Elastic putty is a composition created specifically for work when preparing internal surfaces for applying the finishing coating.

It is indispensable when repairing foundations that are characterized by mobility and the ability to deform. The main condition for performing quality work is not to use this composition as a leveling mixture on the outside of the building. This type of putty is widely used when filling joints between two different materials. For example, it can be used to fill seams and joints between metal and concrete, wood and brick.

What kind of material is this

Elastic putty is a synthetic mixture that contains a polymer resin and various types of fillers.

Main advantages of the product:

- strength;

- durability;

- protection against mold and mildew;

- does not crack;

- provides the best performance characteristics.

Putty is available in 2 forms:

- ready-made mixtures;

- dry powdery.

There are several types of putties:

- Two-component

. The material should be applied to the wall relatively quickly (due to loss of properties after opening the package).

- One-component

. The putty is easy to use and suitable for repairing small areas. Differs in less rigidity in comparison with two-component compositions.

Types of elastic putties

There are special compositions for finishing wooden surfaces on sale. The product can be applied to furniture, frames, parquet floors, door frames and other types of structures.

In specialized stores you can find modeling putties, which are mainly used for working with decorative objects.

Silicone compounds are in great demand.

Their advantages:

- easy to apply;

- dry quickly;

- create a solid foundation.

In stores you can find acrylic putty (a water-based mixture that fills cracks and smoothes the surface of the wall). It contains white pigments, acrylic emulsions and other additives that improve its quality. The mixture is mainly used for interior surfaces. The product is applied to the plastered and primed coating.

The putty is available in both ready-made and powder form. The liquid solution can be immediately applied to the wall after opening without adding any ingredients.

Advantages of acrylic putty:

- has good adhesion and alignment properties;

- resistant to alkalis;

- provides a smooth and matte surface;

- no primer required (when using high-quality compounds);

- does not peel off from the surface;

- makes walls waterproof and thermally insulated;

- improves the appearance of surfaces;

- has antibacterial and antifungal properties;

- dries quickly.

Disadvantages of acrylic putty:

- It has a lower binding capacity than cement-based mortars.

- The price is higher than other formulations. Cost may vary depending on manufacturer.

The putty is suitable for working with wood, stone, concrete, plasterboard and other surfaces. The solution is mixed well before application. The drying time of the mixture is 4-6 hours.

The consumption of the acrylic mixture depends on the porosity and texture of the surface. 1 package can contain 1, 5, 10, 20, 35 kg of mixture.

Store the product in a dry, cool, well-ventilated place, away from children and sources of fire.

What does elastic putty consist of?

Elastic putty consists of a number of components. These are mainly polymer resins and fiberglass. Acrylic elastic putty retains all the properties of standard putty. The difference is increased adhesive abilities. The elasticity of this material practically eliminates shrinkage of the material and the formation of cracks. On the market you can see elastic putty based on silicone. A different composition from the previous one allows you to create a grainy surface. The first option makes the surface smooth.

The elastic putty is white with a milky tint. The consistency is viscous and resembles a paste. For some manufacturers, the color of elastic putty may be gray.

Compound

Manufacturers add the following components to the silicone mixture:

- liquid potassium glass;

- silicone resins;

- marble chips;

- titanium dioxide.

Acrylic putty is made on the basis of:

- water;

- acrylates;

- plasticizers;

- modifiers.

Features of the composition

The seams must withstand the loads during deformation.

Elastic putty is used as a material that allows not only to efficiently hide the joints between surfaces with different properties, but also to ensure a high level of strength of the top layer of coating.

After the composition hardens, a durable film is formed on its surface, and the inner layer retains its elasticity, withstanding the loads that arise when the structure deforms.

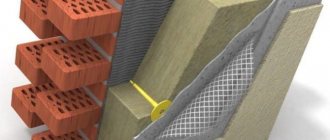

When constructing a thermal insulation layer, many craftsmen install polystyrene foam boards, and fill the seams between them with polyurethane foam. In most cases, puttying must be done before finishing.

The joints of polystyrene foam boards can be properly and reliably closed using elastic putty.

Modern manufacturers produce two types of such compositions, which differ from each other in their basis. A polymer is used as a base, on which the quality of the resulting surface depends.

Acrylic elastic putties are used to create a flat and absolutely smooth surface in preparation for painting or wallpapering.

Silicone - allows you to create a grainy, rough surface suitable for laying tiles.

Features of elastic putty:

- applied to all types of substrates;

- used when filling joints of various materials;

- has high elasticity.

It does not flow off the spatula and easily lays on the wall, providing a high level of moisture and vapor permeability. Most often, this material is used when working on wooden, concrete, and metal coatings, since it is in such conditions that elastic putty shows all its best qualities.

