Check valves are installed on hot and cold water pipes. As an example, consider a standard city apartment in a multi-story building. The following are connected to the riser with cold and hot water:

- Washing machine,

- Kitchen sink,

- water heater,

- Bathroom,

- Bathroom and washbasin.

What is it and what is it for?

A check valve is one of the elements of protective pipeline fittings.

The main purpose is to prevent changes in the direction of water flow. It automatically closes the pipeline if the flow direction changes in the opposite direction.

Water check valve

Also performs the following functions

- When the water supply is turned off, it prevents its outflow through the riser

- Blocks hot water from entering the cold water supply system and vice versa

- Significantly reduces the likelihood of water hammer

- Increases the operating time of equipment (pumps, meters, etc.)

- Reduces the risk of broken connections in the plumbing system

How to make the right choice

For each hydraulic system, it is necessary to select a water check valve that is most suitable for operation under the specified conditions. It is necessary to take into account the nominal pressure in the system, installation dimensions and method of fastening.

In heating systems with metal pipes, it is advisable to install a rotary check valve, since constant circulation of water causes its contamination. Rotary check valves are insensitive to environmental contamination.

When using modern metal-plastic pipes, contamination is minimal, so it is possible to use a spring-loaded disc check valve.

Purified water flows through water supply systems; the diameters of the pipes are small. In this case, the best choice is a ball check valve with a coupling mount.

Where is it used?

A non-return valve is very useful in the water supply of a private home.

If for some reason the pump stops, it prevents water from flowing back into the well or borehole. In the event of a power outage or pump shutdown, there is no need to refill the system with water.

On water pipes.

The supply of hot and cold water in private and apartment buildings is carried out through different pipes. Sometimes different water pressure causes hot water to fill cold water pipes. The valve allows you to bring the pressure back to normal.

In front of the cold and hot water meter.

Helps protect against damage in the event of a water hammer.

At the inlet to the water heater.

The boiler is filled under pressure. When warming up and pressure increases, the displaced coolant will be directed back into the cold pipe. Prevents churn

Purpose and range of shut-off valves

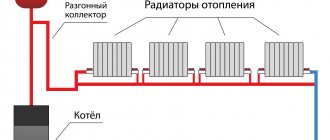

For heat supply systems, this fitting is used to control the supply of hot coolant and open the heating circuit.

As a rule, a shut-off valve on a heating device is mounted in areas where radiators are piped. In addition to functional advantages, such a solution has practical benefits. After closing the shut-off valve of the battery, the home craftsman will have the opportunity to repair it without stopping the functioning of the entire heating structure.

Today, shut-off valves for heating are offered in a wide range on the domestic market, and among the most commonly used products are the following devices:

- shut-off valves;

- valves;

- needle valves;

- Ball Valves.

Operating principle of a check valve

- The flow of water flowing through the pipes under pressure acts on the shut-off element and presses out the spring, which keeps the valve closed.

- After the spring has compressed, the valve opens and water flows freely through it in the desired direction.

- When the pressure in the water supply drops or when water moves in the opposite direction, the spring mechanism of the device moves the valve to the closed state.

- All the actions of the shut-off valve prevent the formation of backflow in the water supply system.

Operating principle of a check valve

Dry valve for sewerage

In terms of design, a dry sewer valve is fundamentally different from a hydraulic one. It is made in the form of a polypropylene tube with threads at the ends.

The internal structure of dry valves contains a special membrane that acts as a check valve. Therefore, unlike a hydraulic valve, such a valve performs a regulatory function - it prevents water from moving in the opposite direction through the system.

The dry shutter is more functional; it works both independently and in combination with a water device. It requires monitoring less often, but it is not allowed to be installed in kitchen sinks where dishes are washed - in such an environment the valve will last very little.

Types of dry seals:

- Membrane. The most common option is in which liquid enters the sewer as a result of a membrane opening under the pressure of water.

- Float This is a combination of dry and water valve types. It consists of a drain with a vertical outlet equipped with a ball-shaped float valve.

- Pendulum dry. It has only one attachment point and deviates from the axis under the pressure of the liquid, opening the passage. Returns to its original position under the influence of gravity.

- Valves with molecular memory. They are considered high-tech devices, the elements of which, thanks to molecular memory, always return to their original position and seal the structure.

When selecting a valve, it is necessary to take into account the number of drains passing through the device. For a washbasin, the diameter of the shutter passage can be 50 mm, and for a shower cabin - 100 mm. If there is no large free space, a horizontal shutter option is better.

