Open-type balconies, not equipped with a roof or canopy, are subject to all types of atmospheric influences, therefore, appropriate requirements are put forward for the finishing materials used here. One of the main problems that arise when arranging open terraces is the selection of a suitable finishing coating for the balcony floor. Indeed, in addition to durability and weather resistance, the aesthetic load placed on the material underfoot plays an important role. What kind of flooring is used to decorate the floors of open spaces will be discussed in the article.

Terrace board

Terrace boards will be an excellent solution for an open balcony, since they are distinguished from solid boards and block parquet by their production features. In fact, this is a type of lumber, but during manufacturing the solid wood undergoes high-temperature treatment or sawdust is mixed with polymer, and then each board is additionally treated with protective materials, which allows the material to be used in outdoor conditions.

The advantages are as follows:

- high strength;

- resistance to mechanical stress;

- resistance to temperature changes, precipitation, sunlight and aggressive environments;

- ease of installation and maintenance;

- decorative and environmentally friendly;

- ability to retain heat;

- The boards differ in color, so you can always choose the right option.

Since the material is treated with all protective agents during manufacturing, there is no need to worry about rotting and fungus. Deck boards are made from larch, tropical hardwood, or wood-polymer composite. The latter is made from sawdust, wood flour and a mixture of polypropylenes. The material is superior to solid wood in all respects, except, of course, naturalness. The main disadvantage of decking is its high price, which is more than offset by its appearance and resistance to negative environmental factors.

A natural stone

This type of balcony floor covering belongs to the elite category

. This type of balcony floor covering belongs to the elite category, since floor finishing elements made of granite or marble cost a lot, and also require high skill when installing. In addition to the rich appearance, the plus is that such material has no restrictions on its service life, constantly maintaining its original appearance. There is also a drawback, which is the large mass of finishing material, so it is advisable to use it if you are confident in the strength of the balcony structure.

Linoleum

Linoleum decorates many modern kitchens, hallways and living rooms, and is also used on balconies and loggias. Why do they love linoleum so much? Its main advantages:

- low price;

- a huge selection of colors and patterns;

- ease of installation and maintenance;

- high wear resistance, linoleum tolerates moisture well;

- excellent heat and sound insulation properties;

- There is no noise when objects fall, and dents are unlikely to remain.

There are not so many disadvantages compared to the number of disadvantages. These include:

- sensitivity to ultraviolet radiation, so it is better to use linoleum on glazed balconies and loggias;

- heavy pieces of furniture leave dents, but this is unlikely to threaten the floor covering of the balcony;

- The modern market is overflowing with linoleum from unscrupulous manufacturers, which may even have a characteristic unpleasant odor. It is better to spend a little more, but purchase material from a company with a good name.

Although linoleum has a fairly warm surface, many people prefer to use a heated floor system with it. In this case, not any material will do - you need to choose multilayer heterogeneous linoleum. All its layers have the same expansion, so when heated the material will not deform.

What is the best way to glaze a balcony or loggia?

- Wooden glazing.

- Aluminum glazing.

- Plastic glazing.

- Folding frameless glazing system.

Before glazing the balcony, you need to decide on the glazing system: wooden, aluminum, plastic or folding frameless window glazing system. Each system has its own pros and cons; let’s look at each of them in detail.

Wooden glazing.

Previously, the wooden balcony glazing system was more popular among residents.

Pros: low cost compared to other types of glazing, dirt is not visible on the frames, environmentally friendly material.

Cons: over time, the wood loses its color and will need to be repainted approximately 2 times a year. If this is not done, microcracks will appear in the future, which will lead to larger cracks. The window will lose its seal. Wooden glazing has poor resistance to moisture and temperature changes. Susceptible to aging and drying out over time.

Wooden balcony glazing

Aluminum glazing.

The second most popular option when choosing balcony glazing is aluminum glazing.

Pros: savings on balcony space, as the design resembles a wardrobe. The glass in the frames runs on rails. You can install a cornice and hang curtains.

Cons: low thermal insulation; in severe frosts, the sashes may freeze and they will not open. Windows can only be opened in one position.

Aluminum glazing of balconies

Plastic glazing.

The plastic balcony glazing system has become most popular among residents.

Pros: high thermal insulation, good tightness, durability, the window can be opened in 2 positions (when installing this design).

Cons: high installation cost, you cannot install a cornice and hang curtains. When opened, windows take up additional space.

Plastic glazing of balconies

During installation, it is very difficult to open and close the windows because the system has just been installed and requires force. Over time, the handles may become a little loose and therefore not close tightly, which leads to the entry of air from outside. Therefore, the handles need to be checked periodically and the handles must be tightened.

Folding frameless glazing system.

This type is new in the world of glazing. The system consists of an upper and lower profile; the windows are not in frames. The tempered glass plates located in the frame move. When folding, one plate moves towards the other and they fold.

Frameless glazing of the balcony

Most often, this system is used for verandas, country houses, cafes, restaurants, hotels, terraces, gazebos and dining rooms.

