Home gas line pressure

The nominal gas pressure for a home gas pipeline should be in the range of up to 2 mPa ÷ 1000 (artificial gas) – up to 3 mPa ÷ 1000 (natural gas) – up to 4 mPa ÷ 1000 (liquefied gas). Main gas pipelines can have a pressure of 0.1-0.6 MP. The gas pressure is reduced before it is supplied to the internal gas pipeline of the house using a house gas control point (DRP).

The DRP is mounted on the wall of the house in a cabinet or on the site in a cabinet raised on a fireproof platform, with a separate grounding.

Service

How to clean such a chimney?

To clean a horizontal chimney, it is necessary to provide either special doors or areas with knockout bricks. Without these technological holes, it is impossible to clean the snake chimney.

Craftsmen advise periodically heating the stoves with dry aspen firewood and potato peelings.

These methods are not a panacea, but a good way to prevent soot formation.

How to connect gas pipes

Preferably a welded connection of pipes for gas. Connection points for gas fittings can be connected with flanges and threads. The threads are sealed with flax, which is coated with red lead paint or lead white paint. A more modern seal is FUM tape (fluoroplastic sealing material).

When laying an internal gas pipeline, you will have to bend it. Bend radii are standard. When installing pipes up to Ø4 cm, the bending radius must be at least 2.5 times the pipe diameter. For pipes 4-5 cm, the bending radius is at least 3 times the diameter. Pipes of other diameters do not bend in the gas pipeline.

Flange connection of gas pipeline pipes

You can see the flange connection of the pipes in the photo. This connection requires gaskets. They are made from paronite. A flange connection is unlikely to be needed in the internal gas pipeline of a house, although it is possible in a DRP.

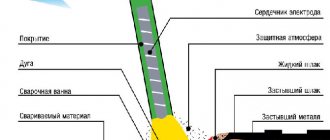

Connecting gas pipes by welding

The main connection of gas pipes in the house is welding. Any welding can be used:

- Electric arc welding by hand (electrodes No. 42, 42A, 46, 46A, 50A).

- Automatic welding with fluxes and wire Sv-08-A, Sv-08-GA.

The same wire is used in gas welding. In the internal gas pipeline of the house, you need to use fittings (valves, valves, taps) only designed for operation in a gas environment.

Main reasons for the transfer

The placement of a gas pipeline in apartment buildings and individual buildings is provided for at the design stage, choosing the best option for this. Typically, the gas riser runs close to the windows in such a way as to ensure ventilation of the area next to the gas stove. At the same time, the gas outlet should not be located too far from the water supply - this will lead to inconvenience when installing the kitchen unit.

Basically, the need to move the gas pipe in the kitchen is related to the technical requirements set out in regulations, the main one being that the shut-off valve should not be located at a distance of more than 1500 mm from gas-consuming appliances.

From the above standard it follows that it is prohibited to use a flexible line of greater length and if the normal distance between the shut-off valve and the gas-consuming installation is exceeded, it will have to be compensated by lengthening the steel pipe.

If an owner needs to move a gas pipe, most often he does this for the following reasons:

- Installation of new equipment to replace old or additional equipment. If a water heater is installed in a room (for example, in the bathroom of an apartment), you will have to stretch a pipe from the kitchen to another room to supply gas. A similar situation may arise in an individual cottage when placing new or additional appliances: gas boilers, hobs, water heaters.

- One of the common reasons for transfer is related to regulatory requirements, for example, if the consumer previously had a stove with one entrance installed, then when placing a separate hob and oven, each appliance will need its own connection. To provide two inputs, you will have to change the configuration of the pipe with cutting in the connecting fittings and performing operations equivalent to transfer.

Rice. 2 Methods for connecting gas consuming equipment

- Redevelopment. The gas stove is moved if for some reason the kitchen layout is changed, partitions are demolished or added, or the kitchen area is increased by adding a balcony or loggia to it. When implementing the latter option, the slab is sometimes taken out onto an insulated balcony, with a pipeline connected to it (the option is not very acceptable from the point of view of legality and safety standards).

