You cannot do without a staircase in a house with more than one floor. At the same time, it must be durable, functional, and, of course, attractive. A wooden staircase is appropriate in any interior style, although, of course, it should resonate with the overall interior idea. Wood, as a material, brings an atmosphere of comfort and sophistication to the environment, and also has characteristics that are most suitable for residential premises.

An alternative solution for a residential building, administrative or industrial premises is concrete staircases, which, after installation, are lined with various materials, including wooden steps and balusters.

Wooden stairs are environmentally friendly and allow you to realize an endless number of variations. To preserve the structure and impart the desired properties, the wood is subjected to special treatment.

The design of stairs is now carried out using special computer programs that allow you to see the future product “in all its glory” in three-dimensional form even before construction.

Design and shape options

A step is the main component of a flight of stairs. According to experts, the minimum permissible number of steps in a staircase is 3, and the maximum is 18. There are three main criteria that determine the type of steps.

By location:

- Frieze - there are upper and lower ones. The first one ends the climb at the upper level, and the second one starts it at the lower level.

- The rank and file are all the other steps that form the march.

By geometry:

- Straight - ordinary elements that have equal depth along the entire length of the tread. The predominant number of flight stairs consists of them, especially for direct ascents.

- Winders are elements used in modeling turning marches. They are used in screw structures and have unequal tread depths: narrower at the inner edge and wider on the opposite side.

Types of steps

Depending on the presence or absence of risers, stairs are:

- Open - have steps in which there is only a horizontal part or tread. The distance between structural elements remains empty.

- Closed - have steps with risers.

In addition, the elements of a flight of stairs differ from each other in shape:

- Direct. They look like a rectangle. This type is not recommended for screw structures. You can attach such elements in any way.

- Round ones are characterized by radial edges. They are often used to decorate a porch on the street and as the lowest step when climbing.

- Semicircular steps are also used when entering a house from the street. They have a semicircle on one side and a straight line on the other.

- Trapezoid-shaped elements form the design of spiral staircases and rotary staircase models.

Steps are made from different materials: wood, concrete, metal, glass, brick, veneered plywood. According to experts, it is easiest to work with wood: the blanks are easy to make and the tools for making them are quite easy to use.

Finishing and design of staircases

Various finishing options for stair steps can be used here. In the case when you work with wood, you should take care of patterns, drawings and engraving.

If porcelain stoneware is used, interesting design solutions can be found here. You can simply select some steps that will match the color of the baseboard.

Types of wood for steps

Reliability, aesthetic appearance and durability of elements directly depend on the characteristics of the material. The following requirements apply to the tree:

- Structural uniformity of wood fibers. High-quality workpieces are free of cracks, delaminations, knots and other defects.

Unacceptable defects in raw materials

- Integrity. Before buying wood, you should pay attention to ensure that there is no rot or traces of wood-boring beetles on the workpieces.

- Humidity is within normal limits. This figure should not exceed 12%. Otherwise, the boards should be thoroughly dried before use, avoiding direct sunlight.

It is recommended to make elements that will be subject to constant load from solid wood. If this is not possible, then it is permissible to use laminated veneer lumber.

Different types of wood are suitable for making steps with your own hands. But the most popular are:

- Pine. This is an inexpensive and easy to process material. It is characterized by a low degree of hardness, therefore, when working with it, you can use the most common tools. In addition, pine is always available: it is not particularly difficult to find lumber of the desired size and shape. The disadvantage of pine products is considered to be low wear resistance and the appearance of yellowness on the tree a few years after installation.

- Birch. It is distinguished by its durability and special textured pattern. Unlike pine, it is more difficult to process, but birch parts will last much longer. When using birch in construction, the selection of blanks is especially difficult. It is almost impossible to find large boards of uniform color and without defects. Therefore, experts recommend covering the composite structure with veneer.

- Larch. Steps made from this type of wood do not deform, do not shrink, or rot due to the high content of tannins. The main disadvantage is the high price.

- Beech. It is considered a more suitable material for stairs inside the house. The appearance of the blanks is beautiful color and texture. The main disadvantage of wood is its instability to temperature fluctuations and humidity. Even beech blanks soaked in varnish will change shape under the influence of natural factors.

- Ash. It has a high degree of hardness and is therefore ideal for the production of steps. However, due to the complex processing and bright texture, the material is not to everyone’s taste.

