Often, when arranging a floor covering, a technique is used to combine several decorative materials that have different textures, thicknesses and colors.

The most popular of them are laminate and ceramic tiles. And in this case, a rather serious problem arises - how to correctly join laminate and tiles in order to get a reliable and practical floor?

Forms of joints between laminate and tiles

The connection of floor coverings can vary in configuration and length. Depending on its shape, there are three main types of joints.

Straight line

The easiest joint to arrange. It can be issued as a threshold or done without it. If the seam is located in the space under the interior door, a threshold is considered mandatory.

Photo: Instagram remont.detected

Curved joint

Not an easy option to make. The main difficulty lies in precise cutting of the material, which requires a professional tool. The seam can be made without a threshold or with it, but if mistakes were made during the work or defects appeared when cutting materials, only a threshold can disguise them.

broken line

An effective connection that involves laying uncut tiles end-to-end with laminate flooring. The main problem is the exact fit of the parts. The threshold in this case is extremely undesirable, since it greatly spoils the appearance of the floor.

Grout Ceresit CE 40 Aquastatic

Flooring requirements

High demands are placed on the floor in the kitchen, since kitchen flooring is susceptible to moisture and severe contamination . Under such conditions, many materials cannot withstand long-term use and after a few years become completely unusable. As an alternative, natural oak floors are used, but due to the high cost, this option is not suitable for everyone.

In any apartment and private house there are specific requirements for the flooring of the kitchen area :

- high moisture resistance: the coating should not absorb moisture;

- dense, non-porous structure of the material;

- anti-slip effect;

- high abrasion resistance;

- High resistance to cleaning agents without compromising color or quality.

In the kitchen, linoleum, laminate or natural wood floors in areas of the busiest traffic wear out quickly. The area under the kitchen unit, along the kitchen facade and refrigerator is deteriorating, while the main part of the floor looks normal. This negatively affects the overall appearance of the kitchen.

The most effective solution to this problem turned out to be the simplest. Where the floor wears out most quickly, a block of tiles is laid out, and the rest of the kitchen is covered with laminate.

When you can't do without a threshold

The connection of two floor coverings without a threshold looks very attractive, but in practice it is not used so often. Making a joint with a threshold is universal and often more practical. Its use is justified in the following cases:

- Masking the difference in height between two coatings. The part can be installed if the difference does not exceed 1 cm.

- Zoning of the premises. Using a threshold will emphasize the division of the room, especially if a contrasting color is used.

- Masking of joint defects. It will help hide uneven cutting of the material and other defects.

- Separating the hallway space. This is necessary so that small debris and dirt that enters the room from the street are retained by the threshold and do not enter the living rooms.

It is important to know that the threshold poses a certain danger, since it is easy to trip over it. The part makes cleaning somewhat difficult because dirt can accumulate under it. It is quite difficult to extract it. In addition, the threshold can somewhat spoil the appearance of the floor, although if you choose it correctly, this will not happen.

Scope of application

Liquid cork sealant is suitable for sealing joints and cracks in any cork or wooden products : panels, boards, parquet, substrate. In addition to wood, concrete, glass, plastic, ceramics, and metal can be treated . The material has high adhesion and is used in all cases where it is necessary to insulate or soundproof a structure.

The scope of application is:

- sealing interpanel joints and seams;

- sealing assembly joints when installing doors and windows;

- compensation – when laying floors on a concrete screed, for example,

- sealing joints in panel frame houses;

- sound insulation of interior partitions and floors - in the latter case, inserts and panels are more often used;

- formation of sealing contours - here the cork composition acts as a joint filler and sealant;

- assembly of heat-insulating systems;

- floor finishing - used when laying parquet, tiles, laminate, installing baseboards, during repairs, when installing black flooring to eliminate squeaks.

Cork sealant is used for interior and exterior work.

What to consider when choosing a threshold

To choose the threshold correctly, you need to determine why it is being installed. It can be installed to zone space, to disguise multi-level floors, etc. It can emphasize or, conversely, hide the junction of materials. This must be taken into account when choosing. In addition, you should pay attention to such characteristics.

