Pumping stations are one of the parts of the home water supply system.

They are used everywhere. Regardless of the design and water source, the package includes a pumping station. The pump pumps water into the subsystem, and the hydraulic accumulator helps maintain the required pressure levels. It is in the hydraulic accumulator that such an important part as the membrane is located. She participates in all processes. A pump with a hydraulic accumulator without a membrane operates at a higher load. It is on all the time when water is needed. This also increases energy consumption. Jumps in pressure indicators in this case are not excluded.

How to check and diagnose faults

Most hydraulic accumulator malfunctions can be corrected independently. All reasons can be divided into several groups.

Table 1. Malfunctions in hydraulic accumulators

| Signs | Possible cause of malfunction | Diagnostics | Remedy |

| Pump malfunctions - frequent on/off | Membrane failure | Disconnect the hydraulic accumulator from the system: Start draining the water. If air escapes, the membrane has mechanical damage. | Replacing a damaged unit with a new one |

| Leak behind the air valve | |||

| Intermittent streams from the faucet | |||

| Liquid leaking from nipple | |||

| Low system pressure | Nipple failure; lack of compressed air in the tank. | Replacing the nipple; Pumping air to the required pressure | |

| Leaking from under the flange | Depressurization of the connection | Tighten the fasteners or replace the part with a new one | |

| Weak water pressure | Pump fault | Install a pump of the required power, replace the faulty one with a working one | |

| Incorrect hydraulic tank volume selected | Make a calculation and replace the equipment with a suitable one |

To extend the service life of the hydraulic tank, it is necessary to regularly carry out external inspection and diagnostics of the main components, and monitor the pressure level in the system.

Recommendations for servicing hydraulic accumulators:

- Monthly inspection, checking that operating parameters comply with the standard (for each model and system individually).

- Check for corrosion stains on the body and connections.

- Check for leaks and surface moisture at joints.

- If there are malfunctions or malfunctions, correct them immediately.

- Checking the integrity of the membrane (inspection every six months).

- When not in use, store the hydraulic tank in a dry place, avoid contact with heating devices (to avoid drying out and destruction of the membrane material).

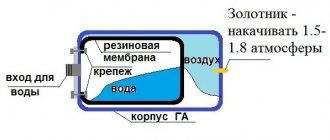

Diagram of the hydraulic accumulator

How to check the initial pressure in a container:

- Disconnect the tank from the system.

- Drain the water.

- Connect the pressure gauge to the nipple.

- If the readings are lower than the default ones, it is necessary to pump up the pressure to working pressure (with a car compressor, for example).

This is interesting: Installation of a heating cable in a pipeline: Operating principle and Types of heating cable

Operating rules

Optimal pressure in the accumulator ensures constant water pressure and prevents wear of system parts

In order for the hydraulic tank diaphragm and the device itself to serve for a long time, you must adhere to the following recommendations:

- Inspect and test your battery monthly to ensure it meets specifications. The latter are individual for each drive model.

- If you are not using the hydraulic tank, keep it in a dry place, away from contact with heating devices. Otherwise, the diaphragm material may become dry, causing it to fail.

- Check for corrosion and leaks at the connections and on the body of the hydraulic accumulator.

- Periodically measure the air pressure in the product and monitor its stability.

- Check the integrity of the diaphragm approximately every six months.

If malfunctions occur in the operation of the device, immediate troubleshooting is required to avoid aggravation of the situation. Otherwise, you can bring the device to a state beyond repair.

When operating a pressure device with a hydraulic accumulator without a membrane, the load increases and wear accelerates. The pump constantly turns on when the tap is opened. This increases energy consumption and the risk of water hammer. A high-quality diaphragm will help protect your equipment from these troubles.

Expansion tanks with rubber bulb

Replacing the bulb in a hydraulic accumulator with 20, 24, 50, 80 and 100 liters is done the same way.

Hydraulic accumulators are energy storage devices. Like batteries in electrical systems, they store and discharge energy in the form of a pressurized fluid.

The accumulator itself is a high-pressure vessel that contains hydraulic fluid and a compressible gas, usually nitrogen. The body or shell is made of steel and aluminum, titanium and fiber-reinforced composite materials. A movable rubber bubble inside the housing separates the water from the gas.

In these hydropneumatic units, fluids are slightly compressed under pressure. But gases are compressed into smaller volumes under high pressure, and engineers use this property in the design of expansion tanks for plumbing. Potential energy is stored in the compressed gas and released on demand to displace liquid from the battery and direct it into the home's water supply.

The hydraulic pump increases the pressure in the system and forces fluid to flow into the accumulator. The bulb for the expansion tank inflates and compresses the volume of gas, and the battery stores energy.

Water injection stops when the system pressure and gas are balanced. When water flows from a faucet or shower, the pressure in the hydraulic system drops and the accumulator releases the accumulated fluid under pressure into the circuit. And the charging cycle begins again.

Drillers recommend rubber diaphragm batteries as the best expansion tanks. They are made in standard sizes (24, 50, 80, 100 liters). Depending on the design, you can replace the bulb in the hydraulic accumulator in case of failure or damage to the tank yourself.

Self-production of a hydraulic accumulator

To save money, you can make a hydraulic accumulator yourself. In general, all materials are available, and the manufacturing process is not too complicated. However, at the very beginning, you need to decide on the future design of the device. And the easiest way would be to make a hydraulic accumulator without a membrane - this simple design is quite functional.

Preparation

First of all, you will need to prepare all the necessary materials:

- the most important part is the capacity. You can take a steel, aluminum or plastic tank. The volume should be within 100 liters. However, you should not take a tank that is too small; if its volume is less than 30 liters, it will be ineffective;

Plastic tankBalloon

- gaskets, you can simply prepare a piece of rubber and cut them in place;

- pressure gauge;

- sealant;

- tee and five-piece for connecting the tank to the water supply system;

- taps;

- pressure switch;

- nipple for air injection.

Unit design

As a rule, the hydraulic tank device has the following important components:

- metal case;

- flange with valve;

- rubber membrane.

It is worth noting here the fact that the membrane plays a key role in the design of the accumulator, so its condition always plays an important role.

