A washbasin built into the countertop looks much more interesting than one standing separately, without any decoration.

And it’s more convenient to use - cosmetic accessories or a razor can be placed nearby, rather than held in your hands.

Many users will be interested in a homemade countertop in a bathroom made of tiles - this will be discussed in detail below.

Manufacturing

The entire countertop manufacturing process consists of several stages:

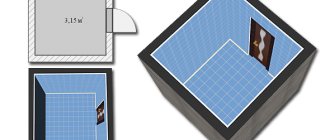

- creating a sketch, during the work you need to decide on the shape and dimensions of the future product;

- marking at the installation site;

- creating a frame;

- sheathing;

- performing finishing work.

Create a sketch

When creating a sketch of a future countertop, you need to focus not only on aesthetic appeal, but also on convenience and functionality. There are standard parameters:

- height – 80-110 cm;

- the distance between plumbing elements is 70 cm or more;

- the distance from the wall to the washbasin bowl is 10 cm or more.

However, these are standard settings, so they can be changed for convenience. For example, if everyone in the family is tall, then you can place the tabletop at a higher height. In addition, you need to consider the need for additional parts - shelves, niches, etc.

Marking

After the sketch has been created and the materials have been purchased, you can begin marking. First of all, you need to free the installation site from unnecessary objects so that nothing interferes with the work. If the countertop is not built immediately after repair, then you need to carefully inspect the finish to identify defects.

If they are found, then you need to take measures to eliminate them (fill potholes in the flooring, replace broken tiles, etc.). The markup is done like this:

the height of the tabletop is noted and a mark is placed on the wall (if the floor is uneven, you will first have to mark the zero level, and then measure the height of the tabletop from it); then, at the height of the tabletop, its length is marked; next you need to make a projection of the future structure on the floor, measuring its length and width; Marking is done using a level; it is very important that the lines are laid strictly vertically or horizontally without distortions.

Assembling the frame

Now you need to cut the profile or beam according to the dimensions of the sketch. It is recommended to try on each part on site and number it so as not to confuse where to install which during the assembly process. Once all the parts are prepared, installation can begin. To complete the work you will need:

- a hammer drill or drill with an impact function for creating holes in a concrete wall;

- screwdriver;

- dowels;

- self-tapping screws

Completing of the work:

- drill holes in the frame elements for installing dowels in increments of 20 cm;

- the prepared part is applied to the installation site, a point on the floor or wall is marked through the hole in the part;

- holes are drilled at the designated points;

- drill holes in the walls and floor, the diameter of the hole should be 6 mm, and the depth should correspond to the length of the dowel;

- install the frame parts in place, insert the dowels and screw in the screws. During the assembly process, you need to periodically check the correct installation using a level;

- to make a protruding stand, you need to use two identical sections of the profile, they need to be inserted one into the other and fastened with self-tapping screws. A double profile is much more reliable than a single one, so it’s not worth saving;

- It is also advisable to make horizontal jumpers (stiffening ribs) double. The prepared jumpers are inserted into the groove of the profile installed on the wall and secured with self-tapping screws. The jumpers are attached to the protruding post through a bracket, which can be easily cut from a profile trim;

- the upper part of the frame is reinforced with stiffening ribs; when placing jumpers, it is necessary to leave space for installing the sink. The spacers must be made double, otherwise the finished tabletop will sag, even with a slight load;

- The last stage of frame installation is the final check of the correct location of the parts using a level.

Sheathing

The finished frame needs to be sheathed with plasterboard. They do the job like this:

- cut blanks corresponding to the profile dimensions;

- The upper blank is placed in place and the outline of the shell is drawn on it according to the template. This is a very crucial moment of work, since if you cut the hole incorrectly, then after installing the sink there will be unsightly gaps;

- then the cut parts are hemmed to the frame, screwing in self-tapping screws every 15 cm;

- GKLV sheathes the top and side parts of the structure, according to the sketch. At the last stage, narrow strips covering the ends are attached;

- cut a hole for the sink and install it;

- Next, all seams are grouted and finishing begins. Tiles or mosaics are used as finishing.

