Gabions are supporting and decorative structures made of durable metal mesh filled with stones. Gabions have evolved from military fortifications into landscaping structures. Since the 16th century, such products have been used to build defensive fortifications for guns and trenches. In the 19th century, builders became interested in gabions - they used them to strengthen steep slopes and areas with unstable soil, erect supports for bridges and dams, and strengthen river beds. Modern landscape designers use gabions to build fences, terraces and create small architectural forms.

Interesting! Properly made gabions are as strong as a concrete slab! The main thing is to choose the right materials.

Concept and history of gabions

A gabion is a welded or woven cage of metal wire filled with rocks, concrete, wood or other hard material . 7,000 years ago, similar structures were used by the ancient Egyptians to strengthen the banks of the Nile. The word gabbione itself came to us from Italy and is translated as “big cell”.

Interesting: during the construction of the Milan Church of St. Mark, Leonardo da Vinci developed wicker gabions and named them in his honor - “Leonardo's Baskets”.

Gabion fence

In the Middle Ages, gabions were made from wicker and stones for the construction of military forts. Later they were laid in the foundations of houses. Today, “cages with stones” are used to strengthen banks, roads, combat erosion of slopes, terracing areas, decorating landscapes and interiors .

Filling options

The filler can be almost any material, which opens up wide possibilities for the implementation of design ideas. Therefore, you should proceed from your tastes, financial capabilities and location of the structure (underwater or on land).

Usually natural or artificial stones of various shapes, types and sizes are used. But, as a rule, fairly large stones are used. The color also depends on your tastes.

Non-traditional materials can also be used as filler, for example:

- broken tiles;

- pieces of PPR pipes;

- tin and aluminum cans;

- glass bottles;

- tree bark;

- brick, including broken brick;

- tree;

- pieces of tires from vehicles;

- big shots, etc.

Advantages and disadvantages

Gabions have much more advantages than disadvantages:

- Durability: resistant to corrosion and destruction, can last 30-40 years.

Important: over the years, the strength of the gabion is strengthened by plants that fill the voids between the stones.

- Strength: form strong structures that are ready to withstand flooding, heavy rainfall, ice and earth pressure.

- Drainage properties: water easily passes through rows of stones without stagnating.

- Cooling properties: effective in hot climates as shade screens, allowing air to pass through and providing ventilation.

- Simplicity and speed of installation: professional installation of gabions does not take much time and effort.

- Cost-effective: less expensive materials and installation.

- Aesthetics: look natural and fit well into the environment.

- Eco-friendly: The mesh can accommodate recycled materials, and the spaces between the stones allow plants to thrive.

Important : the construction of gabions does not harm the surrounding landscape.

Zoning a site using a gabion wall

Minuses:

- Bulky design. In a small area it looks unaesthetic and eats up space.

- Standard forms. Most gabions are rectangular, and obtaining other shapes will require effort and financial investment.

- Animal house. Undesirable living creatures, such as snakes, rodents or insects, can live in the spaces between stones or other fillers.

Important : the height of the gabion structure should not exceed 12 m, otherwise there is a high risk of its collapse.

Design and production features

Gabions consist of a mesh reservoir (cage, basket) and filler. Depending on the manufacturing method, the cells can be welded or woven, which affects the choice of material and the shape of the cells

| Basket type | Material | Cell shape | Cell diameter | GOST | Properties |

| Wicker | Double twisted steel wire | Hexagonal | 2.2-4 mm | Eat | Plastic, well tolerates loads on uneven areas |

| Welded | Steel rods or wire fragments | Quadrangular | 4-5 mm | No | Rigid, holds its shape well in complex geometric structures, but does not tolerate high loads on slopes |

Important : when purchasing ready-made gabions, be sure to make sure that they comply with the GOST R 51285-99 standard. GOST is not yet provided for welded gabions in Russia.

Welded gabion baskets

There are two ways to make a gabion tank: industrial and manual. In the first case:

- the mesh fabric is woven or welded on the machine,

- it is divided into equal segments,

- an edge wire is woven into them - a stiffener,

- diaphragms-partitions are attached,

- the finished mesh is folded and pressed into bundles.

Advantages of industrial production:

- special equipment simplifies the process and guarantees product quality,

- products undergo certification and GOST control.

Self-installation of gabion

When making a tank yourself, the mesh is woven or welded by hand, using a board with nails driven in evenly. A reservoir is formed from the finished fabric using side cutters and knitting wire. The main disadvantage of homemade meshes is the lack of stiffening ribs, which makes them shapeless and violates the dimensions of the structure .