Types of membrane for hydraulic accumulator, purpose and types, replacement instructions - Review + Video

An autonomous water supply system in a country house cannot do without its two most important modules - a water accumulator and a pump.

Both structural elements are very important for supplying water to the building. But while there is a lot of information about pumps that supply water from a well or a well to a building, there is practically no information about hydraulic tanks. From this article you will learn a detailed description of how a hydraulic accumulator works, the functional purpose of the product in an autonomous water supply, and the importance of a replaceable hydraulic accumulator membrane in the design of a hydraulic tank.

Advantages of a hydraulic accumulator

A hydraulic tank, properly integrated into the water supply system of a private home, performs several tasks:

- stabilizes pressure in the water supply system;

- protects water pipes from water hammer when starting pumping equipment;

- increases the operating life of the pump, since it limits the start and shutdown of the latter;

- provides compensation for water leaks from the water supply main.

Thus, the hydraulic accumulator is a very important structural component of an autonomous water supply system.

The performance of the entire water supply system mainly depends on the stable operation of the hydraulic tank.

How the unit works

A standard hydraulic tank consists of three elements:

- metal case;

- rubber membrane;

- flange equipped with a valve.

In the design of a hydraulic tank, the membrane is of key importance, and the condition of this membrane must be monitored.

Which membrane to buy for a hydraulic accumulator?

Depending on the purpose of use, such membranes come in two types. The former are used for heating systems, the latter for plumbing.

Products for hydraulic water supply tanks are white, made from natural rubber, resistant to bacteria and meeting hygienic standards.

The operating temperature of such membranes for the hydraulic accumulator of a pumping station is in the range from 0 to 70 °C. The maximum permissible pressure for them is 7 bar.

- Products for hydraulic heating accumulators come in black color and are made from special EPDM rubber, which is resistant to pressure surges and high temperatures in heating systems.

- The operating temperature of the membranes is in the range from -10 to 99 °C.

- The maximum permissible pressure for them is 8 bar.

Today on the pump market, manufacturers usually offer membranes for two types of hydraulic accumulators - balloon and diaphragm. Products of the second type are flat.

Balloon membrane

These products are rubber containers with a volume of 5 liters or more, similar to a medical heating pad or a standard jar. Larger models - accumulator membranes of 24 liters or more - are pear-shaped.

The balloon membrane works as follows:

- water is pumped into a rubber balloon using a pump;

- When the pump is turned off, the excess pressure that arises between the membrane walls and the accumulator body pushes water into the water main.

Thus, the balloon membrane significantly reduces the impact of water hammer on the water supply system.

Flat membrane

The product is hermetically sealed in the body of the hydraulic accumulator, dividing the latter into two parts - “wet” and air.

In this case, the membrane works like this:

- when the pump turns on. water is pumped into the unit and the membrane is compressed, creating pressure in the air compartment;

- when the pressure in the hydraulic tank reaches a certain level, the relay turns off the pumping equipment, and the membrane pushes the accumulated liquid into the water supply;

- when the pressure reaches a minimum value, the pump is turned on again and the process is repeated cyclically.

Thanks to the use of a diaphragm membrane, electricity and the energy resource of the pump are saved.

Classification of membranes by design

In accordance with this classification, the product can be:

- flat;

- balloon

Let's look at each of the varieties in more detail.

Flat products

Each such membrane for a hydraulic accumulator is fixed inside the tank, dividing it, as we have already described above, into wet and dry zones. When the pumping equipment is turned on, water begins to be pumped in, causing the membrane to compress and create excessive pressure in the dry compartment. When this pressure reaches a certain level, the pump will be turned off, and the membrane, in turn, will begin to push the accumulated liquid into the pipeline. When the pressure drops to the minimum permissible value, the pumping equipment will turn on again and the cycle will repeat.

As we can see, electricity is really saved, as well as the resource of the pumping station itself.

Balloon type products

They are also a rubber container shaped like a can or pear. The principle of operation in this case is not anything complicated and looks something like this: first, the pump pumps liquid inside this cylinder, then, when excessive pressure forms between its walls and the walls of the accumulator, it will push water out into the water supply after the pump is turned off. .

Note! It is obvious that balloon products significantly reduce the negative impact of water hammer on the water main.

Causes of wear

Among the factors influencing membrane wear are the following:

- temperature changes in the accumulator;

- a constant process of compression and stretching;

- friction of the membrane against the walls of the unit housing.

The membrane naturally wears out from the above factors. As a rule, the following important points indicate signs of membrane failure:

- the hydraulic accumulator began to operate jerkily;

- the pump turns on too often at short intervals;

- the pressure gauge readings suddenly reach a high level and then rapidly fall;

- the faucet seems to “spit” water.

In situations of this kind, the obvious fact is that it is necessary to replace the hydraulic tank membrane.

This is interesting: Finding water on the site with your own hands for a well or well: Secrets, step-by-step instructions

Role in the water supply system

Before dwelling on the pressure parameters in the accumulator, it is necessary to consider its main role in the water supply. The first purpose of this object is to support, as well as gradually change the level of pressure of the fluid present in the system.

In addition, the hydraulic accumulator performs such important functions as:

- provides reliable protection against water hammer (in this embodiment, a change in fluid pressure is meant, which was caused by a very rapid change in its speed);

- is responsible for the availability of a minimum water supply;

- limits the repeated and short-term start of the pump.

From the coverage of the listed functions, we can conclude that the hydraulic accumulator makes it possible to use a pressure switch, as well as automate the fluid supply process. If the system does not have a hydraulic accumulator, the relay will not be able to function correctly, since a rapid change in pressure in the system will provoke its frequent operation.

Hydraulic accumulator without membrane

In addition to standard factory-made hydraulic tanks, you can make such a device yourself. A hydraulic accumulator without a membrane is a regular water tank because... It is the membrane that helps maintain pressure in the system. It is much easier to buy an inexpensive ready-made hydraulic accumulator.

In order to build a hydraulic accumulator yourself, you need the following materials:

- tank (container) with a volume of at least 30 liters;

- shut-off valves;

- ball valve;

- half-inch tap;

- fasteners (washers and nuts);

- sealant (sealant);

- rubber gaskets;

- nipple;

- fittings (tee, screw).