So, if you want to make a countertop in the bathroom, it is convenient to use moisture-resistant plasterboard. Working with this material is not difficult, but you need to be extremely careful when marking. It is best to decorate the countertop with ceramic tiles. The mosaic finish will look elegant.

Mounting with brackets

We remember the main rule - the strength of the surface on which the washbasin is supposed to be installed. If the surface is loose, you need to increase the drilling depth slightly, use larger-than-standard fasteners and anchors of a length appropriate for the specific case.

The process itself is not complicated:

- a line is marked at the selected height;

- the thickness of the bowl wall is measured;

- this measurement is laid down and a mark is made;

- direct fastening is carried out;

- markings are made through the recesses;

- holes are drilled, dowels are driven in;

- We install brackets;

- we bring communications;

- We carry out a final check and finally secure the washers;

- We will carefully inspect the system by opening the water and checking for leaks;

- Let's make sure the installation is secure.

Best answers

Nikolay Todorov:

It depends on what shape you want the base of the sink. If it’s not very massive, then it can be made from metal profiles and gypsum fiber sheets, and there is also an option from foam blocks, and then you can finish it with tiles and stone and mosaics

Sergey Gudovsky:

Artificial stone, I heard it happens. Lightweight and no tiles needed.

Luke' :

If the wall is thin, it won’t come off, but your movements will crack the entire tile. Strengthen it and frame it with mosaics - it looks amazing when the master does it.

Teamen:

I have just such a tabletop. Made by a good master. The frame of the countertop is made of profiles (aluminum profiles are light and durable) and is attached to the wall and there are two more stands made of the same profiles, plus the sink itself is attached to the wall on brackets. The frame is covered with plasterboard and covered with tiles. Everything is holding up very well. But if the wall is so fragile, then you can make four or more supports on which everything will rest. Is the wall between the bathroom and toilet that fragile? It is probably made of foam blocks, it must support the weight of the sink, and the weight of the countertop is distributed on the supports. But in Lute everything is as it should be. In any case, it weighs 5 kg. it won't. The weight of the tiles + the weight of the glue + the weight of the drywall is no longer a small weight. The wall can still be strengthened. Or make supports from metal corners and distribute all the weight on them.

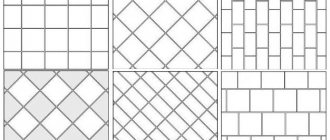

Tile sizes

In ceramic cladding, the seams are a weak point, so it is advisable to use tiles that are as large as possible. But in a small room, large modules look bulky and emphasize cramped spaces.

Mosaic tiles

It is recommended to use tiles of the following sizes:

- in a spacious bathroom: from 30x30 cm to 60x60 cm or mosaic (5x5 cm or less);

- in compact: from 10x10 cm to 20x20 cm.

Finishing a plasterboard tabletop

After the plasterboard structure is ready, it should be brought to its ideal appearance using decorative finishing. Most often this is done using ceramic tiles. The tiles should be the same tone as the room. You can make it the same color, but the difference is literally 1 tone lighter or darker. Drywall tiles can be broken into different pieces to create different shapes and chaotic abstractions.

Regular ceramic tiles should be laid using special crosses that keep each tile in the correct position and identically spaced from each other. The tiles must be laid with a special adhesive applied to the drywall with a notched trowel. The glue must be moisture resistant.

An example of finishing a countertop with special tiles

In order to cut the tiles along the edges of the sink, you should use a template made and used previously from cardboard. The tiles should be cut carefully and so that they exactly follow the contours of the washbasin. The seam between the countertop and the washbasin should be treated with silicone or another sealant. In order for the tiles to replicate a perfectly flat surface, after laying, a flat board must be placed on top, which will press down the tiles.

After the glue has dried, the seams should be sealed with cement mortar or the same glue. Again, after drying, the seams are rubbed with a special solution with paint that matches the general background of the bathroom.

The process of grouting joints with cement mortar

Mosaics usually come in smaller sizes and often form part of drawings. It is laid according to the principle of laying tiles, only it requires more patience and time. The drawing is laid out in a separate place, and then each individual mosaic is taken from the drawing and laid on a surface prepared with glue. Excess glue can be removed with a wet cloth or sponge. The seams are sealed using colored grout, which is matched to the color of the tile.