- Transferring the slab. Sometimes the designers’ decisions on the placement of the gas pipeline do not always coincide with the owners’ vision of arranging the kitchen space; for example, they decided to create a cooking area in the middle of a large kitchen. In this case, gas pipes have to be moved or hidden to ensure a convenient, aesthetic supply of gas to the hob.

- Purchase of a kitchen set with built-in gas equipment. The gas riser in all city apartments is designed to connect one stove in a certain place; if the owners purchase cooking appliances built into the kitchen furniture, it is highly likely that the standard position of the riser outlet will not fit them - it will have to be moved.

- To improve the aesthetics of appearance. Gas pipes made of low-carbon steel, painted with light paint, which turns yellow over time, spoil the appearance of many modern kitchens, where the owners want to achieve a high decorative effect. If it is not possible to hide the gas pipeline in the upper cabinets of the kitchen unit, consider one of the rare options of placing the pipes in the grooves (channels) of the walls under easily removable decorative panels.

- Changing the location of the gas meter. A gas meter is a rather large device that takes up a lot of space on the wall. If it creates inconvenience or too clearly disrupts the aesthetic appearance of the kitchen, it is not possible to place the device in a kitchen wall cabinet; consider options for moving it to another location (usually downstairs) along with the piping.

Rice. 3 Pressure characteristics of gas pipelines for various purposes according to SNiP 2.04.08-87

Related article:

How to hide a gas pipe in the kitchen - various legal options . It is possible that after moving the gas pipe, you will want to hide it or somehow decorate it in the interior; in this case, we recommend reading a separate article about various options for decorating a gas pipe.

Preparation for installation work

Before installing the systems, you need to complete the following preparatory work:

- Make passage holes for pipes (walls, floors, foundations) for laying gas pipeline pipes;

- If you plan to hide a gas pipeline, you need to prepare grooves for it;

- The floors where gas equipment will be placed must be ready;

- When installing equipment on the wall, the walls are plastered;

- Plumbing and equipment to which gas and hot water will be supplied must remain in place.

Why gasify housing?

Today, natural gas is the most convenient and, importantly, profitable type of fuel. Sooner or later, every owner of a private house will want to gasify their property. Of course, there is an alternative - electricity. However, its cost is too high and it is very expensive to heat large areas in winter in this way. Plus, you will always depend on weather conditions - any hurricane can cause a break in the cables and then you will have to be left for some time without food, hot water and heating. But damaging a gas line is much more difficult.

Photo of natural gas

There is, of course, another “grandmother’s” way to heat your home - a stove or fireplace. But ash, coal, firewood, all this will lead to excess dirt. Lighting a stove takes a lot of time and labor, so it's best left as an option in case of an apocalypse. So, whatever one may say, blue fuel occupies a leading position today.

Installation rules

Gas pipes are connected by welding;

- Control, shutdown, and regulating devices are connected with threads or flanges. Distortions in connections are unacceptable;

- Pipe joints cannot be hidden in a groove or box;

- Connections require direct access;

- The pipes need to be painted;

- When closing the pipes with a box, gas. pipes to the box should be at least 10-11 cm;

- 10-15 cm should separate the weld from the passage through the wall and base of the house;

- For convenient installation and dismantling of taps, inlets, branches, you need to install squeegees with lock nuts;

- Usually, the distance from gas pipes to the walls of the house is indicated in the house gasification project. If this is not the case, a distance of at least the diameter of the gas pipe is taken.

Design features

Heating of the room from a wood-burning stove is carried out by heating the brickwork of the stove during combustion. The burning interval of firewood is short, so it is important to use the generated thermal energy as efficiently as possible.

Horizontal wells in the chimney of a brick stove enhance the heat transfer of combustion products. If the vertical chimney has minimal contact with gases and smoke, then the horizontal sections slow down their removal, forcing them to come into contact with a large area. The stronger the draft of the smoke exhaust channel, the more intense the fuel burns. The slower the smoke passes through the chimney, the more heat remains in the room.

