The drainage and storm sewer system on the site is a necessary engineering and technical structure that improves the quality of life of people, protects gardening plants from excess moisture, and protects the foundations of buildings from destruction.

What are drainage pipes for and what is their principle of operation?

Drainage pipes allow for the removal of groundwater from a site or local area. They are thick corrugated hoses with perforations, which are buried at a certain depth. The principle of operation of pipes for groundwater drainage is quite simple. As you know, water always goes where the passage is easier. This law of physics applies to many areas and is never violated. Having leaked through the perforation, moisture freely rushes through the pipe to where the master directs it. This way, water does not need to seep through the soil. As a result, the soil dries out.

Good to know! If water stagnates in a certain place in a garden plot in the fall, then the soil, not receiving the necessary oxygen, begins to die. As a result, next year the harvest in this place will be negligible or there will be none at all.

Drainage is of particular importance for the foundation of a residential building. If there is an excess of moisture, the foundation of the house will quickly collapse, which will negatively affect the building itself.

Drainage products are flexible enough to make them easier to install

Nuances of drainage installation and operation

Nuances of installation and operation of drainage.

Typically, pipeline installation begins during site development. To ensure effective operation of the drainage system, it must be provided with sufficient water flow. To do this, the drains are sprinkled with filtration materials - crushed stone, gravel, small stones.

If this is not done, the drainage will flood and will not work. During operation, it is necessary to periodically check the functionality of the pipelines, as they may become clogged.

The degree of clogging is determined through the inspection well. Cleaning is carried out in two ways: mechanical and hydraulic. In addition, it is advisable to monitor the level and quality of groundwater in the area, as this will help determine the effectiveness of the drainage system.

Drainage pipes for groundwater drainage: main technical and geometric characteristics

The main difference between such products is the presence or absence of perforation in them. It is based on this parameter that pipes for draining groundwater are selected. In one case, it is necessary to remove excess moisture from the soil (perforation is used), and in the other, simply conduct the removed moisture without allowing it to be absorbed into the soil (in this case, the pipe will be solid).

The diameter of the drainage is also important. It should be understood that the larger the pipe, the more intense the moisture removal will be. On the other hand, if the product is not perforated and is used only as a discharge element, there is no point in using too large a diameter - it will simply be irrational.

Still, the material from which perforated pipes for drainage are made is of greater interest. There are quite a lot of such materials, and each of them has its own advantages and disadvantages, as well as specific areas of application. Let's consider this issue in more detail.

The perforation is clearly visible here - through it water enters the hose

Which drain to choose based on characteristics

Flexible single-layer products equipped with perforations can be used at a depth of no more than 3 meters. The category of products based on ring stiffness can also indicate the desired depth of installation. For example, SN-2 products can be buried no more than 2 meters, and SN-4 - 3 meters.

The two-layer drainage has smooth inner walls. Its outer layer is corrugated. In most cases, the strength of such products is SN-6. When laying the drainage network, two-layer elements no more than 4 meters long are used. They can be wrapped in geotextile or coconut fibers as a filter layer.

Flexible single-layer perforated and corrugated products belong to strength class SN-8. They can be equipped with a textile filter or supplied without it. They can be laid to a depth of up to 10 meters. Double-layer drains of this type are buried no more than 8 meters. They do not come with a filter.

Materials for the manufacture of drainage systems for groundwater drainage

The main materials from which such products are made include:

- PVC;

- HDPE;

- Ceramics;

- Polypropylene;

- Asbestos cement (chrysotile cement).

A separate item can be called pipes with coconut winding, which have a higher cost. But knowing the materials used is not enough. It is necessary to understand what the differences between them are, and in what case the use of one or another pipe is justified.

Products without a filter casing must be sprinkled with crushed stone

Polyvinyl chloride and polyethylene: advantages of the material

Drainage pipes made from such materials are used only to drain water; they do not collect it themselves. Most often, such products are made in the form of a regular pipe, but recently flexible hoses have also begun to be produced, provided that their diameter is large enough. Corrugated PVC drainage pipes with a diameter of 400 mm or more are now quite common.

