Ventilation is one of the most important engineering systems of any building. It is responsible for proper air exchange, ensuring comfortable climatic conditions in the interior. Grilles must be installed at the inlet and outlet of ventilation ducts that are within accessibility. Their purpose:

- aesthetic design of holes;

- protection of the mine from clogging due to foreign objects or animals getting into it;

- correct distribution of air flows, which is more typical for supply ventilation.

How the grille should be placed on the ventilation depends on its material, design and installation location. But there are always several acceptable options for the installation method to choose from.

Aluminum grilles

Aluminum models are considered another universal option for ventilation grilles. This material is used for the manufacture of gratings of any type:

- internal;

- external

At the same time, the aluminum profile allows you to make a grille of any cross-section, namely round, rectangular and square options. Among the advantages of protective aluminum grilles for ventilation systems it is worth noting:

- material strength;

- environmental friendliness, allowing use both outside and indoors;

- light weight, ensuring ease of installation and maintenance;

- protection from moisture and aggressive detergents;

- aesthetics.

In our online store you can buy at an affordable price various types of aluminum gratings, which differ in the following parameters:

- color – natural metallic color or coated with paint;

- scope of operation – external, internal;

- intended purpose - decorative, adjustable or unregulated, louvered, for supply or exhaust ventilation;

- Design features: dirt-proof, with mosquito net.

Here you can choose both ready-made options and order the production of models with original characteristics.

Round ventilation grilles

Circular ventilation grilles are universal products that are made from various materials and can be suitable for both external and internal installation. In this case, the scope of operation will depend not only on the material of the grille (metal, aluminum, steel are most often used for the manufacture of outdoor models), but also on its design. If we talk about internal models, they most often are:

- wooden;

- cast iron;

- plastic;

- made of stainless steel.

Such grilles most often serve not only a decorative purpose, but also ensure uniform air dispersion between rooms. As for external-type grilles, they have a simple design that ensures reliable fastening (most often on a flange) and long service life. At the same time, they are equipped with a mesh to protect against the penetration of insects, dirt and dust. Such a protective barrier helps protect the internal components of the ventilation system from contamination. Among the requirements for round grilles with blinds and mosquito nets, protection from moisture should be noted. Moreover, protection should be provided not only by outdoor options, but also by internal grilles that are installed in bathrooms in areas with high humidity. Grilles are used for any ventilation system (supply, exhaust) with air ducts of adjacent diameters (100 mm, 125 mm, 160 mm, 200 mm, 250 mm, 300 mm).

Examples

The basic diagram for installation in country houses and dachas is ventilation with natural air circulation. It is suitable for brick and wooden buildings, as well as expanded clay concrete structures. As a rule, designing just such a scheme prevails in the construction of apartment buildings. If you purchased an apartment in a Khrushchev building, then be guided by the fact that there will be natural ventilation.

Natural air exchange is based on the phenomenon of pressure difference in the air column. The ventilation system is easy to install and operate, does not depend on the availability of electricity, and does not require the installation of expensive equipment. However, the system depends on weather conditions, in particular wind, and temperature indicators, since natural circulation requires that the temperature in the room be higher than outside. Otherwise, air movement stops.

In the age of developing technologies, many people use forced ventilation. It can be partially automated, when the equipment is used only to pump air into the building, or, conversely, to remove fumes outside, or fully mechanized, which involves the use of fans at both stages.

Since the ventilation shaft in the kitchen usually has a larger diameter, all flows rush towards it. In windy weather, this powerful channel can “overturn” a smaller one in the bathroom, forming a reverse draft, that is, a cold wind will begin to blow from the toilet. In this case, proper installation of forced supply ventilation is necessary.

A glazed balcony or landscaped loggia also requires a ventilation system. There are several options for its arrangement. First of all, it is natural due to opening the windows, but during the cold period this is not always convenient. Some window manufacturing companies build ventilation holes into them to provide micro-ventilation. More often, owners install a hood that allows condensation to escape.

A supply and exhaust circuit is necessary for installing ventilation in a room without windows, for example, a storage room. In particular, for safety reasons, many technical premises require to be equipped with a forced system (garages, boiler rooms, boiler rooms, warehouses).

The ventilation complex in the case of a mixed scheme is a system of pipes, some of which draw in air from outside, others remove exhaust air outside the building. The influx is provided by a convector, which additionally heats, filters and disinfects the flow from the street with ultraviolet light. In order to prevent the forced air from expelling heat from the room during the cold period, we developed a special heat exchanger - a recuperator, which is designed to use the temperature of the outgoing flow to heat the incoming one.

How the grille works

Ventilation grilles consist of a frame installed in the channel opening and a central section with slots. Flow guides can be fixed or adjustable (to change the direction of air masses).

At industrial facilities or warehouses, there are structures with a damper to protect against backdraft and the entry of dust or insects into the room.

Instead of a shield, several small screens can be used, connected to each other by a rod. The valve is opened by air flow; power drives are not used.

Installation method

Installation is usually not difficult. As a rule, products are supplied with instructions.

There are several ways, here are the most common ones:

- Some products are already equipped with their own spring spacers. The model is inserted into the hole in the ventilation duct and snaps into place.

- Lightweight aluminum grilles are glued to a smooth surface (tiles, drywall).

- Models with holes in a removable frame are mounted using dowel screws.

- If the product is not equipped with an overhead frame, then countersunk screws are used for fastening, which are then painted.

- Heavier structures are mounted on anchors.