Manufacturing procedure:

- Make holes in the container (on the lid and bottom, on the side).

- Install a half-inch tap in the upper hole (on the lid), seal the joint with gaskets and sealant, and secure with washers.

- Place a tee on the tap.

- Fix a ¾ shut-off valve in the lower hole and place a tee on it.

- Install a ball valve on the side hole.

For reliable fastening, all connections must be sealed with sealant.

A faulty hydraulic accumulator can affect the operation of the entire water supply system. Using the tips and methods described in the article, you can easily troubleshoot your home plumbing system. Timely prevention can prevent serious breakdowns and premature failure of hydraulic tanks and the entire system as a whole.

What about a hydraulic tank without a membrane?

In addition to standard industrially produced hydraulic accumulators, there is another alternative option - to make such a device yourself. In fact, a hydraulic tank without a membrane will be a simple reservoir for water, since it was it (the membrane) that was “engaged” in maintaining pressure in the plumbing system. However, it is much easier to purchase a ready-made hydraulic tank - even the most inexpensive one.

To make such a hydraulic tank yourself, you will need the following equipment and materials:

- fitting;

- container with a volume of at least 30 liters;

- nipple;

- ball valve;

- gaskets made of rubber;

- 1/2 inch tap;

- sealant for sealing;

- nuts and washers for fasteners.

After preparing everything you need, you can proceed directly to the work process. The latter is not complicated, and the algorithm for the necessary actions is presented below.

Step one. First, make holes in the tank - in several places (on the side, on the bottom or lid).

Step two. In the hole located on the lid, install a 1/2-inch tap, be sure to use sealant and rubber gaskets to seal the connection, and at the end securely secure it with washers.

Step three. Place a tee on this faucet.

Step four. Take a 3/4 stopcock with a tee fitted and install it in the bottom hole.

Step five. There is only a hole left on the side - install the ball valve here.

Note! Once again, we note that all connections should be treated with sealant for more reliable fixation.

As a result, we emphasize once again that if the hydraulic tank is faulty, the plumbing system will not be able to function normally. And the cause of the malfunction is, as a rule, the membrane for the accumulator. But if you follow our tips and instructions, you can easily fix any problem that arises!

Do not forget about timely prevention - it will help extend the service life of the hydraulic tank and the pipeline itself!

How to replace the bulb in a pressure water tank

A pressure accumulator with an internal rubber membrane is a method of supplying water to the plumbing system. When the tap is open, the pressure in the tank pushes water out of the bag, and the pump is inactive. The pump only works to fill the tank to a set pressure.

Frequent activation of the pump or problems with low water pressure lead to malfunctions and the replacement of the rubber bulb in the accumulator.

- Disconnect the water supply and electricity from the pump.

- Open the tap closest to the accumulator to drain the water and relieve pressure in the system.

- Disconnect the tank from the plumbing system and drain any remaining water.

- Remove the nuts holding the cover flange in place. Remove the cover flange.

- Remove the damaged rubber bag for the hydraulic accumulator. Tear the rubber bulb rim seal off the edge of the accumulator and pull it through the hole.

- Installing a membrane in a hydraulic accumulator requires caution. Install the new membrane by rolling it up and sliding it through the hole in the tank.

- Press the edges of the bulb firmly into the opening of the reservoir.

- Replace the cover flange, making sure that it does not press against the rim of the rubber accumulator bulb, damaging it.

- Tighten the nuts to hold the flange in place. Be careful not to overtighten them and damage the flange.

- Remove the air valve cap and charge the tank to the desired pressure. Check for leaks around the flange. Tighten the air valve cap.

- Reinstall the tank in the plumbing system. Turn on the water supply and reconnect power to the pump. Monitor the new installation for any leaks.

How to change

To replace a worn membrane with your own hands, you must perform the following sequential steps:

- disconnect the hydraulic tank from the water supply system;

- remove air pressure in the unit through the nipple;

- drain the remaining water from the hydraulic accumulator;

- the lid with the pressure gauge is unscrewed;

- the worn membrane is pulled out through a special hole at the bottom of the body;

- the new membrane is installed in the reverse order;

- the flange with the valve is installed in place.

By following these simple steps, you will restore the hydraulic tank’s functionality with your own hands.

Thus, in this article we talked in detail about accumulator membranes, as well as the reasons for their breakdowns. We hope that by using the tips and recommendations outlined in the article, you will easily replace the hydraulic tank membrane.

Watch the video in which the user demonstrates in detail how to replace the accumulator membrane with your own hands:

Rubber cylinder ruptures when charging with nitrogen

Nitrogen is pumped into balloon accumulators instead of air. The nitrogen is compressed more strongly and the tank supplies water to the pipes under high pressure.

On newly repaired batteries with a rubber bulb, the case must be lubricated before precharging. When precharging begins, nitrogen is introduced slowly.

A rupture at the end of the cylinder may indicate a loss of elasticity in the material due to the cold nitrogen gas during precharge. High-pressure nitrogen, rapidly expanding and cold, straightens the folded bulb and concentrates at the bottom. When cooled, the rubber is brittle and may break in the form of an asterisk (a).

If the balloon is inflated under the poppet valve, (b), then the casing may receive a C-shaped cut from the poppet valve.

Too much precharge in the accumulator can cause the accumulator bulb to get caught in the poppet assembly when cycling between stages.

This causes fatigue failure of the spring and poppet assembly or pinching and cutting of the balloon if the bag gets stuck under the poppet when it is forced closed. Too high pre-charge pressure will cause the rubber bladder to collapse.

For batteries with a rubber bulb, precharging is not done too low. The membrane can be crushed in the upper part of the body, then squeezed into the gas valve and punctured. One such cycle is sufficient to rupture the rubber balloon.

Sincerely, Alexey Plotnikov - water well drilling engineer. My page is here.

What causes the failures?

If the pump cannot lift water, external factors often contribute to this:

External malfunctions in the pump.