Tip: the easiest way is to buy a welded gabion mesh and cut it with a grinder into panels of the required size, then use galvanized mounting or binding wire to tighten them together.

Properties

The characteristics of the gabion are influenced not only by the diameter of the metal mesh and the frequency of the rods, but also by the way the wires are connected to each other. Thus, the chain-link mesh cannot provide a strong connection, because the wire in it is not fastened, but only intertwined, and the rods will slide off under the influence of even a small load. To prevent this, during manufacturing they use the technology of double torsion of rods for their high resistance to loads of various types - rupture, compression, torsion. The result is a very strong and reliable reinforced structure that is capable of transmitting moisture.

Materials

Net

It is woven or welded from steel wire (less commonly rods). According to GOST R 52132-2003 and GOST R 51285-99, the wire density should be 250-280 g/m², the cross-sectional diameter should be 2.2-4 mm, and the surface must be galvanized . This ensures corrosion resistance and long service life of the entire structure. Additional PVC coating allows the use of gabions in aggressive environments.

Important: the thickness of the main wire determines the diameter of the knitting wire required for assembling and fastening the parts of the gabion (on average 2-2.4 mm).

Wicker mesh for gabions

Another option is European galfan-coated wire with a characteristic shine. It contains an alloy of aluminum, zinc and rare earth metals. The product is ready to serve up to 75 years, which explains its high cost compared to domestic products.

Important: double-twisted wires hold loads better and preserve the frame of the structure if it is partially destroyed.

Fillers

- Stone

This is the most common and reliable material for gabions, which should be:

- hard,

- dense,

- heavy,

- resistant to temperature changes,

- with low water permeability (no more than 0.6%).

Important : choose stones 2-3 times larger than the size of the mesh cells. For structures placed under water, the filler size should be 50% larger than the cell, and for land-based products - 30%.

Different types of stones for gabion

Both natural and artificial stones are suitable. Their shape and appearance depends on the objectives of the project. If you need to mask gaps between stones, use fine gravel, pebbles or crushed stone.

Stones for gabions:

| Most popular | Less frequently used |

| granite, basalt, limestone (hard and soft), sandstone, marble | tuff, quartzite, diorite, labrodarite, slate, gems |

What is gabion mesh filled with?

The first, “soldier’s” containers were filled with earth, grass and driftwood, with everything that came to hand.

The most popular, however, are gabions with stone “insides”. By the way, these have been made since ancient times not only in Europe, but also in Japan. Suitable fragments of granite, sandstone, dolomite, marble, gypsum spar, quartzite, limestone, gneiss, basalt, crushed stone, river pebbles... An ordinary cage filled with stones will suit any architecture, any style of landscape art.

But it’s not a sin to deviate from the classics. Let's say, add artificial ones that glow in the dark to natural minerals - can you imagine how enchanting this structure looks with luminescence?

Quite often, different types of stone are also combined to create, for example, a color gradation: a dark base and a light, “airy” top. Or lay out a pattern - with stones of one shade against the background of stones of another, contrasting one.

It turns out beautifully when, for example, black labradorite is alternated with light, silvery quartzite, rich red or green granite, forming stripes or waves.

It also happens that pieces of glass are interspersed into gabions and LED lighting is attached inside. These luminous boxes look like frozen, petrified flames.

Do you like naturalness and ease? – Then we recommend not filling the containers to the very top, but leaving them half empty: over time, grass will grow in the gaps between the stones, and you will get half-grass gabions.

In addition to stones, mesh containers are filled with saw cuts, logs, fragments of brick or tiles, bark or glass bottles... Anything that fits into the style and design.

Types of gabions

Depending on the purpose, shape and properties, there are three main types of gabions:

Box-shaped

Made in the shape of a parallelepiped of different sizes. Most often, their length is up to 4 m, height – 0.5-1 m, and width – 1 m. If the box is longer than 2 m, then a membrane partition is provided inside it every meter. It increases the resistance of the box to fill pressure. Such gabions are used as retaining walls, for laying foundations, strengthening banks, roads, and decorating flower beds and fences.

Box gabion diagram

Mattress

The shape resembles mattresses with a width of 2 m, a length of 3-6 m and a height of 17-30 cm. For strength, as in box-shaped ones, partitions are made in them every meter of length .