- Oak. Wooden steps for stairs made of solid oak are the best choice. Such steps will last for decades. The only disadvantage of this material is its high cost.

Step fastening methods

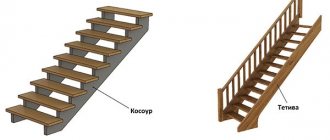

- Bowstring. These are boards that hide the end parts of the steps and serve as the basis for their fastening. The string can be attached to the ceiling and floor, and sometimes to the wall if the staircase is in the corner of the house.

- Stringers. In this type of bowstring, gear-type structures are used, and the steps are located using nails.

- Log steps. These stairs have a slightly rough appearance, but look stylish in a wooden frame. The strength of such a structure can be given by special nails.

Calculation of stair steps

Having decided on the material of the workpieces, it is necessary to begin making calculations.

Geometric parameters of steps

Dimensions of steps

When manufacturing steps, standard dimensions are used:

- The height of the step is equal to the length of the riser and varies from 150 to 220 mm.

- The depth of the element is the segment from the outer edge of the tread to the riser. It should be such that the foot is completely on the tread. The minimum depth is 25 cm, the maximum is 40 cm.

It should be noted that the depth of the step may not be the same along the entire length of the tread. This is observed in spiral and rotary models. It is larger on the outer edge than on the inside. The depth of the tread remains unchanged only in the center of the step. However, this disadvantage can be dealt with in two ways: using protruding steps or eliminating risers.

- The width of the step is the distance between the edges of the tread. This indicator depends on the intensity of traffic. The standard value is from 900 to 1000 mm. If the traffic is busy, then the flight of stairs can be increased to 1.5 m.

- The thickness of the tread is in a ratio of 1:20 to the width of the step. So, with a width of 900 mm, the tread thickness will be 45 mm. It should be remembered that the minimum permissible tread thickness is 35 mm.

- The thickness of the riser varies from 1.8 to 2.5 cm.

Based on the data obtained, the angle of inclination of the structure and the number of steps are calculated.

Optimal slope of the stairs

The most convenient inclination of a staircase structure is recognized to be a slope from 23 to 37 degrees. The usable area occupied depends on the steepness of the structure. Naturally, steeper structures require significantly less space than flat ones.

Selecting a slope for a structure

Stairs with a slope of 45 degrees are quite difficult to climb, and with a slope of less than 23 degrees they can be replaced with a ramp.

Calculation of the number of steps in a march

To get the exact number of steps in the staircase, you need to divide the height of the floor by the height of one step. The number of marches does not matter at all. It should also be noted that the floor height refers to the distance from the floor covering to the floor on the second floor, taking into account the thickness of the covering.

Knowing the staircase structure and the height of the upper floor, the number of steps can also be determined using a graphical method. Then, using safety formulas, find the width of the tread.

The dimensions of the steps must be taken based on the safety formula

Having decided on the scale, a flight of stairs is drawn on graph paper. Errors that appeared as a result of rounding are distributed to the frieze stage of the lower tier. All remaining steps are made the same size.

Calculation of riser height

Characteristic design features of the steps

The appearance of the steps, no matter what material they are made of, also depends on the design of the outer edges of the treads. Thus, the edges of wooden treads are rounded or sheathed with rollers or paneled slats, and their joints with risers are covered with figured overhead belts. On the inside, the junction of the tread with the riser can be sealed with wooden triangular slats with glue for greater strength of the connection.

The outer edges of the metal treads are slightly beveled; the same is done when monolithing concrete steps, and the sharp edges of natural stone treads are ground to a radius of 3-5 mm. However, you should not get carried away with excessive “smoothing” of the outer edges of the treads - this can lead to a deterioration in the performance of the steps: if you do not rest on the step with your entire foot (and this happens quite often and especially on narrow or too wide steps, forcing a person to change the usual step width), the foot may slip off.

If the steps are not wide enough (for example, less than 25 cm), the danger of walking on them increases and the wear rate of the outer edges of the treads increases. This is especially true for wooden and concrete steps. To avoid this, the outer edges of such treads are trimmed with metal or durable plastic. Such problems can be avoided by ready-made L-shaped overlays for steps from.

How to make steps from wood with your own hands

Making steps for stairs from wood requires the following set of tools:

- electric plane;

- a circular saw;

- grinding machine;

- router for edge processing.