Note! A well-chosen diameter and configuration of the chimney allows you to find a balance between the draft force and the level of heat transfer.

The design of the horizontal chimney is a vertical snake. Each turn is called a revolution, and the chimney itself is called multi-turn. The passage of smoke through such a coil should be as free as possible so that the effect of smoke being sucked back into the room does not occur.

Design features of a horizontal chimney:

- the channels are built the same size throughout;

- horizontal sections have a length of up to 1 m;

- the total length of horizontal channels should not exceed 3 meters;

- horizontal sections have a small angle of elevation in the direction of smoke exhaust;

- on turns, corners are made rounded so as not to provoke the formation of gas vortices;

- the inner walls must be smooth; protrusions and irregularities are not allowed.

It should be understood that it is better to entrust the construction of an effective and safe chimney to professionals. To install a horizontal chimney, you will need a competent engineering design that takes into account the features of the internal design and the correct external outlet of the chimney. This takes into account the height of the pipe, its location relative to the roof ridge, and even nearby tall buildings or trees.

Laying a gas pipeline

Let's look at the permitted minimum distances from the gas pipeline to other communications.

- From the surface of the gas pipe to the open wiring there should be 25 cm when laying parallel and 10 cm when intersecting;

- For hidden wiring, these distances are reduced to 5 cm and 1 cm, respectively. The same rule applies to wiring in pipes;

- Distribution and input panels with gas pipes should not intersect;

- There must be a distance of at least 1000 mm to the “bare” electrical wiring busbars;

- Utilities (water, sewerage) intersect with the gas pipeline no closer than 2 cm. Parallel installation is selected locally and is not standardized.

By condensation or smoke

We must not forget about the main feature of the chimney for a gas boiler: they have high efficiency and a fairly low temperature of the exhaust gases:

Condensation always and quickly forms in the chimneys of a gas boiler.

Therefore, the chimney installation must be done in such a way as to solve the condensation problem. Due to the low temperature of the exhaust gas, chimneys on modern gas boilers are made “through condensate” and not “through smoke”.

VadimProFORUMHOUSE Member

For smoke, this is when the pipe of the lower bend goes inside the pipe of the upper bend, and, accordingly, for condensate - vice versa.

Chimneys for modern gas boilers are collected strictly according to condensate.

This installation method allows condensate to flow calmly down inside the chimney without leaking out (this is dangerous and can cause a fire).

Installation of gas consumers at home

- The gas water heater is installed 2 cm from a fireproof wall and 3 cm from a fire-resistant wall. The walls are insulated with a “sandwich” of 3 mm asbestos and roofing steel. The insulator must be 100 mm larger than the dimensions of the water heater on each side.

- A tiled wall does not require additional protection.

- The wood is plastered over a grid. Next, they are covered with asbestos or asbestos plywood, and covered with roofing steel.

- The wall where the stove stands is closed from the floor. The distance from the slab to the wall is taken to be 70 mm.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

Delivery and acceptance of internal gas supply systems

- Hidden work is accepted during the installation process;

- The finished gas pipeline is tested by contractors together with the customer and the distribution network of the Oblgaz branch. The results are recorded in the construction passport or in a separate act.

- The gas pipeline is checked with air under pressure.

Water testing is prohibited.

- Checking for defects in connections is carried out with pressure: 100,000 Pa;

- Checking the density of connections by pressure: 4000 Pa with a meter and 5000 Pa without a meter.

- Tests are carried out with the devices turned on. The gas pipeline is in good condition for tight connections if the pressure in the pipes drops by no more than 200 Pa in 5 minutes.

Based on the tests, a report is drawn up. The act is signed by the installation organization and the district distribution network. According to this act, the acceptance committee consisting of: the customer, the installation organization, the Distribution Zone and Technical Supervision gives permission to start the gas. Gas is released into the house by the repair and maintenance service of the district, in the presence of the organization that did the installation. Next, the system is accepted into operation according to the act. Acceptance of the gas supply system for operation is formalized by an act.

©Obotoplenii.ru.

