Ytong wall material from Xella is aerated concrete, which stands out among other building materials due to its excellent thermal insulation and high technical characteristics. Despite their low weight, Yutong blocks are quite strong, fireproof and resistant even to earthquakes, so they can compete perfectly with both brick and wood, combining the best properties of these materials. Such blocks are in great demand among private developers and large construction companies because they have exceptional properties and affordable prices.

According to experts, such aerated concrete blocks are ideal for constructing external and internal walls of buildings. This material is especially popular in the construction of private low-rise buildings.

Guarantees for clients

For the construction of each aerated concrete house, projects are not limited to specific frameworks and requirements, so all clients have the opportunity to turn into reality any requirements regarding the layout, area of the building and arrangement of rooms.

Turnkey aerated concrete house projects are not limited to standard options, but are based on company standards and regulations. All small house projects have been tested and implemented repeatedly, so clients can be confident in creating an energy-efficient, durable and safe house made of aerated concrete.

The production time for projects for country houses made of aerated concrete can reach several working days, depending on the level of complexity of the architectural documentation. The preparation of a project for a country house made of aerated concrete can be influenced by the area of construction, the level of technical complexity and the presence of personal wishes regarding construction.

For a house made of aerated concrete, projects and prices will include a full package of technical and architectural documentation that will be required during the construction of a country house made of aerated concrete. The construction of a house and the preparation of a project for a house are always accompanied by long-term guarantees, so all clients receive a guarantee for a period of about 5 years, as well as long-term warranty service.

Types of Ytong building materials

Our company offers a wide selection of products covering any type of construction:

— Ytong blocks for building a house;

— U-shaped blocks;

— lintels made of aerated concrete, reinforced with reinforcement;

— prefabricated monolithic floors;

— products in the shape of an arc (optimal for installing arches);

- blocks for partitions.

The main advantages of working with

Construction offers cooperation to private and corporate clients who wish to organize the construction of a permanent house made of aerated concrete. Clients have at their disposal ready-made aerated concrete house designs with a simple standard design or an individual turnkey layout.

Thanks to the construction partnership with the YTONG brand, all clients have the opportunity to buy ready-made projects of aerated concrete houses for organizing capital construction. Have you decided to buy ready-made projects for an aerated concrete house? Enjoy all the benefits:

- an individual approach to the production of an aerated concrete house project for each client;

- preparing a financial estimate for the house and drawing up an agreement under which payment is made;

- warranty obligations for each home;

- professional specialists who are well aware of YTONG house construction technologies.

Are you interested in the prices for preparing a house project? Call or write to the manager of the construction company to agree on the timing of creating a house project and order an individual project of your own house.

Range of Ytong blocks

To ensure construction with Ytong blocks, our company supplies the widest range of blocks:

- Wall aerated concrete blocks;

- U-shaped aerated concrete blocks;

- reinforced aerated concrete lintels;

- prefabricated monolithic floor;

- arcuate blocks;

- blocks for interior solutions.

We not only supply blocks to construction sites, but also assist in the design of future structures. Our company takes an individual approach to each client, helping to select and deliver materials, as well as build a Yutong house that will be warm and comfortable!

Advantages and disadvantages of Ytong aerated concrete blocks

The Ytong brand belongs to the German company Xella, which arose as a result of the merger in 2003 of three aerated concrete manufacturing companies: Haniel-BauIndustrie from Duisburg, Fels-Werke from Goslar and Ytong AG from Munich. The latter ceased to exist as an independent enterprise, but products under this brand continue to be produced, since, thanks to the highest quality, it is known to builders all over the planet.

- Blocks under the Ytong brand have been sold in Russian markets since 2007. They were already positioned as domestic products, since at that time a branch of the Ksella company began operating in Mozhaisk. It produces blocks for laying load-bearing walls and partitions, trays for armored belts and lintels, ready-made lintels and some other types of auxiliary products.

- The main advantage of aerated concrete, as such, is its excellent thermal insulation characteristics. With the same density of products, the thermal insulation coefficient of different manufacturers may not differ much, but the strength class of concrete may be different.

