Drinking wells on a personal plot have one unpleasant property - they can become polluted over time. One option is the appearance of sand impurities.

The reasons for this can be very different, but the consequence is always the same - such water cannot be used for its intended purpose. Therefore, you first need to determine why water with sand comes from the well, and then eliminate the reasons and clean the source. And you need to act immediately.

- Causes of sand in water Problems with the filter

- Silted spring

- Backfill problems

- Casing problems

- Pump cleaning

Water with sand from a well

Reasons for the appearance of sand in well water

Sand gets into well water due to damage to the casing, rupture of filters or too powerful a pump

. Experienced experts identify several reasons for the appearance of sand in water from a well. Each of them has its own location relative to the length of the casing.

Problems with the filter mesh

When installing the casing pipe, its lower section must be perforated and covered with a special fine-mesh mesh. It serves as a filter. The following problems may occur:

- Grid break when installing the lower part of the column. In this case, sand will appear in the water almost immediately after pumping the well. Its volumes will gradually increase in direct proportion to the flow rate of the source. Signs of a filter mesh rupture are sand particles of different sizes in the water - from the smallest to almost stones.

- Incorrectly selected grid cells. If they are too large, and the sand grains are of very fine caliber, they will freely penetrate into the casing space and mix with the supplied water.

If there are problems with the filter, there are two options for changing the well’s performance:

- Sand particles that are too small fall through the large filter cells into the source shaft and settle to its bottom. Gradually increasing its layers, such a layer will completely fill the lower part of the settling tank and completely cover the filter zone. The master will note a gradual and then complete decrease in the productivity of the hydraulic structure.

- With a high aquifer, water will continue to flow into the mine even with sand, but the owner of the source will find large volumes of foreign impurities in the liquid.

Due to highly contaminated water, working units of pumping equipment, automation, and pipeline elements may fail. Therefore, this problem should not be left to chance.

Casing depressurization

More often this happens for the following reasons:

- Metal corrosion when pipe sections are not completely screwed together. If there are open thread zones due to improper joining of two elements, under constant exposure to water they rust and develop a fistula. This can cause the well to become sandy in any section of the pipe. On average, correctly screwed columns last up to 50 years.

- Incorrect, not fully welded joints. Here, too, over time, holes appear through which groundwater and sand seep into the source. Such phenomena are also bad because not entirely pure water resources (with an admixture of nitrates, acids, atmospheric precipitation absorbed into the soil) are mixed with particles of earth into the casing. The average service life of welded columns is 20 years.

- Displacement of the casing relative to the limestone formation at artesian springs. This occurs when drilling and column installation technology is violated. Only experienced specialists should drill and equip such deep hydraulic structures.

If the pipe is depressurized, complex repair work will have to be carried out, which is best left to professionals. But if the casing has moved relative to its axis in one of its sections, in most cases it will no longer be possible to save such a mine.

Problems with gravel backfill

If previously the correct technology for installing a casing string was considered to be blind welding of its bottom, today, instead, the lower part of the pipe is covered with a layer of different fractions of gravel. The following may happen:

- The filter mesh first fully performs its function.

- Later, colmatage occurs (dense filling of the cells with grains of sand of different calibers). The filter just gets clogged.

- Since water needs to find an entrance to the casing, its pressure begins to wash away the gravel backfill, swells it and opens access to sand grains of different sizes into the column.

Another cause of problems with gravel backfill is an overly powerful pump located very close to the bottom. Such equipment not only draws in water, but also overcomes the resistance of gravel stones, gradually lifting them. As a result, over time, the mine opens up to sand from the bottom. The layer can reach a level of several tens of centimeters, which will reduce the productivity of the well and lead to the appearance of dirty water.

How to clean a well yourself. Available methods

There are three main principles that can be used - pumping, washing with circulating water, blowing with compressed air. As for the methods, there are several more of them.

Method number 1. Bleeding using a vibration pump

A simple, but not always effective method. The vibration pump is good for cleaning, but is not recommended for regular use. Another advantage of the vibrating device is that it doesn’t require water – it can easily cope with sand and even small stones. Of course, the check valve may fail because of this, but it costs a penny and can be replaced in just a few minutes.

Irregular use leads to silting of the bottom

The vibration pump is quite simple and reliable. When pumping, there is a high probability of valve failure, but it is inexpensive and easy to replace.