Construction and design of a simple plasterboard countertop

Important tips.

- For a long service life of a plasterboard bathroom countertop, you need to buy high-quality materials, fasteners and dowels.

- Tiles or mosaics should be laid with waterproof adhesive.

- The primer must also be of high quality moisture resistant.

It’s not difficult to make a plasterboard countertop in the bathroom with your own hands. You should not skimp on materials. Because metal is susceptible to corrosion (galvanized profiles are required), and ordinary drywall can swell and deform from moisture.

Advantages and disadvantages

The following arguments speak in favor of a homemade countertop with ceramic cladding:

- affordable price . Branded granite and marble countertops, especially those made to order according to consumer sketches, are much more expensive;

- diversity. There are countless types of tiles on sale with different textures, colors, patterns and surface types. This allows the home designer to create an exclusive product that fits perfectly with the bathroom interior;

- excellent characteristics. Ceramic tiles are moisture-resistant, durable, stable to temperature changes, and are easy to keep clean. Porcelain stoneware has the best characteristics: due to the absence of pores, it is close to natural stone in terms of strength, wear resistance and water resistance.

Frame assembly

It is carried out in the following sequence:

- In order not to confuse the blanks, it is better to number them. Holes of 6 mm are made in each.

- Each profile is applied along the marking lines and through the holes it is marked where the dowels will be located.

- Drill holes for hardware in the wall. If the surface is tiled, scratch the enamel at the designated point.

- Using a puncher, which is inserted into the holes in the frame blanks, holes are drilled again to the length of the dowel in the walls. and on the floor.

- They take the profiles and put them in place, insert the hardware and fix the guides. The evenness of their location is checked using a level.

- The protruding stand is formed from two guide profiles, inserted one into the other and secured with self-tapping screws along the joint line.

- Along the upper markings, horizontal jumpers are fixed, which are also made double. Fastening is carried out with a bracket made from profile scraps and screws.

- Strengthen the frame with spacers. Two are placed on the sides, and two more are placed under the base of the tabletop.

Check the evenness of all guides and the quality of the connection, as well as the absence of gaps and backlash.

Let's consider their types

Individual supports that are developed for mounting a bowl of a certain model. These are design works and often have an unusual configuration. Such plumbing fixtures are supplied with brackets in the form of specially shaped pins. Such fastenings are additionally treated with special compounds that carry a decorative load.

Wall-mounted sinks are fixed with cast iron and steel brackets coated with an anti-corrosion compound.

Racks are also available in various configurations (T or G), and are also made in the form of frames with a movable unit that allows you to adjust the installation. They are characterized by increased safety and stability.

The volume of the bowl affects the size of the mount. The length of the anchor is of great importance, since the depth of its insertion into the wall is at least thirty millimeters. The recommended mounting bracket size ranges from fifty to one hundred and twenty millimeters.

Execution Process

In order for the tabletop to turn out beautiful and functional, you need to know the stages of its creation, follow the recommendations and correctly use all the necessary tools.

Tools you will need:

Installation diagram of aluminum strips for countertops.

- drywall;

- self-tapping screws;

- screwdriver;

- pencil;

- sandpaper;

- dowels;

- metal profiles;

- moisture-resistant glue;

- sealant;

- primer;

- decorative slats;

- jigsaw;

- putty knife;

- brush;

Treatment of gypsum plasterboard for waterproofing

Despite the fact that drywall is moisture resistant, it is necessary to take care of its additional waterproofing. Its moisture resistance is ensured by the coating, and it does not require additional processing on top and bottom. Sections are at risk; slats and moisture-resistant glue are useful for them.

The exposed edges of the drywall need to be sanded using sandpaper. After sanding, it's all a matter of primer. It is best to choose one that is waterproof too.

Installation and Installation

Bath countertop dimensions.