Seam configuration

Any thresholds can be installed on straight joints. For curved ones, only flexible options made of metal or plastic. The depth of the joint is also important. If it is small, it is optimal to use parts with a flat inner side. They can be glued to the seam. The easiest way is to purchase self-adhesive thresholds.

Photo: Instagram double_v_design

Part material

Various materials are used to produce thresholds. Metal and plastic thresholds are most in demand. Wooden ones are used less often. They are very capricious because they cannot tolerate high humidity and sudden temperature changes.

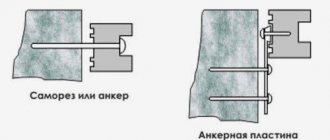

Fastening method

Parts can be installed openly or hidden. In the first case, self-tapping screws are used, the heads of which remain visible. For hidden installation, glue or special decorative overlays are used to cover the fasteners.

The color and size of the part are also important.

Photo: Instagram germes.bsp

TOP 3 best threshold manufacturers

In search of quality products, you can interview friends, surf the Internet, request information through “Okay, Google” or Alice. But it’s better to read our mini-rating of top manufacturers of profiles for laminate and ceramics.

Cezar

Since 1997, the Polish manufacturing company Cezar, under the brand of the same name, has been producing a variety of products for construction and finishing purposes. Including:

- Skirting boards made of plastic and aluminum.

- Door frames, fillets,

- Panels for walls and ceilings.

- Substrates for floor coverings.

- Profiles for ceramic tiles, plasterboard, furniture.

- Aluminum and PVC thresholds (flexible).

The last category includes flat, semicircular and corner elements with open, hidden and adhesive fixation systems. Color range – more than 50 decors and shades. Domestic consumers are well acquainted with the brand, because Caesar products are famous for their quality and durability.

Arbiton

One of the largest Polish companies, Decora SA, is a whole network of factories producing construction and finishing products produced under the brands Afirmax, EwiFoam, Vidella and Arbiton.

Arbiton TM products are often found on the domestic market:

- Vinyl tiles.

- Substrates for flooring materials.

- Thresholds made of metal and PVC.

Flexible and aluminum profiles are produced in a wide range, including joint-bridging, corner, and finishing. The color palette includes more than 50 decors, including metal and wood designs. Products are certified according to Russian and European standards.

Tips for designing a joint

To make the joint of materials neat, you need to follow simple rules:

- It is necessary to decide on the type of joining coatings even before the screed is laid. This will make it possible to subsequently make their levels the same by selecting the thickness of the substrate, material, etc.

- If you plan to lay it on a ready-made screed, you can remove the height difference using glue on which the tiles will be mounted.

- To design a joint with a large height difference, more than 0.5 cm, it is optimal to use a multi-level profile.

Photo: Instagram vera_v_remont

- For materials laid in a floating manner, it is worth using a T-shaped metal threshold. If the area is small, you can firmly fix both coatings at the joint area. In this case, compensation gaps will only be under the baseboards.

- The easiest way to choose a threshold to match the color of the coating is to choose it from those that the manufacturer offers for its collection of materials.

- It is better to perform pruning with the help of good equipment, otherwise the result will be disappointing. It may be worth seeking help from specialists, especially if you plan to perform a joint with a complex configuration.

Photo: Instagram elista.stroydomsnami

If you wish, you can safely choose different flooring coverings for your home. The section of their connection can not only be straight, but also have a complex configuration. If you know the installation technology, it is not difficult to create a neat joint between the tiles and the laminate.

How can you connect the transition?

To neatly design the gap between functional areas, four materials are most often used.

Grout

An easy way to seal winding, shallow seams. Such thresholds are difficult to find, and other fillers will not look so organic. Often in modern interiors there is an interesting way of finishing the floor: polygonal ceramic parts “incline” a little into an area with a different coating. This separates the hallway area from the rest of the house and the kitchen area from the living room. In this case, the transition is also carried out using grout. Do it in the following order:

- Carry out preparatory work.

- Treat the edges of the second material with silicone compound.

- Fill the resulting seam halfway with it.

- Wait for it to dry.

- Dilute the grout, spread it on top and level it with a spatula.

- Wipe the finished dried layer with a damp cloth and cover it with clear varnish to extend its service life.

Photo: Instagram @remont100lvl

- Decoration

Colored grout for tiles: 8 pros

Silicone and acrylic sealant

Joining two sections with elastic sealant is even easier than with grout. The advantage of the method is that there is no need to additionally treat the boards to protect them from moisture. But there is one point - you need to take into account that after drying the filler will turn light brown. The acrylic filler can be painted in a suitable shade after it has dried. Both expansion joints are suitable for renovation work in new buildings, as they are able to adapt to the shrinkage of the building.

Sequence of work:

- Place masking tape on both sides of the seam so you don’t have to waste time scrubbing it off later.

- Make a hole in the silicone paste tube so that it can be squeezed out, or insert it into a special gun.

- Fill the gap so that the sealant extends slightly above the floor surface.

- Use a spatula to remove excess mixture. If you don’t have a spatula, you can wait until the mixture dries and cut off the excess.

Keep in mind that it takes one or two days for the sealant to dry completely. Silicone expansion joints are recommended for use in rooms where the flooring is secured with glue or fasteners.

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @prinesite_pechenki

Liquid plug

Liquid cork for laminate and tile joints is a moisture-resistant mixture of an adhesive base and cork chips. It has an unusual texture and looks good in seams no larger than 7 mm. On wide crossings it will look alien. This is a simple connection method for areas of any shape.

The hole that is filled with the mass is first cleaned of dust and degreased.

Rules for working with the mixture:

- The coating levels must match. If there is a slight difference, the glue is aligned along the higher edge.

- Do not let the cork get on the floor, as it is difficult to wipe off and, once dry, almost impossible. You can pre-coat the floor with oil or apply masking tape to it.

- The material must be sanded a day after pouring, until it hardens.

The layer turns out to be very durable and it is almost impossible to remove it.

Photo: Instagram @centraparketarf

Photo: Instagram @parquet_design

Cork compensator

One of the most popular ways to design boundaries between two floor coverings. The filler is a soft, pressed lath or whole sheets with the same characteristics. The compensator has several advantages:

- Possibility to choose the appropriate color.

- Ability to withstand building shrinkage and dimensional fluctuations of laminated strips.

- Suitable for wide seams.

- Looks beautiful in the interior.

For this material it is also desirable that both areas are at the same level. Otherwise, the result will not look aesthetically pleasing.

Sequence of working with the filler:

- Adjust the rail to the desired size or cut the part from the sheet.

- Apply adhesive to the entire width of the laminate or tile, and a thin layer of sealant to the bottom.

- Glue the compensator and cover it on top with an antiseptic and clear varnish.

- The rail can be tinted, but you need to take into account that it absorbs paint well and the color turns out saturated.

Photo: Instagram @centrpola.ru

Photo: Instagram @centrpola.ru

Composition and properties of sealant

The basis of this sealant is cork chips (up to 90–95%). The composition also contains water, polymer additives, binders and fillers, which give the product the desired texture and thickness. The reliability of the finished sealant will depend on the quality of the cork: the best raw materials are obtained from the bark of the cork oak, and materials based on it will cost much more than substitutes from other types of wood.

Cork crumbs for preparing a sealing composition

After hardening, the sealant has the following properties:

- firmness and elasticity,

- small specific gravity,

- low thermal conductivity,

- environmental Safety,

- resistance to physical and chemical influences.

The properties of a particular sealant will also depend on the type of binding components. Most often, their role is played by polyacrylate adhesives - water-soluble compositions that do not emit harmful substances when hardened. Polyacrylates enhance the degree of adhesion of the sealant to various materials, while being perfectly combined with cork and eliminating its disadvantages: hygroscopicity, instability to UV radiation, acidic environments.

Polyacrylate glue is used as a binding component in the liquid stopper.