Pros: make the space aesthetically perfect; natural precipitation does not penetrate. Impact-resistant (vandal-proof) glass. Even if the glass breaks, it turns into small crumbs. Frameless lighting provides more light. Suitable for buildings that do not have a straight parapet. Convenient to wash the entire balcony.

Cons: the glass is huge and requires strength to move and move it. Low thermal insulation. The need for curtains (or blinds), because there is complete transparency and everything is visible. You cannot install a mosquito net. Due to the fact that this system is opened by hand, small fingerprints remain, so you will have to wash the glass more often. There is no complete tightness, it is only a protective structure. Poor sound insulation.

Painted floors

Wood and concrete floors need painting. For the former, this is additional protection, for the latter, it is a simple way of decoration.

- acrylic paints are universal, suitable for concrete and wood. They are resistant to sunlight, waterproof and frost-resistant;

- Aqualak is an excellent option for wooden floors; it has the highest moisture-resistant properties;

- alkyd varnish is another option for wood. It is resistant to ultraviolet radiation, moisture and temperature changes;

- polyurethane paint is suitable for concrete and wood. It is long lasting, easy to apply and water resistant.

If painted wood floors are a good option for an indoor loggia, then a painted concrete floor is the easiest and most cost-effective way to create a cozy feel on an outdoor balcony. Of course, the floor surface must be smooth and completely hardened before painting. Experts recommend ironing, which ensures the perfect smoothness of the finished surface. When the concrete floor has not yet completely dried, it is evenly sprinkled with dry cement and the surface is leveled with a brush. The process is similar to dyeing. When the floor dries well, it can be painted in the desired color.

The advantages of painting floors are obvious: low cost and simplicity.

Leveling the floor with a self-leveling solution

If the existing unevenness on the concrete floor is less than 3 cm, then it is not advisable to apply a regular cement screed. Most likely it will crack. There is a more reliable way to make a thin, absolutely flat and smooth surface - use self-leveling solutions. The thickness of such ties can vary from 3 mm to 3 cm.

To install a self-leveling screed, you need: a primer, a self-leveling mixture, a spatula, a brush or roller (for priming), a needle roller (for deaerating the screed) and a mixer.

The alignment goes like this:

- The floor is cleaned of chips, paint, grease and oil stains. Cracks in the floor, between the slab and the walls are repaired. Dust the surface with a vacuum cleaner - construction or household.

- The cleaned floor is primed with a brush or roller. According to the instructions, the primer takes 4-6 hours to gain strength. It is advisable to maintain this interval before moving on to the next stage of work. Despite the fact that the primer dries much faster - in the summer in 1-2 hours.

- Add the leveling mixture with water and mix with a mixer until it becomes liquid and flowing.

- Pour the mixture onto the floor, trying to distribute it evenly. Level the screed with a metal spatula.

- Roll over the liquid surface with a needle roller to remove air bubbles from the mixture.

- This screed hardens in 1-2 days, after which you can walk on it. Finishing is carried out only after 1-2 weeks, according to the recommendations of the manufacturers of specific mixtures.

How to level the floor using this technology, watch the video:

Wooden floor

We are talking about solid boards and block parquet. Both materials can only be used for closed loggias and balconies, since wood will quickly deteriorate under constant exposure to moisture and sun. The advantages include:

- naturalness, environmental friendliness and chic appearance;

- warm surface;

- With proper care, a wooden floor will last a long time.

Everyone can easily list the disadvantages on their own: the tree is sensitive to temperature changes, humidity, sunlight, and pests. In order for it to serve for a long time, it is necessary to carefully care for it and use protective impregnations. On the other hand, a wooden covering that has lost its former appearance can be easily restored by removing the thin top layer and applying varnish or paint on top.

A wooden covering is incompatible with a heated floor system due to its low thermal conductivity, but the surface of the wood itself can hardly be called cold. To ensure that the coating lasts as long as possible, it is better to choose oak or yew wood, or, in extreme cases, birch. Boards made from linden, pine or cherry are much softer and will last much less.

Finishing of floorboards

Wood is a fairly soft material, so it wears out easily. In order for the floor to last long enough, it should be covered with varnish or coloring compounds. The paint coating will reduce the ability of wood to absorb moisture, and this in turn will prevent it from swelling and the formation of rot.

Finish floor covering

To finish wooden floors, paint and varnish compositions intended for outdoor use are used. If the boards are well sanded and have a beautiful texture, it is better to coat them with a tinting varnish that penetrates deeply into the structure of the wood. Floor painting is used in cases where new boards of different sizes are not used for flooring. A solid coat of paint will hide unevenness in the wood texture.

Self-leveling floors

Today, Levl Coat flooring is in increasing demand, and is widely used not only on year-round sports fields, but also on open balconies and loggias. Among the main advantages it is worth highlighting:

- record wear resistance;

- moisture resistance;

- ease of operation;

- resistance to sunlight;

- stylish appearance.

Self-leveling floors can be safely called indestructible. They are made according to the principle of concrete screed, and the main disadvantage is the high price. In addition, the surface turns out to be quite slippery, so it is better to additionally use polymer mats.

Garden parquet

Garden parquet, decking, decking - all these are names for very practical and decorative coverings made of wood-polymer composites or very hard wood.

