The market offers a wide range of different doors. But sometimes it is difficult to choose a model that fully meets the owner’s needs. There are plenty of reasons - a significant difference in dimensions (block/opening), low quality products, poor external design, high cost, and so on. For a person who is familiar with household tools, making interior doors with your own hands is not a problem. In many cases, this solution is the most rational.

Do-it-yourself features

Why even bother with such a complex campaign? In fact, there are plenty of arguments in favor of creating a door on your own. Here are some of them:

- the presence of a non-standard opening - ordering a non-standard door in a workshop will cost much more. If the dimensions of a product go beyond the standards, its price soars at jet speed;

- the inability to purchase a suitable model that will fit into the design and be combined with other interior elements;

- desire to save money - if there is an opportunity to make a budget door from natural wood yourself, and not buy a ready-made one for crazy money, why not take advantage of it;

- the presence of outbuildings in the courtyard of a private house - a barn, a bathhouse, a barn - they have no need for expensive doors;

- the desire to create a unique, inimitable product and to know that you made this wonderful door yourself.

Hardwood

- birch is a hard, difficult to process material with a beautiful texture;

- alder – low hardness, not suitable for use in conditions of high humidity;

- walnut – easy to process, moisture resistant, has a beautiful texture;

- beech is highly durable, but can change shape due to changes in humidity;

- oak – high hardness, moisture resistance, beautiful texture, but can split;

- maple – medium hardness, difficult to process, average moisture resistance.

Entrance doors are usually made of oak or beech.

What type of wood to choose

One of the most critical stages is the choice of source material. Each type of wood is endowed with special mechanical and physical qualities. It is necessary to know the features of different types in order to determine which one is ideal for solving a particular problem. All wood can be divided into two categories - deciduous and coniferous.

Hardwood

This series contains the most valuable species, endowed with extraordinary strength, high density, expressive texture and attractive natural shades.

Wood has the highest value:

- beech;

- nut;

- mahogany.

If there is no reason to spend money on expensive raw materials, you can get by with more affordable ones. Pay attention to the advantages:

- cherries;

- oak;

- ash

These rocks also have high strength, but will not require such significant costs as representatives of the first category.

Oak wood is very durable and resistant to rotting. Due to the content of tannins, which react with dyes during etching, it allows you to achieve intense color effects. Processing the material is not difficult - it lends itself well to simple tools. Making parts of unusual, curved shapes from it is not a problem.

Ash is as hard and durable as oak. However, this material requires regular treatment with antiseptic compounds. Otherwise, when the first wet season arrives, it will begin to rot.

Conifers

Coniferous wood never loses its popularity. This is explained by its availability and a wide range of positive qualities. The most popular materials are those made from pine, followed by spruce.

The strength characteristics of pine are slightly lower than those of deciduous trees. This disadvantage is more than offset by high resistance to biodegradation, mold and mildew, excellent thermal conductivity and extraordinary flexibility during processing. High air and moisture permeability guarantees decent quality of treatment with protective compounds.

Spruce is more susceptible to rotting compared to pine, but has less hygroscopicity and thermal conductivity. Products made from this material retain their original shape much longer.

If you choose between these two species, you should give preference to pine.

Deciduous tree wood is ideal for making interior doors. And for entrance structures, pine would be the best choice.

Materials

Basic materials include:

- dried tongue and groove board;

- screws;

- wood glue.

The thickness of the material depends on the location of the door and the requirements for it. The interior door can be assembled from 25 mm boards.

The front door should be at least 2 times thicker. After purchasing, it is advisable to additionally dry the wood for some time.

For accessories you need to buy a lock, awnings, handles and, if necessary, a peephole.

How to make antiseptic with your own hands: the best instructions for making antiseptic at home + photo reviewsDIY medical mask - TOP 100 photos and step-by-step instructions with diagrams of the best ways to create

- What are paintings by numbers?

Types of doors by design

Doors are classified according to various criteria - the design of the door leaf, the method of opening.

The following types of door leaves are distinguished:

- massive;

- paneled;

- panel;

Groups of door structures by opening method

- hinged - with one or two doors;

- sliding – so-called compartments, equipped with a guide system;

- folding - doors resemble an accordion or a book;

- radial.

To make wooden doors, boards, beams, and furniture panels are used. To decide on the choice of material, you need to understand the pros and cons of each of them. Let's look at the characteristics of the various options.