- To understand what we are talking about, you need to make a specific comparison. Take, for example, D400 brand blocks. If we are guided by the Russian standard, with a density of 400 kg/m³, autoclaved cellular concrete belongs to the category of thermal insulation, since it has a compressive strength class of no more than B1.5.

- However, from manufacturers working using European technologies, such blocks have a strength class of B2.5. This allows them to be used not only as insulation, but also as a structural material for the construction of walls of low-rise buildings. And the advantage is that they will not only have normal strength, but also, due to their low density, a lower thermal conductivity coefficient.

So it’s not surprising that you have to pay a little more for Ytong blocks than for products from another brand, whose strength characteristics are almost half as strong.

Characteristics of Ytong aerated concrete

We present a list of the main characteristics of Itong gas blocks - those density options that are most often used in housing construction:

| Material properties | Unit | Brands of aerated concrete blocks Ytong | ||

| d400 | d500 | d600 | ||

| Density | Kg/m³ | 400 | 500 | 600 |

| Concrete strength class | — | B2.5 | B3.5 | B5.0 |

| Compressive strength | MPa | 3,4 | 4,8 | 6,8 |

| Dry thermal conductivity coefficient | W/m*S | 0,088 | 0,099 | 0,112 |

| Frost resistance | cycles | 100 | 100 | 100 |

| Fire resistance | hour | 4 | 4 | 4 |

| Vapor permeability | Mg*(m*h*Pa) | 0,24 | 0,21 | 0,17 |

| Shrinkage deformations | Mmm | 0,45 | 0,4 | 0,35 |

| Deviations in sizes | ||||

| By lenght | Mm | 0,3 | 0,3 | 0,7 |

| Width | Mm | 0,3 | 0,4 | 0,5 |

| By height | mm | 0,7 | 0,8 | 0,3 |

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Please note: As can be seen from the table, even the largest deviation in size for Itong blocks is less than 1 mm. And this despite the fact that according to GOST 31360 (for autoclaved wall products made of cellular concrete), for blocks of category 1, deviations are allowed in height 1 mm, width 2 mm, length 3 mm.

Representatives of the manufacturer claim that the plant operates according to its own standard - STO, and even announce its number: 73045594-001*2008, which imposes even higher requirements on products than GOST. But there is no such document on the Internet, although it would be interesting to read it. It is possible that it does not exist, and this is all just a marketing ploy. However, it is impossible to deny that Itong blocks are one of the few that can be called super-strong. Strength class B3.5, and even more so B5, is enough to build a three-story mansion - albeit without a helipad on the roof.

The straightness of the edges is quite a decent indicator, for which you can pay a little more. And that's why. Thanks to the precision of the geometry, the blocks fit perfectly to each other, which allows the thickness of the seams to be minimized. Provided that the base under the first row is carefully leveled, there will be no differences in planes between the blocks. You will have to use a grater and brush less, the work will go faster in general - and time also costs money, especially when contractors work.

We can’t help but mention environmental friendliness. Aerated concrete, as such, is an environmentally friendly material. But only YTONG was awarded the Ecomaterial Absolute certificate (absolutely environmentally friendly). Such a document is issued only if the release of harmful substances from a product is 40% below the maximum permissible levels. If the toxicity simply corresponds to the maximum permissible concentration, a certificate is issued by Ecomaterial Green (safe for the environment and humans).

How to use Ytong gas blocks correctly and where

Aerated concrete blocks are a wall material intended for the construction of houses no higher than three floors. For higher storeys, the building must have a reinforced concrete load-bearing frame, and concrete stones are used exclusively as filler for spans.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Important: You can often find information on the Internet that gas blocks are suitable for constructing basement walls. This statement is fundamentally incorrect and goes against existing building codes. And they say that cellular concrete cannot be used for the construction of basement walls and plinths (and certainly not foundations!).

How to transport and store

From the factory, aerated blocks are shipped in pallets, covered with polyethylene shrink film to prevent not only the packaging from falling apart, but also getting wet in the rain or snow. The blocks are transported on vehicles with a long platform body equipped with tension belts. When unloading at a warehouse or facility, pallets are placed on level ground, in no more than three tiers. The blocks are unpacked immediately before they are sent to work, and only in such quantities that will be installed during the work shift.