Features of different types of gratings

Today “Ventar-S” offers for purchase ventilation grilles in a wide range of price categories, made from a variety of materials. When choosing, it is worth considering the fundamental differences between them:

- Aluminum - products made from this material are characterized by increased strength and relatively low cost. Most often, devices are equipped with an overhead mesh or grille. In some options, more complex equipment is possible, such as blinds. Thus, ventilation grilles for blinds are most actively used in residential premises, but they are no less rare when servicing industrial ventilation.

- Wood - they are made mainly to individual order if the main interior of the room is designed to look like wood. For the manufacture of such products, a special impregnation is used, which protects the products from moisture. The disadvantage of wooden ventilation grilles is their relatively high cost.

- Plastic is the most affordable ventilation grille, which can come in a variety of shapes, sizes and colors. All necessary characteristics are indicated when ordering the product. Often, plastic ventilation grilles are characterized by low strength, so plastic is mainly used for the manufacture of products for servicing internal ventilation.

- Steel is a material primarily used in the production of external ventilation grilles. Such products are distinguished by excellent strength, reliable fastenings and a long service life.

Important: When choosing a ventilation grille, you must take into account its external features and parameters. These characteristics, of course, will not affect the functions of the device, but can significantly spoil the overall appearance of the interior.

Decor

Turn the frame upside down and measure its internal dimensions, they are necessary for cutting the metal sheet. Make markings on the metal, reducing the original values by a couple of millimeters on each side. Open the sheet, cutting off the excess. My husband used special scissors to work on metal.

Glue the metal plate to the inside of the frame with multi-purpose glue. Press the sheet of metal to the wood with clamps all the way around, leaving them until the glue dries completely. If you think that the clamps will not be enough, place weights on the joints; several large containers of water, bricks, etc. will do. Make sure that the weights do not bend the metal mesh.

And no greenhouse is needed: we stock up on disposable cups for seedlings

Vera including: what 5 Russian names attract Italians

Will production of Sputnik V begin in Italy?

If you are not sure about the strength of the glue, then press the metal with wooden glazing beads to the frame, securing them with small nails along the entire perimeter. A special varnish for metal products will help protect perforated sheet metal from corrosion and give it a beautiful appearance.

Types of ventilation grilles

Before you buy a ventilation grill, you need to pay attention to how these devices differ from each other. So, first of all, they are divided according to the place of installation:

- External. The external ventilation grille is located outside the buildings. The main purpose of these devices is to protect the ventilation duct from the penetration of all kinds of debris, precipitation, birds, rodents and insects. The external ventilation grille is preferably metal. Typically, aluminum is used as the basis of the structure. Also, such metal ventilation grilles are almost always equipped with special blinds.

- Internal. The internal ventilation grille is installed directly in the premises. Moreover, it is made of plastic, and in rare cases of aluminum, copper or wood.

- Transfer. Transfer grids differ in their installation location and functions. They are usually installed in walls or door panels. Such grilles must meet some special requirements, including a high level of noise and thermal insulation. Especially for this purpose, such grilles are equipped with blinds that overlap each other.

The following types of ventilation grilles are also distinguished:

- Adjustable. In this type of grille, it is possible to change the position of the blinds, which allows you to control the amount of air masses entering the room. Ventilation grilles for blinds are universal devices and can be used in rooms of various types.

- Unregulated. These grilles do not have an adjustment function and are simpler in design. Depending on how the curtains are fixed, these grilles, in turn, are divided into straight, slotted and inclined.

- Inertial. This type of grating is the most independent. The device is able to independently shut off the air flow at the right time. This exhaust ventilation grille has a higher cost, but it has better performance characteristics.

According to their shape and purpose, ventilation grilles can also be:

- Round;

- Square;

- With blinds.

Special types of ventilation grilles include devices equipped with a valve. The ventilation grille with valve, in addition to the usual distribution bars, has a special shut-off valve. It prevents cold air, dust and insects from entering the premises. Having decided on the material, type of grille and the necessary functions that it should perform, you can begin ordering the design. "Ventar-S" allows you to buy a ventilation grille of any of the types listed above.

Basic Concepts

Indoor air movement is often limited by closed doors. This prevents both temperature and humidity from being distributed evenly. One solution to this problem is the use of ventilation grilles.

This type of door design refers to cross-flow ventilation devices. They consist of several structural elements:

- Lattice. This part is made in the form of a durable frame, between which strips are located at a certain angle. This allows air to move freely.

- Decorative overlay. The product is a small structure that repeats the shape of the previous element. Install it on the other side of the door to hide the places where the hole was cut.

You can install overflow grilles in almost any door, but they are often found only in a few rooms:

Kitchen

This is important if the hood is constantly running here. It removes dirty and hot air, and fresh air enters the room through the holes in the door

Bathroom and toilet

In such places, ventilation systems are used very often.

This is especially important for the bathroom, where a large amount of moisture collects. And to prevent the formation of mold, surfaces should be thoroughly and constantly dried.

Interior doors. This approach is relatively rare. These structures are used in large offices where it is necessary to create comfortable conditions for workers. Such doors can also be seen in large archives or libraries, where it is necessary to maintain optimal conditions for storing paper.

Types of ventilation grilles

Main types of products according to installation location and design features:

- for indoor use;

- for use outdoors or in corridors;

- for indoor use and exchange of air masses between adjacent rooms.

Regardless of the location of the grille, it can have fixed or adjustable guide elements. Occasionally there are inertial-type products with blinds that provide direction of flow and protect the room from reverse draft.

Domestic

The classic version for an apartment or office is made of plastic that is resistant to heat and exposure to food fat or ultraviolet light.