Massive doors

To make doors from solid wood, planed or grooved boards of large thickness are suitable. The latter are convenient because they are easily combined into a single fabric without forming cracks. This becomes possible thanks to the locking system, which consists of a longitudinal protrusion and a corresponding slot on the edges of the board. The canvas, made up of boards, is fastened with transverse or diagonal jumpers.

When making a front door, you should give preference to more expensive breeds. Oak, larch or cedar are suitable. For outbuildings, budget options are quite suitable - pine, linden or spruce.

Panel doors

This is a separate category of doors with its own design features. Their canvases consist of a frame and rectangular inserts - panels.

The main load-bearing element of this structure is the frame, which is otherwise called the frame. The remaining elements are attached to it - wooden inserts. The harness is usually made from solid wood. Glued laminated timber will also work. Four parts connected to each other form a frame. The bottom element is wider than the top and side panels. This provides the structure with additional strength. You can further strengthen the bottom of the door by covering it with sheet metal. Galvanized steel or aluminum will do. This is especially true for strengthening entrance panels.

No less important elements are the transverse strips - in other words - the middle ones. They are bars that are attached horizontally in the middle of the future canvas.

And finally, the details that gave the name to the entire structure - panels. These fragments are inserted into the frame, resulting in the formation of a single piece. Special grooves are provided for their installation. The panels are attached using a tongue-and-groove system or decorative beads, which allow you to quickly and without damaging the door replace the damaged element. Panels can be made from chipboard, MDF, plywood and even glass. They are installed in the door frame, and in addition to their main purpose, they also have a decorative function. They are given interesting shapes and decorated with carvings or paintings.

Panel doors

The design of the panel door is much simpler than the previous version. It consists of a box and the main part - the shield itself. Fiberboard, veneer or laminate are suitable for making the box. The frame is first made from boards. It is advisable to use sheets of chipboard, MDF or fiberboard as a shield.

Panel sheets can be:

- solid - made from interconnected bars;

- hollow - a frame of connected beams is sheathed with lamellas;

- small-hollow - have a variety of fillings, for example, honeycomb.

Brief classification

Coniferous species contain a lot of resin, therefore they are more resistant to moisture.

When starting production, they determine what parameters the design must meet.

Wooden canvases are divided according to the following characteristics:

- manufacturing material - coniferous or hardwood;

- finishing - painting, veneer, MDF, lining, etc.;

- opening method - swing, sliding, swinging, folding;

- functional purpose and location - entrance, interior, special;

- In terms of internal filling - solid wood, panel, paneled, smooth.

Experienced craftsmen are able, in a small home carpentry shop, to produce any product that meets all classification parameters.

For the first experience, it is better for novice carpenters to start with simple wooden products.

Necessary materials and tools for making doors

Before you start, make sure you have all the tools available. If something is missing, it is better to purchase the necessary tools in advance than to discover their absence during the manufacturing process.

So, for work you will need:

- a workbench or large, durable table;

- hand router for wood - with its help you can easily form grooves, holes, grind the surface and trim the corners of the product;

- plane - it will be an excellent assistant in leveling and grinding the ends;

- regular hacksaw;

- different-sized chisels;

- rubber hammer;

- regular hammer;

- sandpaper, or even better, a sanding machine;

- building level, tape measure, pencil;

- screwdriver or Phillips screwdriver;

- self-tapping screws of various calibers;

- wood glue.

Materials are purchased depending on the type of door chosen and its manufacturing technology. It can be:

- grooved or planed boards;

- particle boards;

- plywood;

- glass;

- laminated timber.

Tools for work

Tools you will need:

- to create grooves and holes, you will need a router;

- hacksaw;

- to sand the ends of the doors, you will need a plane;

- chisels;

- hammer;

- screwdriver

Standard set of tools for making doors

To assemble doors you will need the following materials:

- tongue and groove boards;

- self-tapping screws;

- glue.

The purchased wood is additionally dried. The boards are laid so that they do not touch each other.

Step-by-step door manufacturing technology

The first step is to thoroughly dry the purchased wood. This step can significantly delay the manufacturing stage, but is necessary. Drying on average takes from 1 to 2 months. The boards should not touch each other. They are interspersed with special gaskets. This technology ensures unhindered release of moisture from the material. Using undried wood can lead to door deformation and the formation of fungus.

