The ventilation system is designed to supply the room with clean air and remove waste air laden with odors and dust.

But what to do if, on the contrary, the ventilation shaft becomes a source of extraneous “odors”, or if there is a strong wind, frosty air blows into it from the street? Let's figure out why reverse draft can occur, how to deal with it, and how to make a check valve for ventilation with your own hands.

When to think about a check valve

The main sign that something is wrong with the ventilation is the return of odors. There are many reasons for this: from improper planning, especially for private houses, to clogging with garbage, dust or snow. Backdraft also occurs during repairs, when the ventilation duct is specially blocked.

You can check its operation like this: just lean the sheet against the grille, while the window in the room should be open. If the air flow is pulling in the paper, there is no cause for concern. But it still makes sense to insure yourself with ventilation with a non-return valve.

If there is a stove in the house, if there is a lack of air flow, their direction may change. Or if another air outlet point is installed in the finished ventilation system. Environmental changes cannot be ignored. In cases where another one is built next to your house or, on the contrary, demolished, the direction of the wind may change and cause reverse draft. Powerful hoods and ventilation shafts in old houses can also come into conflict.

Some operating tips

When choosing a grille, you should take into account three main criteria: the dimensions of the entrance to the ventilation duct, its geometry, and operating conditions. Perhaps you need a decorative grille that does not have a check valve in its design? In this case, we recommend that you familiarize yourself with the existing types of ventilation grilles and the features of their operation.

When exposed to low temperatures, louvered grilles may become coated with ice.

As a result of icing, the valves will not completely close the duct inlet. Then the flow of air back into the room will inevitably begin.

In addition, due to the formation of ice, the clearance will decrease and the performance of the hood will drop. To solve this problem, the ice must be removed regularly.

Varieties

A check valve for ventilation helps to cope with these problems.

Check valves differ in many ways: shape, size, control method and location Source oboiman.ru

This design is a barrier that prevents air, as well as dust and grease particles, from returning back. This is facilitated by special blades and their movement. There are a huge number of models on the market, so let’s look at the most popular types.

Single valve

This design has another name, which is also often found - gravity check valve for ventilation. It is usually cylindrical in shape and has a flap that completely covers the ventilation duct. It comes into motion from gusts of air. The work happens as follows: when the flow rushes into the hood, it puts pressure on the flap and opens it.

In the case of reverse draft, no pressure occurs and the valve remains closed. When installed correctly, this model performs well, even if it is mounted under natural ventilation conditions.

In some versions, the center of gravity is not in the center, but is shifted to the left or right. If the draft in the system is small, then the sash may simply not open. To help it, you need to balance the sides a little. To do this, attach a small weight - for example, a coin - to the smaller of the petals.

Render of a single leaf valve Source airpromvent.ru

"Butterfly"

These are the usual exhaust ventilation valves that have 2 independent flaps. The analogy with a butterfly arises from the principle of operation of the petals, which open and close autonomously from each other, and resemble fluttering. Such structures are often equipped with springs that help the partitions return to their original position. How wide the valve opens depends on the air pressure.

During reverse draft, the springs hold the petals and do not allow them to open, so even if the ventilation malfunctions, neither odors nor dust will penetrate back.

Under the conditions of a natural system, the pressure will not be enough for the butterfly to operate effectively - that is, the spring will always remain motionless. Therefore, the best solution is to combine double-leaf models with fans. In stores you can find ready-made hybrid structures.

There are various modifications: for example, models with half-ring-shaped doors or options without springs that operate on gravity. In this case, installation of the valve is only possible vertically.

Externally, the “butterfly” is similar to a single-leaf valve, only the flaps are not connected, there is no single trajectory of movement Source smooth-air.co.nz

See also: Catalog of companies that specialize in complex installation of internal engineering systems

"Blinds"

This ventilation valve is installed at the end of the channel. Its task is to block a large vent, which single-leaf models and “butterflies” cannot cope with. The operating principle is based on gravity. The doors are located horizontally, and each has its own axis.

When no flow enters the system, the slats are lowered - this blocks reverse draft. If air is sucked in, the petals rise and the valve opens. This device is similar to ventilation grilles. They are made from plastic and metal.

With flexible membrane

Such structures do not have slats. The shutter is a membrane, that is, a polymer film. It is created according to the shape and size of the ventilation duct. When the air check valve is closed, the inlet is completely blocked. Under pressure, the edges bend and allow flow to pass through. If reverse draft occurs, the film is pressed tightly against the grille and restrains the impulse.

The valve architecture is so simple that some people prefer to make it themselves. Materials play a big role - high-quality film and how it is attached to the body.