Good throughput characteristics of such products are achieved due to the smoothness of the internal walls and the non-corrosion of the materials from which they are made. Such drainage pipes have a fairly long service life and are easy to install. Many home craftsmen, if they have similar products at hand, make perforated drainage pipes from them with their own hands. To do this, small holes are drilled in a chaotic manner along the entire length of the upper part. As a result, water flows freely along the bottom of the pipe, and excess moisture from the soil enters the drainage through the perforation made at the top.

The perforation can be quite large. You can’t do without geotextiles here

The main advantages of plastic pipes are not only their long service life, but also ease of installation. You can handle it yourself without any construction equipment.

Ceramics is a more demanding material

Ceramic drainage pipes are gradually becoming a thing of the past. The reason for this is not even their high cost, but rather the inconvenience of installation and less durability compared to plastic counterparts. Its warranty period is only 15 years, while plastic lasts at least 50 years.

If there are no other options, you can drain the area with ceramic pipes, but it would still be better to use more modern materials, among which polypropylene would be the best.

A drainage well is indispensable if there is no possibility of discharging water outside the site

Polypropylene products: what are they good for

The drainage of storm water with polypropylene drainage pipes is very convenient. They have a corrugated surface on the outside and a smooth inside, which does not allow dirt to linger on the inner walls. These are flexible products and therefore very easy to install. The connection of drainage pipes to each other is made by inserting one into the other - for this purpose we have a special socket on one side of each. Perforation along the walls allows you to collect excess moisture from the soil.

Large-diameter polypropylene pipes are usually covered on the outside with geotextile, which prevents silting and, as a result, increases the service life of the drainage. Such products are very light in weight and quite low in cost, which, coupled with their durability, is what makes them so popular.

Polypropylene is the most popular material for the manufacture of drainage systems

Coconut winding for drainage pipes: what is it for?

A relatively new type of filtration material - coconut coir - is the best way to protect the inside of the drainage from silting. This shell has proven itself well in all latitudes of our country. Its density is varied, which allows it to retain dirt particles of various sizes. If we add to this the environmental friendliness of the material, then the slightly higher cost no longer seems unjustified. In addition, drainage pipes with such a coating do not require preliminary filling of the trench with crushed stone and sand. They are laid directly on the ground, which significantly reduces installation time and simplifies it.

This is what coconut coir looks like, which is an excellent filter.

Asbestos cement drainage pipes

Such pipes differ from ordinary chrysotile cement pipes only in the presence of perforations, which you can make yourself. But from the point of view of ease of installation and durability, such products should be placed only in last place. All pipe turns are made only with special angles and branches, their weight is quite large and their service life rarely exceeds 12-15 years. If previously such material was used everywhere, nowadays rarely does anyone perform drainage with chrysotile cement products.

It is worth considering which drainage pipe material is suitable for a particular type of soil.

Asbestos cement can also be used for drainage systems. It is perforated with a conventional drill

Installation algorithm

The installation procedure for the aeration field is as follows:

- First, the location where the aeration field will be located is determined.

- A trench of the required depth and width is dug.

- Next, a ten-centimeter soil layer is laid, which has excellent throughput.

- Backfilling of crushed stone with a fraction of 30 millimeters. The thickness of the layer should be 35 centimeters. Pipes for drainage go deep into it. The length of the pipes is no more than 25 meters.

- Connecting pipes to the septic tank and risers for ventilation, which are approximately 50 centimeters high. The ventilation risers are equipped with special umbrellas for protection. The slope is 1.5 centimeters per meter.

- Filling the top layer of crushed stone with a thickness of 10 centimeters.

- Geotextiles are laid from the top of the pipes. This is necessary for insulating pipes.

- A soil layer with a height of 30 centimeters is poured from the top.