Note! The cost of such a pump is several times lower than a circulation pump, and even if it completely fails, the financial damage will be insignificant.

Vibrating pump for pumping excavations

Disassembling a vibration pump

For cleaning a well, models such as “Baby” and “Rucheek” are suitable. Such cleaning will not cope with serious siltation, but it will help get rid of a large amount of sand. But only if the well is shallow - if the rise is more than 30-50 m, the productivity will noticeably decrease. Also remember that only a pump with a bottom water intake will do.

This device has a budget price

During operation, the pump must be turned off regularly for about 15 minutes; continuous operation should not last more than half an hour. Note that this method, despite its simplicity and minimum human participation, is not always effective and will cost some money.

Collecting water during well cleaning

Pumping water from a well until it is clear

Master Class. How to clean a well with a vibration pump

Step 1. Prepare a vibration pump with a bottom water intake. In our example, the device is slightly modified.

Vibration pump with bottom water intake

Step 2. The outer nut on the tip of the pump is twisted, after which a metal bracket about 15 cm long is installed in the center. It is well tightened with the nut so that it does not jump down. Thanks to this design, the sludge at the bottom of the well will be better agitated.

The nut is twisted

Metal bracket

The bracket is tightened with a nut

Step 3. A hose and cord are also connected to the pump (the second will lower and raise the pump).

Hose and cord connected

Step 4. The pump with the hose is slowly lowered to the bottom of the well. It must be lowered to its full depth until it comes into contact with contamination.

The pump is lowered to the bottom of the well

Note! There must be some amount of water in the well. If there is none, pour it on top.

There should be some water in the well.

Step 5. When everything is ready, the pump turns on and light rocking movements up and down begin. The device should be located near the very bottom of the well; the bracket, screwed on at the beginning, stirs up the silt. The pump picks up contaminants and throws them out.

You need to make rocking movements up and down

Step 6. The sludge is constantly agitated using a pump. The process may take a long time, which will indicate large deposits in the well, but the result is worth it.

The well cleaning process can take a lot of time

The pump is periodically pulled out and its inlets are inspected. If necessary, they are cleaned.

The water is getting cleaner

Step 7. During the day of work in our example, we managed to remove several buckets of rust, sand and other contaminants.

Rust, sand and other contaminants

Method number 2. Surface water supply

To remove turbidity, rust and fine sand, you can wash the surface with a pump. It is advisable to organize the process in a closed cycle, otherwise the site can be turned into a swamp. Water from an open reservoir should not be used, so you need to prepare containers whose total volume is equal to the full volume of the casing pipe.

It is better to wash from the surface in a closed cycle; this will require a container with a capacity comparable to the internal volume of the casing pipe (+)

The liquid will circulate between the container and the well thanks to the pump. Dirt will settle at the bottom of the container, so it will have to be removed periodically. The pump must be powerful. If you want, add chemical reagents to the liquid - for example, phosphoric acid, which will dissolve calcium deposits and rust. Remember that the acid must be quenched with baking soda; Moreover, after using it, the well must be pumped for at least another six hours.

Instead of a head, a nozzle is installed at the mouth of the source, which will direct the rinsing into the container with a reverse flow. The cycle, by the way, may not be closed - water can be pumped from the neighbors’ water supply.

The water is supplied downwards by a hose; its length should be enough for it to lie directly on the bottom. This method allows you to effectively clean the filter.

Method No. 3. Using two pumps

If the well depth is more than 50 m, then cleaning it using the previous two methods is problematic. However, if you use two pumps simultaneously, you can significantly increase the efficiency of flushing. In this case, deep and surface units will be required. The first will pump water with contaminants to the surface, and the second, located on top, will supply flushing liquid to the bottom.

Cleaning the water intake excavation with two vibration pumps is particularly effective

Dual pump cleaning system

Scheme of water movement when flushing a well with two pumps in a closed cycle

You can remove contaminants using the pump that is located in the well - there is no need to remove it or lower it below the suspension point. You just need to pass the supply hose through the casing pipe near the submersible pump to lower it to the very bottom. And remember: if there are small stones and sand in the water, the pump will be subject to increased wear.

Bottom pump for water agitation

Pumping out water using the top pump

Method number 4. Using a bailer

This method, which involves the use of a bailer, is effective if you need to remove a lot of pebbles, sand or fine compressed sediments. But if the filter or the soil next to it needs to be cleared of silt, the method will be almost useless.