Overhead modifications have a frame located on the wall and can be equipped with a fine mesh to protect against the penetration of insects. Slot options are integrated into the opening, the color of the plastic is selected to match the shade of the wall or ceiling finishing material.

As an additional element, products for indoor installation can be equipped with a reed valve to protect against backflow of air.

External

The main types of exhaust devices for outdoor use:

- frontal, designed for use in attics and characterized by an extended frame;

- door ones, used instead of a standard valve and made of material that matches the color of the door leaf;

- floor, made of light alloys or steel sheet with an external decorative coating, are used to protect heating radiators located in niches in the floor;

- base, made of metal with anti-corrosion coating and protecting air ducts from the penetration of rodents.

External ventilation grilles on the facade.

Internal transfer

The products are designed to distribute flows between adjacent rooms; the design does not use a check valve. V-shaped louvres are installed inside the frame, directing air and limiting the view through the grille. They consist of 2 frames, which are installed from adjacent rooms and fixed with screws.

The adjustable design allows the products to be integrated into walls with a thickness of 25 to 50 mm. For manufacturing, impact-resistant plastics or aluminum alloy with powder coating in different colors are used.

In houses with fireplace heating, interior grilles ensure the distribution of heated flows. Air masses are separated by density, the lower cold layers enter the room with heating equipment, and their place is taken by a heated environment.

For the manufacture of products, non-ferrous metals (for example, bronze or brass) are used that are resistant to combustion products and high temperatures.

Internal transfer grilles for air distribution.

Adjustable and non-adjustable type

The standard product is equipped with a lid with horizontal slots separated by plates. The angle of inclination determines the direction of flow; when the position is fixed, there are zones in the room where air masses do not flow.

The adjustable grille allows you to change the flow path; to change the position of the plates, you must manually turn the rod connected to the blinds.

A number of designs provide functions for blocking the ventilation duct or installing planks horizontally, which ensures maximum air flow into the room.

Adjustable ventilation grille.

Inertial

The products are designed for installation in exhaust ventilation systems. The plates are fixed in a frame on axles and are freely deflected under the influence of traction; the stroke limiter prevents flow in the opposite direction.

There are gaps of 1-1.5 mm between the blinds and the frame, ensuring the mobility of the elements. Products are made of plastic or aluminum and then coated with powder enamels. The inertial grille is a modification of the check valve and is characterized by increased strength and a neat appearance.

Plastic inertial ventilation grilles.

Installation of ventilation equipment

Installation and installation of ventilation equipment is carried out after all finishing work has been completed, except for finishing. This stage involves fastening mechanisms, the set of which varies, but the algorithm of actions is the same for all.

The elements must be installed in the following order, starting from the air inlet into the interior of the ventilation duct.

- Cleaning filter system.

- A heater that heats the air during cold periods. In more expensive models it is equipped with a remote control.

- Fan.

- Recuperator.

- Air conditioning system to cool the air flow during hot periods. As a rule, this block should be the last one before the outlet.

If a household ventilation duct passes through an unheated roof, then the pipes must be insulated. If ventilation involves not only a supply circuit, but also a forced outflow of air, then the next stage is the installation of an exhaust fan. Finally, electrical networks are laid, electricity is supplied to the mechanisms and they are grounded. If the ventilation complex consists of several sections, then it is necessary to assemble each network separately and conduct pre-start tests of each unit.

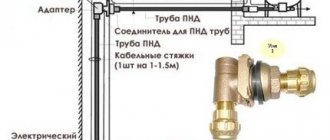

Supply

Installation diagrams may vary depending on the configuration of the ventilation complex.

The standard installation option involves several steps.

- Selecting and marking locations for ventilation holes.

- Drilling the intended entrances and exits with a slight slope towards the street to ensure condensate drainage. The diameter should not be less than 12-13 cm.

- The air duct pipe is cut to the required dimensions.

- Installation of ventilation duct and outlet valves.

- Eliminating gaps between the pipe and the walls using polyurethane foam.

- Fastening the entire installation to the wall or ceiling.

- Installing a filter in the supply air duct.

- Mounting the heater and its connection.

- Installation of protective grilles on outlet openings.

- Power supply.

The simplest option for supply ventilation is a wall valve. It is a plastic pipe, inside of which an external air distributor, a filter, noise and thermal insulation, a regulator, and an internal distributor are located in series. It is more efficient to install such a device between the window sill and the radiator. To do this, a channel with a cross section of 5-6 cm is cut into the wall, into which the valve body – a pipe – is inserted. Then the external distributor is mounted on the outside, and the internal distributor on the inside.

DIY hood

Sometimes natural ventilation is not enough, then experts suggest installing an additional exhaust system to increase the outflow of used air. As a rule, they are installed in the kitchen above the stove and in the bathroom. It should be understood that all devices in the forced circuit operate on electricity. However, an ordinary low-power fan can be powered even from a light bulb regulator in the bathroom.

Natural ventilation in the apartment is focused on air outlet into a single shaft. To ensure that the flows from the bath and toilet do not overlap each other, the fans are equipped with a check valve. As a result, air penetrates through it, but cannot come back out. Small models are attached using ordinary screws, dowels, or using fasteners supplied with the model by the manufacturer. If you do not have the skills to install such products, it is recommended to follow the instructions that are included with any product.

Lattice shapes

The configuration is determined by the size and contours of the ventilation ducts. In multi-apartment residential buildings there are rectangular or square highways.

On the entrance doors, elements in the form of a rectangle elongated in width are used. In office or industrial premises, it is possible to install air supply lines with a circular cross-section.