The algorithm is suitable for sandy and sandy loam soil cover; for a clayey soil layer, more serious backfilling of the excavation bottom is carried out. The soil that is used to fill the bottom of the excavation must have excellent water throughput. The height in this situation is 70 centimeters.

Selecting a material based on the type of soil on the site

There are 4 types of soil, depending on which the drainage pipe is selected. Let's look at them in detail.

- Crushed stone soil - it is possible to use perforated pipes without geotextiles or coconut coir. Groundwater filtration is not required;

- Sandy soil - a perforated pipe with a filter element is used to prevent sand from getting inside and silting the drainage. Sprinkling with crushed stone is also required;

- Alumina – There are two options here. Either it will be a pipe wrapped in geofabric with crushed stone, or laying the product in coconut coir in bare soil;

- Loam - only perforated drainage in geofabric with crushed stone sprinkling.

Drainage from the site can also be done using vinyl plastic

Features of drainage corrugated pipes with geotextile

The main advantage of geotextiles is its compatibility with any type of pipe, regardless of the material of manufacture. This material is vapor permeable, which creates additional air exchange and prevents the development of mold and mildew. Geotextiles themselves do not absorb moisture, but only help redirect it to the drainage pipe. It is resistant to living microorganisms contained in the soil and is completely uninteresting to rodents. This contributes to a long service life, almost equal to the durability of plastic and polypropylene pipes.

It is worth noting that when using geotextiles, the period between drainage cleanings increases by 4-6 times.

Geotextiles must be laid in the trench before backfilling and laying drainage

Types of drainage elements

Based on the material of manufacture, the drainage pipeline can be:

- ceramic;

- reinforced concrete;

- asbestos-cement;

- polymer.

Pipes made from the first three materials are now rarely used, as they have many disadvantages:

- They weigh a lot. Therefore, their transportation and installation are quite expensive. The system must be installed using special equipment.

- Installation of ceramic, concrete and asbestos-cement pipelines is just as difficult. It is produced only by specialists.

- Such network products have low performance characteristics. Its elements in most cases are not equipped with holes. The pipes have to be perforated manually. As a result, they become clogged faster and need to be cleaned regularly.

Why is perforation of drainage lines necessary?

It has already been mentioned that perforation helps remove excess moisture from the soil. But you should be careful here too - fanaticism has never led to anything good. If the drainage pipe is too large, and the perforations are very large and frequent, then there is a danger of drying out the soil of the garden plot.

Good to know! Too large a perforation creates the preconditions for the drainage to quickly become clogged with dirt and silt up. Even if the drainage line is clogged by a third, there can be no question of any high-quality outflow of water. And the well will have to be cleaned quite often.

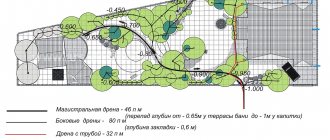

Schematic example of installation of a site drainage system

Manufacturers and features of their products

There are plenty of manufacturers of similar products on the Russian market. Each brand has its own distinctive features compared to others, which means it’s worth focusing your attention on this. Today we will not list all the companies operating in this segment, so as not to burden our dear reader with unnecessary information, but the most famous ones are worth considering.

Drainage pipes "Perfokor" and their features

The technical characteristics of these products are quite good. The company itself positions its products as the best in this segment, although many may argue with this. As they say, “there are no comrades according to taste,” and therefore we will present some technical characteristics of the drainage pipes of this company.