Prepare templates of the required size and transfer them to the workpieces. Then cut out the treads and risers. When performing this work, difficulties may arise only when cutting out the turning steps due to their unconventional shape.

The resulting parts should be treated with protective agents and then installation should begin.

Glass stair steps

Such designs appeared quite recently. Glass steps seem fragile and unreliable. However, in terms of reliability they are not particularly inferior to steps made from other materials. For their manufacture, they use not ordinary glass, but a special multilayer glass called “triplex”. Essentially, these are glass plates held together using a special film. Load-bearing elements for such structures are made of stainless or chrome-plated steel. It is advisable to entrust the installation of such unusual stairs to a specialist.

Installation of wooden steps

There are four types of fastenings for wooden staircase steps:

- Metal carcass. A tread is secured to a corner, channel or metal plate.

- Stringer or bowstring made of wood, plywood. The tread is placed on the ridges and fixed with nails, bolts, and glue.

Stringer mounting options

Methods of attaching to a string

- The central pillar on which the steps of screw models are attached. By the way they are placed, they resemble a spiral with equal distances between the steps.

Installation of screw steps - Console or Bracket. The cantilever type of fastening involves fastening protruding steps to the reinforcement using welding or anchors.

Let's assume that you want to attach elements to stringers. Then the tread and riser are connected in one of the following ways:

- screws;

- using a groove that is cut into the tread at the intended junction with the riser;

- by installing an auxiliary triangular rail that acts as a support.

Attaching to a stringer

Whichever method you choose, it is recommended to additionally glue the parts being connected to ensure greater strength.

In the case of attaching stair steps to a bowstring, they can be fixed using a block, a metal corner or a groove.

The final stage after installing the steps is finishing them with plinths.

Installation of a finished staircase

Today, stair steps can be attached in a variety of ways. Some of them require special skills and knowledge, while others can be installed by anyone. Installation is carried out with the following accessories:

- Kosour.

- Bowstring.

- Bolza.

If the first two methods are suitable for absolutely everyone, then the latter is preferred only by professionals. For fixations the following are usually used:

- Wooden bars.

- Metal corners.

- Fastenings in grooves.

Metal staircase with wooden steps

The wooden elements are attached to the metal base using holes made at a distance of 150 mm. In this case, it is necessary to make an indentation from the edge of 20 mm.

A plywood backing will eliminate errors that arise when welding metal elements

When welding metal components, errors could be made that caused minor differences in height. In this case, to eliminate irregularities, a substrate is glued to the frame. Plywood with a thickness of 10 mm is suitable for this.

Metal structure cladding

To ensure that the substrate is securely fixed, self-tapping screws are additionally used. Polyurethane foam is not suitable for these purposes. After hardening, it will begin to crumble under the influence of load, which will lead to loosening of the steps.

The wooden tread is pressed against the plywood with clamps and secured with self-tapping screws. To make a staircase with a metal frame look attractive, craftsmen advise making steps with protrusions. They will hide the ugly metal frame.

Types of stairs by purpose

According to their purpose, the types of stairs in the house are divided into main and auxiliary. The main ones are designed for easy and convenient movement between floors, have a solid and reliable design, and are usually installed in living rooms, halls and hallways in houses. In order to get into the basement or attic, auxiliary ones are used.

Usually, in beauty and design, auxiliary ones are inferior to the main ones, since the main staircases often serve not only to perform their original functions, but also as an excellent addition to the interior. After all, it is this engineering structure that is often not only a means of moving between floors, but also the most spectacular decoration of home decoration. Just imagine how luxurious and respectable curved railings, carved pillars and steps made from natural wood will look. And the many varieties of rocks of this material and the ease of its processing will help bring any of your ideas to life. It is wood as a material that can create a unique atmosphere of warmth and comfort, as well as complement the interior of a wooden house where the walls are not lined with any material.

Concrete staircase with wooden steps

Despite their strength, concrete structures cannot boast of beauty. Therefore, such structures are usually laminated or decorated with wood. Wood cladding is not cheap, but the results are excellent.

Before you begin installing the steps, you need to wait until the structure is completely dry. Otherwise, the sheathing will be saturated with moisture from the wet concrete and deform in the future. The staircase must dry for at least three weeks.

After the concrete mixture has completely dried, installation can begin.

