Speaking about isoplats, we can mean a lot of advantages of the material that every buyer can appreciate. Among the most common, it is worth noting the following:

- Thanks to the fiber structure, the noise absorption level is 23 dB. Such indicators allow you to create comfortable conditions for rest and sleep.

- As tests show, the thermal conductivity of the isoplat is 0.045 W/(mK). This figure is currently comparable to cotton wool insulating material, which is considered the best of its kind.

- The different thicknesses of the slabs allow the material to be used for apartments of any size, while sound insulation does not take up space.

- When using isoplat plates, finishing can be carried out on the surface, which saves on materials and work time.

- The low weight of the product allows installation work to be carried out without the involvement of assistants and specialists.

- An apartment lined with isoplate is cool in summer and warm in winter, since the material has accumulating properties.

- The porous structure of the boards allows steam to pass through the material well, so it almost always remains dry and is not susceptible to the formation of fungus and mold.

- The service life of heat and sound insulation boards reaches fifty years, without loss of quality and characteristics of the material.

And one of the most important advantages of isoplat is its cost, which is not much higher than other analogues. The optimal solution for soundproofing an apartment is to use isoplat slabs - it is beneficial, convenient and durable.

Installation

Before use, the slabs are left for several days in the room where the renovation will take place. This will allow the building material to equalize the humidity to the level characteristic of this room.

It is mounted to a wooden surface using nails, flat head screws, and construction staples. A gap of 2 mm is made between the elements.

Fastening brackets

They are secured to the sheathing with construction staples and nails. The pitch determines the thickness of the slab:

- a 12 mm slab requires a step of 30 cm;

- product 25 mm – 60 cm.

Nails are driven around the perimeter of the sheet every 10-15 cm.

Prices

The estimated price in 2021 for heat-sound-insulating and windproof slabs 12 mm thick is 250-300 rubles/m2. For thicker material (25 mm) you will have to pay an average of 500-600 rubles/m2.

Roofing Isoplat (25 mm) is sold at a price of 700 rubles/m2.

The thinnest material for lining under laminate (4 mm) can be purchased for 130 rubles/m2. A thicker 7 mm substrate will cost no less than 190 rubles/m2.

Isoplat installation

Internal lining

It is important to prepare the surface for laying the material. Remove protruding parts, seal depressions, chips, and cracks. To prevent mold, the walls and floor are coated with an antiseptic.

The sheets are puttied and coated with primer on both sides.

Important! If you plan to stick thin, light wallpaper on the walls, the bright color of the isoplate will show through. To prevent this, the front part of the slabs is coated with white water-based paint.

Painting

Mount with a gap of 10 mm from the floor. Then it is filled with polyurethane foam and sealant. Door and window openings are sheathed with solid slabs. The distance between products is 10 mm.

The seams are sealed with putty and reinforced with fiberglass tape. The joints are sealed and foamed. The heads of nails and screws are sealed with putty.

If they are secured with construction foam, it is applied to the entire sheet. Press tightly, controlling horizontality. If nails or construction staples are additionally used for fastening, foam is applied along the contour of the tile at a distance of 1 cm from the edge.

Important! To simplify your work and reduce installation costs, buy slabs with a tongue-and-groove lock. Linen fabric and washable wallpaper are glued onto them at the factory using a press. Such slabs are used to decorate the walls of luxury hotel complexes. It's beautiful and practical.

"Tongue and groove"

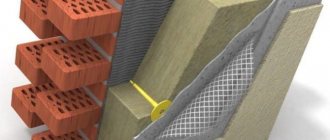

External cladding

Installation outside the building is carried out in a vertical position. Sheath the house in the direction of the length of the slab.

The technology for installing the frame is to use frame racks with a pitch of 60 cm. As a result, the slab is located between three pillars. The isoplat is conveniently attached. No sheet cutting required.

Wind- and heat-protective panels are attached to self-tapping screws and nails. It is better to use self-tapping screws. When struck with a hammer, the integrity of the plate is damaged. Self-tapping screws eliminate this.

Important! The material is soft. The screws are placed 1 cm from the edge. Otherwise, delamination will occur.

External cladding of the building facade

If decorative plaster is applied, the product is attached in 15 cm increments to the frame posts. This method is not used often. The ventilated facade is installed above the windshields. Additional fastening is provided by the presence of wooden blocks. They are packed on top of slabs intended for the facade of the building. It is enough to fix the isoplate in three places on each rack.