Other articles in the section Gasification at home

- Requirements for a room with a gas boiler

- Construction and installation of internal gas supply at home

- Home gasification project

- Grounding a gas boiler and gas pipeline

- House Regulatory Point (DRP)

- Installation of a gas boiler in a house: stage of gasification of a private house

- What is a gas regulatory point

Popular articles

Types of chimneys for boilers

There are different types of chimneys that are used in these cases:

A brick chimney is made of fireclay bricks, which are placed either on clay mortar or glue. In most cases, it is made with a stainless or galvanized steel sleeve inside to protect the brick from the destructive effects of carbon dioxide.

Region190FORUMHOUSE participant, master inspector at VDPO

Over time, the brick will begin to crumble due to carbon dioxide, so the chimney must be lined. In the market you can be deceived with the steel grade; it is better to buy AISI 316 directly from the factory. This acid-resistant steel works reliably with any brand of boiler. Not a single inspection master will ask you about the steel grade or demand a certificate; we do not have the authority to do this, and it is impossible to visually distinguish 316 from 425.

The main disadvantage of such a chimney is that it is heavy, you will have to make an additional foundation, and it is bulky, and you will have to look for a stove maker who will lay it out. Previously, such chimneys were often made for gas boilers; now (if funds allow) homeowners prefer ceramics.

Ceramic chimney . This is a complex structure that includes a ceramic smoke exhaust duct, an air layer (or insulation) and an expanded clay concrete shell. Expanded clay concrete protects the fragile ceramic pipe and serves as insulation (and ceramics have high thermal conductivity).

Andrey50FORUMHOUSE member

Cool specialists with extensive experience in chimneys say that ceramics are the best, but unreasonably expensive.

It is much easier to install such a structure than a brick chimney; it is durable, fireproof (can heat up to 120 degrees), but it is also heavy and bulky, and also expensive.

Asbestos-cement chimney. For this type, it is important to have tight joints inside the channels and good insulation to prevent condensation from forming.

RegularUser .FORUMHOUSE

During my construction period, asbestos-cement pipe was the cheapest option. The main problem here is how to hermetically join the segments; I couldn’t get it to be hermetically sealed. Simply pouring concrete is not an option. It should be a sealed sleeve, clamp, insert, anything that provides a reliable and tight connection. Be sure to insulate your asbestos-cement pipes. Do not forget that the design of the chimney should not allow condensate to drain into the boiler and be sure to make a condensate collector at the bottom at the base of the pipe.

Single metal - chimney made of galvanized or stainless steel.

Sandwich chimney. Such a chimney is made of two metal pipes, one is inserted into the other, and insulation is laid between them. Smoke flows through the inner cylinder. This type is required for use as an external chimney and in unheated rooms.

Coaxial. In this chimney, one pipe is inserted into another without laying insulation. But this is a single rigid structure, united by jumpers along its entire length. Smoke exits through the inner pipe, and air enters the combustion chamber through the outer pipe; the room air does not participate in the operation of the gas boiler, the microclimate is maintained.

Mr LeshiyFORUMHOUSE Member

Sandwich is an insulated chimney made of two stainless steel cylinders, between which insulation is stuffed. Coaxial - the same two cylinders, but without insulation inside. Exhaust gases are removed through the inner cylinder to the outside, and air is supplied into the combustion chamber through the gap between the cylinders.

Roofing passage

At the point where the chimney exits from the attic to the street, measures are taken to preserve the structure of the roofing pie. A hole is made in the roof into which passage elements are mounted. A box is installed to provide insulation for flammable roof elements. The roof around the pipe is sealed with a valley carpet, secured to the air duct with an abutment strip.

How to make a passage through the roof

Use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of cost and heat capacity of a particular wood. As practice shows, the best option can be considered birch firewood, which has the best balance of these indicators. If you purchase more expensive firewood, the costs will be less effective.

To heat a house with a solid fuel boiler, it is not recommended to use types of wood such as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Firewood made from alder, aspen, linden and poplar also has low thermal efficiency due to its porous structure. In addition, sometimes during the burning process alder and some other types of firewood shoot out coals. In the case of an open furnace, such micro-explosions can lead to fires.