The success of the operation largely depends on how carefully the formwork is prepared. But even in the best case, distortions and irregularities appear, which can be easily eliminated with the help of a screed. After it dries, the surface is cleaned and treated with a primer.

To completely level the concrete surface and create a moisture-proofing layer, sheets of plywood are glued onto a special mastic, and additional fastening is done with dowels.

Plywood eliminates possible geometric inaccuracies of the concrete base

Having carried out the preparatory work, they begin to install the steps. The treads and risers are connected to each other using grooves made in all parts.

Installation of steps begins with the lowest riser, which is bolted to the floor. They are screwed into the end of the part so that the caps stick out 8 cm. Then they are cut off and marks are placed on the floor where they will go.

Dowel connection

Holes are made in the marked areas and filled with epoxy resin. Finally, the riser is attached. After this, a tread with another riser attached to it is placed on the plywood with glue. To make the product stick better, it is recommended to use a weight.

Advantages of ready-made overlays

The main advantage of using ready-made overlays for steps is high strength - a consequence of the use of a unique material, whose composition was developed and patented by the company’s specialists. The brand strength of fiber-reinforced concrete used in the manufacture of overlays and finished steps of porch stairs is M1000, which makes the use of such elements an extremely profitable solution. A characteristic feature of C3 steps is the monolithic connection of the riser tread, which eliminates the ingress of moisture and significantly increases the service life of the products.

Steps for outdoor entrance staircase

A neat staircase on the porch has not yet lost its relevance. Solid wood species that are resistant to constant external influences are suitable for its manufacture. As a rule, this is oak, ash, maple, beech.

To protect against external influences, the street structure is treated with protective agents

In order for the structure to serve faithfully for many years, it must be protected from natural factors such as moisture and temperature changes. Elements in contact with the ground are impregnated with oils, and the open surfaces of the steps are treated with drying oil and covered with paint or varnish.

The street staircase should be periodically inspected and, if necessary, rotten areas of the structure should be eliminated.

Exterior wooden staircase design

The facing of stairs on the street has its own specifics. During the construction of the porch, metal bookmarks are left in the concrete, to which wooden steps will later be attached.

Materials

Most often, steps for stairs are made of wood, plywood or metal. Materials can be combined with each other. To make a choice, it is worth comparing their indicators of strength, comfort and aesthetics.

- Wood and MDF . This is the most popular material, which is used both independently and as an external cladding of a supporting structure. For framed steps, you can use sheets of plywood to fill the stairs. Natural wood is more preferable, but is more expensive. The most affordable is pine, but it can deteriorate over time. It is better to use oak, teak, maple, walnut or birch steps. As an alternative, you can use MDF overlays. They are made of something similar to plywood and have a decorative outer layer with a protective film. This coating externally imitates the steps of birch or other species, leather, stone and other materials.

- Metal . For forged structures, on the approach to the house or for technical stairs, it is better to use metal. This can be corrugated sheet material, lattice or perforation. You can limit yourself to a metal frame. A channel or corner is used for it. Subsequently, treads made of wood or plywood are attached to the corner.

- Concrete . Distinctive features: massiveness and solidity. In order to brighten up gray concrete, cladding is used. The steps to the house can be tiled, and in the room itself, MDF can be fixed to a plywood flooring.

- Brick . Steps on the porch to the house are often designed this way. Masonry can be done from scratch or as an outer layer after concrete has been poured. Clinker bricks are used for decoration.

- Glass . Durable reinforced glass creates an atmosphere of weightlessness. This is an excellent option for cantilever and suspended structures. Goes well with stainless steel.

Examples of using different materials for stair steps

Additionally, stone, tiles, carpet, plastic and other materials can be used for cladding the structure.

Treatment of steps with protective agents

Now you know how to make your own steps for a wooden staircase. Next, it is necessary to ensure their protection from damage and exposure to external and internal factors. Special means are intended for these purposes. These include impregnations, varnishes and paints.

Impregnation protects wood from damage

Impregnation is a liquid that penetrates the wood structure and gives it certain properties. The most common are:

- Fire-retardant compounds that increase the resistance of wooden elements to high temperatures.

- Antiseptics are products that protect wood from fungi and bacteria. These compounds prevent rotting of the material even in conditions of high humidity.

- Complex impregnations that simultaneously perform the functions of tinting and disinfection.