The panels are secured with construction clamps 32 mm long. If the thickness of the slabs is 12 mm, pay attention to nails and screws 40 mm long. For products with a thickness of 20 mm, the parameter increases to 75 mm. If you are not sure, buy a special strip. It shows fastening points every 15 cm. The panels are fastened to the beam of the lower frame, where the sheet of material will be mounted.

Fastening sheets outside the house

Laying isoplat on the floor

When installing on the floor, a gap of 5-10 mm is left between the wall and the isoplat. Experts maintain this distance by inserting scraps of material between the wall and the substrate. After installation they are removed.

Gap

Install the rough underlay on the floor at an angle of 45 degrees relative to the finishing coating. This is necessary to ensure that the gaps between the substrate and the laminate do not match. A gap of 1-2 mm is made between the plates. Fastening to the base is carried out using glue, nails, and construction staples.

The final flooring is laminate, parquet, on a pine base.

Reviews

Isoplat is a new building material. You can already find reviews about it:

- Olga, 26 years old: Izoplat has many analogues. For those who care about their health, it is worth using it as a substrate for laminate. Although it sags a little when working;

- Mikhail, 38 years old: The house is located near the railway junction. Sounds and roars are constantly heard. Especially at night. After covering the walls with isoplat slabs, it became quiet and cozy inside. The room was additionally insulated. They didn't put up any wallpaper. The walls are smooth and original. It turned out interesting;

- Pavel, 40 years old: An amateur can work with the material. Construction skills are not required. Izoplat is easy to cut, there is practically no dust, it does not crumble or break. Excellent heat retention and sound absorption;

- Maria, 28 years old: We live in Khrushchev. It was cold and chilly. During the renovation, the floor and walls were insulated with isoplate. Not in vain. It became warm and cozy. We walk without slippers. The carpets were removed from the walls. Now there is no need for them. The interior has been updated.

Flaws

Despite all the positive qualities of isoplat soundproofing boards, the product also has some disadvantages. The disadvantages of the material include the following:

- When installing an isoplat, there is no need to use a traditional primer, since the solution can clog the air channels and the vapor permeability of the product will significantly decrease, and this can lead to negative consequences. If there is no air access to the wall, then fungus or mold may form on it. Pre-installation treatment should be carried out with a water-based solution.

- Another disadvantage is the fact that after installing the slabs, they need to be finished. As a finishing material, you can use paint, plaster or wallpaper.

Using isoplat soundproofing boards, you can replace traditional insulation methods, which are supplemented by the use of plasterboard and other sheet materials. It is enough to do a little work to level the surface and you can paint or wallpaper.

Tips and tricks

Tips from experts to make working with building materials easier:

- install the sheets with the smooth side outward and the rough side inward;

Installation

- The material is used in a room with normal humidity. Increased moisture levels will spoil the properties and geometry;

- the horizontal joint of the sheets when fastening to the frame is made on a horizontal block;

- with the frame method, the wiring is laid to ensure reliable fixation of the material to the wall surface and to prevent damage to the wires;

- work with isoplate begins when the “wet” work is completed. An exception is puttying of plates;

- If the bottom sheets become bent during storage, they should be wetted and left to dry for a day. After this, they will level out and regain their previous appearance and shape;

- if it is not possible to eliminate the unevenness of the rough base, the material is attached to wooden beams treated with an antiseptic;

- To glue isoplats to a brick or concrete surface, use drywall adhesive or polyurethane foam.

Isoplat is a building material that allows you to solve several problems: increase the level of thermal and sound insulation, ensure fire resistance of the coating, protect the surface from strong winds. In different cases, building materials of different thicknesses and sizes are needed. Such pleasure will cost a pretty penny. We must be prepared for this.

Which windproof boards to choose?

Considering the rather low cost, the question often arises of which slabs to choose?

My opinion is that 24mm is best. They are more stable in size, they are easier to attach, and they provide greater rigidity to the frame. 12mm is an “economy option” that has certain disadvantages.

You can try an option that is more labor-intensive, but slightly cheaper than a 24 mm plate. Use a simple heat-insulating board as the first layer (it’s cheaper), and a wind-proof one as the second. This will save on the cost of the material, but not much.

But you can cover the joints of the first with a second layer, obtaining a more reliable structure.

In addition, you can splurge on roofing sheets (now called universal). They have a “tenon groove”, which allows them to be mounted horizontally, without being tied to the pitch of the racks and the size of the slabs. Which is important because there will be less waste. The slabs are laid one after another according to the laminate principle. The last piece in the first row is placed first in the second and so on. And the tenon groove does not create gaps at the joints.