Design Features

Housing material

The most common material used to make a check valve body is brass. This material is highly resistant to chemicals that may be present in water (mineral salts, oxygen, iron compounds, manganese, sulfur and others).

titanium, cast iron, steel, bronze mainly used in industrial systems

Plastic is used in polypropylene pipelines with water temperatures up to 90 degrees

Rubber or silicone sealing gasket.

Check valve device

Shutter element

It comes in the shape of a ball, cone, or “plate”. Double-leaf check valves are also used in pumping stations and water supply systems. They have a shutter in the shape of two semicircular fragments. Most often made of brass

Return mechanism.

To return the shutter to the closed state, the device has a spring. Stainless steel is most often used to make the spring (an important element of the shutter). But there are also models where, under pressure, the shutter rotates on hinges.

Nuances of proper installation

During the installation of shut-off valves, several rules should be strictly followed:

- The valve is installed strictly in the direction of coolant flow. To avoid mistakes, the product body must be marked with an arrow indicating the working direction.

- Paronite gaskets can be used to seal connections, provided that they do not reduce the diameter of the passage hole. Otherwise, the valve will exert more hydraulic pressure than intended.

- The device must be installed so that other elements of the heating system do not exert additional pressure on its body.

- It is highly advisable to install a mesh in front of the check valve for rough cleaning. This will make it possible to prevent solid particles from entering the locking mechanism, which, in turn, can lead to a violation of the tightness of the device when closed. Or use special valves with mesh.

Another important point: before installation, you need to once again make sure that the valve is selected correctly.

For example, for schemes with forced circulation, any type of device is suitable, but for gravitational systems, only a rotary petal device without a spring. Since the coolant moving by gravity will not be able to cope with the resistance of the spring.

Types of check valve

Spring (lifting)

Its design is similar to a shut-off valve. With sufficient pressure, the valve rises up, opens the hole, allowing the flow to circulate. At low pressure it falls down onto the seat and the water path is blocked. All this happens automatically.

It is used only on horizontal pipes, with mandatory vertical axial installation.

Advantages of a spring valve. Repair is possible without dismantling, as it has a removable cover. Plus it can be used at high temperatures.

High tightness. Versatility, can be used in both private and industrial water supply systems.

One of the disadvantages of spring valves is sensitivity to dirt and mineral impurities contained in water, which can damage them. But this can be solved by installing a filter.

Ball valve

The locking element in this device is a metal ball. Sometimes the ball is covered with rubber for reliability.

If there is no pressure in the water supply, the ball, under its own weight, tightly blocks the passage hole and prevents the liquid from moving in the opposite direction. When water is supplied, the resulting pressure lifts the ball, opening the way for the water flow.

Ball check valve

Pros. Ball check valves can be installed in vertical and horizontal pipes

Simple design and absence of mechanical components increases service life.

However, it should be remembered that with an equal internal cross-section, the outer dimensions of a ball valve are larger than that of other types of valves.

Rotary or paddle

The valve received this name because of its design.

It is based on a metal disk (“plate”) and an axis with a spring. The axis of rotation is located above the through hole. When open, the disc is parallel to the movement of water; when closed, it is perpendicular. Under fluid pressure, the disc opens. When the pressure drops, the spring is activated, the disk turns and blocks the flow. rotates under fluid pressure. If the pressure drops, the spring is activated and the disk blocks the path of water

The disadvantage is that in valves of large diameter there is a strong impact when slamming, which can lead to rapid failure of the structure.

Rotary check valves are divided into two groups:

Simple - with a small diameter of up to 400 mm. Used in systems where shocks cannot greatly affect the operation of the hydraulic system and the valve itself

Impactless - valves with a special mechanism that ensures smooth closing of the disc. The downside is that they are more expensive.

Double check valve

This device has two locking segments, which are located on a rotating axis. The plates are located in the center of the passage hole.

Water moving in the right direction opens the doors. If the direction of flow changes, the plates, under the action of springs, close the passage of the liquid.

Butterfly valves come in a wide range of sizes so they can be installed on pipes of various diameters.

They are also recommended for installation in systems where high pressure is present.

Definitions

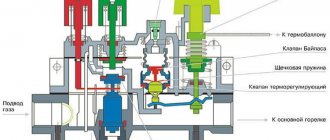

Let's start getting acquainted with the design of thermostatic equipment, moving from simple concepts to more complex ones.

Thermostat

This is a general name for all devices capable of maintaining a stable temperature of any environment under changing external conditions.

In relation to heating, a thermostat is understood as a control valve capable of ensuring a constant air temperature in the room when changing:

- weather conditions and, accordingly, heat loss through the building envelope;

- coolant temperature.