Products for Perfokor drainage systems are popular

| Drainage diameter, mm | Hole width, mm | Total area of holes per 1 m/p, cm2 | |

| Partially perforated | Fully perforated | ||

| 110 | 2,8 | 14,3-26,8 | 28,6-53,6 |

| 160 | 2,8 | 14,3-26,8 | 28,6-53,6 |

| Drainage diameter, mm | Hole width, mm | Number of rows of water intake holes | |||

| 2 | 3 | 4 | 6 | ||

| 200 | 2,8 | 153-205 | 230-307 | 307-405 | 461-615 |

| 250 | 4 | 118-195 | 178-292 | 238-389 | 356-584 |

| 315 | 4 | 135-211 | 202-317 | 269-422 | 403-634 |

| 400 | 4 | 144-224 | 216-336 | 288-448 | 432-672 |

| 500 | 4 | 129-190 | 194-285 | 258-380 | 388-571 |

| 630 | 4 | 104-156 | 156-234 | 208-312 | 312-468 |

Products

According to the manufacturer, Korsis drainage pipes are manufactured using special Italian technology, which makes it possible to increase their service life by one and a half times. Their installation is quite simple. And although there are models that require the use of couplings when connecting, products with a socket on one side, allowing for butt installation, are more popular.

And these are Korsis products. They are almost the same

Turning to the opinions of Internet users, it can be noted that the Perfokor and Korsis drainage systems have much in common, including the ease of laying the drainage pipe. This means that giving advice here is a thankless task and the home craftsman will personally have to decide which manufacturer he likes best.

Drainage pipes "Pragma" and their advantages

With the same two-layer structure, the manufacturer promises ease of pipe installation even at temperatures as low as -200°C, which means you don’t have to wait for the warm season to arrive. These products are capable of withstanding quite large loads, which is quite convenient if drainage is being installed in the courtyard of a private house where cars will enter. Installation of drainage pipes eliminates the need for additional devices such as couplings.

Drainage "Soft Rock" from

According to the opinions of Internet users, there are simply no negative qualities in the products of this brand. They are easy to install, the quality is decent, and the cost is not too high.

One of the interesting features of this drainage pipe. Between the plastic and geotextile there is a layer of special filler that provides additional filtration. It is for this reason that, regardless of the type of soil, such drainage pipes are laid without any backfill in “bare” soil, which significantly reduces installation time.

Quite an interesting design of products for Soft Rock drainage systems

“Uponor” drainage pipes: are there any differences from previous options?

Drainage systems of this brand do not have any special differences from Perfokor or Korsis. The quality is at a high level, the two-layer structure and various perforation options - everything can be called similar to its competitors. The only difference is the black color of the outer layer, but this is more of a visual than a technical difference.

How to install a drainage system on your site

The type of drainage can be closed or open. Closed means the use of perforated pipes dug into the ground, while open is done using trays that can be covered with decorative grilles.

Let's look in general terms at how you can do both of these types of drainage with your own hands. In order for the dear reader to understand the algorithm of the entire work more clearly, we will present several photo examples with explanations.

Open drainage system and its installation algorithm

| Photo | Action to be performed |

| On each tray, which are connected to each other using special locks, the direction of water flow is indicated. This arrow cannot be ignored. Otherwise, you will have to clean the open drain several times a year. | |

| At the end of the line, a special sand trap is installed, where all the dirt that gets into the drainage will settle. This is especially true if words will be produced down the drain | |

| Using the installation level, we derive the required slope of the drainage pipe towards the spillway. A slope of 1-3 cm/m is considered optimal | |

| If it is necessary to rotate the drainage channel, mark the required area, which is cut out using a grinder | |

| The last step is to screw the decorative grille, which also serves as protection against large debris and leaves, onto the special brackets that come with the kit. |

Having understood in general terms how open drainage is installed, you can move on to the backfill system.

Removing excess moisture from the soil using the backfill method

| Photo | Action to be performed |

| First you need to dig a trench along the marks where you need to lay the drainage pipe. There is no point in digging too wide - it will only lead to waste of crushed stone. | |

| The trench can be taken outside the site into a drainage ditch. If this is not possible, you will have to equip a drainage well | |

| We lay geotextiles at the bottom of the trench and pour a small layer of crushed stone. In our case, it was possible not to use bedding, because... a perforated drainage pipe that already has a geofabric shell will be laid, but we decided that crushed stone would not hurt | |

| A drainage pipe is carefully laid and connected to the drain into the well. You can use simple self-tapping screws for this. | |

| After the work is done, we again pour a layer of crushed stone, cover it with geotextiles and sprinkle it with soil. In order to hide the location of the drainage line, you can use turf |

It turns out that installing drainage on a site is not such a complicated process, which a home craftsman can do with his own hands.