When drying conifers in a special chamber, it is unacceptable to set the temperature above 50 °C. The resin will leak out, which will lead to a decrease in the strength characteristics of the material.

Making a solid door

In order to make a solid wood door, you will need to complete the following steps:

- mark and cut the boards into fragments of the required size;

- check the location of the resulting segments - they need to be rotated so that the growth rings “look” in one direction;

- If there is a tongue-and-groove fastening system, connect the fragments into a single web. First you need to coat the joints with wood glue. This will provide the structure with additional strength;

- the spike remaining on the end of the canvas should be cut off and the resulting plane processed;

- the resulting structure must be fixed with clamps and left until the glue dries completely;

- the next stage is surface treatment using a milling cutter and subsequent grinding;

- The final stage is fastening the canvas using crossbars. To do this, it is necessary to prepare bars of the required length, preferably trapezoidal in shape, to ensure a tight connection. Next, you need to form the grooves - usually their depth is equal to half or one third of the thickness of the canvas. After this, all that remains is to drive the crossbars into the grooves coated with glue using a rubber hammer or mallet.

Making a paneled door

Manufacturing a panel door is a complex process that requires a variety of tools, as well as specialized knowledge and experience.

The first step is to prepare the timber for making the frame. It is processed using a milling cutter, after which grooves are cut out on the pillar elements, and tenons are made on the transverse elements. Next, the panels are made. Solid wood, plywood, chipboard, glass are suitable for this.

All elements are connected into a single structure, and all tenons are coated with wood glue. You will need a large space to work.

Step-by-step assembly instructions:

- We coat the tenons of the crossbars with glue and install them in the grooves of the vertical elements.

- We install the middles.

- We install panels.

- We glue the vertical beam.

- We fix the panels with decorative glazing beads.

Use a rubber mallet to tightly connect the parts. Align the corners, focusing on the construction corner. Clamp the product with clamps and leave to dry.

Manufacturing of a panel door

To make a thyroid cloth you need:

- assemble a frame from beams connected at the corners using the “half-tree” technology;

- line the frame on one side with plywood or fiberboard. The material is fixed with glue;

- the resulting void is filled with cellular material or MDF bars. They are glued from the inside to the existing cladding layer.

- The structure is covered with a second sheet of fiberboard and sent under the press.

If desired, you can make an additional facing layer from laminated material or sheathe the canvas with wooden slats.

Making a door from clapboard

The basis of such a door is a frame made of beams. It can be made according to the same principle as the frame for panel panels. We cover the finished frame with clapboard and the door is ready for installation.

It's actually not that simple. Keep in mind that each board needs to be coated with glue for a more secure fit. On the first day, it is recommended to install only two slats - on both sides of the canvas. Glue the lamella and secure it with a self-tapping screw. After this, we clamp it with a clamp until the glue protrudes along the entire perimeter of the rail and wait for it to dry completely. On the other side we do the same actions. Every day we add only two boards and gradually cover the entire plane. It is better to drill the connecting holes in the lamellas in advance, since when screwing in the self-tapping screw, the panel may split.

How to make and assemble a door frame with your own hands

Before describing the process of manufacturing a door frame, it is necessary to familiarize yourself with its structure. It is a frame structure that is mounted on the edges of the doorway. The frame is necessary for installing the door, which is attached to the base using hinges. The following materials are suitable for manufacturing: wood, MDF.

The design includes the following elements:

- counter beam - a post on which the lock's strike plate is installed;

- loop beam - loops are attached to it;

- ceiling beam - top bar;

- threshold - bottom beam, relevant for entrance doors.

Manufacturing stages

- We make the necessary calculations. To the dimensions of the door leaf we know, we add an additional distance to create small gaps - 3 mm on the top and sides and a few mm on the bottom.

- We saw off the necessary parts at an angle of 45°. A miter box will help you avoid making mistakes when forming an angle.

- We connect the bars into a U-shaped or rectangular composition using self-tapping screws.

Manufacturing of accessories and platbands

The following materials are suitable for these elements: MDF, wood, chipboard.

To make the extension, measure the width of the wall that needs to be covered with a plank. We select a wooden lamella of the appropriate size. We file one of the long sections. A chamfer is formed that can easily extend beyond the box part. We sand the surface of the lamella to an ideal state, after which we paint it with stain and cover it with two layers of varnish.