If the valve is of poor quality, then the membrane simply will not hold on and will break off at the first gust of wind Source build-experts.ru

Other differences

The most common models are traditionally rectangular or round. To understand which one to choose, you need to pay attention to the cross-section and size of the air duct. Round valves come in diameters from 10 cm to 15 cm and above. For industrial ventilation, which differs from home ventilation in dimensions, buy a device from 15 cm to 1 m.

The control method also differs - there are automatic models, which are powered by electricity, and manual ones, which are controlled using a lever. Depending on the location of the air duct, installation can be carried out horizontally or vertically.

Features of self-production

Considering the low cost of check valves, self-manufacturing of the device is only relevant when using a ventilation grille or air duct with non-standard geometric parameters. In this case, it is often cheaper and faster to make a valve for it than to convert to a standard shape and size.

The easiest way is to make your own diaphragm or single-leaf valve. A rigid material, such as a plastic or metal plate, is used as a sash.

Particular attention should be paid to the following points:

- tight fit of the plate to the walls of the valve body or fixing protrusion to prevent the formation of a gap and the passage of air;

- eliminating plate knocking, which is especially important in the case of frequent changes in the direction of air movement.

For the diaphragm valve, you can use a sheet of thick paper or Mylar film, larger in diameter than the vent hole. In case of strong backdraft, in order to avoid deformation of the membrane material, it is necessary to install a grid on which it will rest.

Mylar film is suitable as a membrane. It does not lose its properties under the influence of moisture, as well as during repeated bending

How to properly install a check valve

Before starting work related to ventilation, it is necessary to take measurements to diagnose problems. To do this, you need to open the windows in the room and bring the anemometer to the entrance to the ventilation duct. If there is a hood, it is necessary to prevent the penetration of air - just seal the bottom with stretch film.

Natural air movement in the kitchen should reach 60 m3/h, in the bathroom - 25 m3/h. The lower the temperature outside, the higher the indicator will be. Of course, it varies depending on the area of the house or apartment.

Another name for an anemometer is a wind meter, used to measure the speed of wind flows Source allegroimg.com

For example, in a room of 60 m² the flow movement should be at least 180 m3/h.

Method No. 1

First you need to choose where and how to install a check valve for ventilation.

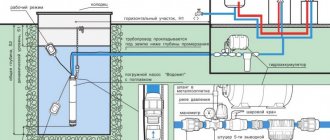

Let's consider the first option, when the device is mounted at the entrance to the shaft and reinforced with a fan. First, they make a seat - a sleeve that can be cut from an ordinary sewer pipe - the entire structure will be located in it. The element is cut to fit the width of your wall, so you will only need a little of it.

If the work is planned in a bathtub, then at the finishing stage it is necessary to choose the correct size and cut the tile to fit the sleeve. If you place it on foam, you may be in for an unpleasant surprise - it will begin to bend and the fan simply won’t go in. To avoid this, it is necessary to use softer adhesive solutions.

A common problem that people encounter when they want to change a device is that the fan sits so tightly in the sleeve that it is impossible to pull it out. You need to make your work easier at the installation stage. Therefore, the body can be wrapped with electrical tape or a special O-ring can be used - it should be slightly smaller in diameter.

There is no need to match the ring to the fan housing in color; it is not noticeable during installation. Source prom.st

In this case, you can additionally fix it with dowels, since the fit is already very tight. However, you can make a couple of attachment points on silicone.

Next, we de-energize the wire, connect our device to it and secure it in the sleeve. After this, we close it using a “blind” type air check valve.

Best Exhaust Fan Models

You can choose a fan not only by calculating all the characteristics yourself, but also by focusing on a selection of the most interesting and practical models.

ERA FAVORITE 4C-01 16 W

This Russian-made device has excellent performance and noise characteristics.

ERA FAVORITE 4C-01 16 W

The ABS plastic case is UV resistant and sealed thanks to rubber gaskets around the perimeter, the internal components are protected from moisture and dust. ERA FAVORITE 4C-01 has a double-leaf valve that will not allow air to flow in the opposite direction, against the fan. Thus, odors from the ventilation shaft will not penetrate into the room. The device motor is protected from overheating by fuses. According to its parameters, the device fits perfectly into small spaces. Mounted in an overhead manner.

Soler & Palau SILENT-100 CZ DESIGN

Stylish, well-thought-out fan from a leading Spanish brand. Its body is completely sealed, the outer panel is flat, which simplifies maintenance of the device. The device can operate uninterruptedly in rooms with temperatures up to +40 °C. The engine is installed in the housing using rubber-metal bushings. They absorb part of the vibration load, making the fan operation virtually silent. The valve prevents the return of air from outside 100%.