In order for the impregnation to be evenly distributed over the wooden workpiece and deeply saturated, it is recommended to apply it to the products before installation.

Paint and varnish products are used at the very last stage of work. The only exceptions are the components of the railing, which are more convenient to paint and varnish disassembled.

Alkyd and alkyd-urethane products are suitable for painting marches; enamels are suitable for railings and risers. It is customary to coat stairs indoors with alcohol-based varnish with a matte or glossy composition. Stair structures from the street are treated with nitrocellulose products.

Types of stairs by construction material

According to the type of material from which the supporting structure of the stairs is made, they can be divided into the following groups:

- Metal

- Concrete and reinforced concrete

- Combined

- Wooden

The basis of metal stairs is an iron frame, which, if necessary, can be sheathed with wooden elements. Among the advantages of this group are durability and ease of manufacture, because having basic knowledge and experience in welding, making a simple staircase from metal will not be difficult.

Concrete and reinforced concrete stairs. The basis of this group is concrete and metal structures. The most difficult and labor-intensive stage in their production is the construction of formwork, into which concrete is subsequently poured. A feature of this design is its high wear resistance.

Combined stairs can combine parts from absolutely any materials such as glass, wood, metal, stone, plywood and many others. If you are a creative person, then this type of design is suitable for realizing your ideas.

The material for making stairs from the last group is wood, and its species can be absolutely any, it all depends on your budget, and the biggest advantage of this group is environmental friendliness.

Manufacturing a single-flight staircase

Let's begin the description of the process of making a wooden staircase to the second floor with our own hands with the simplest marching design. For most parts, a board 50-60 mm thick is sufficient, from which the required blanks are cut. Stringers or bowstrings, which will bear the main load, are made from lumber 60-80 mm thick.

Wooden staircase

To prevent the wood from warping over time, it is dried well. It is desirable that the humidity is up to 6%. To avoid injury, the lumber should not have a large number of knots and cracks. The most wear-resistant wood species that can last for decades include oak, beech, and pine. Lumber made from larch, ash, and alder is considered quite durable. For the manufacture of balusters and railings, you can use less wear-resistant linden or aspen.

The wood used to make the stairs must be treated with a special impregnation and then painted or varnished. This must be done once every few years throughout the entire operation.

Making a drawing

The wooden staircase to the second floor (see photo) has many details, and if there is an error in the calculations, it will be simply dangerous to use it. Therefore, even experienced carpenters will never start work without preliminary calculations. You can use ready-made drawings only in cases where the height of your ceilings and the size of the area allocated for the stairs completely coincide with the specified data. When designing, it is also necessary to take into account the configuration of the room, the location of doors and windows.

Drawing of a flight of stairs

The simplest drawing of a marching structure is easier to make yourself. After all, it looks like an ordinary triangle. The most comfortable is considered to be a structure with an inclination angle of 40-45° (the aspect ratio of the triangle should be 1:1.5). However, this option is only suitable for very large rooms. After all, it will occupy a significant area.

When designing, it is necessary to take into account that the distance from the last step to the ceiling is 1.85-2 m.

There is no point in making the structure even flatter, otherwise it will take up more space. Going down a steep slope with an angle of over 50-60°C will be simply dangerous. Therefore, if the ceilings are too high, to save space, it is better to opt for a turning staircase, for example, “L” or “U”-shaped with small flights of 10-12 steps in length.

To ensure safety, it is worth providing strong railings. Only the staircase to the attic can be made steeper.

When designing a staircase, be sure to consider its lighting. Otherwise, it will be unsafe to use it in the dark.

Basic calculations

There are special programs on the Internet that allow you to make all the necessary calculations automatically. However, it is better to play it safe and do it manually.

Staircase drawing

For example, the height of our ceiling is 250 cm. To this parameter it is necessary to add the thickness of the floor plus the thickness of the ceiling between 1-2 floors. We get 285 cm. Draw a triangle on a sheet of paper, one of the sides of which will be 285 cm (the scale on an unfolded notebook sheet is 28.5 cm).

We draw an inclined line from it at an angle of 45° (as we already know, this is the standard angle of inclination of the stairs). We measure the side of the triangle. It will be equal to 4.03 m.

We check our data based on the Pythagorean theorem. Let's determine the length of the march:

с = sin 45°/b,

According to the table of sines, sin 45° is equal to 0.7071; b in our case will be equal to the height of the ceiling. Let's do the calculations:

285/0.7071 = 403.05 cm or 4.03 m.