In the case of MDF or chipboard, everything is much simpler. You will only need to veneer the edges of the slats, covering them with edge PVC using a hot iron.

It is best to fasten homemade extensions using self-tapping screws. You need to start from the top horizontal bar to leave the opportunity to adjust the length of the side slats.

For homemade platbands, it is better to use solid or glued bars. Solid products require painting. Glued ones often have a coating in the form of veneer or laminate.

When making a decorative element yourself, you can choose their shape to your liking. Your platbands can be:

- smooth - have a flat shape, are the easiest to manufacture;

- profiled - have various recesses or protrusions on the surface. In order to make them, you will need at least a hand router;

- figured - the most complex type of platbands. They are manufactured using special programmable machines according to specified drawings. You can make figured platbands yourself or order them from a wood carver. Products decorated with hand carvings are the most expensive version of curly planks.

What your platbands will be like depends only on your taste and financial capabilities.

Installation of ready-made decorative elements is carried out either using special nails without a head or mounting glue. When fixing massive planks, it is better to choose the first option. The platbands will be securely fastened, and traces of thin nails will be practically invisible.

Before installation, the ends of the platbands are cut using a miter box at an angle of 45°. The planks are fastened in the following sequence:

- strip near door hinges;

- second side element;

- top panel.

To hide the fastening points as much as possible, you can rub these places with mastic or a cosmetic pencil.

Independent insertion and installation of fittings

Mortizing a lock is a rather complex stage at which you cannot make mistakes.

The first step is to lay the door flat. After that, drill a hole at a distance of 100-120 cm from the bottom. Insert the latch and trace the hardware along the outline with a marker. After this, we make a recess under the front cover. For this work, you can use a chisel or milling cutter. We place the housing in the recess so that its edge is level with the end of the door. We mark the places where the handles are attached and drill holes. The latch is installed in place and fixed with self-tapping screws. Next comes the turn of the handles and decorative trims. Special hexagons are provided for their installation.

Manufacturing procedure

The assembly of an interior door is carried out using different methods. But if the meaning of all operations is clear, then developing your own technology is not difficult.

Box

It’s quite simple with it - assemble a rectangular structure, and only then place it in the opening. But installation is recommended only after the fabric has been manufactured. This makes it easier to mark the places where the awnings and latch (lock) are attached. Doing this on a jamb already installed in the opening is much more difficult. In addition, it is necessary to select the grooves for the door. Therefore, after the box is knocked down, you still have to return to it.

Canvas

It all depends on the chosen design, and therefore where to start - with tying or cutting MDF boards - is decided based on the door drawing.

Frame making

The technology is simple - a rectangular shape is assembled according to the size of the sash. But there are options for filling it.

- Stiffening ribs are installed in the form of vertical posts. This solution is advisable if the frame is planned to be sheathed with MDF or plywood - the strength of the coating will be ensured.

- One horizontal jumper in the center. A good solution for insulating an interior door. For example, installed in a passage leading to a cold room (utility room). The canvas is filled with expanded polystyrene, and its slabs are foamed around the perimeter.

- Leave one frame without additional elements (small-hollow design). How to fill it and whether to do it is decided depending on the specifics of the room. But this frame option is only suitable for interior doors that are covered with boards. Otherwise, there can be no talk of strength.

Fabrication

- Its dimensions are known; All that remains is to cut the MDF into 2 - 3 fragments, according to the drawn up drawing.

- The second stage is assembling the harness. That is, the frame is assembled using a ready-made canvas.

Advice. To make work easier, it is recommended to mark all workpieces. On individual samples (according to the diagram), cuts, cuts, and drillings are first made for installing door hardware elements. This is much easier than doing such work on an assembled large structure. The difficulty is that the marking must be extremely accurate.

Door processing

- It is advisable to use the antiseptic again. Since material sampling and drilling were done, individual areas may be “exposed.” Secondary use of the anti-rot composition eliminates this disadvantage.

- Surface design. Options are marked: stain, varnish, veneer, film - depending on the design concept.

Preparation for installation

At this stage, latches, eyes, handles and hinges are installed on the canvas. The box is placed in the opening, aligned and securely fixed.

All that remains is to hang the door, align the second half of the canopy with the mounting holes and secure it with self-tapping screws (included in the kit).