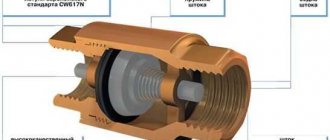

Who doesn’t know, a bailer is a steel pipe 1-1.5 m long, on one side of which there is a lever-eye for the cable, and on the other - a valve. An extremely simple design; if you wish, you can make a bailer with your own hands.

Design of a bailer with a ball valve. When the projectile hits the sand, the ball rises, the valve opens, and contaminants enter the hollow pipe

Standard bailer design

Homemade machine for working with a bailer

The valve is a massive steel ball, which is held in place by a washer attached to a threaded connection.

The water must be completely pumped out of the casing pipe, after which the bailer drops sharply to the very bottom. When you hit sand, the valve will open and some contaminants will get inside. Then the bailer is raised, cleared of sand, after which the procedure is repeated more than once. It is advisable to operate the projectile together; it is more convenient to lower/raise it using a tripod with a winch or a block.

Well cleaning bailer valves

Note! You can make a bailer yourself, purchase it, or rent it. You need to work with it carefully, especially near the filter (there is a risk of damaging the fine mesh).

Reed valve of the bailer

Working with a bailer manually is very tedious; it is advisable to stock up on a tripod with a lifting block.

To remove the last few centimeters of dirt, it is worth using another method that does not involve impact.

Flushing schemes with drilling fluid coming to the surface

Well pump performance calculator

Go to calculations

Do-it-yourself well cleaning

Can liquid be used with sand?

Theoretically, such water is allowed to be used for economic purposes - watering gardens, car washing, etc., but only after its high-quality mechanical cleaning. However, it is worth remembering that completely ridding the liquid of sand requires large costs for installing filtration systems and the need to use a drainage pump to pump and lift dirty water. Such expenses may be considered unreasonable. It is better to completely get rid of sand in the well by taking appropriate measures.

FEATURES OF WELL CLEANING USING THE ZEUS PULSE INSTALLATION

The ZEUS electrohydropulse installation converts an electrical impulse into a powerful hydraulic shock, which quickly and effectively pushes out all blockages, silt and sand from the bottom of the hydraulic installation. The standard charging voltage used for conversion is 30kV. With the help of special capacitors, it can be turned into a water hammer with a force of up to 1500 atmospheres, thanks to which it will clean a well up to 500-700 meters deep. The cleaning process involves the formation of a water-sand column, which facilitates the complete release of contaminated particles onto the surface of the installation.

It is worth noting that the final cost of cleaning a well will depend not only on the depth, but also on the complexity of the contamination, as well as on the time and labor costs required for cleaning. If you want to find out how much it costs to clean a water well using a ZEUS hydraulic installation, taking into account all the individual characteristics of your site, as well as the geological features of the area, you can contact us at. By calling us at our contact phone number, you will receive a free consultation on any of your questions. You can also find out in advance how much it costs to clean a well in a country house or on the territory of a country house.

Effective cleaning methods

Bailer for cleaning

a well The simplest option for dealing with a silted bottom is to use a bailer: a piece of steel pipe with teeth on one side and special flaps there. The principle of its operation is that when it free falls from a height of 0.6-0.8 meters, it crashes into a layer of sand deposits with its weight. At this moment, the bailer flaps open and sludge enters the pipe cavity. When it rises, the blades close, preventing dirt from flowing back into the casing space.

As soon as the volumes of lifted sludge are very low, a stream of water under high pressure should be applied to the bottom of the shaft. This will help wash away any remaining dirt in the filter area. The dirty liquid is pumped out with a powerful pump until a clean water resource appears.

Using a bailer you can clean wells up to 15 meters deep. If it is longer, the master will no longer be able to cope with the problem.

Mechanical flushing

Cleaning a well using two pumps

Here you need to use two pumps - one powerful for supplying water under pressure to the siltation zone, the second drainage for pumping dirty liquid upward. Both units must operate simultaneously.

The supply hose is equipped with a special weight so that it does not rise to the top under the pressure of incoming water. It is lowered approximately 20-25 cm from the silt layer. The intake hose is placed a little higher (30-40 cm from the bottom). Turn on both pumps and start working. The incoming liquid will break up the sludge deposits, and the drainage pump will pump them upward.