But in a small room, a staircase 4.03 m long will look too cumbersome. It is better to make it double-flight with a rotation angle of 180°. The calculations will be similar. Don't forget to take into account the height of the intermediate platform.

Elements of a wooden staircase

To determine the length of the kosour (string) , that is, the longest side of our triangle, we use the Pythagorean formula:

h2 +l2 = k2,

where l is the length of the flight (403.05 cm), and h is equal to the height of the stairs (250 cm). When receiving a fractional result, the figure is rounded to the full number. We get the length of the stringer equal to 474.29 cm.

The width of the stringer (string) is equal to double the height of the riser (we multiply its height by 2).

The number of steps will be equal to 285/17 = 16.77 pcs. The number 17 is the height of the risers we have chosen (their height can be 16-19 cm). Since experts recommend choosing an odd number of steps, no recalculations are required in our case.

If we get an even number, we can change the calculations and make the lowest and highest steps smaller in size.

Marking stringers

Assembling a ladder with stringers is much easier than with a bowstring. After all, you don’t have to prepare grooves for the steps. But working with a stringer also has its own subtleties - after all, for each of the steps in the inclined beam you will have to make cutouts of equal size in the form of a comb.

Marking a stringer using a template

To do this, it’s easier to use a template (see photo). The letter “a” in the figure means the height of the step, the letter “c” means the length of the tread. The already finished first stringer can be used as a template for cutting the second stringer. Be sure to apply both stringers to each other - they must match exactly.

In the lower part of the stringer , at a distance of 7 cm from the edge, a slot is made for installing it on a support.

At the top of the stairs it will also rest on a beam . For this purpose, a groove is also made in it. The width of the cut should be equal to the width of the stringer itself.

Attaching the stringer

If the staircase is too wide (more than 1.5 m), there should be three stringers or bowstrings - two on the sides and one in the center.

Attaching risers to three stringers

Making bowstrings

Bowstring structures are considered more reliable. After all, if errors in the design of the stringer may cause the entire staircase to collapse, then if the step is incorrectly attached to the string, only one will collapse. Plus, the ladder on bowstrings looks more compact. One of them can be wall-mounted and attached to a load-bearing wall. You can’t do without them when making a spiral staircase.

Preparing grooves in bowstrings

The steps are attached to the string in several ways: using grooves or fillets. The fastening is strengthened with glue. The treads are attached only with glue and screws. The grooves cut through are very easy to use. In this case, to replace the damaged stage, removing it will not be difficult.

Attaching bars to strings

The grooves are marked using a plywood template . First, longitudinal lines are applied at a distance of 30-50 mm from the edge. Then the template is gradually moved along the edge of the string along the guides, marking with a pencil the places where the steps are attached. The bowstrings are connected to each other using cords with steel or wooden wedges or screw cords.

If cutting the grooves seems difficult to you, replace them with metal corners or strong wooden blocks attached to the side of the bowstring. Then simply lay it on top of the steps and screw them to the corners.

Installation of railings

The fence consists of 3 main elements:

- handrail : parts designed to be grasped by hand

- balusters : vertically located supports connecting steps and railings

- pedestals (pillars): racks located at two ends of the railing

For ease of use, the railings are made 90-95 cm high . The railing frame is raised to a height of 10 cm. It is also necessary to take into account the height of the handrails - it is equal to 5 cm. Thus, the height of the balusters should be 95 - (10 + 5) = 80 cm. Although they can be attached directly to the stringer or bowstring without using frame.

Baluster fastening diagram

If there are small children in the house, it makes sense to install additional handrails of low height. This is especially true when installing stairs that are too high or steep.

The distance between the balusters is 15-20 cm . You should not make a greater distance, otherwise the child may crawl through the opening and get stuck in it.

- First, cabinets are installed on the upper and lower steps. Their diameter is always larger than the diameter of the balusters, because they bear the highest load. They are made with a cross section of 100x100 mm

- Balusters and cabinets are attached to wooden dowels or metal bolts with a washer . To insert dowels, holes of the required diameter are prepared in advance. You can also use nut ties for cabinet furniture or anchor bolts for fastening

- If necessary, trim the parts using a fine-toothed saw. To install the pillars, use one 20-30 mm or several small dowels. You can hide the seam using a plinth

- Hollow pillars are mounted using a boss - a 15-20-centimeter block inserted into the cavity. It is installed on a stud screwed into the step, with additional coating with thick glue

- Next, the locations of the balusters are marked on the steps.