- A decrease in the fluid level in a hydraulic structure; in this case, the unit initially pumps water poorly, and soon ceases to perform its function, running idle. At the same time, the wear of the device increases, it quickly fails, since there is no provision for dry operation.

- The depth of the hydraulic structure is insufficiently large (up to 8 m), this becomes a cause of failure if the groundwater level decreases. With small well sizes, such changes are more noticeable.

- If you plan to install a pumping station on the site, it is possible to install a filter element. It is located at the inlet of the system - attached to the supply pipe at the bottom of the hydraulic structure and is constantly in contact with contaminants (sand, lime, substances contained in water). If you do not clean the filter, the water will stop rising.

The power of the electric motor was insufficient

If the force of the created water pressure was small initially, there is a high probability that the equipment was selected incorrectly due to an erroneous calculation of its power. As a result, the pumping station becomes ineffective: water is often absent or supplied intermittently.

When calculating the power of a device, a reserve is always made (10-15%), which will compensate for errors and the impact of negative factors during operation. If these nuances have not been taken into account, the unit operates at the limit of its capabilities: it often turns on and off or operates continuously, which leads to rapid wear and malfunctions. At best, the device requires repair, and at worst, it fails.

The power of the pump electric motor may be insufficient even if the unit is operated for a long time. This occurs when the configuration of the pipeline changes: its length or diameter increases, the direction changes due to the transfer of some plumbing fixtures, the restructuring of the facility and its redevelopment.

Low electric motor power.

Another reason for the pressure drop due to the low power of the device is an increase in the depth of the well. Each type of pump is designed for operation under specified conditions. If the source data changes, you should select a different unit option.

Elements of the pump discharge mechanism are worn out

Depending on the type of device, different components may fail: impeller, membrane. These structural elements often operate at high speeds and are therefore subject to high loads, which leads to rapid wear. If water with sand impurities rises from the bottom of the well or other contaminants are present in it, this can accelerate the wear of parts.

If the pressure weakens for no apparent reason (the water level in the well is normal, the power is sufficient, voltage drops in the network are not observed), it can be assumed that the pump has failed. If the pump is cheap, then it is often impractical to carry out repairs, since its cost can be high.

The pipeline leaked

The pipeline leaked.

- communication defect;

- exceeding the permissible pressure in the pipes, for example, if they are of small cross-section and the pump is powerful;

- if a leak has formed in the area of the threaded connection, the reason may be a lack of sealing material;

- The check valve is clogged, preventing it from closing.

Peculiarities

To reduce energy consumption and eliminate pressure level fluctuations in modern pumps with hydraulic accumulators, manufacturers install a special separating element - a membrane.

The shape of the membrane part depends on the volume of the container and comes in two varieties:

- oblong;

- elongated.

The base is rubber or specialized rubber. The material for the manufacture of the membrane must comply with all hygiene standards and sanitary standards. Special rubber that is resistant to mold and mildew can withstand high pressure and a wide temperature range.

Manufacturers produce two types of membranes:

- flat;

- balloon

Different types of membranes perform the same functions and have no technical differences.

Device

The hydraulic accumulator membrane is an element that allows the hydraulic accumulator to be divided into an air section and a water section. An elastic membrane is placed in the tank body, forming two spaces that are independent of each other.

The balloon membrane device is filled with water, and in the cavity between its walls and the accumulator shell there is air pumped under high pressure. A flat membrane is attached to the walls of the battery, forming two isolated spaces.

With the help of alluvial systems, water is pumped into the device until the maximum pressure level is formed. Experts set the required level using a relay on the equipment body.

Principle of operation

The principle of operation of the accumulator is to supply water to the membrane by a pump. In the cavity between the walls of the membrane and the coating of the accumulator, the pressure necessary for the operation of the entire water supply system is created.

When the value set on the relay is reached, the pumping system automatically turns off, maintaining internal pressure. This allows you to avoid changes in water pressure and ensure stable operation of the system. After the pressure drops to a minimum level, the pumping unit will automatically begin drawing water and pumping air again.

Purpose and principle of operation

The purpose of the device is to divide the inside of the hydraulic tank into two chambers: air and water. It works according to the following scheme:

- Water is pumped into a membrane “bag”, and the air between it and the walls of the device is compressed.

- When the maximum permissible pressure is reached - for household devices it is 1.8–3 atmospheres - the pump will turn off. The value must first be set on the pressure switch.

- The liquid is supplied to water consumers with the necessary pressure thanks to the action created by compressed air, which is located inside the accumulator.

- After the pressure drops to the lowest value, the pump will automatically turn on to draw water.

This scheme allows you to eliminate differences in water pressure and ensure stable operation of the system. Electricity consumption is saved and the service life of the equipment is increased, since the pump is turned on much less frequently. The use of a hydraulic tank with a membrane in the water supply network is also good because it minimizes sudden pressure drops that occur when starting up the pumping unit.

Preparation

Replacing a hydraulic accumulator membrane begins, first of all, with purchasing a new one. It is recommended to purchase high-quality products manufactured by leading European brands, rather than cheaper Chinese analogues, which, even with careful use of the storage device, break down extremely quickly.

Then you should prepare the expansion tank:

- Shut off the water supply;

- Vent the air;

- Drain off any remaining liquid.

If, during bleeding of air or draining water from the bulb or nipple, liquid is released, then replacing the accumulator membrane is an extremely necessary procedure that requires immediate implementation.

The occurrence of an air lock

If the heating system is filled with liquid or during emergency downtime, it is necessary to constantly bleed the air. Usually it accumulates at the top of the battery or where the highest point of the pipe system is located. Sometimes bleeding air once does not help: tap water is saturated with a large amount of oxygen, and the process of displacing it from the system can last up to two weeks. The air is released using a special Mayevsky tap until the coolant appears.

Repair stages

The process of replacing the accumulator membrane with your own hands is as follows:

• The flange is removed;

• The old pear is removed;

• The internal surfaces of the expansion tank are thoroughly cleaned of dirt and rust;

• The flange and seat are cleaned with sandpaper to eliminate even the slightest defects, damage, burrs; • The new membrane is straightened and installed in place of the old one;

• The flange is installed and tightened well with nuts.