Interesting: their second name is “Reno mattresses”, since they were first used to strengthen the banks of the river of the same name in Bologna (Italy).

Calculation of partitions:

| Mattress size (m) | Number of partitions | Partition size (m) |

| 3x2x0.17 | 2 | 2x0.17 |

| 4x2x0.23 | 3 | 2x0.23 |

| 5x2x0.3 | 4 | 2x0.3 |

Mattress gabion diagram

Important : “Reno mattresses” make a good foundation for box-shaped gabions, allowing you to evenly distribute the load and increase the stability of the structure.

Due to their low height, the “mattresses” follow the shape of the landscape well and are often used to strengthen ravines, banks, canal bottoms, and terracing areas. Compared to box structures, mattresses are easier to install and require less filling .

Advice: “mattresses” 3m long are lighter in weight and more convenient to install.

Cylindrical

The name matches their shape. The filling resembles a candy bar, and the wire frame, pinched on the sides, resembles its wrapper. The standard length of the structure is 2-4 m, and the diameter is 65-95 cm. The absence of reinforcing partitions gives them special plasticity: they can be laid on an uneven surface . In landscape design, they are used to decorate areas with complex terrain.

Scheme of a cylindrical gabion

Important : in addition to the types mentioned, gabions can be used to obtain a variety of shapes depending on design tasks.

Do-it-yourself gabions: step-by-step construction instructions and its features

To make your work easier, you can purchase ready-made designs. Modern stores offer a wide range of products for forming gabions. But finished frame parts do not always correspond to the required dimensions. In some cases, it is easier to create a gabion yourself. The first stage of construction involves designing the future composition and calculating the required amount of materials. If you want to make the structure yourself, you can use photos of gabions for inspiration and create a design for your own unique project.

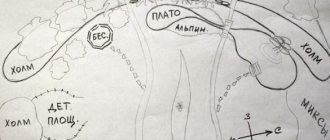

Design is carried out according to the following scheme:

- Taking measurements from the territory.

- Marking.

- Transferring the markings to paper (structure layout plan).

- Drawing up drawings for each object.

- Selection of fillers and materials.

- Calculation of the required amount of materials.

- staples designed to connect adjacent walls, or spiral-shaped wire;

- geotextiles;

- pins made of steel (used to fix products in the soil);

- braces made of steel (designed to tie walls with the opposite type of placement in relation to each other).

Step-by-step diagram for assembling a gabion and filling it with stones

To achieve high strength, it is recommended to purchase mesh with double torsion. It has a flexible structure, is easy to store and transport, durable and resistant to the negative effects of external factors.

Necessary materials for construction

Before you make a gabion with your own hands, you should ensure that you have the necessary tools, basic and consumable materials.

You can use leftover building materials to fill the gabion.

Consumables include:

To protect your actions and reduce work time, you need to use additional tools.

Scheme of construction of a gabion with a concrete foundation

The list of related tools includes:

- mount;

- pliers;

- plumb line;

- shovel;

- hammer;

- gloves for hand protection made of high-density material.

Designers often give the natural landscape of an area interesting and unique relief forms. This type of structure is so strong that it can be used to form hills and depressions.

On top of the landscape, you can create flower beds with your own hands from gabions, as well as waterfalls, artificial ponds, fountains, etc.

Gabion flowerbeds fit perfectly into landscape design

Selection of material for the walls of conventional and welded gabions

Metal mesh is used in cases where the gabion project is based on the use of Reno mattresses. Most often, the need to use such products arises when there is an intention to build an object with a complex configuration on the site. In this case, Reno mattresses are located along the bend lines. They can be installed in an arc or placed on separate sections of the structure where rotation or bending of the frame is necessary. This type of material is used to decorate flower beds or fountains.

For the construction of gabions, it is necessary to choose a mesh with a thickness of at least 2.7 mm

For the manufacture of gabions, it is not recommended to use material whose thickness is less than 2.7 mm. The table shows prices for products made of galvanized steel with a thickness of 3 mm.