The creation of a unique interior object begins with the construction of a frame; a metal profile, which is usually used for working with plasterboard structures, is suitable for this stage. To create the correct frame, you need to decide on the general parameters (length, width), at what height the countertop will be, measure the sink and cut a suitable hole. It should be remembered that drywall can break if handled carelessly. To avoid unpleasant surprises, process it on a flat surface so that the sheet does not hang over the edges of the workspace. The ideal option would be a pre-prepared table surface. To accurately outline the hole for the sink, outline it directly on a sheet of drywall, this way you will get accurate measurements and you will not have to finish or add anything during the installation process.

A simple tabletop without additional sections or sophistications is easy to install. To do this, you will need corners with which you can connect the structure to the wall; for fastening you will need screwdrivers and self-tapping screws. Install the sink and treat the joint between the gypsum board and it with sealant, this way you will protect your structure from moisture.

What is needed for high-quality installation of the product

It is not possible to install and secure a washbasin without certain tools and materials. By contacting a hardware store, you can purchase a high-quality set of tools for attaching a sink. This is a special set that includes all the necessary assortment: dowels, bushings, studs, nuts and washers.

This package is applicable when working with traditional bases. They are also suitable for walls made of natural stone.

Multi-level tabletop

A more complex version of the tabletop is a multi-level tabletop. Before you begin, you need to determine all the components, the number of levels and shelves.

The more elements there are in your design, the more carefully you need to take measurements. First, determine for yourself all the components, the number of levels, shelves, etc. Measure and cut out all load-bearing and decorative structural elements. At this stage, do not forget about proportions and the laws of physics. Cut the hole for the sink according to the already familiar principle. All sections exposed to moisture should be treated with moisture-resistant putty.

From the profiles we assemble the outline of the future tabletop. We cover the profiles with plasterboard. The bottom sheet is attached first; immediately after installing it, we move on to the supports so that the tabletop is stable and does not move around. After installing the sink in the prepared hole, the seams must be treated with sealant.

Overlay design

One of the most common sinks is the countertop sink. Even a non-specialist can install it. The product is mounted on a special surface that does not have a back wall or a cover.

In this case, preference is given to L-shaped fasteners with an oblique slot on one part. To install such a sink, four similar fasteners are used.

Installing a countertop in a bathroom

Installation of the countertop can be done in the following ways:

Floor-standing - when the tabletop is installed on legs or on a cabinet with pull-out shelves or doors.

This is the easiest installation method, as it only requires you to place the furniture where it is most convenient for you, adjust its height and install the sink on the countertop in the bathroom.

For the greatest convenience when cleaning the room, you should use cabinets under the countertop in the bathroom with legs, as this will allow the space to be ventilated and provide access for cleaning.

Countertops are installed using the wall method, leaving the space underneath unoccupied. Such tabletops are fastened with special corners or fasteners.

The product that will be wall-mounted should not be wider than 60 centimeters.

Today, there are a number of models equipped with drawers, shelves and compartments for storing various small items that are often needed at hand.

However, such products should be fastened quite securely, since they are massive and heavy.

Models are attached using a combined method - combining elements of a floor and wall countertop.

In this case, one part rests on the legs, and the other is attached to the wall.

Construction - frame

If you find that the bathroom walls are quite weak for installing a vanity, try an interesting way to mount the sink.

A device resembling a frame and consisting of profiles attached to the floor and walls will help to cope with this complexity. It can be adjusted in height, so the sink will be located the way you want. In addition, all unsightly pipes will be hidden inside this structure.

Installing it is quite simple. The frame is positioned, secured, and the pins are screwed in at the designated level to secure the product itself. The frame is sewn up with finishing material consisting of layers of plaster and paper. Then they are lined with any decorative material of your choice.

In order to reduce noise when operating the washbasin, a rubber washer is placed on the rod located between the wall and the bowl. Then, using pins, the wall-hung sink is installed.

The installation, properly assembled, is able to withstand a fairly large load, and, as an option, it can include space with additional shelves. Beautiful, convenient, economical.

Our next steps

- We attach slats to the bottom of the tabletop, which we used as beacons. They will serve as a support for covering the ends of the tabletop. We attach the corner outer profile to the end part of the tabletop with self-tapping screws. We carefully prime the cement layer and wait for the primer to dry.