Related article:

Drainage system around the house. Drainage arrangement, nuances of installation work and useful recommendations in a special publication in our online magazine.

Some tips

- There is no need to spend money on waterproofing materials; they are not needed here. On the contrary, the better and more evenly the water flows out, the easier it is to use the system and clean it.

- The well cannot be installed in an area where there are problems with a high level of the ground aquifer. It is best to go even below the clay layers so that the effluent undergoes as thorough filtration as possible;

- A thin (200 mm) layer of coarse sand or sand-gravel mixture (small fraction) placed on the bottom of the well will help to avoid soil heaving, clean the wastewater as much as possible and achieve better absorption;

- Perforation of the walls must be done correctly: not lower than 500-800 mm from the bottom level, so that the water comes out evenly;

- To avoid silting of the perforation, it is necessary to cover the circumference of the barrel or ring with expanded clay and medium-fraction gravel;

- High-quality ventilation, waterproofing of the upper part of the drainage well, insulation of the top - all these requirements are mandatory for the uninterrupted functionality of the system. It would be correct to install a removable type cover on the structure in order to have access to the inside;

- Calculation of parameters, corresponding volumes of water discharge, determination of a location for a drainage well are the primary tasks that need to be resolved before the start of construction.

The consumable part of the structure is large, however, following the tips you can slightly reduce costs:

- The depth of the trench is equal to the modular size plus half a meter, the total depth of the pit is 2 meters. The bottom is lined with 500 mm of sand, then 300 mm of crushed stone, the cushion is compacted and only then the module is installed. The method will help to avoid the cost of geotextiles or other expensive filter materials;

- For non-silting of modules, you can use geotextiles (cover), or you can also use fine-grained expanded clay;

- After all, the system is covered with medium-fraction crushed stone, without sealing the holes for the ventilation pipes;

- All that remains is to add the layer to the soil level. You don’t need to take expensive compounds; just make a mixture of soil and sand. In some cases, a geogrid will be required.

Where to buy drainage pipes: average cost on the Russian market

In our age of high technology, drainage systems can be purchased without leaving your home via the Internet. At the same time, many online sellers provide such a service as free delivery, which is also good news. Let's try to figure out the average prices for similar products.

| Name | Length, m | Diameter, mm | Cost, rub./m |

| With perforation in geotextile | 50 | 110 | 130 |

| With perforation in geotextile | 40 | 200 | 350 |

| With perforation without filter | 50 | 160 | 100 |

| Corrugated HDPE | 40 | 50 | 70 |

As you can see, the cost of such products is low.

Drainage plays a very important role in maintaining the foundation of a building.

Wall drains

Wall drainage structures are organized near the foundation. The main feature of such communication is that it contains waterproofing materials. A ditch is dug along the entire foundation. The depth of such a ditch should correspond to the depth of laying the foundation or exceed it.

Wall drainage is done in order to remove moisture from the foundation of the building

The necessary waterproofing is installed on the foundation walls, and the pre-dug ditch is filled with drainage materials. In this case, it is allowed to use special drainage mats, the filter of which is made of geotextile. Such mats are usually waterproofed with polyvinyl chloride (PVC).

Note! Pipes can be laid in the trench to drain rainwater collected from the roof. In this case, it is recommended to use plastic pipes without perforation. With the help of such pipes, water is removed from the tray structures into a special well.

Rainwater must not be discharged into the drainage system, as this may lead to overflow of the structure. If the drainage structure overflows, the water will rise into the foundation of the building, which is fraught with unpleasant consequences.