A number of manufacturers (for example, Vtvent) offer custom-made grilles according to customer dimensions; width and height are selected from the range from 90 to 3000 mm in 1 mm increments.

Ventilation grilles can be made to order.

Preparation

Measure the outside perimeter of the duct, the trim will mask the existing grille. Cut the wooden planks to size. We used a miter saw, but you can also use a hand tool like a jigsaw and a guide to help you get the cuts at the right angle.

How to make a good impression on a woman on a date (checklist for men)

The source of dangerous particles produced during solar flares has been discovered

In Belarus, industrial production of Sputnik V will start at the end of the month.

We glued the ends together with universal glue, tightening the frame with clamps. After drying, the frame was reinforced with nails at four corners. To make the nail heads invisible, we used a hidden fastening tool. Next, these places need to be puttied and wait until the mixture dries.

Sand the wood until completely smooth. The next step is to finish the frame. It can be painted, tinted with stain, covered with protective wax or varnish. It is advisable to do this before the metal decor is installed. We skipped this step and had to paint the frame after installing the mesh, which was very inconvenient. Don't forget to coat the inside surface of the wood with protective agents.

External ventilation grilles

If internal grilles for ventilation systems can be made of materials such as plastic or wood, then external models are often made of durable metal. Such requirements are determined by the nature of operation, since grilles for outdoor installation can be subject to mechanical stress, as well as natural disasters (gusts of wind, rain, snow). The most common types of ventilation grilles for outdoor use are:

- aluminum;

- metal with galvanization;

- made of stainless steel.

Unlike internal ones, they are used not for the purpose of uniform dispersion of air masses, but as a protective barrier against the penetration of birds, insects, as well as dirt and dust caused by gusts of wind into the air ducts. One of the main advantages of external ventilation grilles, which you can purchase in our online store, is reliability and simplicity of design. This ensures not only a long service life (extra parts that artificially “complicate” the grille fail first), but also ease of installation. As a rule, overhead facade options, which are mounted using self-tapping screws screwed into the wall, are in demand.

Such grilles can be used with both supply and exhaust ventilation, manufactured in various forms:

- round;

- rectangular;

- square.

Most models, in addition to blinds, are equipped with a mesh to protect against mosquitoes and other small insects. From us you can buy gratings of any size from minimal (200x200, 250x250) to large-sized (700x400, 1000x500) at a competitive price, as well as order original products with any parameters (125x100, 315x160, etc.).

When is a grille with a check valve needed?

The advisability of installing a grille with a check valve is due to the presence of reverse draft in the ventilation system.

Therefore, if this phenomenon is absent, there is no urgent need for it, but for prevention it is still worth installing a grille.

A high-quality valve shutter should be so sensitive that it can quickly respond even to weak air movement

The following factors can cause backdraft:

- Lack of air flow into the room or reduction in its volume.

- Debris getting into the hole.

- Failure of elements that control air flow.

- Operation of high power hoods.

- The wind that was not taken into account when designing the house was constantly blowing.

- The presence of several pieces of equipment in the ventilation system, the air outflow operating simultaneously.

All these circumstances create conditions for the appearance of reverse thrust. In this case, pure oxygen does not enter the room. There is no guarantee that at least one of the listed factors will not appear. It is better to protect your ventilation system by installing a grille with a check valve.

Ventilation grille materials

Natural or artificial materials are used to make parts. When selecting, take into account temperature operating conditions and resistance to external influences (mechanical or chemical). The type of material determines the possibility of applying paintwork, the shade of which is determined in accordance with the color of the walls or ceilings.

Galvanized metal

Steel coated with a thin layer of zinc is characterized by increased resistance to corrosion. The grilles are designed for installation in office or industrial premises.

The material is resistant to elevated temperatures, ultraviolet radiation and most chemicals.

For production, rolled steel up to 2 mm thick is used, which allows reducing the weight of the structure. If holes are drilled in the frame for fastening, a protective material must be applied, otherwise pockets of corrosion may form along the edges.

Galvanized metal for the manufacture of ventilation grilles.

Aluminum

Metal allows you to reduce the weight of the structure and allows for powder coating. A coat of paint improves the appearance of the grille and increases resistance to external influences.

Aluminum can withstand elevated temperatures and is inert to sunlight. The disadvantage of the products is their increased cost; the gratings can be used in residential and technological premises.

Aluminum ventilation grille.

Tree

The advantage of wood is its ease of processing; the material makes it possible to produce gratings with complex patterns. The surface is impregnated with compounds to prevent rotting, and then covered with a layer of glossy varnish.

Wood can only be used indoors; when installed outdoors, the lattice is destroyed within 1-2 years of use. The disadvantages of the material are low resistance to elevated temperatures and fire hazard (the problem is partially compensated by impregnation with special liquids).

Ventilation grilles made of wood.

Plastic

For manufacturing, ABS plastic is used, which is resistant to chemicals and ultraviolet radiation. Grilles can be installed outdoors, but due to exposure to external factors, the material becomes fragile.

If cheap plastic is used or the technological process is violated, yellow spots may appear on the surface of the products.

The advantages are low manufacturing costs and the ability to obtain material of different colors by adding pigment at the stage of obtaining granules used in casting machines.

The most popular plastic grilles.

Gypsum

Gypsum structures are designed for use inside the house, the material can be painted, and there are grilles with ornaments. The products are made using casting technology, the disadvantage is fragility. When installed outdoors, the gypsum becomes saturated with moisture and gradually deteriorates.

Plaster ventilation grilles are quite fragile.