- We dilute the glue according to the instructions. To ensure strength, you can add a primer to the mixing water (1 part primer to 3 parts water).

- We carry out the cladding from the “red corner”, i.e. from those sides that will be visible. We will start from the outer sides of the tabletop, which we will cover with full-size tiles. Using a notched trowel, apply a layer of glue to the cement layer.

- We lay the first tile on the corner of the countertop. Next, we lay out the first rows, maintaining an angle of 90°, checking the outer line using a level. Also, do not forget to check the horizontal plane in all rows using a level. The inner sides of the tile should be at the same distance from the lines we cut off.

A small nuance that we should think about before we start laying out the first rows: how will we veneer the end parts of our tabletop? There are several options to solve this problem. Let's consider one of them. The tile extends approximately one centimeter. The trimmed end tile or decorative border is glued at a right angle, with the factory side up. The size of the seam is adjusted with crosses and subsequently filled with grout. The underside of the undercut is hidden in profile. This is the easiest way to cover the end of a tabletop. To simplify the work, when laying the first row, we immediately set the end tiles. We observe the seams in the same way as on the main masonry. You can replace the end trim with a border. You can move the end tile up and attach the main masonry to it. It's just the way you like it.

- You can mount an external corner using an external corner tile profile. In this case, I advise you to place it under the top tile.

- Another option is to cut the tiles at a 45° angle. Please note that this is quite a complex job and, without special skills and additional equipment, it is better to do it using the two methods described above. If you decide to file, do not forget to sand the edges so that they are not sharp. It is possible to cover the end of the tabletop with shaped tiles or ceramic plinths. I’m not afraid to repeat myself: everyone here is their own creator and artist.

- Further installation should not cause any particular difficulties. We lay the tiles in rows - it is best to keep “long” rows. Don’t forget to insert crosses into the seams and remove excess mortar. We control the plane: when applying a level, there should be no gaps between it and the tile.

- When cutting tiles under the sink, you can allow an error of within 0.5 cm. The most important thing is that the sink must rest on the tiled surface along the entire plane. Note that porcelain stoneware is quite easy to cut with a lever tile cutter and very difficult to cut with an angle grinder with a diamond blade. In the case of sawing tiles under the hole for the sink, it is possible to make a template from cardboard and further mark it according to it. More details on how to lay tiles are described in the article “Tiles. DIY apron in the kitchen.”

So, we place the cut tiles against the walls and at the junction of the countertop with the refrigerator, cabinets, stove, etc. In the future, these joints can be closed using a plinth, having previously coated the seams with silicone sealant.

Which wood is better

Different types of wood are used for the bathtub, taking into account that the top is coated with a special polymer varnish. For the tabletop, it is recommended to use wood, which is used in shipbuilding, since it is not susceptible to rotting. Let's look at the characteristics of these wood species:

- oak is considered one of the most popular types of wood for interior decoration. The oak tabletop is processed using several technologies and is impregnated with special oils; stained, perhaps the most precious of the varieties, is obtained by soaking in water, where tannins reveal the unique strength of the wood; charred, the technology originates from Japan, but Dutch shipbuilders perfected a process that gave oak wood incredible strength. After treatment with fire, the wood turns black, then the layer is removed with hard brushes, revealing the texture of the wood. Such a board is not subject to rotting, and impregnation adds additional decorativeness;

- beech is used less frequently for bathrooms because its wood is susceptible to deformation. Modern technologies preserve the beauty of beech wood, thanks to special wax;

- Siberian larch has dense wood, is resistant to deformation, and can be processed in a variety of ways, such as brushing. The top is varnished;

- teak has an original texture, a pleasant honey shade of wood. Teak contains natural rubber, which has a positive effect on the quality of the finished product. Teak oil is used as an impregnation for moisture resistance of the structure;

- elm (elm) has a high wood density and colorful texture. It is usually impregnated with oil intended for wood. Elm visually combines with stone;

- walnut is an expensive type of wood and is used for luxury interiors. The rich texture does not require separate tinting of the board;

The constant influence of steam, water, high humidity and temperature changes creates specific requirements for the materials from which it must be made.