- The shape of the balusters can be any - round, square, rectangular. These decorative elements can be combined with each other - for example, alternating square and round parts

- After attaching the balusters, they are sawed at an angle parallel to the bowstring or stringer

- At corners and turns between flights, small handrail inserts are made. They are cut out in the form of segments or radius segments. Such parts are connected in advance using hidden tenons or dowels and additionally glued

“Staircase to the house” - professional production and installation of staircase structures

Our company supplies high quality stairs of all types to private and commercial customers. We also provide installation and structural assembly services to buyers from Moscow and Moscow Region. Our company:

- maintains low product prices through direct cooperation with material suppliers;

- professionally designs custom staircase systems and provides free calculations;

- uses certified materials, checking their characteristics for compliance with standards.

We deliver manufactured structures to the regions by transport companies. All products come with a 12 month warranty.

Characteristics of railings

Handrails are very important when using stairs. They create traffic safety and serve as the basis for decor that shapes the overall style of the room.

The railings consist of balusters, filling elements and handrails themselves, which serve as support when moving up the stairs.

Railings can be made from a variety of materials, the most popular of which are wood, glass, metals and other materials.

Railing elements can be sold as a kit, so you can save time and money and make this part of the staircase yourself, but in order to create a truly individual project, you will need to turn to specialists.

Choosing a location for the main staircase

- As a rule, the staircase is most often placed in the hall. Its type should be chosen according to the style and area of the hallway, and thanks to properly selected lighting, the space can be visually made wider.

- The staircase can lead upstairs directly from the living room. There is no need to worry that it will take up a lot of space, since the design can be made more compact and you can arrange bookshelves, plants or various designer decorations under the stairs.

Dream books say that going up the stairs means success, but going down means failure. To make movement in both these directions as comfortable and safe as possible in real life, it is necessary to fulfill the entire range of requirements for materials and design features, and thus choose the option that suits best, according to the interests of all family members.

Manufacturers

Wooden stairs will fit perfectly into the interior of a house or cottage with two or more floors. Based on the design solution, products come in both straight flights and screw ones. The modern market offers ready-made stairs of any complexity and configuration. The products fascinate with their naturalness and amazing texture of natural wood.

Modern manufacturers offer the following types of services:

- production of wooden structures;

- facing with an array of concrete stairs;

- production of log products;

- production and installation of bent railings.

Article on the topic: Staircase with a 180-degree turn: types of structures, their features and calculation of parameters

Wooden stairs with curved railings look especially elegant.

The cost of wooden stairs depends on the following number of factors:

- dimensions;

- the type of massif used;

- complexity of the design of structural elements;

- the presence of additional decorative components;

- coating option - varnish, paint, tinting, wax.

To calculate the exact cost, preliminary measurements are taken, details and nuances are agreed upon. Afterwards, drawings are developed and a detailed estimate is provided. Payment methods are agreed upon with each customer individually. Since companies try to meet customers halfway, customers are offered favorable discounts and promotions, which allows them to buy stairs at the best price.

The production of wooden models of stairs is carried out in several stages:

- Carrying out the necessary measurements.

- Creation of sketches and drawings with exact dimensions.

- Calculation of the required number of wooden elements.

- Installation of the product and installation of steps.

The custom order service is popular. Designers and constructors will quickly develop a sketch of the staircase based on the dimensions of the room layout.

On video: making a wooden staircase.

Styles

You can make a structure of almost any style from wood:

- Russian estate.

It is characterized by an abundance of wood in the design of the space and a large number of massive interior items.

In Russian style

- Country.

The rural orientation, characteristic of this style, is embodied in the simplicity of decoration, devoid of grace, and sometimes “clumsy” processing of interior items. The design uses exclusively natural materials, often specially aged.

"Country"

- Japanese style.

Japanese style is characterized by laconicism, a combination of dark and light shades. The main highlight of such structures are fences made using elements of complex geometric shapes.

In the "Japanese" style

- Classic.

The interiors of this style are distinguished by sophistication, luxury, and the use of expensive materials in the design. The classic variety is characterized by elegance and sophistication.