Soler & Palau SILENT-100 CZ DESIGN

Based on reviews from users and service technicians, we can conclude: the engine installed here is reliable, it will not break even once during the entire operation of the device.

AURA DiCiTi 4C MR

Thanks to additional rubberized gaskets, AURA DiCiTi 4C MR operates very quietly. With their help, the device body becomes sealed. The engine is reliable, does not require any additional maintenance and has optimal performance for use in domestic bathrooms.

AURA DiCiTi 4C MR

This fan is equipped with a Fusion Logic smart timer that can be programmed according to the needs of a specific consumer . This nice feature allows you to organize the operation of the device in such a way as to squeeze out maximum efficiency with minimal energy consumption.

Video description

In this video, the master talks about the location of the valve in combined ventilation conditions

Method number 3: in the kitchen

Usually, most people do this: they install a corrugation at the entrance of the ventilation shaft, stretch it with a clamp and combine it with a flanged fan. In this case, everything works well only when the artificial system is turned on. And when it is turned off, the channel of the natural system is forced to pull directly through the hood. The result of such a connection is no traction.

For efficient operation, the types of systems in the kitchen are combined - an artificial one is added to the natural hood. Installation of a check valve for ventilation is done in a non-forced air duct system. As soon as the hood is turned on, the flap closes to prevent air from entering the room.

To improve noise-reducing properties, the air duct is covered with heat and sound insulation. This will help reduce the noise level in the corrugation. It is better to install and glue all elements with silicone, so that it is possible to disassemble the entire structure if the time comes to change any parts. If you glue it with liquid nails, this maneuver will not happen.

Important! In 2021, Russia banned the connection of hoods with forced circulation in gasified houses as part of fire safety.

Double leaf version with springs

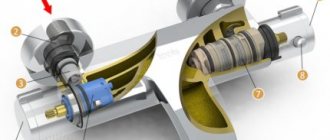

The valve, in the form of a butterfly, has two curtains in its structure. They fold under the influence of pressure forces from a certain side or slam shut when there is no pressure factor. The slamming mechanism is due to the action of built-in springs.

Such a device can be placed on the floor at any angle.

As practice shows, such a device works clearly in the presence of a hood. When purchasing such a device, be sure to test the springs for air pressure. Modern devices require adjusting the force of the springs.

Video description

This video shows how to adjust the valve and how to install it in the duct:

Method number 4: in the bathroom

For a bathroom, backdraft is a real problem, since cold air and, as a result, low temperature interfere with hygiene procedures - the level of comfort decreases.

To maintain the aesthetic appearance of the room, you can install flat air ducts with a cross-section of 200x60 mm under a suspended ceiling - this is the most optimal size. Taking less may affect the quality.

It is better not to rely on natural ventilation in the bathroom and toilet. Even if there is no reverse draft, moisture and odors take a long time to disappear. Therefore, the best option is a fan with a check valve. You can buy them separately or a ready-made hybrid. If you plan to mount the fan and valve in the adapter, then it is better to try it on in a store.

Tee installation

Tees ensure uninterrupted operation of ventilation and allow you to successfully combine its types. This is the only way the air exhaust duct can cover two rooms instead of one - for example, a kitchen and a bathroom. Therefore, you can install the valve on the tee. This is not difficult to do - just insert the filter into the structure and secure it with silicone.

Installation of ventilation grille

Before installation, a ventilation grille with a backdraft valve is checked to ensure that the valve is properly oriented so that the correct air flow will open the locking element. You should also carefully study the product passport and fully comply with all the requirements given therein.

If the kit does not include fasteners, you must purchase the required products. The surface is being prepared for installation of the grille flange. Places for fasteners are marked, holes are made for dowels, and dowels are installed. The product is installed with self-tapping screws. After installing the grille with an effective non-return valve for ventilation, leaks in the joints are sealed.

How to choose

- The valve, fan and ventilation duct must be the correct size for each other. Universal model of exhaust valve - 100 mm and square in shape for the corresponding shafts.

- Plastic models are used for natural ventilation in a residential building, since a reaction to any change in flow force is necessary. Also, plastic does not create much noise during operation. Industrial buildings should have analogs made of steel or aluminum so that the chemical composition of the air and high temperatures do not deform the device.

- Be sure to consider the temperature conditions. Not all valves are capable of operating in the cold - for example, double-leaf models quickly become covered with ice.

- The power factor of the fan for the kitchen should be 10, and for the bathroom – 7. Otherwise, the slats will not be able to fully open.

- It is important at what speed the air flow passes through the entire system. This is ensured by the lightness of the cylinder material and the fan - without it, the air check valve is only a barrier. Minimum throughput – 4 m/sec.