Steel

Carbon steel gratings are manufactured using stamping technology, which reduces production costs. To prevent the formation of corrosion centers, the metal is primed and covered with a layer of enamel.

The products are inert to external natural influences and can be used outdoors. Disadvantages include a rough appearance (this note applies to budget grilles, on the edges of which, after stamping, irregularities or burrs remain).

Steel gratings are installed on the outside of the house.

Decorative grilles

One of the most popular types of ventilation grilles are decorative products that are installed indoors. These models are often mounted in interior walls, providing not only natural ventilation, but also providing an aesthetic component. Decorative grilles are usually:

- wooden;

- steel;

- cast iron;

- plastic;

- aluminum.

Products made of wood and metal are often installed between rooms, while plastic models and galvanized and stainless steel grilles are suitable for bathrooms and toilets where there is high humidity. In our store you can buy decorative grilles from the following manufacturers:

- Vents;

- Blauberg;

- Europlast;

- Shamray;

- First.

A wide range of products of various shapes (round, square, rectangular) and materials will allow you to choose a product that suits both design and price.

Unlike radiator grilles, which are installed on top of the radiator, decorative ventilation grilles must have the following parameters:

- durable materials that are durable and maintain their original appearance throughout their entire service life;

- attractive design that allows the grilles to be used indoors with different types of interior;

- protection from moisture and aggressive detergents (grids for bathrooms and kitchens);

- ease of installation and dismantling;

- perfect alignment in size with the ventilation duct to minimize backlashes and cracks;

- high-quality assembly.

All products sold by our company meet the above requirements. You can also order in Moscow the production of components for ventilation systems according to individual parameters. We offer products of the highest quality at reasonable prices.

Conclusion

Having read the information described above, you have definitely found the answers to the questions posed and now have an idea of what a ventilation grille is and how it is attached to the wall. Do not forget that ventilation of the room is necessary not only for aesthetic reasons (to remove odors), but also for health benefits (air space is discharged).

Sources

- https://mystroiteli1.ru/ventilyaciya/ventiliacionnaia-reshetka-vidy-razmery-i-ystanovka.html

- https://TopVentilyaciya.ru/ventilyaciya/elementy/kak-ustanovit-ventilyatsionnuyu-reshetku.html

- https://StrojDvor.ru/ventilyaciya/kak-pravilno-vybrat-ventilyacionnuyu-reshetku-podxodyashhego-vida-tipa-i-razmera-metody-ustanovki/

- https://ventazbuka.ru/v-zdanii/v-kvartire/ventiliacionnie-reshetki.html

- https://AeroClima.ru/ventilyaciya/ustanovka-reshetki/

- https://uchebniksantehnika.ru/ventiliatsiia/vyiasniaem-kak-verno-ustanovit-ventiliatsionnuiu-reshetku.html

- https://SavoPenza.ru/sistemy-otopleniya/kak-postavit-ventilyacionnuyu-reshetku-2.html

- https://StrojDvor.ru/ventilyaciya/sposoby-pravilnoj-ustanovki-ventilyacionnoj-reshetki/

What nuances should you pay attention to when purchasing?

When purchasing a ventilation grille, you should pay attention to the following details:

- Installation features - they should be taken into account, since the simplest structures are fastened using ordinary nails or screws. More complex designs require additional inserts, cut-ins and press fittings.

- Size and shape - when choosing, be sure to take into account the width, height and thickness of the purchased product, since in the future changing the size of the ventilation hole is difficult or completely impossible. In some cases, it is possible to produce ventilation grilles of non-standard shapes.

- Purpose – unregulated and adjustable ventilation grilles are produced. Some models of the device have a check valve that can only allow air to flow in one direction.

- Holes – in ventilation grilles they can take the form of slits, squares, diamonds, circles. Some models are equipped with slats and blinds. If you need more significant protection from insects, then you should pay attention to grilles equipped with special protective meshes.

Important: Ventilation grilles must fully comply with the conditions in which they will be used.

Device and principle of operation

A ventilation grille with a check valve consists of a protective housing, a mounting flange, a front decorative panel and a damper. The valve flap is able to open due to the forced circulation of air masses moving under a certain pressure. The grille is connected to the air duct using a flange, which is available in different sizes and is fully compatible with all types of air ducts. For the manufacture of grilles with a check valve, plastic is mainly used, which is due to the operation of the device in conditions of high humidity, where the use of metal components is impractical.

The principle of operation of the check valve is as follows: exhaust air masses leave the room through the decorative trim and, under a certain pressure, pass through the valve, lifting the damper. When the air flow pressure drops, the valve valve closes and acts as a reliable barrier to street dust, insects and unpleasant odors. Models are often installed in kitchens and bathrooms adjacent to similar rooms in neighboring apartments.

We recommend: How to make a stepladder with your own hands

The check valve prevents the penetration of air masses and noise from adjacent rooms, which compares favorably with a conventional ventilation grille that is not equipped with additional protection. Installation of gratings can be done both from the side of the room and on the external wall of the building. The devices are connected to the end of the air duct, and the joints are additionally sealed.

Materials and colors

Galvanized ventilation grilles

Their main advantages:

- long service life - approximately 10 years;

- excellent strength;

- resistance to any serious impact.

Such gratings can begin to rust much earlier than their 10-year service life. One of the significant disadvantages of these ventilation elements is their complex installation and significant weight.

Aluminum grilles

They have many excellent characteristics:

- quite light, and in a certain sense durable, although more fragile than steel products;

- do not rust;

- are not afraid of temperature and humidity differences;

- resistant to various influences;

- look decent;

- easy to install;

- are inexpensive;

- have been used for decades.