“Finishing chord” - checking the correct operation of the canvas, tightness, absence of distortions; If deficiencies are identified, eliminate them. All further measures - insulation of the opening, installation of platbands, decorative design - are a slightly different topic.

Making an interior door at home is quite possible. Success largely depends on proper work planning, choosing the optimal design scheme and your own diligence. And quality is ensured by a good tool, the purchase of which is not worth regretting.

Installation of door frame and door

The next step is to install the frame and hang the door.

- We install the formed box in the opening and fix one side with long self-tapping screws in places that will be closed with hinges.

- We attach the hinges to the door leaf and frame and hang the door.

- We close the door and mark a place for the locking plate. Drill a hole to fit the latch.

- We secure the second side of the box. Before this, you need to close the door and adjust the gap, making it the same over the entire height of the door.

- We install a wooden wedge between the frame and the doorway at the latch level and fix it with a self-tapping screw through the hole provided for the locking hardware.

- We install the locking plate and secure the box with wooden wedges.

Painting

At the next stage, the finished structure is processed and decorated. It is recommended to adhere to the following plan:

- processing the coating with sandpaper or a grinding machine;

- impregnation of wood with antiseptic. The first layer should dry well. The processing is then repeated;

- the canvas is covered with a special putty, which can be replaced with a primer. In this case, the canvas is processed 2 times. But each applied layer must dry well. This will take about 2 days;

- Paint, varnish, and stain are used to finish the coating. The stain must be applied over the primer. Taking into account the desired shade, the appropriate number of layers of stain is applied. Each layer will take 4 hours to dry. To fix the result, the stain is coated with two layers of varnish.

To finish the door, paint, varnish, and stain are used

Experts advise treating the door with special protective agents against moisture and pests . If the door leaf will be installed in an apartment, then it is coated with a fire retardant. To perform a more complex decoration option, you will need the help of a specialist. Read more about painting and treating doors in the article “Painting wooden doors.”

How to seal cracks

In order to ensure additional stability of the structure, and to insulate a house or room, it is necessary to fill all the cracks with polyurethane foam.

Before starting work, cover the face strips with masking tape. We moisten the cracks with water and fill them with foam. After hardening, we trim the protruding bubbles of the sealant with a construction knife and tear off the tape along with the splashes adhering to it.

Eliminating gaps using a sealant

When choosing how to insulate a wooden entrance door, you should not ignore different types of sealing elements, but to determine the best one, it is better to consult with the seller. Seals are specially designed products whose function is to maximally fill the gaps and cracks between the door elements: the frame and the wooden leaf. In addition to thermal protection, the insulation serves as soundproofing for the entrance door to an apartment or house.

Installing a seal and sealing reduces the overall heat loss through a wooden door, solving the insulation issue by about 60%.

Types intended for wooden doors

To insulate wooden entrance doors, different types of doorway seals are used:

- tubular made of porous rubber;

- silicone;

- foam rubber.

There are options for attaching the seal: to the adhesive layer applied by the manufacturer or using small nails with your own hands. When choosing sealing strips for a wooden door, you should take into account the performance characteristics and durability of the material. The best choice is a rubber seal.

Ideas and options for processing and decoration

Before decorating a wooden door, you need to thoroughly sand its surface. The next very important stage is treating the product with an antiseptic solution. After the product has dried, you can begin decorating.

First, cover the door with primer or putty in two layers. After this, the door can be painted or a couple of layers of varnish applied to the surface. If you have the necessary available tools, minimal artistic abilities and decorating skills, you can decorate the canvas with carvings, polyurethane stucco molding, stencils, and mosaics.

Interior doors can be “revitalized” with wallpaper, fabric, and vinyl stickers.

Coniferous wood

- pine is the most common material, soft, easy to process, and has low moisture resistance. Suitable for interior doors;

- larch is moisture resistant (due to its high resin content), has an attractive texture, and high hardness. Can be used for making entrance doors;

- spruce – has many knots, is very soft and light, less durable than pine.

Read here - DIY crafts - interesting ideas, beautiful options for creating furniture and decorative features

Measuring, marking and making cuts

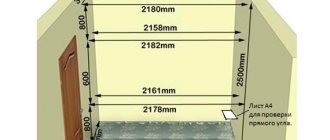

To determine the parameters of the door frame and leaf, the configuration of the product, measurements are taken. When the opening is no wider than 0.8 m, the door is single-leaf. For large dimensions, you will need to make two canvases. This will give a beautiful look and reduce the load on the hinges. For the frame, subtract 2 cm from the results obtained, and the gaps will be filled with cement mortar or polyurethane foam.