It is advisable to prepare a special barrel or other reservoir for dirty water. A bucket without a bottom, covered with fine mesh underneath, is attached to its upper edge. Water will pass through such a homemade coarse filter and be cleared of grains of sand.

Periodically, the drainage pump must be turned off and washed to remove accumulated dirt.

Use of special equipment

If the well is driving sand, special equipment can come to the rescue - a fire truck. Renting equipment will cost a pretty penny. But the work can be done in half an hour.

The principle of operation is that the operator will supply large volumes of water into the well through a fire hose, and with its help will pump out the liquid contaminated with silt.

What to do on your own?

find out exactly why sand is coming out of a well , but you can try to solve the problem yourself:

- pump water to the very bottom using a vibration pump;

- raise the pump 15-30 cm so that it is above the sand level.

If these basic measures do not help, do not hesitate and call specialists.

You can leave a request on the company’s website or by calling 930-317 in Tyumen, and our specialist will contact you shortly.

Preventive measures

To prevent the well from producing sand over time and causing trouble to its owner, it is important to take a number of preventive measures.

- Completely pump (flush) the source after drilling it. It is important to do this until the water comes out completely clean.

- Correctly calculate the fraction of filter mesh cells based on the size of sand grains. This can be done by experienced professionals.

- Monitor the strength and reliability of all connections of the casing pipe during its installation.

- Use a pump whose technical characteristics correspond to the performance of the source. A unit that is too powerful will either deplete the well or drive sand.

- Operate the hydraulic structure regularly (even in winter). Seasonal downtime leads to silting of the filter. If it is impossible to avoid seasonal operation of the well, it is advisable to come to the site once a month and pump out at least 100-150 liters of water.

It is always easier to prevent a problem than to solve it later.

How to avoid well clogging? Important points

So, we found out that sooner or later problems arise for all well owners. Of course, if the aquifer dries up, then it will be necessary to deepen the mine or drill a new well, which can hardly be considered easy and cheap procedures.

For most private homes, a well is the main and often the only source of uninterrupted water supply

Reasons for well siltation

It’s a completely different matter if the well is clogged - this can even be avoided if you operate it according to all the rules. How to extend the service life of the water supply source on the site?

Table. Well operation rules.

| Rule | Short description |

| Follow the selected drilling technology | Carefully ensure that the casing pipe is sealed and the filter is intact. |

| Make sure the well is not idle | Ideally, several tens/hundreds of liters need to be pumped out every day, and this is not a problem if people live in the house permanently. Otherwise, try to pump out at least a hundred liters every two months. |

| Well flushing | Once you have finished drilling, immediately flush the source until clear water appears. |

| It is better to abandon the vibration pump | The fact is that such a pump, vibrating, will contribute to siltation of the soil or the entry of sand into the well (to a greater or lesser extent). It is better to use a centrifugal pump for this purpose. |

| Protect the well from contamination and surface water ingress | Install a head or caisson for this. As an option (but only temporary), seal the top of the casing. |

| Choose the right submersible pump | Do this before you start operating the well, taking into account the water flow, and install the device at the desired height. |

Abyssinian water well

Note! If you follow all these recommendations, you still will not be able to prevent the well from clogging. But you will be able to delay the problem and achieve maximum effective use of the resource.

Proper construction of a well is the key to its longevity. It is necessary to install a special head on the casing pipe, which seals it and serves for reliable installation of equipment

General information

Sanding of water wells occurs quite often in shallow hydraulic structures. Most often, sand appears in a well at water intakes built with regular or blue sand . Such wells are called sand wells because the aquifer is located in sandy rock with inclusions of stones, clay and other components.

Water in such a layer passes freely through the sand (sometimes it can be blue), like through a filter. In this case, sand can move in the formation along with the water flow. A well becomes clogged with sand when grains of sand enter the fluid intake area. That is why a filter is mounted in this place - a steel mesh and a wire winding. The dimensions of the filter cells are such that sand contamination of the well itself and the pipeline cannot occur through them.

However, this filter does not always work properly and the owners of such water intakes have a question: why is sand constantly observed in the well? There can be many reasons for this. Such problems can be caused by equipment breakdowns, casing depressurization and water leakage, filter failure and other phenomena.