When choosing one or another composition, you should carefully study the recommendations and instructions for use. This is due to the fact that some products can be used at a certain temperature and humidity.

Working with material

Before starting application, prepare the necessary tools and materials.

Preparing for work

An important stage of finishing is preparing the surface: remove dust, dirt, and thoroughly dry the wall. This will ensure a strong connection of the new layer with the base and reduce the risk of cracks.

After this, they begin priming the surface. The mixture creates a transparent and vapor-permeable coating, increases adhesion and ensures proper drying of the new layer. The primer contains resins that bind the loose elements of the base and strengthen its structure.

After the primer has dried, begin applying elastic putty.

How to work with putty

The finished mixture can be applied to the wall or ceiling immediately after opening the package. Powdered putty is mixed with water, following the manufacturer's instructions. Most often, about 0.35 liters of water are consumed per 1 kg of substance.

After combining the ingredients and obtaining the required consistency, wait a few minutes (the mixture is used within an hour). Immediately before application, the mass is mixed again. The elastic material can be applied by hand or by machine.

Putty for sealing cracks

After preparing the solution, finishing begins. Apply a layer 2 mm thick. The room temperature should not be lower than +5°C and not higher than +30°C. The drying time of the putty depends on air humidity, type of composition and other factors. Further work is carried out approximately 48 hours after applying the mixture.

Scratches and cracks are repaired with putty using a metal spatula. Remove excess and wait until dry.

If necessary, the surface is treated with sandpaper (sanding the dry topcoat should not take more than 20 minutes).

Preparing to work with elastic putty

To work you will need:

- Elastic putty. The quantity is calculated by surface area;

- Tools for work. Spatula, trowel, trowel, reinforcing mesh;

- Prepared work surface. The wall must be cleaned of dust and dirt. If they have deep revivals, they must be eliminated. For better adhesion, a primer is applied.

Cost of putty

The following products can be found on the market:

- Acryl Putz

(3.6 RUR/2 kg). The composition contains polymer resins and fiberglass additives. The components improve the strength characteristics of the material and increase the adhesion of the putty to the base. The elastic mass can be used for both internal and external repair work. Suitable for concrete, cement-lime, wood and plasterboard surfaces. The product can be used to seal cracks up to 5 mm wide.

- Kreisel

(475 RUR/20 kg). Used to level wall surfaces and fill installation openings (for example, on window and door frames, window sills). The composition contains special fibers that cover small cracks on the surface. The material can be used to restore and fill defects in cornices. Suitable for coating concrete, brick, ceramic, silicate surfaces.

- Smaltofill

(1.4 euros). The putty is suitable for interior and exterior use. The mixture is used for seams, sealing cracks in brick, wood, concrete and other surfaces. Product advantages: does not crack, tightly fills cracks, provides a smooth finish. Drying time is 3-6 hours.

- Semin Fiberlastic

(600-2400 rub.). The material is applied to concrete, wood, plaster, and drywall. Seal cracks, joints, seams. Suitable for indoor and outdoor use.

How to work with elastic putty

Elastic putty is sold ready-made. It is applied with specialized tools. If elastic putty is used in hard-to-reach places or corners, use reinforcing mesh. When applying, a certain temperature must be maintained. From 4 to 32 degrees Celsius.

If something doesn’t work out for you, you can wash off the putty layer with water. This should be done until it dries. After drying, the surface can also be adjusted. Dried putty can be sanded. This way you will get rid of roughness and excess.

Preparation and execution of work

Slots and cracks are filled with polyurethane foam.

Careful preparation of the surface is carried out regardless of what kind of mixture will be applied. First of all, you need to remove all contaminants and get rid of dust. Of great importance in preparation is the high-quality filling of all detected cracks and cracks.

The deepest ones can be filled with polyurethane foam or cement-sand mixture. After hardening, excess foam is cut off with a stationery knife and priming begins.

When choosing a primer, it is necessary to pay attention to compositions that have a high level of penetrating ability and contain antiseptic substances. This will reliably protect the treated surface from mold and mildew.

Apply two coats of primer

Apply the primer in two coats. The drying time of the first one is from 2 to 4 hours; you can start puttying 12 hours after the formation of a thin and durable film.

On such a surface, the elastic putty is distributed evenly and laid down in a thin layer. This will not only enhance the adhesion of the putty to the surface, but also reduce material consumption, avoiding unnecessary material costs.

To perform the work, either a ready-made solution or a dry mixture can be selected. In any case, the composition should be thoroughly mixed before starting manipulations. Do not neglect this advice. Refusal of additional mixing will cause the loss of some qualities and main properties of the mixture.