The disadvantage is that aluminum cannot be combined with other metals, especially copper.

Wooden

These products are installed only in rooms with an optimal level of humidity. They are quite expensive. Without a special type of treatment, models quickly lose their decorative appeal. Most often, these devices can be found in saunas or baths. Wooden products are produced only for decorative purposes; they can be made from valuable types of wood, and the design on their surface is usually developed by a designer to order.

Plastic

Grilles made of high-quality plastic will not be afraid of high temperature fluctuations and moisture. Their prices are quite reasonable, which attracts buyers. They are produced in various types and parameters (from 15×15 cm to 30×30 cm). These grilles have a fine mesh that protects the ventilation from insects or dust. A significant disadvantage of this material is that the plastic may turn yellow, fade or become scratched over time.

Steel

They are quite heavy, but very durable. They are made to order and made using hand welding. To install such a grille on the hood, you will need to choose a serious mount for it.

Plaster

Such gratings are considered an excellent addition to classic interiors, especially if they have other plaster elements. Grilles made of other types of materials would not look very harmonious in such rooms, but plaster structures covering the ventilation holes will help you maintain the unity of the chosen style.

Devices made of brass, copper or bronze are elements of a luxurious interior. All kinds of monograms, stylish and elegant ornaments - all these are the original attributes of these products. They are produced for installation on floors and walls; they can also be found in window sills. Quite rarely, such models are used on the ceiling. The owners are offered a choice of a certain number of already created options, but many companies are ready to offer the production of such products to order or to recreate the design according to the sketch of the home owner himself.

By playing with color options, you can highlight the grille against the general background or make it invisible by matching it to the color of the main surface. Many experts advise choosing a product that matches the color of the building’s facades. But at the same time, you should not stop at the red colors of the product for a green or blue background, if there are no secondary details of the same color. Often, grilles that have contrasting colors can harmoniously modify and even significantly embellish the decor of a room, but they should be chosen so that they are in harmony with other decorative items. For example, a black or brown grille on a light floor or ceiling will be quite appropriate.

What is attic ventilation and why is it needed?

Air exchange in the under-roof space is important at any time of the year. In summer, ventilation helps to avoid overheating of the house from the roof covering, which is heated in the heat, especially if the latter is made of metal materials.

In winter, the heat and moisture emanating from the house contribute to the formation of frost and, as a result, dampness. Without intensive ventilation this problem cannot be avoided.

If, in addition to the lack of ventilation, the heat-insulating layer is not made well enough, in winter the roof can heat up to above-zero temperatures, leading to the melting of the lower layer of snow and the formation of an ice crust and icicles during the thaw period.

Without air exchange in the space under the roof, the microclimate throughout the house is disrupted: on sunny summer days, living spaces will quickly heat up, and from autumn to spring, condensation will accumulate under the cladding. Accordingly, without the release of steam, which is formed as a result of the life activities of the inhabitants of the house, the humidity will increase in the rooms.

But the main danger of the lack of air exchange is that the wooden elements of the roof will wear out much faster than their allotted time. Moisture accelerates the process of rotting, fungus and mold.

Therefore, it is impossible to do without ventilation of the under-roof space.

In addition, it is important that air exchange is efficient. What you need to consider when arranging ventilation in the attic:

- The area of the holes should correspond to the area of the attic. The ideal ratio is 1 to 500 (1 sq.m. of ventilation per 500 sq.m. of space).

- The entire internal space of the roof must be involved in air exchange. If the air stagnates in certain areas, condensation or frost will form.

- The ventilation system must have two channels: air enters through one, and goes out into the street through the other.

The most difficult stage of the work is the calculations. Too many or too many vents are just as bad as too few vents. This task is best left to specialists.

How to choose an installation location

When selecting an installation point, you should take into account the position of ventilation ducts, which can be integrated into load-bearing walls during the construction of apartment buildings.

Regardless of its location, the grate should not be filled with melt or rain water. Products made of plastic or wood should not be placed next to gas or electric stoves; the hot air flow will quickly destroy the material.

In room

Standard ventilation grilles are located at a height of 2 m or on the ceiling surface, ensuring the removal of heated air. The product should fit tightly to the plane, the resulting gaps should be covered with plaster or silicone sealant. An alternative is to use frame grilles that have extended slats.

Grate in the room under the ceiling.

Outside

The channels are brought out onto the surface of the walls, the inclined part of the roof or the gable. The grille should not become clogged with snow or flooded with rain, since water entering the air ducts causes fungal growth and the appearance of an unpleasant odor.

Basement ventilation windows must be located above the meltwater flood level (a similar requirement applies to grilles built into the entrance door).

Installing a ventilation grille outside the house.

How to grow onions in the cellar

Growing onions in the basement The price of green onions, especially in winter, is quite high. It is much more profitable when growing onions by forcing them

. The basement is a fairly acceptable room for these purposes. For these purposes, it is best to use racks that occupy a small space and allow you to grow a good harvest (read). Onions will grow well in soil or sand. The main thing that is necessary is to prepare high-quality planting material. To do this, the top of about 1 centimeter is cut off from the bulb and kept in warm water for several hours.

Growing green onions will be effective if certain conditions are met:

- Ensuring optimal air temperature. It should be from +18 to +22 degrees.

- . The lack of natural light should be compensated by artificial lighting. Good lighting is the key to quality feathers.

- Presence of wind. It is necessary to periodically turn on the fan in the basement, which improves air circulation.