Thermostatic valve

The thermostatic radiator valve solves the problem of stabilizing the temperature in the room in the simplest and most obvious way - by limiting the flow of coolant through the heating device. The less water or antifreeze passes through the battery per unit of time, the colder it is; the more, the more its heat transfer increases.

What is the working principle of a thermostatic radiator valve? The vast majority of devices in the lower and middle price categories use the expansion of liquids and gases when heated and the reduction of their volume when cooled.

Thermostatic valve device.

When the contents of the bellows heat up, it lengthens and forces the valve against the seat, thereby limiting the coolant flow. Some time passes, and due to the decreased heat output of the heating device, the air in the room becomes colder. Compression of the working medium leads to a decrease in the length of the bellows; the opened valve allows the coolant to warm up the battery again.

Straight thermostatic valve for radiator 1:2 inches in diameter.

A more complex and expensive version of the thermostatic valve is an electric drive with digital control, which is carried out based on the analysis of data from a built-in or remote thermocouple.

Thermal head

Strictly speaking, a thermostatic head for radiators is a simple device for manually adjusting the valve position of a thermostatic valve. By rotating its handle, you can set the target temperature in the room, which will then be maintained automatically.

Head and valve.

Thermostatic kit

A typical heating device piping includes a certain gentleman's minimum, which allows you to flexibly regulate its heat output. The set includes:

| Device | Functions |

| Throttle or thermal head with thermostatic valve | Manual or automated adjustment of the supply permeability to maintain optimal room temperature |

| Shut-off valve | Complete shutdown of coolant supply to the radiator for its repair, replacement or temporary dismantling |

In some cases, the valve on one of the threads can be replaced with a check valve that stops the supply of coolant during counterflow (read: water is being discharged from the battery), or an additional throttle. In this case, the throttle provides preliminary balancing of the heating device (adjusting the permeability to equalize the temperatures of near and far heating devices).

A thermostatic kit is a set of shut-off valves from one manufacturer, including at least a thermostatic valve and a thermal head; More often, the kit additionally includes a balancing throttle.

In addition, the package can be supplemented with:

- radiator plugs;

- American ones for quick-connection of the radiator (they can be a separate element of the fittings or be part of thermostatic valves);

- Brackets for mounting the battery.

The price of a kit from a decent manufacturer starts from about 1000 rubles; the upper limit is 3 - 5 thousand, depending on the brand level and configuration.

Set of throttle, thermostatic valve and head for it.

Classification by installation method

Flanged valve

With this type of device, the return flange and the supply flange are welded to the valve body and a single structure is obtained.

This type of valve is mainly used in industrial systems for large diameter pipes.

Due to its large size, it can cause water hammer, since at the moment of closing, increased pressure is created in the system. To avoid this, systems use shock-free shutters with soft closing.

Advantages: ability to work in systems with water pollution. Application on main pipelines with large pipe diameters.

Wafer

These devices have virtually no mounting hardware. The valve itself is mounted between two flanges, at the ends of the connected pipes. A special seal is placed at the installation sites. After this, the flanges are tightened together with threaded connections (bolts or studs).

If installed correctly, the valve will be securely fixed. In terms of reliability, this type of connection is almost as good as a flange connection.

Coupled

The most common in household plumbing.

With this connection, the valve is connected to the pipe using a threaded coupling.

Pros: No need to use additional fasteners. Not suitable for large diameter pipes.

Components and operation

Design

General structural elements:

- collapsible metal case (galvanized), which has the best anti-corrosion properties and is resistant to active substances, including:

- spool chamber;

- coupling with internal thread for outlet/inlet;

Operating principle

The movable locking device moves freely inside the product. If the flow moves in the required direction, the ball moves away from the seat, opening the gap to the flow.

With reverse flow, the shut-off device is pressed against the seat, and flow becomes impossible, as shown in the photo.

Classification

Signs of classification.

1. Type of locking device:

- lifting - the lock moves up and down. After water is supplied from the pump, it opens slightly; in the absence of pressure, it closes due to spring pressure;

- rotary - locking doors that open under pressure or close with a spring when the pump is turned off;

- ball - a ball lock supported by a spring, which moves away from the flow, allowing water to pass through;

- disc - the lock slides along a pulley under a spring;

- double-leaf - shut-off valves fold under pressure or close when there is no flow.

For domestic purposes, lifting type products with a replaceable spring are usually used, due to the breakdown of which the device often fails.

2. Mounting type:

- coupling - due to two threaded transitions along the pipe. At home, thread from 15 to 18 mm (½” - 3”);

- flanged - due to a flange connection. In industry they are used for large pipes;

- wafer - by means of two flanges tightened with bolts. Used with large pipes;

- for welding - for long-term tightness.