After the membrane in the hydraulic tank has been repaired, it is necessary to check the device for serviceability through a test run. To do this, air is pumped to the level recommended by the manufacturer (on average 1.5-2 atmospheres), then the tank is connected to the water supply and pumping starts.

In order for the membrane replacement to be successful, the accumulator should not be immediately started at full power. It is advisable to ensure a gradual intake of water - this is the only way to avoid premature wear of the rubber distributor.

To prevent rupture of the bulb and other damage to the expansion tank, you should check the pressure at least 2-3 times a year and pump it up if necessary.

Similar articles

Service life of the accumulator membrane

Hydraulic accumulator membrane rupture

What to do if the accumulator membrane is torn? Read more in the article.

Repairing the diaphragm

Repair of the accumulator membrane is possible if the damage is minor. This is especially true in units with non-removable diaphragms. After all, if a rubber part wears out, the entire device will have to be replaced.

A very tiny crack is sealed using a rubber adhesive.

You can repair the part yourself using a vulcanizer for bicycle or car inner tubes. A similar problem is addressed to the tire shop. Before installing the repaired diaphragm, you need to carefully check the internal surface of the drive. Protrusions and burrs are not allowed.

Repair work will extend the life of the membrane, but not for long, on average by six months. After that you will still have to buy a new one.

Main causes of wear

Factors that negatively affect the condition of the membrane:

- continuous compression and tension;

- changes in pressure and temperature and an increase in these indicators above the standards;

- friction of the diaphragm against the walls of the device body.

Operating conditions in water supply systems and heating networks are such that it is simply impossible to avoid negative impacts. Manufacturers provide a five-year warranty on the operation of diaphragms. But in reality they have to be replaced more often. With constant use of the hydraulic tank, the pear usually lasts no more than three years, and in harsh conditions - about a year. In order to detect the problem in time, it is recommended to carry out a preventive examination of this unit every six months.

No water gets into the hydraulic tank

If water does not enter the hydraulic tank, you should check the filters

This reason for the hydraulic tank not working is common. It's all about the degree of contamination of the water that is pumped from a well or borehole. Filters are installed in front of the pump and the entrance to the house, which periodically become clogged. This leads to the fact that the accumulator does not take in water.

With the first filter, the pump has the least problems. It rarely clogs because it has a mesh structure with large cells. Its task is not to allow stones and debris to enter the pumping unit.

Filters installed inside the house in the water treatment system often become clogged. The dirtier the water, the faster the blockage occurs. Usually they replace the cartridges with new ones. The passports of these products establish standards for the service life of devices. They should be taken as the basis for prevention.

Another reason why hydraulic accumulators do not fill with water is a sharp decrease in voltage in the network. This causes the pump to not work correctly. Its characteristics such as pressure and productivity decrease. A decrease in pressure is a drop in the pressure of the water flow itself. It cannot withstand the nitrogen pressure inside the accumulator. The gas pumped into the tank simply prevents the liquid from penetrating the rubber bulb.

The problem is solved by purchasing a step-up transformer, which is installed between the connection point and the pumping station.

The third reason is airing of the water main. This phenomenon occurs quite often in autonomous networks, especially if a surface pump is installed in them. An air plug forms in some area, which stays in place and prevents water from moving further.

To do this, a tee is usually mounted on the suction circuit with a drain tap or valve installed. When such a situation occurs, you just need to open the tap and drain the water along with the air.

The reasons for airing can be different situations:

- deformation of the suction hose, the appearance of through cracks or holes on it, in this case it is better to replace the hose with a new one;

- a decrease in the water level in a well or well, due to which air is drawn into the suction pipe, the problem is easily solved - you need to lower the hose lower.

Signs that replacement or repair is needed

A drop in pressure or the flow of water in jerks indicates a violation of the integrity of the membrane

The following problems indicate a failure of the membrane element:

- the pressure device often turns on and off;

- the hydraulic tank operates jerkily;

- nipple is leaking;

- the pressure gauge readings rapidly start to rise, and then drop sharply;

- the flow from the tap flows intermittently;

- There is a leak behind the air valve.

To confirm damage to the diaphragm, diagnostics are necessary, since these same signs may indicate cracks in the battery case.

The test is carried out by disconnecting the hydraulic tank from the water supply system, after which the remaining water in it is drained. If air comes out along with the liquid, it means that there is mechanical damage on the rubber part. The same thing means if the nipple starts to leak when bleeding air. Therefore, it is necessary to change or repair the membrane in the accumulator with your own hands, which, in principle, is not difficult.

A loose connection between the battery housing and the flange fitting can also be the reason that led to malfunctions.

When using equipment without water supply, pressure may press the diaphragm against the inlet fitting. Because of this, the liquid does not enter the accumulator through the supply pipeline. To solve the problem, you need to unscrew the flange and straighten the membrane, at the same time checking it for damage.

If the cause of the failure is cracks in the hydraulic tank housing, there is no point in fiddling with the membrane. If the damage is minor, it can be repaired by cold welding. If there are serious defects, you will need to buy a new device.

Tank installation

In general, there is nothing complicated here, but when installing it, you need to take into account some nuances:

- the container must be well attached to the base. To do this, it is best to fix it with an anchor. This is necessary because the tank will vibrate during operation;

- connection to the water supply is best done through flexible hoses;

- the battery itself should be located in such a way that it is easy to maintain;

- Do not allow the electrical cable to touch the metal surface of the battery - if it breaks down, a short circuit may occur.

Installation example

Connection diagram in the general water supply system

Making a hydraulic accumulator on your own should not be particularly difficult. The main thing is to follow the basic rules - monitor the tightness of the connections and carefully connect the pressure switch. Moreover, all the work will take little time - if you don’t rush, you can get it done in one day.

What affects wear?

The membrane is a consumable element of hydraulic accumulators, which breaks or becomes deformed during operation and requires constant and timely replacement. Manufacturers of this group of products provide a guarantee of up to 5 years for the uninterrupted operation of their products.

The rate of wear and tear of a part depends on several factors:

- pressure drops in the system;

- constant compression and straightening;

- continuous friction process;

- constant and sudden changes in temperature;

- increased level of pressure.