- low weight of the coating;

- water resistance;

- weather resistance;

- aesthetics;

- ease of installation.

Garden parquet (decking)

The coating is produced in the form of compact modules that can be laid on logs or mounted on a flat surface, connecting like a construction set. The only disadvantage of decking is its cost, since not everyone can afford it. Garden parquet is suitable for floors on both open and glazed balconies, goes well with any type of decoration and gives the room a touch of originality.

Ceramic tile

This is a universal material that is suitable for open and closed balconies and loggias. This option is often chosen by owners of unglazed balconies and those who prefer to use heated floors. Among the main advantages it is worth highlighting:

- high strength;

- water resistance;

- heat resistance;

- hygiene and ease of maintenance, which is important for open balconies;

- a huge assortment that allows you to choose material of any color, size, with any pattern you like, and tiles can be laid in many different ways;

- excellent thermal conductivity is a key indicator for heated floors.

It is worth noting that the latter property is a minus for owners of balconies and loggias without heated floors, because the surface of the tiles will always remain cold. Another disadvantage of the material is the slippery surface, which becomes even more slippery when water gets in. It is better to choose tiles with anti-slip properties: they have a rough or embossed surface, maybe with notches.

When choosing tiles for a balcony , you should make sure that the marking contains a foot icon - evidence that the material is intended for finishing the floor. It is important for owners of open balconies to take into account the water absorption rate - the lower it is, the more frost-resistant the tiles are.

READ Is it possible to make a suspended ceiling on the balcony?

How to fill the floor on a balcony with your own hands

The balcony slab is constantly exposed to destructive factors: sun, rain, wind. Because of this, its gradual destruction occurs. One way to protect a balcony slab is to pour a screed. In addition, a screed is needed to level the slab when insulating the balcony. The quality of the floor covering depends on its condition. Since the technology for filling the floor is simple, the work is most often done with your own hands. Initially, it will be useful to familiarize yourself with the existing methods of pouring screed.

Types of screeds

The final floor covering is laid on the poured screed. There are three filling methods:

The solution is prepared from cement with sand or crushed stone, and then poured onto the prepared surface of the balcony slab. The drying process lasts about a month. To crystallize the solution, the surface is regularly moistened with water.

The balcony slab is covered with a layer of expanded clay or other bulk material. Special materials are laid on top. This screed is quickly installed, but has the disadvantage of low resistance to moisture. This limits its use for unglazed balconies.

There are special mixtures diluted with water. Leveling the surface of the slab occurs due to the spreading of the liquid composition of the mixture. Such a mass has a limited action time, so installation is carried out at an accelerated pace. The mixture cannot be laid on a frozen balcony slab. After a week, you can apply the topcoat.

The method for cleaning a balcony slab depends on the existing coating.

- The painted surface is cleaned with a solvent. In this case, it is necessary to ventilate the balcony area. But the thick layer of paint has to be knocked off.

- The glued linoleum is cut into strips and removed with a scraper, and the unglued sheet is rolled up.

- Ceramic tiles are removed with a hammer drill or knocked down with a chisel. In terms of labor intensity, this is the most difficult option for cleaning a balcony slab.

- The wooden covering is removed using a nail puller or sawn into separate parts.

Preparing to pour the balcony slab

The technology for preparing the base for any screed is almost the same. Due to the great influence of ambient temperature and humidity on the balcony slab, reliable insulation of the finishing coating is required. Only a high-quality screed guarantees its safety for a long time.

To save time, sometimes the screed is poured directly onto the existing coating if it is in satisfactory condition. This is wrong, firstly, the height of the balcony is reduced, and secondly, the strength of the screed is greatly reduced. Only a cleaned slab will ensure a decent condition of the screed.

First of all, all things are taken out from the balcony, and then the baseboards and door frames are removed.

Floors on open balconies, loggias and terraces, durable and beautiful, made by yourself

During dismantling work there is a lot of dust and debris, so it is better to work in a respirator and spray the walls with water from a spray bottle to protect against dust.

After inspecting the cleaned slab, it is prepared for pouring screed:

- chips and loose areas of the surface are removed;

- bare areas of the tension reinforcement of the balcony slab are coated with primer or paint to protect against corrosion;

- chipped areas are sealed with cement mortar or glue.

Preparatory work is completed by removing debris and dust with a vacuum cleaner. It is known that a wet screed does not bond securely to a dusty base.

At the final stage, the slab is primed. The primer not only removes dust, but also creates an insulating layer. Most often, the primer is applied in two layers. The drying period usually takes up to 8 hours.

Closed balconies

On glazed balconies, the floor is protected from rain and snow, fades less in the sun, and is less dirty. The most important factor here is the presence or absence of heating. A heated, insulated balcony is practically no different from a living room, and any covering can be laid there. If the balcony is not heated, but is insulated, the floor covering must withstand temperature fluctuations in winter and summer. If the balcony is simply glazed, without insulation of the walls and floor, the floor covering must be frost-resistant.