How to install correctly - the main nuances

To obtain high-quality masonry, it is very important to ensure that the base is horizontal, which here is the upper plane of the foundation. It is rarely even, and deviation is allowed no more than 30 mm. Therefore, you need to start with alignment. Then waterproofing is carried out with rolled material, with an overlap of the strips of at least 15 cm. It is best to glue them to the base wall with bitumen mastic.

The first row is the most important

In each corner of the building a block is laid that will act as beacons. Their laying is carried out on the DSP, the thickness of the layer varies depending on the existing deviations of the base. You should follow the marks to the angle that turns out to be the highest. The remaining blocks are adjusted to the desired level due to the thickness of the mortar layer underneath them.

Having adjusted the position of the lighthouse blocks according to the level, a mooring cord is pulled between them. If the wall span is too large (more than 10 m), an additional beacon is installed between the corners. It will prevent the cord from sagging, and this is important for controlling the evenness of the rows.

The space between the lighthouse blocks is filled. Each element of the masonry is leveled, minor differences in the surface are eliminated with a float, and dust is removed with a brush. In the first row, the last block has to be cut to cover the distance into which the solid block does not fit. The use of an additional element ensures the movement of vertical seams - you just need to start laying the second row from the place where the first one ended.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: The first row must be reinforced along the entire length of the wall.

Which glue to choose

The YTONG brand sells not only blocks, but also everything necessary for their installation. First of all, it's glue. The manufacturer offers two cement-based options: for thin-seam installation - summer and winter (price 275 and 351 rubles per 25 kg bag), as well as universal polyurethane-based DRYFIX foam.

The consumption of cement glue is 32.5 kg per 1 m³ of masonry. A bottle of foam glue with a capacity of 750 g, which costs 440 rubles, is enough to install one pallet of blocks, which is 1.4 m³. The costs are approximately the same, but with foam it turns out faster, since you don’t need to spend time mixing with water. Plus, you don’t need to buy containers and a toothed bucket.

How to process blocks

Aerated concrete is soft enough to be cut with a hand saw with a reinforced blade. Such a tool, costing 2,685 rubles, is also available in the Ytong product line. For a more accurate cut, it is worth marking the cutting line with a pencil on all sides.

To level the cutting plane, the manufacturer offers a special tool - a plane for cellular concrete (costs 1,100 rubles). However, when performing large volumes of work, it is better to use an electric saw - preferably a band saw. When you need to level out minor differences in masonry, it is more convenient to use a trowel to polish the surface - it costs 740 rubles.

If the walls are reinforced with reinforcement bars, you will also need a wood shaving cutter. This manufacturer offers only a manual version costing 480 rubles, although a similar tool is also available as an electric one.

Arrangement of openings

Starting the first row of masonry, it is necessary to outline the boundaries of the doorway. As the height of the wall increases, the masonry will have to be interrupted in those places where there will be openings for windows. Since they need reinforcement, you need to have a drawing or sketch in front of you, which will indicate in which rows the reinforcement should be made.

- For example, the lower border of the opening will begin through three rows of blocks (if their height is 25 cm, from the base to the opening there will be 75 cm). This means that the third row of blocks must be strengthened. This must be done so that the reinforcement not only covers the future opening, but also extends beyond its vertical boundaries by at least 90 cm.

- Next, the walls are laid to the point where another reinforcement should be provided. Which row it will be depends on the type of jumper device. If it is a monolith, a prefabricated monolith or a finished lintel, you need to reinforce the penultimate row along the height of the piers.

- They reinforce those places where the lintel rests - at least 50 cm deep into the masonry from the boundaries of the opening. If the opening is made without a lintel (this is allowed if the opening width does not exceed 120 cm), it is not the piers that are reinforced, but the row that covers the opening.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: For arranging openings, Xella offers not only U-blocks, but also ready-made reinforced lintels with a density of D600. The range is quite large: the length varies from 1300 to 3000 mm, the section size is 124 mm in height, and 115, 150 or 175 mm in width. The dimensions are chosen so that the products can be doubled in height and combined in width.