Onions contain a lot of iron, which helps increase hemoglobin levels in the blood. Green onions have a beneficial effect on the cardiovascular system, lower blood cholesterol levels, and reduce the risk of vascular atherosclerosis. The presence of potassium helps improve the contraction rhythm of the heart muscle. Green onions are a natural antioxidant that help prevent cancer. Onions are a real storehouse of vitamins, and storing them in the cellar is not difficult. => How to store onions in the cellar until spring => => publish => open => closed => => kak-hranit-v-pogrebe-luk-157 => => => 2016-01-18 17:47: 06 => 2016-01-18 13:47:06 => => 0 =>?p=553 => 0 => post => => 2 => raw => index,follow) => 0 => - 1 => 334 => 334 => 0 => => => => => => => => => => => => => => => => => => 1 => = > => => => => => => => => 6129f5cdc20b4c1e94260eff05cd3b0b => => => => Array ( => query_vars_hash => query_vars_changed) => Array ( => init_query_flags => parse_tax_query))

Ventilation is one of the most important engineering systems necessary to ensure a comfortable climate in any type of premises. In household ventilation systems, the most common equipment is grilles. They are installed in the opening of the ventilation duct directly at the entrance of the air flow that has already washed the room.

Flow gratings

A separate type of ventilation grilles are ceiling models. They are used for both supply and exhaust ventilation, made from various materials (plastic, aluminum, steel). Unlike decorative wall models, ceiling grilles are most often equipped with diffusers. Diffuser models are used in a supply and exhaust ventilation system, connecting to air ducts of various sections (round, rectangular).

Equipping with a diffuser is necessary to ensure regulation of air masses in ventilation systems, as well as air conditioning systems. In this case, the installation of diffuser grilles is carried out using adapters for air ducts of a specific cross-section or using self-tapping screws. You can buy ceiling grilles from us by choosing the appropriate size (600x600, 800x800, 450x450, etc.) and type of fastening. You can obtain detailed information about this type of grating from our consultants.

Arrangement in a brick house

Most modern houses are equipped with combined supply and exhaust systems, as they are more efficient than conventional types. The exhaust ducts are fixed in the main walls with a minimum thickness of 38 cm. One room can have from 1 to 3 such ducts, and when choosing a suitable model, the architectural design of the building is taken into account.

When installing a hood in a private brick house, you need to adhere to the following recommendations:

- The optimal parameters of the ventilation channel are 13 x 13 cm. It is better to build such a space during the laying of the wall structure.

- The inlet from the room to the channel is located under the ceiling.

- To bring the hood to the roof, it is necessary to arrange a pipe with a height of at least 50 cm above the ridge. If this rule is not followed, cravings may worsen.

- The optimal thickness of the channel walls is 2.5 bricks. If they are thinner, the air duct system will cool down, which will prevent the natural discharge of exhaust air to the outside, but will lead to cold masses being drawn in from the street.

When performing installation work in a brick house, you can additionally buy a wall fan and secure it at the base of the air duct. Bearing-type models are characterized by maximum strength, but during operation they create a lot of noise. Bushing devices operate almost silently, but their cost is much higher.

It is quite difficult to install ventilation in a private house or apartment. But if you follow simple rules, this problem becomes solvable.

Ventilation grilles "Ventar-S": main and secondary functions

Ventilation grilles are an important part of the ventilation system, used for the full maintenance of residential and industrial buildings. These devices are installed in ventilation ducts or on the outside of air ducts.

Most often, decorative ventilation grilles are perceived by potential buyers as an appropriate element of the interior, allowing them to harmoniously complement the overall design of the premises and hide the exit of the ventilation duct.

The main function of ventilation grilles is air distribution in the air duct network. It is this simple but very necessary device that can ensure uniform circulation - removal and supply of air masses in a particular room. The hood also helps get rid of foreign odors, polluted air, smoke and fumes.

Thus, the ventilation grille performs a function similar to the general ventilation system, protecting the channel entrance from the penetration of foreign air impurities, insects, and rodents. You can buy a ventilation grille that meets all the necessary requirements on the Ventar-S website.

Purpose and role

In fact, the ventilation system is one of the most important engineering structures of any house, regardless of whether it is private or multi-apartment. It is ventilation that is responsible for proper air exchange, as well as for comfortable climatic conditions in each individual apartment or room. The system has its own ventilation ducts, at the inlet and outlet of which a grille is mounted.

It performs several functions at once, namely:

- protects the mines from possible clogging, as objects and animals may accidentally fall into them;

- correctly distributes air flows, especially for supply-type ventilation grilles;

How to install the ventilation grill correctly will depend on the material from which it is made. But, as a rule, all work options can be completed independently, without the help of specialists.

Shapes and sizes

Modern ventilation grilles have different, sometimes unimaginable, shapes, which is very convenient for those who need to choose a product for a specific type of interior design.

In stores you will be offered a huge assortment of gratings with various shapes, including:

- polygonal (there are even six- and octagonal);

- oval;

- square and diamond-shaped;

- rectangular;

- round.

Ventilation grilles in the form of a square and rectangle are more in demand, as they allow rational use of wall space. A vortex flow will be created inside them, which will disrupt the movement of air that is not clean.

You can easily purchase products with dimensions of 15x15 cm, 24x24 cm, 37.5x37.5 and more.

There are recommended size restrictions, depending on the type of louver grille:

- standard external grilles – 150x300 cm;

- reinforced external grilles – 250x300 cm;

- reinforced grilles with hollow slats – 300x300 cm.