3. Material:

- Brass - with good anti-corrosion properties, durable and unpretentious. Used on small pipes, often used in everyday life.

- Cast iron - for large pipes.

- Made of stainless steel - durable to any pipes, and also resistant to active substances, but expensive.

size 4:

- standard - for most pipes:

- 1 inch – the highest demand;

- ½ inch - less popular products due to low throughput;

- ¾ inch – for small diameter pipes;

Do I need a check valve for a water meter?

If you turn on several taps at the same time in an apartment building, pressure drops will occur in the water supply system. To avoid this, it is enough to install a check valve on the water meter, which will equalize the pressure drops.

The internal space of the meter must be constantly filled with water. This requirement allows the hydraulic check valve to be fulfilled. This will allow the meter to not fail for a long time.

If the pressure in the cold water pipe is greater than in the hot one. The meter will also start counting cold water. This will result in an increase in your utility bill accordingly. The check valve prevents cold water from entering the hot water system.

Valves that reliably block the water flow and prevent movement in the opposite direction. They will help prevent the consequences of water hammer for the water meter. This significantly increases the service life of the device.

Materials, markings, sizes

The check valve for water is made of stainless steel, brass, larger sizes are made of cast iron. For household networks, brass is usually used - it is not too expensive and durable.

Stainless steel is, of course, better, but it is usually not the body that fails, but the locking element. This is where you should approach your choice carefully.

For plastic plumbing systems, check valves are made from the same material. They come in polypropylene and plastic (for HDPE and LDPE). The latter can be welded/glued or threaded. You can, of course, solder adapters to brass, install a brass valve, then again an adapter from brass to PPR or plastic. But such a unit is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are check valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it’s hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to functionality. Plastic wears out faster, but it doesn’t jam. In this regard, it is more reliable. It’s not for nothing that some manufacturers of pumping stations install check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to “poison” and is replaced.

What is indicated in the labeling

A few words about the marking of the check valve. It states:

- Type

- Conditional pass

- Conditional pressure

- GOST according to which it is manufactured. For Russia, this is GOST 27477-87, but there are not only domestic products on the market.

Return valve for water: marking according to GOST

The conditional diameter is designated as DU or DN. When choosing this parameter, you need to focus on other fittings or pipeline diameter. They must match. For example, you will install a check water valve after a submersible pump, and a filter next to it. All three components must have the same nominal diameter. For example, all should have DN 32 or DN 32 written on them.

A few words about conditional pressure. This is the pressure in the system at which the shut-off valves remain operational. You should definitely take it no less than your working pressure. In the case of apartments - no less testing. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. You can find out the pressure for your home from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it is indicated in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. That's why they are popular.

Opening pressure characterizes the “sensitivity” of the valve. For private networks it rarely matters. Only on supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation. Don't forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of a check valve for water is calculated according to the nominal diameter and they are produced for all - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are the same sizes as all other shut-off valves: taps, valves, drains, etc. Conditional pressure can also be referred to as “dimensions”. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Next come the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And also, please note that for different companies, with the same nominal diameter, the external dimensions of the device may differ. The length is understandable. Here the chamber in which the locking plate is located may be larger or smaller. The diameters of the chambers also differ. But the difference in the area of the connecting thread can only be due to the thickness of the walls. For private houses this is not so scary. Here the maximum working pressure is 4-6 Atm. But for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. No air should pass through. At all. No way. Also try pressing on the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a check valve: blow into it and check for smoothness

Also inspect the seat and disc. Especially in the place where they are adjacent to each other. Everything should be even/smooth. The tightness of this type of fitting depends on how accurately everything fits. In more expensive models, a rubber/polymer/plastic sealing ring is installed on the plate. Needless to say, it should lie flat, without waves, and there should be no scratches or burrs.

Where to install

- If necessary, a check valve is installed where it is necessary to ensure flow movement in one direction.

- After the water meter, to protect against water hammer

- On hot and cold water pipes when used simultaneously. Due to the pressure difference, overflow through the mixer is possible

- At the water heater inlet to prevent heated water from escaping into the cold water supply system

- In front of the pump or pumping station to prevent the outflow of water in the event of a power outage or breakdown

- At the very inlet of the suction pipe

- In the anti-drip protection system of the dishwasher and washing machine

Where in the apartment should I install a check valve - video

How to install correctly

The easiest way to install a check valve is through a threaded coupling. Suitable for installation in the water supply system of an apartment or private house.

Work order (step by step instructions)

Select location, see above

Prepare fittings of the required diameter.