Average price of mesh for gabions:

| Name | Price | Unit |

| Twisted mesh with hexagonal cells 8.0*10, (2m*50m) | from 130 | RUR/piece |

| Gabion 1.5*1*0.5 Zn (zinc) | from 1 300 | RUR/piece |

| Gabion 1.5*0.5*0.5 Zn (zinc) | from 1 090 | RUR/piece |

| Gabion 2*1*1 Zn (zinc) | from 2 530 | RUR/piece |

| Stone for gabions (rubble stone) | from 2 550 | RUR/ton |

| Mattress structures 3*2*0.17 | from 3 100 | PC. |

| Mattress structures 3*2*0.23 | from 3 500 | PC. |

Selecting a material for creating a gabion from welded mesh

In welded-type structures, the mesh is created from thick rods. These elements are laid perpendicular to each other, and the places where they intersect are connected by welding.

The cross-section of the rods is selected based on the purpose for which the object is being created. In most cases, it is recommended to choose a material with a large thickness. However, it should not exceed 0.8 cm.

The gabion frame can be assembled using wire or welding

Installation of such structures is carried out in those areas where Reno mattresses will be subject to significant weight loads. They are very convenient for filling with samples from large fractions.

The following are created from welded elements:

- grounds;

- supporting elements;

- supports.

Gabion fence constructed using double twist mesh

They are much stronger than reinforcing elements, but their installation is accompanied by certain inconveniences. The walls of the gabions, made of double-torsion mesh, are connected to each other using wire. But in the case of a welded frame, this method will be less reliable and more time-consuming. It is better to use a welding machine to connect all the elements of such a structure.

To obtain a more durable structure, it is better to use a welded frame

Choice of filler: stones for gabions

Almost any material can be used as a filler. When choosing a filling you should be guided by:

- own preferences;

- budgetary possibilities;

- type of location of the object (underwater or surface).

Designers mainly use stones of natural or artificial origin. They can be rounded or crushed, but must be large in size. The colors can be very diverse. The shade depends on the type of stone and its composition.

Various vintage items were used to fill the decorative gabion.

In most cases, gabions are filled:

- diorite;

- granite;

- quartzite;

- basalt;

- pebbles.

Sandstone is considered an equally popular filler. It is highly durable and resistant to low temperatures.

Gabion can be filled with granite, basalt, quartzite, sandstone and other types of stones

It is possible to manufacture structures with less standard filling in the form of:

- broken tiles;

- solid or broken bricks;

- cut propylene pipes;

- wood cuts with different patterns of growth rings;

- aluminum cans;

- car tires, cut into pieces;

- glass bottles;

- big cones;

- pieces of tree bark, etc.

Glass bottles were used to fill the box-shaped gabion

Technology for creating a fence from gabions with your own hands

A gabion fence takes up much more space than a regular fence. But there is no need to create a basement base, because the installation of the fence is carried out directly on the ground.

Steps 1-3: preparing holes, installing supports and filling them with concrete

Step-by-step instructions for implementation:

Steps 4-6: strengthening the frame and filling it with stones

To form the frame, cut six pieces from a roll of mesh of the appropriate length. One of them will be at the bottom, the others will become the front and back walls of the fence, the lid and the side parts. After laying the bottom, the side walls are attached, which are fixed with spiral wire. They are then secured in the soil with metal pins.

The lid is mounted and secured only after the containers have been filled and the filler has settled. You can use a metal profile to strengthen the corner parts of the frame.

Features of filling structures with stones

The stage of filling the mesh frame is specific. Certain rules should be followed when working with stones or other types of filling for gabions.

Do-it-yourself filling of the gabion frame with stones

Rules for filling out structures:

Step-by-step technology for filling gabions with filler

Application

In construction

Initially, gabions were intended for construction, where they are still used to create:

- retaining structures (walls, cladding and supporting embankments and cuttings),

- strengthening slopes (near highways, bridges, ravines),

- protection of banks from floods and floods (dams, fencing of river banks, canals, dams),

- building foundations,

- noise barrier,

- cooling systems in hot climates.

Retaining walls on a highway slope

In landscape design

In landscape design, gabions are indispensable assistants, performing several functions at once. From them you can get:

- framing paths, flower beds and beds,

- retaining walls to strengthen garden buildings,

- base for lawns and rockeries,

- partitions, arches and other garden design elements,

- decorative figures,

- material for landscape stairs,

- outdoor furniture,

- fence foundation,

- flower pots,

- framing a pond, barbecue area, summer shower, patio, etc.

The use of gabions in landscape design

In the interior

Gabions work no less effectively in the interior decoration of houses and apartments. With such brutal decor, the interior takes on a unique character. With the help of different fillers, lighting and coloring, gabions can fit into almost any style . Here are just a few ideas:

- wall in the living room,

- decorative partition,

- Column,

- arch,

- fireplace trim,

- furniture detail,

- accessories (pots, figures), etc.