The dimensions of the door leaf are calculated from the door frame. Measure from the selected quarters, then subtract 3 mm from the results obtained (up to 15 mm in height). This is necessary to create a gap so that the door can open freely. The box is not necessarily made in width equal to the thickness of the wall. The beam may be narrower, the space will be closed by additional space.

Stages of manufacturing a paneled door

By this time everything is clear about the design: it will be a panel or panel door. The latter is easier to do; some complex operations are not performed. In any case, you need to make a harness, and to do this, mark the material and make cuts. A very careful approach is needed because mistakes often cannot be corrected. They adhere to the law: measure, mark, check, once again make sure it’s correct - you can cut.

When the values are transferred to the board, add 1 cm for adjustment. If the sawing turns out to be uneven, it is possible to correct it. When the result is positive the first time, the excess is removed. To transfer lines to the other side of the board, use a square. The angle is exactly 90°, so the initial marking is completely repeated. It is necessary to cut the vertical profiles and cross members to length.

Next, if a paneled door is planned, grooves are made in these parts using a router - exactly in the middle along the entire length. Their width is equal to the thickness of the panel - usually for a product made of chipboard 16 mm, and their depth is 15–20 mm. For a panel structure, this step is skipped.

The most important point is marking and sawing out the connection elements. Recommended methods for beginners: half a tree if the door is a panel door and a spike into the socket when it is paneled. The second option requires particularly high precision. The place for the eye is marked exactly in the center, holes are drilled, and cleaned with a chisel. The parameters are 0.5 mm smaller than the dimensions of the spike. For it, the thickness is equal to ⅓ of the board, and the length is the entire width of the rack.

Sequence of making connections

To make a corner connection of the panel door trim, align the ends of the parts. On the upper side of one, draw a line perpendicular to the edges, retreating to the width of the second. They repeat the same thing with her. Use a thicknesser to mark half the thickness, saw off crosswise, then carefully lengthwise or remove excess with a chisel.

Half-tree connection

With a paneled door it is more difficult: vertical profiles are cut from the groove at an angle of 45° using a shaped cutter or plane. On the crossbars, in order to make tenons, a counter slot is made inward, also at 45°. This operation is difficult for beginners, but it gives a more beautiful look. A possible lightweight option is to not make bevels on the boards; instead, curly beads are placed on both sides of the panels. How to make a paneled door - watch the video.

How can you insulate your front door?

The guarantee of future comfort, for the sake of which insulation was started, depends on the chosen material. And if several decades ago only felt, foam rubber and dermantin were available, today the choice is much greater. And here's what the manufacturers offer:

- Mineral wool;

- Styrofoam;

- Izolon;

- Expanded polystyrene.

Mineral wool, like polystyrene foam, is most often used as the basis for insulation for metal door panels . Both materials perfectly retain heat indoors and are not affected by microorganisms. Mineral wool is also worth noting because no rodents will spoil this insulation.

Mineral wool absorbs moisture

But these materials have some restrictions on their use.

Polystyrene foam belongs to the category of flammable insulation, so its use for working with wood is possible only when treated with special compounds. And the “disease” of mineral wool is subsidence. Over time, the sheathing may end up at the bottom of the canvas and stop retaining heat. In addition, mineral wool accumulates moisture inside itself, which adds weight to the entire structure. Therefore, this material should not be used to insulate a bathhouse or sauna.

The use of isolon is more justified to achieve the goal of heat retention. This material is made on the basis of polyethylene foam, which gives it minimal thermal conductivity . The advantages of the material include the fact that a sheet with a thickness of 10 - 15 mm will be sufficient for work. This allows you to maintain the attractive appearance of the door leaf without thickening it or making it bulky.

Izolon has low thermal conductivity

Expanded polystyrene has excellent performance. A door insulated in this way will become a reliable and safe barrier between a warm house and a cold street. Among the advantages of polystyrene foam, its non-flammability should be highlighted. When a flame appears, it will gradually disappear on the surface of the material.

For inexpensive insulation, you can always use foam rubber . The material is convenient in all respects and will be a real find for a novice home craftsman. Foam rubber will forgive mistakes and allow you to correct them painlessly.