For uninterrupted operation of the system, experts recommend checking it every 6 months, and, if necessary, replacing parts once a year.

Signs of membrane damage:

- changes in water pressure;

- chaotic movement of the needle on the pressure measuring device.

How much will a replacement cost?

As noted earlier, the membrane is the element of the equipment described in the article that breaks most often. And it’s not surprising, because it constantly stretches and contracts. As for the specific cost of replacement, it depends, first of all, on the manufacturer, the type of membrane and the hydraulic tank itself.

If you continuously use the plumbing system, we recommend that you give preference to a more expensive membrane that can withstand a large number of operating cycles. Also note that an imported membrane will cost about the same as half of a new hydraulic tank. But the service life of such a product is several times longer than that of cheaper options.

Kinds

A membrane tank is a special container in which a certain amount of water accumulates. The main function of the expansion membrane tank is to collect water and supply it under a set pressure.

Manufacturers produce several types of rubber membranes:

- pear;

- ball;

Small types of membranes up to 100 L are similar to a rubber heating pad or glass jar. Models with a volume of more than 100 liters resemble a pear or bottle.

On the shelves of specialized stores you can purchase two types of expansion membrane devices:

- with a replaceable membrane - has a high price, it is possible to timely replace the part if ruptures and deformation occur;

- with a stationary membrane - has a low price range, there is no possibility of replacing damaged elements and restoring the operation of the water supply system.

Modern manufacturers produce a wide range of membranes for hydraulic accumulators, the volume of which starts from 10 liters. For home water supply systems, the most popular tanks are 24, 50, 60 and 80 liters. In residential cottages with a large number of people, membranes with a volume of 100, 150 and 300 liters are installed.

For uninterrupted operation of heating systems in rooms of various types and purposes, experts recommend installing Wester expansion tanks , which monitor the pressure in the pipes and, if necessary, automatically reduce it to an acceptable level.

Material

One of the main criteria when choosing the required membrane is the type of material from which the part is made. Due to the fact that the rubber element is in constant contact with water, the material from which the membrane is made must comply with all sanitary standards and requirements.

Modern manufacturers offer five types of material:

- natural rubber;

- artificial butyl rubber;

- artificial material EPDM;

- material for heating systems type SBR;

- Nitril type material for oil and flammable substances.

For systems with process water, it is possible to use membranes made of any type of material.

Characteristics

The technical characteristics and properties of membranes depend on the type of systems in which they will be used. Manufacturers produce membranes for heating and water supply systems.

Technical features of membranes for water supply systems:

- withstand pressure up to 7 bar;

- operated in a temperature range from 0 degrees to 70 degrees above zero;

- the base is natural rubber, which has high environmental performance and resistance to the formation of microorganisms;

- White color.

Characteristics and properties of membranes for heating systems:

- base – special rubber;

- has a wide temperature range from -10 degrees to +100 degrees;

- withstands pressure up to 8 bar;

- black color.

Varieties and selection criteria

Parts that look like a medical heating pad are installed in small hydraulic accumulators - no more than 100 liters. In large hydraulic tanks - over 100 liters - the diaphragms are shaped like a bottle or pear. All these options can be flat or balloon in volume. The principle of operation is similar for different types.

When choosing a membrane, it is also taken into account that the products differ in the purpose of the hydraulic tank:

| Characteristics | For water supply | For heating |

| Color | White | Black |

| Material of manufacture | Natural or bottled rubber | Temperature-resistant EPDM or SBR rubber |

| Temperature (°C) | from 0 to 70 | from -10 to 99 |

| Maximum pressure (bar) | 7 | 8 |

Rubber is less resistant to low and high temperatures, but it is immune to the action of bacteria, mold and mildew. These properties are important for maintaining the quality of drinking water. Under no circumstances should tanks with SBR diaphragms be used for connection to water mains. Styrene butadiene rubber is a non-food grade material. It can only be used in liquid storage tanks for technical use.

There are other ways to classify membranes for hydraulic tanks that should be considered when choosing.

By size

Dimensional indicators are very important: if there is an error, it is impossible to replace a worn part with a new one. The following criteria are taken into account when assessing:

| Capacity(L) | Dimensions (mm) | ||

| Flange size (inner/outer) | Length | Section | |

| 0,16 | 45/65 | 65 | 58 |

| 2–3 | 45/65 | 135 | 80 |

| 5–8 | 45/65 | 155 | 105 |

| 8–12 | 45/65 | 200 | 115 |

| 12–18 | 45/65 | 265 | 135 |

| 24 | 80/110 or 90/120 | 260 | 200 |

These indicators must be indicated in the technical documentation for the hydraulic accumulator.

It is also important to consider the fastening of the diaphragm. This is usually carried out at the bottom of the tank through a flange. But in volumetric devices, called walk-through devices, they also provide for mounting from above. A hollow rod with a sealing element at one end and a thread at the other passes through the hole in the upper part of the membrane. The threaded end is brought out of the tank and is attracted to the latter by a nut. In fact, the outer part is a threaded fitting that can simply be plugged or a pressure switch and/or pressure gauge can be installed on it.

By replaceability

Manufacturers produce two types of expansion membrane units - with a replaceable and with a stationary diaphragm. The former are more expensive, but they can promptly replace the element if ruptures occur or it becomes deformed. The second ones are inexpensive. But in this case, there is no provision for replacing damaged parts and resuming operation of the water supply system.

It is rational to give preference to the first type of hydraulic accumulators. Otherwise, the device will work as long as the diaphragm can withstand.

Replacing a worn part is not difficult; you can do it yourself; prices for rubber spare parts are relatively low. They depend on the volume of the element, material of manufacture and manufacturer. Prices for the Gilex membrane for a hydraulic accumulator start from 600 rubles, the most inexpensive replacement parts, Aquasystem, cost from 260 rubles, Reflex - from 1,100 rubles.

Stages of installing a new part

Replacement membrane for hydraulic accumulator

The problem of replacing a hydraulic accumulator membrane arises quite often. It’s good that this process is extremely simple; you can do it yourself, without the involvement of professionals. And the price of components is relatively low - from 200 rubles, depending on the volume.