Open balconies

The floor on an open balcony is constantly exposed to temperature changes, exposure to sunlight, rain and snow. Therefore, the floor covering must have high strength, frost resistance, not absorb moisture, be easy to clean from dirt, be non-flammable and non-slippery. Such requirements greatly limit the choice of materials, but it is still quite wide: ceramic tiles and porcelain stoneware, rubber tiles, decking, special rubber paints, PVC panels. Linoleum is also suitable for balcony floors, but not ordinary, but frost-resistant, which appeared on the construction markets not so long ago.

- withstands long-term loads;

- does not fade in the sun;

- tolerates temperature changes well;

- fireproof;

- Resistant to chemicals.

The range of laminate flooring is very wide, the colors and textures are incredibly varied. You can easily choose a covering to match the interior of your balcony.

What requirements should you consider?

To understand what kind of floor to make on the balcony, you should understand the requirements that the floor covering must meet.

- Temperature changes. On a closed balcony this is noticeably less, but even it is subject to these surges, not to mention an unglazed one: the material must be resistant to heat and frost.

- Variable humidity. In some cases, even dampness, so the future balcony floor must be absolutely hydrophobic. And in the case of a balcony floor without insulation, where humidity meets cold air, it is also protected from fungus.

- Sun rays . It will be unpleasant if after the first summer season the coating becomes deformed or fades in the sun - therefore, for southern balconies, choose materials that do not have this drawback.

The photo shows tiles on a loggia with panoramic glazing

In order for the floor on your open balcony to serve you long enough, you need to take a responsible approach to choosing the material. It must withstand changes in temperature and humidity well, and frequent cleaning using abrasive and chemical cleaners.

This is due to the fact that on open balconies and terraces the coating will be used practically in outdoor conditions.

A prerequisite for open options is that the floors be injury-proof. That is, when snow, moisture or frost forms, the balcony coating should not become slippery.

Therefore, for open design options, such as flooring, tiles and linoleum are absolutely unacceptable.

In addition, under the summer rays of the sun, linoleum will “fade” very quickly and lose its brightness and color. The influence of the external environment can also negatively affect other materials used as flooring indoors and not intended for outdoor use (laminate, parquet, etc.).

Tile

- highly decorative;

- long service life;

- strength;

- frost resistance;

- resistance to chemicals;

- environmental friendliness;

- absolutely non-flammable.

It is easy to care for; installation, although it requires some skill, is not particularly difficult. All this makes tiles an almost ideal floor covering for a balcony. To reduce the load on floors, lightweight tiles are produced, and for open balconies there are a lot of options with a rough anti-slip surface.

- tile floors are cold to the touch, so on closed balconies it is recommended to lay them on top of underfloor heating systems;

- The surface of the tile has very low sound insulation, and when walking there are booming sounds from steps.

READ Is it possible to install air conditioning on the balcony?

The range of floor tiles is unusually wide; models differ in manufacturing method, decorativeness, size, presence or absence of glaze.

Linoleum

Using linoleum is the simplest and most affordable coating option. It is easy to work with, the main thing is to cover it in one piece, without joints, to avoid moisture getting under the flooring. There are many designs on linoleum, and the variety of their colors is also pleasing. You can even find imitation of various stones, tree species, etc. True, if there is high humidity on the balcony, then this flooring will have to be changed after a few years.

Ceramic tiles

Ceramic tiles look beautiful, but they are cold materials, so it is better to have heated floors or wear slippers all the time. It is advisable to choose one with a rough surface and light weight, so that the suspended structure of the balcony is not subject to heavy loads and does not reduce its reliability. There are several classes of tiles; you need to choose them based on operating conditions. For a more insulated balcony, you can purchase tiles of a smaller class, 2 or 3 are quite suitable. You also need to pay attention to its moisture absorption and frost resistance, because even on a closed balcony the flooring will feel temperature changes. You need to buy tiles with a reserve, because... There will inevitably be a large amount of waste. Ceramic tile flooring is durable and will last at least one decade. It is also practical, it will be easy to clean and wash.

How to determine the level of a clean floor?

When the material has been decided, another question arises: to what level should the floor be leveled? You can use a water level (spirit level). To do this, place a line on the balcony wall in an arbitrary place, and use a spirit level to make marks at the same level on other walls. A line (horizon) is drawn along the obtained points. In the highest places of the floor (determined visually), measure the distance to the horizon. From the smallest measurement, subtract the thickness of the floor structure and set aside the resulting distance from the horizon to the floor. Based on this point, using a water level, o.

An easier to use laser level. It is enough to install it in the highest corner of the balcony, turn it on, and it itself, using laser dots or a line, will indicate an even horizontal line. This is what you need to measure up to when installing the floor.

Home craftsmen often use a regular bubble level to create a horizontal line. You need to act like this: determine the highest corner of the room by eye and place a mark near the floor. The height of the floor structure is measured from the resulting mark upwards. Using a level, draw a straight line along the mark, extending it along the perimeter of the balcony. However, this method has too large an error, so it is not used for high-quality alignment.

For open balconies, it is recommended to make floors sloping towards the street (away from the wall of the house) to ensure the drainage of atmospheric moisture. A 1 cm slope per 1 m width of the balcony is enough.