Re-sheathing

Before you figure out how to insulate an iron door with your own hands, you need to think about the exterior finishing. We're talking about upholstery. So, leatherette or leather substitute is perfect for these purposes. Next we do this:

- We lay the material on the door.

- We cut off the canvas, leaving a margin of 10-20 centimeters on each side.

- Fold leatherette or leatherette beautifully.

- Secure with special decorative nails.

- We return hinges and fittings

Once the door is insulated and finished, we return the hinges and fittings to their places. To do everything right, it is better to photograph their location in advance. It is better to choose new handles - to match the color and style of the new design.

Cutting and laying insulation

The next stage of insulating the door leaf will be laying material that will make it warmer. To do this, you need to arm yourself with a stationery knife. Thermal insulation is cut to the length and width of the sheet so that there is no empty space left. If the door is a frame with voids, then they need to be filled with insulation.

The insulation is tightly inserted between the bars

All pieces must be tightly inserted between the bars to prevent the formation of cold bridges. At the same time, the material should not bubble, which would indicate an excessively large supply. In this case, it is worth cutting off a little excess material. Once everything is adjusted, you need to secure the insulation with staples. A construction stapler allows you to do this quickly and efficiently.

Upholstery fabric

At this stage, insulating a wooden entrance door with your own hands consists of several separate operations:

- Materials are cut according to previously taken measurements of width and length. The insulation must be cut without an allowance, and decorative upholstery, if necessary, is cut with an allowance for tucking the edges (1-1.5 cm). It is necessary to tuck the edge when the sealing rollers are not installed. This is what they do if they perform internal insulation of the wooden entrance group of an apartment with insulation and leather.

- Installation of insulation consists of attaching it to a wooden door leaf. To do this, you can use glue, a construction stapler or wallpaper nails. The cut out rectangle needs to be aligned and attached to the canvas, leaving the edges of the material free for tucking the sheathing under them.

- The leatherette part is placed on top of the insulation and smoothed. Upholstery material must be attached from the middle of the fabric. If you want to make a decor, then its design is marked out in advance, and when attaching the upholstery, a fishing line is pulled between the nails along the intended lines. The edges of the upholstery must be tucked under the insulation and nailed with decorative nails at even intervals along the entire perimeter.

Features and models

Entrance doors are installed both in apartments and in private houses. Regardless of the location of this structure, its direct purpose is considered to be reliable protection of housing from cold, noise and burglary. Therefore, when choosing this or that front door model, you need to take into account many nuances. Recently, homemade structures made of metal and wood have become extremely popular, while metal doors are distinguished by their functionality and design features; they are resistant to explosions, burglaries, fireproof and bulletproof.

Today there are many types of entrance doors. According to their purpose they are:

- Fireproof and bulletproof. Such products are made of high-strength metal. In addition, these types of doors are additionally treated with reinforcing compounds.

- Shockproof. They are the most reliable option for protecting your home.

- Soundproofing. Prevents noise and sounds from entering the house.

- Sealed. Often installed in outbuildings.

Entrance doors can open in different ways. There are swing and sliding models of structures. In addition, doors are classified by the number of leaves and are:

- Single leaf. Made from solid fabric.

- One and a half. They are a structure consisting of two parts, where only one opens.

- Bivalve. Large doors with two opening leaves.

All entrance doors differ in appearance and shape, so a distinction is made between rectangular and arched products. Designs with a blind transom are also popular.

How to weld awnings?

Before installing the entrance doors, it is necessary to weld the hinges (canopies). As a rule, to hold a standard structure you will need two hinges, the distance between them should not exceed 20 cm. Before work begins, the canopies are thoroughly cleaned and treated with a special solution. It is advisable to weld the hinges horizontally in relation to the door frame. In the event that the opening is already installed, the welding seam is carried out vertically.

The hinges are welded according to the following scheme:

- The prepared blanks are divided into two components, one of which is welded to the canvas, and the second to the box.

- First, the lower loop is attached, it is welded in several places.

- The location of the loop is checked using a building level.

- A final check is being carried out.

As for the upper hinge, the work on its installation is carried out in the same way; the only thing worth considering is the location of both canopies in the same plane. They must be placed clearly on top of each other. At the end of the work, it is important to thoroughly clean the seams from plaque, then weld the fittings themselves.