You must first check the compliance of the new membrane with the volume and other parameters of the battery. If all indicators match, you need to disassemble the drive. Before replacing a worn-out bulb in a hydraulic accumulator, you need to relieve the pressure in it by shutting off the flow of water and draining the remainder, then disconnect it from the power supply.

To change the aperture, you need to proceed as follows:

- Loosen the flange mounting bolts and remove them.

- Remove the damaged part through the special hole at the bottom of the tank.

- Inspect the diaphragm and assess the extent of the damage - maybe it can be repaired.

- Clean the hydraulic tank itself from corrosion and plaque, and the flange from possible burrs.

- Take the holder and insert it into the hole that is on top of the diaphragm.

- Place the membrane in the hydraulic tank, and after screwing the bolt into the holder, insert it into the opening located in the bottom of the housing.

- Straighten the neck and tighten the flange, tightening the bolts from opposite sides.

After assembling the device in reverse order, pump air into the hydraulic tank. This will allow the device to function normally. Injection is carried out using a conventional pumping device through a spool located at the bottom of the body part.

Then there is a connection to the water supply and electrical networks and the operation of the equipment is checked. The water must be connected gradually so as not to provoke a rupture of the new diaphragm.

To ensure that problems with the membrane part arise as rarely as possible, you need to ensure comfortable operating conditions for the device. In particular, ensure that there are no pressure drops or temperature surges in the hydraulic tank, and regularly carry out preventive inspections. If the device is not in use, it should be stored in a dry place, away from heating devices, so that the diaphragm rubber does not dry out or crack.

Installation nuances

You can carry out the repair procedure yourself, saving about 1,000 rubles - about the same amount you would have to pay to a master for the replacement work, which, in principle, is nothing complicated.

Replacing the membrane in a pumping station in stages is as follows:

- The work is carried out after the water has been pumped out from the tank and the pumping station is de-energized.

- Actually, the front flange is removed from the accumulator tank, and the old membrane is removed.

- If it was not possible to completely remove water from the system, it is better to loosen the flange mounting bolts gradually, and remove the leaking water using improvised means.

- If the membrane is intact, the inner surface of the tank must be absolutely dry. Accordingly, after removing the “pear”, if there is any water left there, the surface needs to be dried as much as possible.

- Then a new one is installed in place of the old container (sometimes it is recommended to additionally treat the junction of the “pear” and the tank with sealant), and the flange is screwed into place.

- After installing the membrane, you need to restore the internal pressure of the accumulator. To do this, using a compressor, air is pumped through the nipple on the back side of the tank (you should achieve the same pressure that was when the pumping station was operating in normal mode, checking the pressure gauge).

After this, the station is connected and a test switch is performed. If the membrane was replaced due to a rupture, there should now be no problems in the operation of the pumping station.

The membrane needs periodic (about once every year or two) replacement, otherwise it may burst during operation, and you will still have to change it.

In addition, with prolonged use, the “pear” greatly stretches and fills the volume of the accumulator tank, which forces the automatic pump to constantly pump up in order to normalize the pressure. This, logically, does not affect its wear for the better.

A sign that repairs are needed and the membrane needs to be replaced can be a situation when the pumping station, for example, suddenly turns on or stops every time the tap is opened, or operates jerkily.

The pressure gauge shows a sharp drop in pressure immediately after reaching the design operating mode.

This usually means the membrane has ruptured. On the back of the tank there is a small valve (a fitting used to pump air if you need to adjust the pressure inside the tank), through which water should not flow when the pumping station is in operation (when nothing is broken).

If this happens (it’s easy to check), the membrane needs to be changed. During normal operation of a hydraulic pump station, water should not get between the walls of the tank and the membrane.

In total, replacement of the membrane is necessary:

- Periodically, to increase the service life of the pumping station;

- If the membrane is damaged.

Timely replacement of a worn-out bulb is a very important and necessary matter. After all, it is precisely the accuracy of its operation that determines the correct maintenance of pressure in the system

For example, if it does not work correctly, the pump may turn on more often unnecessarily, which means it will consume more energy, increase its own wear and create additional load on the pipeline.

Naturally, such consequences are not very useful, so the membrane should be inspected periodically and, if necessary, replaced immediately.

Prevention

To prevent a breakdown of the hydraulic accumulator from taking you by surprise, you need to carry out periodic maintenance. It's easy to do:

- once every 3-4 months the tank is inspected for damage;

- Once every six months, you need to check the operation of the pressure gauge, pressure switch, and also check the air pressure level in the tank.

In addition, all experts recommend replacing the membrane in the accumulator every three years. Naturally, subject to its constant and uninterrupted use.

The fact is that the average service life of these products rarely exceeds this figure. Therefore, it is better to replace it in advance - this way you can protect yourself in advance from a sudden breakdown.

Previous articles Next articles

How to determine that the membrane has become unusable

In general, manufacturers claim a service life of 5 years for these products. However, in practice, this rarely happens. After all, they really don’t like membranes:

- temperature rise above the set value;

- frequent pressure changes;

- intense compression.

In practice, it is rarely possible to avoid operating the hydraulic tank in hard mode, so the service life of the bulb is reduced to 3 years.

How to determine when it’s time to change the membrane in a hydraulic accumulator:

- the pump started to turn on too often;

- The water pressure does not maintain constant pressure.

These are clear signs of damage to the membrane, however, it may also indicate damage to the accumulator housing. Therefore, before disassembling the container, it is advisable to check the condition of the tank itself.

How to check membrane integrity

The service life of the membrane declared by the manufacturer is 6-8 years. However, in some cases, the rubber accumulator wears out much earlier.

Checking the integrity of the rubber bulbSource https://proraboff.rf

How to check the integrity and whether it is necessary to replace the membrane in the accumulator:

- When water is drained, air comes out with it. This is a clear sign indicating a violation of the integrity of the membrane and requires replacing the bulb in the accumulator. Proper operation of the accumulator does not involve mixing gas and water.