Flooring materials for an open balcony

The balcony flooring should be durable, practical and even aesthetic. After all, no matter how ideal the cleanliness is in the entire apartment, dust from the balcony can disturb it. The choice of material is greatly influenced by the type of balcony: open or closed. For the first type, many floor coverings will be unsuitable, because not everything can withstand constant precipitation, high or too low temperatures.

For an open balcony, you can make a regular concrete screed, simply painted. You can also lay ceramic tiles. Some believe that the floor can be covered with thick linoleum with a maximum protective layer and high density. To make the right choice, you need to carefully consider each flooring option suitable for an open balcony.

Porcelain tiles

A more expensive, yet durable coating can be made using porcelain tiles. It is also applied to the finished concrete screed as smooth as possible. Tiles are divided into 5 classes according to their wear resistance; you need to choose 4 or 5, because... they have the highest degree of strength and abrasion resistance. Also, when choosing a porcelain stoneware slab, you need to pay attention to its weight; the balcony support slab may not be able to withstand too heavy a material.

You can safely place furniture on the tiled flooring and walk on it in high-heeled street shoes. But you can’t go out onto the balcony with such a floor barefoot; you’ll need to wear slippers or lay down a small rug, otherwise your feet will freeze.

What is the best way to cover it?

A variety of materials can be used to finish the floor on the balcony. Let's take a closer look at the pros and cons of each of them.

Linoleum is presented in retail outlets in a wide range; it can be rubber, as well as glyphthalic, colloxylin, natural or PVC. The most durable coatings are considered to be rubber-based materials - for balconies, preference should be given to this type of coating, since it is not afraid of water and temperature fluctuations, is fire-resistant and can withstand loads.

Linoleum resists moisture, does not rot, has noise and heat insulation properties, is easy to clean and is inexpensive. At the same time, it is characterized by increased sensitivity to chemically active solutions and fats, and at temperatures below -20 degrees the coating may crack. The cheapest products will not be the best choice. As a rule, they are made from synthetic, non-ecological materials.

Carpet is another budget covering option, but when using it on a balcony you should weigh the pros and cons. On the one hand, this coating is warm and pleasant to the body in any season, therefore it is optimal for a place to relax, however, due to its low fire resistance, this material is not recommended if you plan to use the balcony as a “smoking room” or a storage room.

Carpet quickly absorbs dust and odors, including cigarette odors, which means you will have to clean it regularly, especially if small children will have access to the room. If you plan to use the balcony as a place for drying clothes or as a winter garden, preference should be given to rubber-based models.

Laminate is a material based on wood and polymers. The top layer is made of patterned paper coated with several layers of acrylic resin, and the more layers there are, the more resistant the surface will be to moisture and pressure. Currently, you can find materials on sale in a wide variety of colors and textures. Imitation of wood or natural stone is in greatest demand.

Laminate is more expensive than carpet and linoleum, but its appearance is much more aesthetically pleasing and impressive. The material prevents the occurrence of fungus and dangerous mold. At the same time, the coating is difficult to install - this work requires a perfectly leveled surface and finishing skills. In addition, laminate does not withstand temperature fluctuations and prolonged frosts, so the inside of the balcony, even in winter, should not be colder than -5 degrees.

Parquet board is a natural, environmentally friendly and exceptionally beautiful coating. However, most types of wood are not particularly resistant to water, so installation of such floors is allowed only if there is high-quality thermal and waterproofing and general insulation of the balcony. If it is damp and cold there, the parquet will quickly become unusable - it will begin to deform and crack.

If you are persistent in your desire to decorate the floor with environmentally friendly coatings, then preference should be given to types of wood that are poorly susceptible to cold and water, and after installing the floor, the panels need to be coated several times with moisture-resistant varnish for effective protection from external adverse factors.

Ceramic tiles are a practical material that is ideally suited for open spaces, as it is not afraid of ultraviolet rays, precipitation and can withstand temperature changes. Such a surface is easy and simple to clean from dirt, even with the use of abrasives. When choosing, give preference to coatings with a rough surface, otherwise there is a high risk of slipping after wet cleaning on the balcony. High-quality ceramics can withstand temperatures down to -50 degrees, so the tiles do not lose their performance qualities either in winter or in summer.

However, ceramics are cold materials, and therefore walking on such a surface is unpleasant.

Well, the most budget option is paint; wooden and concrete floors can always be simply coated with enamel. For this, it is best to take acrylic compounds that are resistant to direct sunlight, do not lose their physical properties under the influence of high and low temperatures, and are not afraid of moisture. For wooden floors, alkyd varnish is a good option - it will preserve the impressive texture of the wood. Polyurethane paint may also be a good option.

If you are not limited by budget, you can finish the floor on the balcony using self-leveling technologies.

Flooring materials for an enclosed balcony

It is much easier with closed balcony spaces; there is a wide choice of flooring materials, especially if the balcony is also insulated. When using any floor covering, a concrete screed is first made, after which at least a sheet of fiberboard is laid, and only then the selected material is used. After all, even on a closed balcony, the floor suffers greatly from high frosts and winds, so it is better to insulate it a little, because it would seem that not everyone would want to constantly wrap their feet on a warm balcony.