Wrap a sealant around the thread (linen, fum tape, thread)

Use a fitting to secure the check valve

Open the tap and check for leaks

If you are unsure or doubt your capabilities, call a plumber

It is important! There is an arrow on the valve body. The direction of the arrow must coincide with the direction of water flow in the pipeline

Even the most reliable shut-off valves fail over time. Therefore, you need to know how to remove the check valve yourself.

- First you need to turn off the water flow with taps

- if necessary, drain from the system

- Then unscrew the nuts.

- Dismantling flanges or fittings

- Remove the check valve.

- If possible, replace failed parts (for example, a spring)

- Reassemble in reverse order.

.

Attention! If the valve is installed near the water meter. You must act carefully so as not to damage the seal installed by the management company.

Scope of application of shut-off valves:

Valves and valves are used for liquid and gaseous media with a wide range of operating parameters: pressure - from vacuum 5·10−3 mm Hg. Art. up to 250 MPa, temperatures - from -200 to +600 °C. Valves are usually used on pipelines of relatively small diameters, since in the case of larger sizes one has to deal with a significant increase in effort to operate the valve and a more complex design to ensure correct seating of the valve on the body seat. Masterprom company sells shut-off valves

, classifying them

according to areas of application

: heating, heat supply and hot water supply, high-temperature steam networks.

Possible errors and problems during installation

The device may fail due to installation errors.

During the installation process, be sure to follow the instructions

It is advisable to inspect for problems once a month.

Possible problems:

No water flow

Incorrect installation. The arrow shows the direction of flow.

What to do: Disassemble and unfold the valve

During installation, the plug or the shutter retainer was not removed. This will result in the device not allowing liquid to pass through.

Solution: Dismantle, remove plug or retainer

The valve does not hold well

does not seal tightly.

A solid particle may enter and prevent the passage from being completely blocked.

What to do: First, try to wash off the trapped debris with a stream of water. You need to open and close the nearest shut-off valve several times. If this does not help, disassemble the check valve, rinse it well and reinstall it

The threaded coupling has burst.

This happens when there is a heavy load in the pipeline, a defective product, or too much sealing material is wound.

What to do: Can only be fixed by replacing the product

Tapping

After installing the check valve, knocking noises are heard. This can happen due to the larger valve diameter. Another option: installed too close to the pump.

Solution: in the first case, purchase a device with a smaller diameter. In the second, rearrange it to a more suitable place.

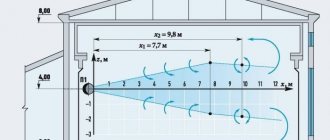

Direct and indirect acting valve

Pressure control valves are divided into direct and indirect acting devices.

- The first type of valve has a simple design: a spring is driven by a shutter, which is directly pressed by the coolant. Such devices are inexpensive, easy to operate, reliable, insensitive to dirt, but not very accurate in settings.

- Indirect-acting devices, also called pulse devices, have a piston-actuated main valve, a smaller pulse valve, and a pressure transducer. When the pressure changes, the small valve presses on the piston, which moves the main valve, which regulates the throughput of the device. Thus, flow control occurs indirectly, in an indirect way. Valves of this type are less reliable due to the larger number of parts and are expensive, but they can be adjusted more accurately.

Advice and recommendations from experts

To avoid mistakes during installation, we recommend reading expert advice:

- The direction of the arrow on the valve body and the direction of fluid flow in the water supply must match.

- The device must be installed in places where there is easy access. This is necessary so that the check valve can be inspected or repaired in the future.

- Before installation, check the device for leaks.

- Valves made of steel and brass have a longer service life. Since they are more resistant to corrosion and pressure changes.

- It should be installed after the metering device.

So that the water check valve installed in the water supply system can function correctly for a long time. It is necessary to carry out installation according to the rules specified in the instructions

Flow direction:

Based on the design of the body, shut-off valves are divided into straight-through, corner and direct-flow. Globe valves

are designed in such a way that the flow of the working medium at the inlet and outlet has the same direction, but inside the valve itself it makes 2 turns by 90°.

Such valves can be used to shut off working media with high temperatures and pressures, withstand significant overloads and maintain tightness. However, such a design leads to high hydraulic resistance and the appearance of stagnant zones in the housing. Angle valves

rotate the flow of the working medium by 90° and are used on rotating sections of the pipeline.

Compared to straight valves, angle valves have less hydraulic resistance. Direct flow valves

are somewhat similar to straight-through valves. In them, the direction of flow is maintained, but the spindle axis is not perpendicular, but inclined to the axis of the passage. The design of a direct-flow valve makes it possible to significantly straighten the flow and reduce hydraulic resistance, however, this increases the stroke of the shut-off element, the overall length and weight of the valve.