- When air is released, water oozes out of the nipple. Requires checking the rubber bulb. If it is intact, then the problem is in the nipple itself.

- There is a sharp change in temperature in the mixer.

- The pump turns on and off periodically.

- The condensation formed on the outer walls of the tank indicates that the inside is in contact with cold water.

When installing the device, it is recommended to choose a vertical position with the inlet hole down. The correct position will reduce the risk of suspended particles entering with unclean water, and will also extend the life of the membrane storage tank.

Correct position of the hydraulic accumulatorSource https://terman-s.ru

Checking and diagnosing hydraulic tank problems

Let's start with the fact that the normal functionality of the entire plumbing system largely depends on the operation of the hydraulic accumulator. And if the water supply fails, then you are obliged to find the cause as soon as possible and make quality repairs. Otherwise, this can lead to more serious breakdowns, which, in turn, will inevitably lead to the failure of all equipment. And the most common reason is the membrane for the accumulator.

Let's look at how to find out, how to diagnose and replace this element.

As a rule, all problems can be easily fixed with your own hands. Let's get acquainted with the main “symptoms” and what needs to be done in a particular situation.

The pump malfunctions and turns on/off frequently

Most likely the membrane has failed. To diagnose this malfunction, disconnect the hydraulic tank from the water supply system, and then start draining the liquid. If air escapes during this, it means that there is mechanical damage to the membrane. The problem can be solved by replacing the failed membrane with a new one.

Water leaks from nipple

This is also evidence of membrane failure. The diagnostics in this case are the same, but replacing the damaged element can solve the problem.

The faucet is leaking intermittently or there is a leak behind the air valve.

Everything here is the same as in the previous two cases.

Water pressure is weak

In this case, there are two possible reasons: failure of the pump or incorrectly selected volume of the accumulator. In the first case, the problem is solved by installing a new pump, and in the second, by carrying out calculations and replacing the product with a more suitable one.

The system pressure is too low

Everything is simple here: either the nipple is broken, or there is simply no compressed air in the container. Therefore, to solve the problem it is necessary to replace the nipple or pump up the pressure to the required level.

Removable and non-removable membranes

A perpetual motion machine does not exist, so, of course, the membrane fails, however, in practice, this happens much earlier than planned, since in theory it should serve faithfully for about 5-10 years. But most often it breaks against the walls of the tank when the pressure is not properly controlled by the operator, and the air escapes.

If we return to the original formulation of the question, which membrane to choose: removable or not, then we need to consider these 2 types in more detail:

- The vast majority of models of modern hydraulic accumulators require the presence of internally removable membranes, for example, the well-known manufacturer Reflex UNIPUMP. Since the material wears out, the issue of replacement can be easily resolved.

- However, sometimes there are also models of units in which the membrane (it is also commonly called a diaphragm here) is non-removable. As a rule, the price of such hydraulic accumulators is significantly lower than that of analogues with a removable membrane. In this situation, replacement is not possible. Based on practical experience, we can say that such tanks will fail with absolutely the same frequency, because they cannot be repaired, and you will have to spend money on a new tank. A striking example of such tanks are models PressureWavePWB 2/,24 LH, WiloA 24-H and many others.

The answer to the question of which membrane option to choose (removable or not) is very simple. If you have the opportunity, it is better to spend a large amount, but purchase a tank with a removable type of membrane, ensuring that in case of repairs you can carry it out without any difficulties. But, since tanks with a diaphragm instead of a membrane are not widespread in our country, it will be difficult to buy such a tank.

In addition, it is worth paying attention to other parameters that are no less relevant for membranes. They will be discussed further.

Options for membrane closed containers

Membrane tanks are used as part of pipelines installed for various purposes, including:

- Cold water supply. The tank is used to accumulate and supply cold water and protects various household appliances from water hammer when the pressure in the system changes. Extends the life of pumps by reducing the number of pump starts.

- Providing hot water. The device used in this case must operate successfully in high-temperature conditions.

- Heating systems. Such tanks are called expansion tanks. They function as part of closed heating systems and are their important components.

Depending on the configuration, hydraulic tanks can be horizontal or vertical. However, the principle of their operation does not depend on the configuration.

Hydraulic accumulators intended for inclusion in the water supply system are painted blue, and those that operate in the heating circuit are painted red. These two types of membrane tanks also have some design distinctive features, which is clearly visible in the presented diagram (+)

A special feature is the presence of a special valve for bleeding air in the upper part of vertical models, the volume of which exceeds 50 liters. This air, as mentioned above, accumulates in the upper part of the chamber as the device operates. Therefore, the presence of a bleed valve in this place is a completely justified measure.

If it is necessary to bleed air masses when operating horizontal models, then a drain or a separate tap located behind the membrane tank is used for this purpose. To remove air from small devices, you will have to completely drain the water from it.

Since vertical and horizontal models are equally effective and functional, you should choose a suitable device based on the dimensions of the room in which it will be located. Whichever model fits best into the room is the one they take.

In addition to design features and different purposes, tanks may also differ in their capacity: this photo shows hydraulic accumulators of various volumes, designs and purposes

Selecting a membrane tank wisely

A hydraulic tank is a container whose main working body is a membrane. Its quality determines how long the device will last from the moment of connection to the first repair.

Products made from food-grade (isobutane) rubber are considered the best. The metal of the product body is important only for expansion tanks. Where water is contained in the pear, the characteristics of the metal are not decisive.

If you don’t pay special attention to the thickness of the flange of your purchase, then in a year and a half, and not in 10-15 years, as you plan, you will have to buy a completely new device or, at best, change the flange itself

When choosing a device, special attention should be focused on the flange, which is usually made of galvanized metal. The thickness of this metal is very important

With a thickness of only 1 mm, the service life of the product will be no more than 1.5 years, since a hole will certainly form in the metal of the flange, which will damage the entire device.

Moreover, the warranty on the tank is only a year with a stated service life of 10-15 years. So the hole will appear just after the warranty period expires. And it will be impossible to solder or weld thin metal. You can, of course, try to find a new flange, but most likely you will need a new tank.

To avoid such misfortunes, you should look for a tank whose flange is made of stainless steel or thick galvanized steel.