As insulation material, you can use mineral wool, polystyrene foam, or lay an electric or infrared heated floor. Linoleum, laminate, wooden boards, ceramic tiles and even carpet can be used as flooring materials. But the final choice depends on the required capabilities and characteristics of the material and its operating conditions.

Painting concrete screed

To create this flooring on your balcony, you first need to fill the entire floor of the balcony with a solution that contains 1 part cement, 3 parts sand and water. After the concrete screed has dried, it can be painted. The paint must be suitable for outdoor use and resistant to harsh weather conditions. For best results, apply several layers.

The resulting layer of paint will repel moisture well, protect the concrete from minor mechanical damage, and give a beautiful color and shine to the floor. But it is worth noting that paint will not be able to save the screed from strong impacts or pressure from furniture legs. And after 3 years, the coating needs to be changed again, remove the old one and apply a new one. Painting the concrete screed is the most economical option.

Laminate

Laminate is well suited for flooring an enclosed balcony space. cover the concrete screed with a backing. Moreover, this cement surface must be made perfectly flat.

Laminate is a light and beautiful material. Can imitate valuable species of trees and expensive stones. Laminate flooring is warm. But this material has low resistance to moisture, so the balcony must be dry.

Ceramic tile

This material has gained popularity due to its properties.

Ceramic tiles are not afraid of temperature changes and precipitation, they are strong and durable, and are not afraid of sunlight.

At the same time, this coating looks very good - you can choose tiles with a pattern or a plain one, the product range is very rich.

This type of flooring is easy to clean from dirt; simply wash the floor with water.

Ceramic tiles are practical, but their surface is cold, and even in the hot summer it can be unpleasant to walk on them without slippers.

Laminate

Laminate can only be laid if good waterproofing and leveling have been done. It is advisable that the room be glazed and insulated. Then the slabs will last a long time.

Pros:

- Aesthetics.

- Strength.

- Light weight.

- Easy installation.

- Fade resistant.

- Easy care.

Minuses:

- Poor sound insulation. Footsteps will be heard.

- The need for preliminary alignment.

For an open room it is better to choose products of class 33, for a closed room - 31. Both types of laminate are laid on a substrate made of isolon, polystyrene foam or cork. It is needed to insulate the structure, improve sound insulation, remove small differences in height and increase the strength of the finish.

Instagram @realclimat

Instagram @realclimat

- Decoration Materials

Linoleum, laminate or PVC tiles - which is better? Comparison of materials and expert opinions

What floor to lay on an open and closed balcony

High demands have always been placed on flooring, especially if you need to decorate the floor on a loggia or balcony. Everyone sees their space differently, but the quality of flooring materials must meet criteria such as wear resistance, waterproofing and strength.

Let's talk today about choosing which flooring will be the best in all these parameters.

If you want to create the best conditions on the loggia for a long stay in it at any time, especially the cold season, you need to work hard on the thermal insulation of the walls and floor. It is here, on a closed balcony, that most often, when laying the floor, a “warm floor” heating system is used.

READ How to make a bathroom with plastic panels with your own hands

For open balconies, it is important that the floor covering is durable and can withstand temperature changes and exposure to precipitation. Next, we will consider the most suitable facing materials for this.

Carpet

You can put carpet on the floor of the balcony space. Moreover, the surface of the concrete screed must be made as smooth as possible. It will be pleasant to walk on such a floor. But in terms of practicality, it is inferior to other materials. It will need to be constantly vacuumed and washed and cleaned as often as possible due to the constant presence of dust.

Ceramic tiles are a traditional covering for outdoor recreation areas

Ceramic tiles are rightfully considered the best coating for unglazed balconies and loggias. It withstands weather conditions well: rain, hot ultraviolet rays, hail. No problems with cleaning! It is enough to wash even very dirty tiles with water and they will become clean again. When choosing tiles for uninsulated balconies (loggias), pay attention to their frost resistance. The best characteristics in this regard are products that were originally intended for outdoor use. Naturally, the tile adhesive and grout for joints must also be frost-resistant, otherwise the life of the ceramic coating on your balcony will not last long.

Ceramic tiles with a rough surface - a durable coating for an open balcony

Ceramic tiles can be smooth, glazed - it is not advisable to use them for balcony coverings, they are too slippery. Select products with a rough surface for external coatings.

What not to use

Materials intended for interior finishing work are strictly not suitable for decorating the floor of an open balcony:

When choosing the material for the future flooring of an open balcony, you should not engage in false economy. Cheap material will certainly save on repairs right now, but will require earlier and more frequent updating. At the same time, many expensive materials will pay for themselves due to their long service life.

choosing the most suitable flooring material

Almost every apartment has a balcony , which is used as a kind of warehouse where temporarily unusable things are stored or a small garden with beautiful flowers. Some people turn the balcony space into an office or a secluded place to relax. Whatever the purpose of the balcony, you need to select a floor covering that can withstand harsh climatic conditions (temperature changes, sunlight, precipitation) and at the same time should be comfortable to stand on. There are a lot of materials for flooring, and it will be very difficult to understand what is best to cover the floor on the balcony.