Bar counter made of gabions in the interior

Tip: an insert of colored glass and LED strip inside the structure will give a unique play of light.

Basic types of gabion products

There are, in fact, three main varieties: gabions are box-shaped, cylindrical and mattress-mattress (in other words, Reno mattresses).

The first, in the form of parallelepipeds, are to strengthen steep banks, slopes, walls, and make high fences from them.

The latter are presented in the form of cylindrical baskets, more suitable for creating decorative accessories - columns, columns and the like.

Third, they line flat areas and fix the bottoms of reservoirs.

These are the basic types of gabions, but of course there are more variations: cubic, spherical, conical...

Gabions can be of almost any shape, with any filling, which makes these structures especially attractive in the eyes of landscape design specialists.

Installation

Although installing gabions does not require complex machinery and equipment, knowledge of the nuances is indispensable. Here's a quick step-by-step guide:

1. clear the laying area of debris, stones, roots and plants,

2. level the soil,

3. dig and compact a trench along the width of the future structure,

4. lay geotextiles on the bottom of the gabion cage and sprinkle with gravel,

Important : if the purchased mesh is not assembled, then reinforcement must be driven into the corners of the structure in order to dig it into the ground.

Laying box gabions

5. assemble the walls of the gabion into a box, connecting first the corners and then the edges with wire and staples,

6. place the finished box in a trench,

7. after it shrinks, slowly and evenly fill in the filler,

Tip: fill the gabion a few centimeters above the side walls, as the stones will sag a little.

8. Having loaded the box to a third, its walls need to be tightened using special hooks,

9. Finally, install the box cover, first fixing it at the corners, and then tying it around the perimeter and at the same time leveling the filler,

10. Rinse the finished structure with water from a hose.

Gabion structure with hidden lighting

Tip: Gabions can be decorated with vines, flower pots, water features, wood panels or paint.

Important: Large tanks for retaining walls or high fences are mounted on stabilizing posts, which are first concreted.

Which stone to choose?

Do you want to see gabions in your garden? We will tell you how to make them yourself, but first we will decide on the source materials. The design consists of 2 components: a box and a filler - stone.

Firstly, the stone must be larger than the cells - otherwise it will simply fall out. Secondly, remain solid, reliable for many years. For example, talc or gypsum will simply collapse after a few rains.

Suitable stone options for decoration:

- pebbles;

- granite;

- crushed stone;

- sandstone;

- basalt.

Choose the shade of gabion filling according to your taste: you can use plain stones, mix them, lay them in layers.

Decorative gabions can be filled not only with stones: brick chips, terracotta flowerpots, pieces of tiles, and artificial materials are suitable. There are even wooden gabions filled with individual branches or slabs.

Tips from the experts

- When planning the height of a gabion structure, consider the building restrictions in your area (fencing requirements, permissible height).

- Always think in advance about utilities for water features and lighting in gabions.

- For fillers with a fine fraction, use geotextiles so that the “fines” do not spill through large stones.

- To save money, place coarse filler along the outer walls, and place trash or remaining small items in the central part.

- The ends of the wire can be spliced by twisting or extension no longer than 20 mm, and the number of twists is no more than 1 piece. for 20m².

- For a tall structure, provide reliable lateral support. A structure that greatly exceeds its width looks unaesthetic.

- If you are planning a tall gabion fence or a complex, multi-sectional structure, it is better to consult a specialist to install the correct supports.

Gabions for home, cottage/garden

Landscape gabion structures will be an excellent design element for any garden or local area. In addition, these structures can perform not only design, but also functional tasks. For example, they can strengthen slopes and unstable soils. Flowerbed designs are also popular when stones are laid along the outer contour of a metal mesh, and soil is poured inside, into which plants or trees are planted.

One of the main areas of application is landscape design. These structures not only decorate the area, but also perform a practical function - they strengthen the soil, so they are actively used to create flower beds, arches, columns, and benches. Lianas or other climbing plants are often allowed to grow along the metal trellis, creating an even more impressive look. The price of landscape gabions depends on the filler material used, but, as a rule, it is affordable.

Gabion is such a versatile material that you can even build houses from it using these structures as walls. In addition, they are used in the design of the local area. This material can perform decorative functions, or have a practical purpose. For example, benches, cabinets, tables are made from it - these elements can be installed in the courtyard of the house.