To create a lintel from tray blocks, you need to create a reliable base from a board or OSB board, fixed in the opening with the help of supports. Then the U-blocks are mounted on glue in such a way that the outer ones rest at least 25 cm on the masonry walls. A spatial frame of AIII reinforcement with a diameter of 8-10 mm is laid inside the tray, after which B15 concrete with fine-grained filler is poured (crushed stone fraction no more than 10 mm). After it hardens, the supports are removed - and the lintel is ready.

Flexible connections for junctions

Very often, aerated concrete houses are designed with external brick cladding. It is attached to the load-bearing wall using flexible connections that provide the necessary space for a ventilated gap and the laying of thermal insulation. The connection is a spacer-connecting element consisting of a stainless steel rod and a screw-shaped polyamide sleeve.

For installation, a 10*60 mm hole is drilled in the load-bearing wall, into which a sleeve is installed using a special nozzle. Then a rod is screwed into it, and its free end is inserted into the seams of the brickwork. YTONG offers such connections in packs of 250 pieces, the price per set is 13,160 rubles.

This type of anchors can be used even when the cladding is carried out after the construction of aerated concrete walls. If you carry out the laying at the same time, you can use another type of connections - Multi. They are designed in such a way that both ends are embedded in the joints of the masonry. A package of 250 pieces costs 6,460 rubles.

Examples of Ytong aerated concrete houses

For those who purchase Yutong brand blocks, the Xella company has developed about 40 projects of houses for year-round use, in classic and modern styles, with a wide variety of square footage. Moreover, projects are provided to our clients free of charge. Let's look at a few of them as an example.

One-story house - Klausdorf project

Not counting the terrace, the size of this house in plan is 8.04 * 11.55 m. The total area is 93 m². There is everything necessary for a family of three to live here: two bedrooms, a living room, a kitchen separated by a partition, and a spacious eight-meter bathroom. In front of the entrance there is a concrete porch with flower beds. The house is adjacent to a 25 m² terrace, accessed by glass doors from the kitchen and living room. The estimated cost of the house is 2,178 thousand rubles.

House with attic – Heidelberg project

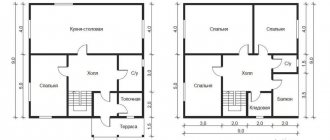

The total area of this chalet-style house is 120 m², plus there is a terrace and porch with a total area of 29.3 m². It will take up less space on the site than the previous option, since the plan dimensions are only 9.8 * 9.6 m.

The house has 3 bedrooms and 2 bathrooms, one of which serves as a guest toilet on the ground floor. There is also a combined kitchen-living room with a bay window with an area of 31.5 m² and a technical room that combines a furnace and laundry room. A vestibule leads from the entrance, from which you enter the hall. There is enough space in it to put a large wardrobe for outerwear or organize convenient storage systems. The attic traditionally houses private rooms - bedrooms and a bathroom with a bathtub.

House structure: insulated slab foundation; external walls 375 mm thick, internal walls 250 mm, partitions 125 mm; prefabricated monolithic ceiling (T-shaped blocks and metal beams for its assembly are also sold under the Itong brand); metal roofing. The minimum price of such a house is 2569.8 thousand rubles.

House on two floors - project Freiburg

The overall dimensions of this house, designed in high-tech style, are 9.6 * 12.2 m, but the house itself does not take up that much space. 4.33 m in width of the building is allocated for a garage, the roof of which also serves as a balcony for the second floor. The balcony is so spacious (20.5 m²) that it can easily be called a terrace.

The height of the floors is 280 cm. On the first floor there is a modest-sized living room, a small kitchen, a pantry, a guest toilet and a boiler room. Upstairs there are only 2 bedrooms (one has a dressing room) and a large combined bathroom with shower. The building structure is the same as in the Heidelberg project, with the exception of the roof. Here it is single-pitched, with a slight slope, and is covered with bituminous shingles. The approximate price of the house is 3360 rubles.