It is worth noting that no matter what the wood is, if it is damp, it burns worse than dry wood and does not burn completely, leaving a lot of ash.

Where to place it?

It is allowed to make a chimney for the boiler inside the house or outside. Both options have their advantages and disadvantages, shown in the table:

| Location | pros | Minuses |

| In the house | Part of the structure in the attic and roof is insulated | Fires and carbon monoxide leaks are more common |

| Outside the building | Safer to use | The entire pipe requires thermal insulation |

| Repair work is easy to do |

Categories of gasified objects

According to Decree No. 1314 of the Russian Government, homeowners need to find out how much it currently costs to supply gas to their homes by contacting the regional gas distribution service.

First of all, household expenses for technological connection depend on the volume of gasification work. In this regard, three categories of capital objects have been defined.

The first category of objects . The first category consists of private households whose total natural gas consumption does not exceed 5 m³/h.

These include small business enterprises whose technological equipment consumes no more than 15 m³/h of a mixture of propane and butane. Those. The smallest fee for connecting to the gas distribution network is charged to cottages with an area of less than 300 m² and small enterprises from the public utility area.

The installation work on connecting the gas pipeline will be completed at the border of the site. Distribution of a gas pipe to a household's consuming equipment on its territory is carried out according to a separate project

The possible scope of work on laying connecting gas communications to a household of the first category is limited:

- the greatest distance from the main gas distributor to gas-consuming equipment is less than 200 m;

- gas pressure in the gas supply source is up to 0.3 MPa.

In addition, the laying of inlet gas pipelines is carried out without building reduction points (pressure reduction) for main natural gas.

The fee for connecting a gas pipeline for objects of the first category is 20,000-50,000 rubles (clause 8 of the appendix to the order of the Federal Tariff Service of the Russian Federation No. 101-e/3 dated April 28, 2014). The exact price is determined by the local gas distribution organization according to the conditions in the given territory, but cannot exceed 50,000 rubles.

The second category of objects . The objects of the second category include households whose connection requires gas distribution pipelines and/or the creation of main gas reduction points. Their estimated gas consumption is higher than the norm for first category facilities; a higher gas supply pressure is required (i.e. 0.6 MPa or more), etc.

Compliance with the cost of connection in the first category is observed if the pipeline is inserted into a low-pressure gas main. If gas reduction is needed, the connection price will exceed 50 thousand rubles.

In the private residential sector, properties falling into the second category usually have an area of over 300 m². For their gasification, standardized tariff rates are used, calculated according to the methodology developed by the Federal Tariff Service of the Russian Federation (appendix to order No. 101-e/3 of April 28, 2014).

It should be noted that applicants for natural or artificial gas consumption volumes of 300 m³/h and above are required to coordinate gas connections with a gas distribution facility that has a technological connection with the contractor’s gas pipeline.

The approval of tariff amounts for gas connections to households of the second category is carried out by the local executive authority of the Regional Energy Commission (i.e., the regional energy commission).

The third category of objects . Capital construction projects of the third category include farms that require an individual gasification project. For them, the amount is determined according to the design and estimate documentation, which has previously passed the examination.

The amount of gasification costs for households of the third category is established by the Regional Energy Commission, which relates to the location of the household connected to the main gas.

Prices for laying a gas pipeline along the section from the border entry point vary from company to company. However, it is worth considering the need for numerous approvals for a gas project. With an experienced performing company, full-fledged gasification will happen faster

The following conditions are considered to be characteristic features of applicants’ facilities in need of gasification:

- planned natural gas consumption from 500 m³/h;

- work on connecting to the gas main requires the pipeline to be routed through forested areas, through rocky soils, swamps and water obstacles;

- gas pipeline installation work requires passing through obstacles that force the use of horizontal directional drilling.

Those. According to Government Decree No. 1314, there are virtually no fixed prices for the technological connection of applicants to the gas network. The cost of gasification work depends on a number of conditions that determine its size within the framework of the relevant methods of the Federal Tariff Service of the Russian Federation.