When using a wooden model in the bathroom, you should select a faucet - water from which does not splash, in order to avoid traces of drops. Variations made from bamboo - a highly durable alternative to traditional wood

Making the base of a future bathroom countertop with your own hands

3 sections of cabinet furniture are taken as a basis:

- cabinet under the sink, size 500x560x820;

- cabinet with retractable shelves 500Х560Х820;

- two-door cabinet, size 600x560x820.

In the future, the cabinets will be lined up along the bathroom wall. The section will be 1600 mm long and 560 mm wide.

To work you will need

Diagram of the grinder device.

Tools:

- Angle grinder (grinder) and disc on tiles;

- rasp (for processing the edges of cut tiles);

- putty knife;

- notched spatula;

- rags;

- jigsaw;

- stainless steel screws (3.5-3.8 cm) 200-400 pieces;

- felt-tip pen;

- pencil;

- electric drill;

- mixer;

- wood drill (5-6 mm);

- bucket for solution.

Materials:

- tile adhesive;

- crosses for tiles 2.5-3 mm;

- silicone sealant;

- protective composition for wood processing;

- primer;

- wood glue;

- waterproofing compound or quartz sand + liquid glass.

Scheme for installing overlays on the tabletop.

The base of the table top should be made of two sheets of softwood plywood, dimensions 1500 X 1500 X 20 grade FB or FSF.

FB is bakelized waterproof plywood (impregnated with bakelite varnish). This moisture-resistant plywood can be used in seawater and hot, humid climates.

FSF is a waterproof plywood glued with phenolic resin. Moisture-resistant plywood can be used outdoors.

Fastening the plywood must be done in at least 2 layers, overlapping. Before starting work, the plywood must be properly treated with bitumen mastic or a waterproofing compound for wood and impregnation.

Plywood should be cut taking into account that the fibers in all layers should run along the section. The plywood should protrude from the walls of the section on all sides by 3-5 cm. The joints of the plywood strips should not overlap the hole that needs to be cut for the sink. Plywood should be cut using a jigsaw.

The design will be quite heavy, so there is no need to skimp on the legs for the body.

The first layer of plywood must be fastened especially securely. The structure should be motionless. You need to attach the first layer of plywood to the side ties of the housings from below with your own hands (3-4 self-tapping screws on each side). The side walls must be tightened with self-tapping screws (1.5-1.8 cm) to the first layer of the future tabletop using metal corners.

Then you need to apply wood glue (wood glue, moisture-resistant PVA) to the top layer of plywood. The glue must be moisture resistant. It should be applied to the surface in a zigzag manner, and then the second layer of plywood should be pressed and tightened with self-tapping screws. To prevent the caps from sticking out, you need to first countersink the places where the screws will be attached with a drill. It is necessary to place screws in 15 cm increments both around the perimeter and deep into the sheets.

Using a stapler, you need to attach a painting mesh with a mesh size of 0.5-2 cm to the top of the second layer of plywood. It needs to be placed on the side edges of the plywood sheet and fastened with tension.

Care

Care instructions:

- Difficult-to-remove contaminants, such as fat, iodine, brilliant green, coffee, tea and others, must be washed out immediately.

- Glass countertops can be easily washed with window or mirror cleaners.

- All wooden products are afraid of water. They must be wiped with a damp cloth and then wiped dry. Hard to remove stains can be removed with baking soda. Sometimes it is worth impregnating with special means (so that the wood does not deteriorate).

- It is enough to wipe the artificial stone with a damp and dry sponge. It is advisable not to use detergents (such as soda, powder).

- Marble countertops can be wiped with a damp cloth and a small amount of detergent. Do not use metal jaws. To remove heavy stains, it is advisable to use a special marble cleaner.

Conclusion! The choice of countertop, wall or floor, material and everything else is an entirely individual decision. But a person who does not like constant changes and wants to install it for a long time should pay attention to a marble countertop.

And for those who have not decided what exactly they want and love constant changes, you can look at cheaper options, such as drywall, glass, wood.