Adviсe

On a small balcony that you want to make visually larger, you can use rough and processed natural materials. Ornamental plants will also help highlight the beauty of such a space. If you want to make the floor more pleasant and beautiful, put a carpet on it.

It would also be a good idea to use the art deco style, which is characterized by bright and catchy, even acidic tones. In a setting with metal furniture and exposed concrete floors, hanging lanterns and candles can help improve the look.

If there is a large carpet on the balcony, you can add textiles with a distinctly bohemian look to the decor. When used skillfully, the most ordinary paint can create a look no less pleasant than brickwork, decorative plaster or “wild” stone. In addition, painting eliminates the need for tedious preparatory work and the cost of creating a frame.

If it is very difficult to know what decision to make, it is worth considering using the concept of a winter garden. It is popular, comfortable, and beautiful.

In any case, the sequence of work will be as follows:

- strengthening external walls;

- glazing;

- floor arrangement;

- insulation and decoration of walls;

- other necessary manipulations.

Features of using ceramic tiles

Ceramics on the balcony

Before covering the floor on your balcony with this or that material, we recommend that you pay attention to ordinary ceramic tiles, which are particularly resistant to most destructive factors.

In the most general case, when using ceramic tiles, you must adhere to the following recommendations:

- One should not lose sight of such significant indicators of a protective material as the moisture absorption coefficient and frost resistance. This is due to the fact that even for closed balconies, differences in temperature and humidity in the floor area can reach significant values.

- When preparing for work, you should pay attention to the quality of the tiles and select samples with a rough surface.

- Another indicator that determines the choice of covering for balconies of any type is the specific gravity of the material. The use of lightweight ceramic tile samples reduces the load on the base of the structure and increases its reliability.

Regardless of the type of tile covering used, the material for finishing the floor on the balcony should be purchased with a small margin. Some of it will go to waste, and part of the supply will be useful to you in case of unexpected repairs.

Carpet

In a dry and insulated room, you can lay carpet made from natural raw materials. If there is a greenhouse on the balcony, laundry is often dried or it is open, it is better to choose an artificial covering with a rubber base. There are three types of it: polyamide, polyester, polypropylene.

Pros:

- Softness. Ideal for additional living room.

- You can lay carpet on an uneven surface.

- Strength. Polyester and polyamide carpet will last at least 15 years. The minimum service life of polypropylene is 5 years.

- The artificial material is resistant to moisture and mechanical stress.

Minuses:

- Dust quickly accumulates on the surface. You need to clean frequently.

- Polyamide fibers accumulate static electricity.

- Polyester does not look like natural coating. This may be a disadvantage for some interiors.

- Polypropylene may break when bent.

Open balcony

Painting the screed

Since the floor on open balconies is constantly exposed to sunlight and bad weather, you should focus on special coatings that can protect it from these troubles. The optimal option for arranging the floor in this case involves building it up using a layer of screed, on top of which the type of coating you choose is applied. The following options are possible:

- coating with moisture-resistant paint;

- finishing with ceramic tiles;

- use of plastic materials to cover the floor.

The floor on the balcony over the screed can simply be painted with a special paint used for external construction work, which will provide you with the opportunity to do without repairs for about 3-4 years. If you decide to thoroughly strengthen the floor, you will have to use other methods of protecting the coating, which involve the use of materials of increased resistance.

You can cover the floor on the balcony with ceramic tiles or thick linoleum. This way you can protect the screed from destruction caused by high humidity and precipitation.

Screed, its manufacture and features

- If you plan to insulate the balcony, then it is most advisable to make a strong and high-quality screed on it under a wooden floor or ceramic tiles. The concrete base can also be covered with beautiful linoleum, carpet, or simply painted, after leveling the floor using a special self-leveling mixture.

When talking about what to make a balcony floor from, you should take into account that making a screed yourself is not so difficult, and besides, it is a budget option. However, this simple method also has a downside:

- The screed significantly increases the height of the floor on the balcony (about 10-15 cm), which of course puts additional load on its base - that is, the slab. If the house is very old, the balcony may simply collapse.

- Concrete floors are considered the coldest. Of course, it can be insulated (for example, with polystyrene foam), but this will not help much; thermal insulation still leaves the floor cool.

If the above circumstances do not scare you, then you should study step-by-step instructions on how to make a floor on a balcony with your own hands.

Home comfort on the loggia directly depends on how well it is insulated

Do-it-yourself screed manufacturing technology

First, the floor is prepared for installation work. The first step is to carefully close all noticed cracks. They usually occur in those places where the wall is adjacent to the slab - the base.

Conventional polyurethane foam or acrylic sealant will help you with this preparatory stage. After all the cracks are sealed, you can begin arranging the floor.

Sealing cracks is an important step in the process of constructing and installing a floor on a balcony.

Waterproofing

Laying a waterproofing film is necessary so that when pouring the solution, excess moisture from your screed does not leak to the neighbors below.

To waterproof the floor on the balcony, you don’t have to make any special efforts. Just carefully lay a thick sheet of polyethylene in the form of a neat “trough”.