Video about methods for ventilating gable walls

The following video will introduce you to the attic ventilation device by installing a grille:

Video instructions will help those who want to install a ventilation valve with their own hands:

A demonstration of the installation process of a technically complex ventilation device will help you understand the essence of the work:

The installation of ventilation for the gable wall is an event that leaves no doubt about its significance and necessity. To organize it, it is enough to use the methods we have proposed. They should be used in combination so that both the gable and the attic remain in impeccable condition.

Source

How to choose?

In order for the grille to serve you as long as possible, you need to choose it correctly. For this reason, it is extremely important either when designing a structure or when directly choosing the element itself to pay attention to certain points.

- It is worth thinking carefully about where the grille will be placed. You need to choose a product in such a way that its design looks most harmonious in the design of the room or facade.

- Before purchasing a grille, it is necessary to decide exactly what design, shape, type, and color you need. Consider whether you will need an adjustable or non-adjustable grille. Much of your choice will depend on where you want to place the product.

- Pay attention to the live section coefficient. It is responsible for good ventilation of all rooms of the house.

- The size of the product also plays an important role. The hole in which the grille will be installed must completely match its dimensions.

- It is also worth remembering that in some cases or if installed incorrectly, these products can become a significant obstacle to the flow of clean air. For this reason, you need to select devices as carefully as possible. If you have any doubts, it is best to consult a specialist.

Standard distances

Air ducts are attached to different surfaces:

- ceiling slab

- ceiling trusses or load-bearing elements attached to them

- walls

- floor

When installing the system, the following standards must be observed:

- the distance from round air ducts to the ceiling must be at least 0.1 m, and to walls or other elements - at least 0.05 m

- the distance between round air ducts and communications (water supply, ventilation, gas lines), as well as between two round air ducts should not be less than 0.25 m

- from the surface of the air duct (round or rectangular) to the electrical wires there must be at least 0.3 m

- the distance from the surface of rectangular air ducts to the ceiling must be at least 0.1 m (for air ducts with a width of up to 0.4 m), at least 0.2 m (for ducts with a width of 0.4-0.8 m) and at least 0 .4 m (for air ducts 0.8-1.5 m wide)

- all channel connections are made no closer than 1 m from the point of passage through the walls, ceiling or other structural elements of the building

The axes of the air channels must be positioned parallel to the planes of the ceiling slabs or walls. Exceptions occur when ducts transition from one level to another or in the presence of equipment, protruding elements of the building structure, which do not allow the installation of air ducts parallel to the plane of the building structure.

In addition, it is allowed to install pipelines at a slope of 0.01-0.015 towards drainage devices if the transported medium is prone to condensation.

Methods for installing ventilation grilles

Before carrying out finishing work, you should read the factory instructions and find out how to properly install the ventilation grille. The product is fixed using screws, spring strips or magnets. At home, you can use glue or decorative strips made of plastic, wood or metal.

Using screws and self-tapping screws

For installation you need:

- Separate the front part from the frame and mark the attachment points with a pencil, using the frame as a template. It is recommended to correct the position using a hydraulic or laser level.

- Drill holes with a hammer drill or drill, and then install guide plastic dowels.

- Place the frame and screw in the screws without applying excessive force. The frame should fit evenly against the wall; cracks indicate poor quality of finishing work or dowels coming out of the holes (a defect occurs when drilling partitions made of soft materials).

- Install the insect protection net and insert the façade part into the guides (until the latches engage).

Installing the grille using screws.

On glue

When using glue, it is necessary to separate the frame and mark the installation location. Then an adhesive mass (for example, “liquid nails”) should be applied to the inside of the frame. Place the frame against the wall, adjust the position with a level and hold for several minutes to allow the glue to polymerize.

The material squeezed out from the joint line should be removed with a dry cloth or rag. After the adhesive mass has hardened (depending on the brand and manufacturer), the facade part is installed. The technology is suitable for walls with a durable finish coating (for example, tiles).

Fastening with glue.

Fastening with plinth

The technique is used to fix wooden gratings that do not have a guide frame. The frame is cut out of the plinth in accordance with the dimensions of the existing product, and then attached to the wall with screws or glue.

It is difficult to make a neat frame with your own hands, so many craftsmen use flat wooden, metal or plastic strips. To cut at an angle, you will need a carpenter's miter box and skill in working with the tool.

On springs

On some rectangular-shaped gratings, spring clamps located on opposite faces can be used. The products are designed for installation in a ventilation socket.

For installation, simply squeeze the plates with your fingers, insert the frame into the channel, and then release the springs. Using a similar method, it is recommended to fasten gratings up to 300 x 300 mm in size; products with increased dimensions should be fixed with screws.

Installation of the grille on springs.

The most common grating options

The most common type is a plastic supply and exhaust grille. It is intended for wall or ceiling installation, promotes high-quality air distribution throughout the room and is used for decorative purposes.

This grille includes additional elements - latches for the removable inner part. Mounted with screws. Some models have inclined slats.

Supply and exhaust

You can also find plastic exhaust models. Serve for outdoor installation and decoration of the exhaust vent outside the house. Such models are mounted using screws and include blinds that serve to prevent reverse draft.

Often a combined type of grille is used, designed to connect the hood in the kitchen and for general ventilation of the apartment. The material used is durable plastic. The design includes a deviator that prevents backdraft through the bottom. Installation is carried out using screws. Cleaning channels with such a grille is not difficult, since its lower part is removable.

Door grilles are mounted at the bottom of the door and allow free movement of air between rooms. The material used is durable plastic. To protect against insects, a mesh is used, which is mounted with screws.

Door grill