Single-leaf product based on gravitational action

Such a device operates on flows directed from the room with pressure exerted on the valve leaf. In the presence of reverse draft, there is no pressure, and the flap closes under the influence of gravity.

This device is used with natural ventilation. When installing, be sure to observe the placement of the valve based on its design features. This is done horizontally or vertically.

Photo 1. Scheme of installing the product horizontally and vertically.

Common mistakes in installing a check valve

- The non-return ventilation valve is mounted at the wrong angle, and as a result it works only once in a while. Also, the shutters do not always open when the filter is in a horizontal position. Therefore, it is necessary to take into account the design features of the device and the location of ventilation. The optimal installation angle is 2°, since the doors open and close under gravity.

- The fan and valve are too tight. Over time, dust, grease, and cobwebs accumulate on them and require cleaning or even complete replacement. There are many reasons why a structure is difficult to dismantle: from improper installation to strong fastening, for example, with liquid nails or dowels. If you use installation rings, you can fit the fan tightly into the shaft without additional fastening.

Silicone ensures soft fit and easy dismantling Source materik-m.ru

- The doors slam loudly. This is not to say that this is an installation error, but rather a problem that anyone can encounter. To remedy the situation, attach a small piece of foam or rubber, but so that the petals can close. Otherwise, the valve will not be able to operate effectively during reverse draft.

- Fight backdraft using a check valve, rather than looking for the cause. And there is only one problem - lack of incoming air. Doors, plastic windows - these structures prevent wind and cold from the street from passing through so well that natural exhaust becomes a supply. That is, the flows choose the path of least resistance and are sucked into the mine from the street. It’s easy to restore the balance - you need to periodically leave the window open. Also, the doors should not fit closely to the floor, it is advisable that 2 cm remain, in addition, you can install valves - all these measures will maintain circulation in the room.

This is what door ventilation looks like Source sdelaidver.com

Device design

The check valve for all similar devices for home use is made of plastic. The specific design of the check valve is widely used in various exhaust systems for various rooms and kitchen hoods. It is based on the principle of operation of butterfly wings: during flight they are straightened, and the rest of the time they are folded. Two equal halves reliably shut off the air supply inside the room after the fan stops working using special springs - they are opened by the blown mass of air.

This design, along with obvious advantages, has some disadvantages:

- opening the valve flaps consumes engine energy, so the fan efficiency decreases slightly;

- The valve flaps do not have sufficient tightness.

But in everyday life, such a fan copes with all duties perfectly.

Briefly about the main thing

The non-return valve protects against the return of odors from the hood. There are 4 main types: single-leaf and double-leaf, “blinds” and with a membrane. There are also differences in shape. The most common ones are rectangle and cylinder. You can choose models with manual or automatic control.

There are several ways to install the valve: installation for natural ventilation, forced and hybrid. In the first case, you will need an amplifier - a fan - to act on the blades. In the second, the filter is mounted inside the air duct. But the most common is installation in a mixed system. This is necessary so that when the hood is turned on, the air does not escape through the natural ventilation shaft.

Ratings 0

Blinds on the ventilation grille

The valve installed on the outdoor grille may be in the form of a louvers. The operating principle is similar to a single-leaf product and is based on gravity. When using several sashes, the operation of the device is more efficient. Dimensions are based on possible hole patterns. The valve can be installed over the entire grille area or exclusively on the hole.

Photo 2. An example of ventilation grilles with blinds.

Use of flexible membranes

The use of a membrane version of the valve is due to the action of the air flow, which will change the position of the plate.

One direction of flow serves to open the membrane, the other vector of pressure closes it. A strong backdraft process can deform the plate. To avoid such a situation, you need to purchase a product with stiffeners. If you try to save money and buy a device without ribs, then there is a possibility of deformation of the product. The result will be the passage of air in an unwanted vector.

Sources

- https://sovet-ingenera.com/vent/montazh/ventilyacionnaya-reshetka-s-obratnym-klapanom.html

- https://TopVentilyaciya.ru/ventilyaciya/elementy/reshetka-s-klapanom.html

- https://stroy-podskazka.ru/ventilyaciya/reshetki-s-obratnym-klapanom/

- https://ventilaciya.info/ventilyatsiya/ventilyatsionnaya-reshetka-s-obratnym-klapanom.html

- https://StrojDvor.ru/ventilyaciya/ustrojstvo-ventilyacionnoj-reshetki-s-klapanom-obratnoj-tyagi/

- https://oventilyacii.ru/ventilyaciya/ventilyatsionnaya-reshetka-s-obratnym-klapanom.html

[collapse]