Important! The film should be laid overlapping, laying about twenty centimeters on the walls. After the work is completed, the edges of the polyethylene are carefully cut off.

Waterproofing a balcony with polyethylene film

Reinforcement process

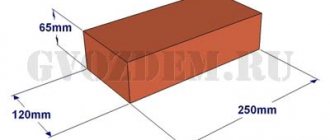

Basically, a steel mesh made of three-millimeter wire is used for this. The cells of the reinforcing mesh can be 50×50 or 100×100 millimeters.

The sequence of work is quite simple:

- All visible dirt and other debris are removed from the surface;

- The first row of mesh is carefully laid on the insulation and pressed tightly;

- The second row is placed overlapping 1-2 cells.

After the mesh is laid, you can begin installing beacons for the screed. This issue must be approached with special responsibility, since the evenness of the constructed floor will depend on the correct installation.

Reinforcement mesh increases the strength of the screed and significantly increases its service life

Lighthouses

- In construction, beacons are special guides (landmarks), by moving along which you can level the applied coating to a perfectly flat and flawless surface. When making a balcony floor in the form of a screed, you can’t do without such little things.

Beacons are installed in one plane, which is determined in accordance with the height of the threshold in indoor block doors. Also, all beacons must be carefully aligned horizontally.

The top edge of the lighthouse should be at the same height as the subfloor surface

Important! To ensure that the beacons do not move during the screed leveling process, they must be firmly fixed. To secure them firmly, it is best to use building plaster or cement mortar.

Installation of screed beacons using thick cement mortar

Filling the screed

After all this preliminary work has been done, you can prepare a solution of sand and cement (four parts cement and one part sand). The finished mixture is carefully poured between pre-installed beacons and carefully leveled using the rule.

To make the floor level, the rule must be applied slowly with little pressure, while simultaneously resting it on two beacons

After completing the concrete work, the screed is covered with a sheet of polyethylene to slow down the drying process. If you neglect this, it may crack during hardening.

It is also necessary to ensure that the thickness of the screed laid on foam plastic or other insulation is at least fifty millimeters. Otherwise, the base of the floor on the balcony will crack under the influence of gravity - for example, from the weight of furniture.

If all work on arranging the concrete screed is carried out according to the instructions, the floor surface should be perfectly flat

Glazed balcony

Concrete floor screed on the balcony

The preparation of flooring on glazed balconies is usually carried out in a strictly established sequence:

- Production of concrete screed.

- Laying over the screed of plywood sheets (fibreboard).

- Arrangement of the selected type of coating.

Leveling the floor

The simplest and most affordable coating is considered to be linoleum. A huge range of products in this class, differing not only in design, but also in color, significantly expands the possibilities for choosing materials for landscaping a balcony.

Laminate coverings can also be considered as an option for arranging the floor on a closed balcony. In addition, it is allowed to lay ordinary wooden floors or the well-known parquet.

Performing a dry screed

A dry screed on the balcony will help you out if you need to not only level, but also insulate the floor. At the same time, there is no desire to interrupt the technological process while the cement mortar hardens. A dry screed is ready for further finishing immediately after its creation. Another advantage is the speed of installation. On the balcony, dry screeding will only take a few hours.

To install a dry screed, you will need to purchase: bulk thermal insulation material - expanded clay (or coarse sand, slag), subfloor elements (GSP, GVL, DSP, OSB), polyethylene film (waterproofing), self-tapping screws, edge tape (made of polyethylene foam), tape or masking tape, U-shaped profiles as beacons, a grater and a rule.

Technology for creating dry screed:

- Prepare the floor. Clean it from debris and dust. Cracks are sealed with cement mortar. The gaps between the slab and the walls are filled with polyurethane foam.

- An edge (damper) tape is laid along the perimeter of the walls, acting as a soundproofing material. If you skip this installation step, the floor slabs will make quite noisy sounds when they come into contact with the walls.

- Start waterproofing. To do this, place a plastic film on a concrete slab, placing it over the walls 6-10 cm above the level of the future floor. The edges of the film are fixed with tape.

- Beacons are installed - thick-walled U-shaped profiles that will help more accurately level the expanded clay layer. They are laid on the floor along long walls without fastening, with the wide (supporting) side down, checking the horizontality as a rule. The level of the upper edges of the profiles must coincide with the planned level of the expanded clay layer.

- Expanded clay is poured between the profiles in a layer of 3-7 cm. By stretching the rule along the beacons, the resulting surface is leveled. The remaining irregularities are smoothed out with a grater. To move along the expanded clay layer, “pedestrian paths” made of square sheets of plywood or gypsum fiber board laid out in the form of paths are used.

- Covering slabs are laid. To be able to connect them together (they will not be attached to the floor!), use plates with grooves. They are laid, pressing them as tightly as possible against the wall. Then the structure will be able to withstand any load no worse than a concrete screed. The joints in the grooves are glued with construction adhesive and fastened with self-tapping screws in increments of 5-10 cm.

- The parts of the edge tape and polyethylene film that rise above the floor are cut to the level of the coating slabs.

This technology is reproduced step by step in the video: