Cables and wires in residential and non-residential buildings are laid from a switchboard with an electricity consumption meter, safety plugs or circuit breakers under the floor, along the walls to distribution boxes, where they are connected by twisting or using terminal blocks (electrical clamps).

From the distribution boxes, electrical wiring is laid to other junction boxes or switch boxes, which are connected to one machine or the same group and to switches, sockets, and lamps. It is possible to make a connection without special education or experience as an electrician; just follow these instructions.

Usually 3–4 groups come to the apartment (including a separate group that comes to the electric stove, which is laid with independent cables or wires). Thus, if there is a fault on the line, only part of the building or apartment is disconnected from the power supply. Pay special attention to the proportional and uniform distribution of the load between the circuit breakers or safety plugs in the electrical panel.

Before starting work, it is necessary to de-energize the line on which work will be performed by unscrewing the plugs or turning off the machine.

As a rule, one distribution box is installed for each room; if the sockets are significantly distant, an additional one can be installed, specifically for the sockets.

Connecting the cable for lighting in a box: How to do it yourself - Instructions + Video

Cable wiring diagrams.

For a residential building that was built in the 60-70s. a simple electric meter, which was installed in the hallway of the apartment, was sufficient. At that time, automatic or more often ceramic plugs were used as fuses. This was enough for low-power appliances, and not everyone had a TV or washing machine. But times are inexorably changing, and almost every apartment has a washing machine, boiler, PC (one or more), dishwasher, etc. For this reason, they began to install input equipment that is able to withstand the entire load.

General information

Among what will be required for improvement is the selection of elements, installation and disconnection of cables in the electrical panel. I would like to immediately note that to perform such work you need special knowledge and practical skills in electrical engineering. But if you have instructions, ready-made diagrams, an electrical panel and you know all the safety requirements, you can assemble the panel and figure out how to connect the cable cores yourself.

Electrical panel - what is it for?

The distribution panel that is familiar to us, which is installed at the entrance to a private house or apartment, is needed in order to ensure safety when using electrical equipment and devices. In houses of a new type, such panels are already provided, but even in old buildings they are gradually replacing traffic jams and meters. Using a shield, you can intelligently distribute energy between all groups of consumers and create excellent protection against short circuits and overloads.

For placement you will need a plastic or metal box. First, they install an electric meter and a general switch to completely cut off power to the apartment. This shutdown can be done manually, or it will work itself in an emergency (network overload). If an input machine is installed in front of the meter, then it must be sealed (and the meter too).

Of the group of devices, circuit breakers have the most number of devices. They not only protect the wiring, but also the household appliances themselves. For each machine, a group of consumers is defined, and for each powerful device they install their own machine. Thus, you can turn off the devices individually, or the switch will work automatically in the event of an emergency.

In addition to automatic machines, residual current devices are also installed in the panel. They are needed to compare outgoing and incoming currents and are triggered if the balance is upset. This usually happens due to uncontrolled current leaks, and shutdown occurs due to exposure to current that is safe for humans.

And lastly, there are special busbars in the distribution panel, which are made in the form of copper strips. You can connect machines and other devices to them. The neutral wires go to a special block with terminals - the zero bus. To connect grounding, use a grounding bus.

Consumers and their distribution

All electricity supplied to the facility must be evenly and correctly distributed among all consumers.

When distributing and disconnecting cable cores, you must be guided by special rules and regulations:

- Consumers that are considered powerful (from 2,000 W and more) are grouped into different groups. Each group should be connected to a machine that can withstand the load.

- Connect the washing machine and dishwasher, as well as air conditioning and other devices that are not very powerful, to 16 A machines. Please note that the cable cross-section should not be less than 2.5 mm 2.

- Powerful devices (over 380 V) must be connected to 20 Am or 32 Am circuit breakers. In this case, the cable cross-section must be at least 4 mm 2. The cable should not have branches, and it should be laid in whole pieces.

- Connect separate lines to the sockets for each room and, if using a three-core cable, the cross-section of which will be at least 2.5 mm 2. Separate branches are provided for the sockets in the distribution box.

- Lighting devices are also divided into groups and connected to a separate cable, which has a cross-section of 1.5 mm 2 and to a 10 Ampere circuit breaker.

Only at first glance, connecting with cable lines seems like an unnecessary and unnecessary stage of work. The best option is a single-line diagram. It received a self-explanatory name due to the group display of wires. Standard diagrams indicate all the wires that belong to each line. The difference between a single-line diagram is that the total number of conductors is depicted with oblique dashes. At the bottom of the diagram there is a special layout with consumer lines, as well as general markings of power and cable that will be used for installation.

Each device is identified by symbols. H1 is a load switch (switch), with which you can open an electrical circuit that is under load. A circuit breaker can be used instead of this switch, but due to its technical characteristics it does not tolerate switching off under load. The remaining symbols H2, H3 and others correspond to the circuit breaker, and the symbols A1, F2, F3 refer to residual current devices.

For clarity, there are diagrams that show devices and equipment, as well as the connections between them. Near each device you can find marks and denominations.

Electrical installation work on disconnecting junction boxes and electrical equipment

Date: March 3, 2009 |

Category: Articles, Artistic lighting, Electrical measurements, Electrical installation, Electrical installation work Tags: Cable installation, Cable laying, Junction box, Electrical installation, Electrical installation work, Electrical wiring This material was prepared by specialists.

Do you need electrical installation or electrical measurements? Call us! Junction box

The power system consists of a large set of auxiliary equipment that ensures a safe and uninterrupted power supply to electrical equipment. Junction boxes are an integral part of the power system and serve for the safe disconnection of wires and cables, as well as for protection against electric shock. You can wrap a kilogram of electrical tape on the wires and convince the “customer” that this is the cheapest way to disconnect the wires. However, we live in the 21st century and we have many decent technologies at our disposal in order to carry out high-quality and professional electrical installation. Our mobile electrical laboratory, when performing electrical measurements, often reveals gross violations of the PUE (rules for electrical installations) and PTEEP (rules for the technical operation of consumer electrical installations). Let's look at where and how junction boxes are installed, and in what cases you can do without them.

When performing electrical installation work on laying cables and disconnecting electrical equipment (sockets, lamps, switches), we plan to install junction boxes, since a large amount of electrical equipment can be powered from one electrical line. There are several types of junction boxes: for open wiring, closed wiring, sealed and semi-sealed, metal and plastic. Junction boxes must be installed in an accessible place, due to the fact that servicing electrical equipment requires access to all parts of the power system. Electrical installation of deep socket boxes does not facilitate visual inspection, since checking the wire connections will require dismantling the socket or switch, and frequent dismantling will lead to breakage of the cable cores. We conclude: Deep junction boxes are not convenient to use.

Switching on the chandelier

Electrical wiring of apartments, country houses, small office premises does not require the mandatory installation of junction boxes, although such electrical installation entails an increase in cable consumption. We propose to figure out step by step how to do this. Let's consider lighting power. Everything is very simple. We lay the cable from the chandelier to the switchboard, then from the switch to the chandelier. We do all the wiring in the chandelier. If electrical installation is carried out in a wooden house, then all electrical equipment must be installed on metal platforms. When using an electrical installation diagram without junction boxes when choosing electrical equipment for electrical installation work, pay attention that the base of sockets, switches, lamps and sconces is metal.

This wiring diagram is more reliable, since electrical equipment is powered directly, avoiding breaks in cable lines. Be sure to use high-quality electrical equipment that ensures reliable connection of cable lines and guarantees continuous grounding of all sections of the power system included in the circuit. Do not forget that as the distance of cable lines increases, a voltage loss calculation will be required.

To disconnect cables, wires and electrical equipment, use special clamps that will provide you with reliable and safe contact. VAGO clamps meet all of the above requirements. They can connect aluminum wires with copper wires, multi-core wires with single-core wires. Another advantage of VAGO clamps is fast and convenient electrical installation; there is a control hole for electrical measurements. After completing all electrical installation work, it is necessary to carry out a set of electrical measurements.

Compression "VAGO"

Other and useful information

Other and useful information

Installation and connection

Installation steps

All devices that are mounted in the electrical panel have standardized dimensions, which greatly facilitates installation. For the main fastening, you can use a DIN rail, which is made in the form of a metal profile. Seats are measured in modules. This unit corresponds to 1 unit of space occupied by a single-pole automatic switch.

When calculating the places that will be used in the panel, it should be taken into account that 2 modules are one two-pole circuit breaker, and 3 modules are one three-pole circuit breaker. When installing a single-phase RCD, 2 modules will be required, and for a three-phase RCD, four. One module fits one terminal block, and an electric meter may require from 6 to 8 modules (it all depends on the design).

In general, it is recommended to assemble the shield on a flat, flat surface, for example, on a table. Doing the same thing on a wall will be much more expensive. Be that as it may, strengthening the shield must be done before filling from the inside.

First, install an input device for automatic protection. After this, the cable connection diagram can be made in two versions:

- In a linear diagram, all RCDs are located after the input circuit breaker, and after the circuit breakers. In this case, it will be difficult to find the fault that has appeared on the line.

- According to the group scheme, we first install a common RCD for the group, and only then the machines. In this case, in the event of an emergency, one group will be disabled, and the rest will operate in normal mode.

Drawing up an electrical panel diagram

At the next stage, you can proceed to drawing up a diagram. The most optimal would be a single-line option. This circuit got its name because of the group display of wires. On conventional diagrams, all the wires associated with each line are drawn. On a single-line diagram, the number of conductors in groups is depicted by inclined transverse lines. At the bottom there is a layout with consumer lines, indicating their power and cables used for installation.

All devices are identified by special symbols. H1 is a load switch or switch that opens the electrical circuit under load. Instead, it is possible to use a circuit breaker, but it does not tolerate switching off under load due to its technical characteristics. H2, H3, H4... etc. correspond to circuit breakers, symbols A1, F1, F2, F3 – residual current devices.

Wiring diagram or connection of electrical cables in a junction box

Cables and wires in residential and non-residential buildings are laid from a switchboard with an electricity consumption meter, safety plugs or circuit breakers under the floor, along the walls to distribution boxes, where they are connected by twisting or using terminal blocks (electrical clamps).

From the distribution boxes, electrical wiring is laid to other junction boxes or switch boxes, which are connected to one machine or the same group and to switches, sockets, and lamps. It is possible to make a connection without special education or experience as an electrician; just follow these instructions.

Usually 3–4 groups come to the apartment (including a separate group that comes to the electric stove, which is laid with independent cables or wires). Thus, if there is a fault on the line, only part of the building or apartment is disconnected from the power supply. Pay special attention to the proportional and uniform distribution of the load between the circuit breakers or safety plugs in the electrical panel.

Before starting work, it is necessary to de-energize the line on which work will be performed by unscrewing the plugs or turning off the machine.

As a rule, one distribution box is installed for each room; if the sockets are significantly distant, an additional one can be installed, specifically for the sockets.

Box wiring

Disconnection of distribution boxes is carried out in several ways: Soldering, crimping, welding, using terminals, clamps. All these methods can be used when disconnecting junction boxes . The most reliable method is crimping and welding, but this takes more time and requires special equipment and experience.

Network switching

Switching is the process of switching in electrical circuits when different sections of the circuit are closed or opened. Each element of the electrical circuit (socket, switch, lamp) is combined into a distribution box . Then in this junction box it is necessary to connect the wires in the required ratio so that the switch is a switch and not a socket and vice versa. To do this, you need to be guided by the PUE.

Step-by-step guide to installing a junction box

- Insert cables or wires into the box through seals in the holes (for overhead boxes) or through pre-drilled holes in boxes installed inside the wall.

- Fix the box to the ceiling or wall using 2 self-tapping screws or dowels for an overhead installation method, or seal it flush with the wall or ceiling for a hidden installation.

- Carefully remove the outer insulation of the cable right up to the entrance to the junction box. At the same time, it is necessary to maintain the integrity of the internal insulation of the cores. It is good to isolate accidentally damaged areas with electrical tape.

- Adjust the length of the wires or cores, leaving a maximum margin, while taking into account the possibility of laying them inside after completion of the work. Usually a margin of about 15 cm is left. If there are a large number of wires in one junction box, they are shortened to 12–10 cm.

- Strip the ends of the wires or cable cores.

- Connect the cores (wires) according to the operating diagram using terminal blocks (electrical clamps), insulating PPE caps or twisting.

- Insulate the twisted ends with electrical tape or screw on insulating caps.

- Separate the bundles of phase, neutral, and grounding wires to the sides, then carefully lay the wires inside; to make the task easier, you can carefully push them in using the wooden handle of some tool.

- Close and screw the lid.

Learn more about choosing a connection method and features of video editing

Wiring in the box

The basic pattern of actions for unsoldering wires.

— We run the cable into the distribution box (from sockets, switches, lamps, power lines)

— Cut off the excess cable length (leave about 15-20 cm)

— Remove the top layer of cable insulation to the base of the box

— We remove the insulation of the wires of the required length (approximately 1.5-2 cm for Wago type terminals, 5 cm for twisting)

— We connect the wires according to the diagram

— Place the connections in the junction box and close the lid

Here is an example of a standard diagram

Switching diagram

When disconnecting boxes, follow the electrical diagram. As a rule, a standard three-core cable has the following colors: white, blue, yellow-green, where

white-phase conductor and designated as “L”

blue is the neutral conductor and is designated as “N”

the yellow-green-grounding conductor is designated as “PE”

The most optimal method when disconnecting boxes is twisting using a PPE CLAMP (self-insulating clamp), it will maintain the twist in a reliable connection under maximum loads.

Distribution box wiring diagram

All protective or grounding (marked as PE in the diagram, highlighted in yellow) and neutral conductors (marked N in the figure, marked in blue) are connected to each other by color, as shown in the diagram. There will be no ground conductor if the wiring is two-wire.

Phase conductors (highlighted in black and red) are a little more difficult to disconnect; if the wiring from the distribution box goes only to the sockets, then the phases are also connected to each other.

In the case when the wiring goes to a lamp with a single-key switch (as shown in the figure), the wire that comes from the switch is connected to the phase going to the lamp (in the picture L to lighting), and the phase coming to the switch is connected to all phase wires (on the diagram L for the switch). There should be 4 connections.

When distributing conductors to a luminaire with a two-key switch, a four-core cable is laid before it (2 on-phase conductors, 1 off-phase, 1 neutral, 1 “ground”). In the case of two-wire wiring, it is three-wire, since there is no ground conductor. The phase conductors going to the sockets are connected to each other. The phases of the power cable coming to the common terminal of the two-key switch are also connected, 2 wires from which go to the lamp lamps separately. Below are wiring diagrams for a two-key switch without ground.

All neutral and grounding conductors (if the latter are present) are connected together. There should be 5 connections inside the box (including the connection of the grounding conductors). Below is a wiring diagram for a two-key switch with ground.

Consumer distribution

All electricity supplied to the facility must be correctly and evenly distributed among existing consumers. When carrying out the distribution process, you must be guided by special norms and rules:

- Powerful consumers of 2 kW and more are combined into separate groups. Each of them is connected to an automatic machine capable of withstanding the specified loads.

- Dishwashers and washing machines, as well as air conditioners and other low-power appliances are connected to 16 A machines. The cable cross-section must be at least 2.5 mm2.

- Devices with higher power (380 V) must be connected to 20 or 32 ampere circuit breakers. The cable cross-section accordingly increases to 4-6 mm2. These cables should not have branches; they are laid in whole pieces.

- The sockets are supplied with separate lines for each room using a three-core cable with a cross-section of 2.5 mm2. In the distribution boxes, individual branches are provided in the direction of the sockets.

- Lighting devices are divided into groups and connected to a separate cable with a cross-section of 1.5 mm2 and to a 10 A circuit breaker.

Connecting with separate cable lines seems unnecessary only at first glance. In fact, this is the only way to ensure electrical safety and ease of use. In the event of an emergency, only one group of consumers is disconnected, and not the entire network. In this case, troubleshooting is greatly simplified.

How to disconnect the box

In any room there is at least one branch box, called a junction box. Sometimes an additional one can be mounted on sockets - provided that they are significantly removed from each other. Disconnecting the box is necessary for many preventive and repair work.

All wiring in residential and domestic buildings is laid in the floor or along the walls. Cables and wires in a garage, country house, apartment have an exit from the electrical panel, where a meter is located that takes into account electricity consumption, safety plugs or circuit breakers, and come to the location of the branching and junction boxes. Here, the conductors are twisted and connected using special clamps.

The sequence of installation of the box and its disconnection

Let's take a look at the step-by-step instructions for the correct installation process:

- We knock out holes in the box or use special-purpose seals in the holes for overhead in order to carry out internal installation. In these places we insert cables or wires inside.

- Two methods are used to attach the distribution box. The first is to use self-tapping screws or a pair of dowels to fix it on the wall or ceiling, as an overhead element of external wiring. Second - For hidden execution, the junction box is covered with a solution flush with the wall surface.

- The outer insulating layer is completely removed from the cables along the entire section up to the entrance to the box. In this case, extreme care should be taken to avoid damage to the second insulation of the conductors. It is advisable to try to do this on a piece of wire that has become unusable. If you find damaged areas, wrap them with a layer of electrical tape.

- Another important point is that when biting off excess strands or a section of wire, it is important to ensure that the remainder is sufficient for twisting and laying in the inside of the box. Personally, I prefer to leave a length reserve of 15 cm. In a situation with a large number of cables, I shorten the cables to 10-12 cm.

- Having decided on the desired length, we strip the ends.

- In accordance with the operating diagram, we use electrical clamps to connect the wires.

Not so long ago, to obtain joints, they used the method of twisting and applying a layer of protective coating to this place. This technique has given way to a more improved method using terminal blocks or PPE. You can find a lot of materials describing all the nuances and features of this process.

- Next, you will need to place the zero or ground and phase beams in the internal part and separate them into separate groups. If the conductors are located loosely enough, an elementary method is used to push them into the required area of the box with the handle of a hammer.

- After completing all of the above procedures, put the cover back in place.

Diagram for making connections

Twisting is carried out strictly according to the colors indicated in the figure, all protective conductors (“Earth”), which are yellow-green in color, and “Zeros” with blue wire insulation. With a two-wire option, there is no “Ground”.

The soldering of the phase with black or red color occurs a little differently. Connecting the phase conductors together is carried out in the case where only cables exit from the box to the sockets.

In a situation with a single-key lamp, you will need to twist one of the phase wires connected to the switch with L on the switch - all phase conductors of the device. And then twist the phase wire L for lighting, going to the chandelier, with the conductor removed from the switch. As a result, we will have 4 connections.

Let's consider the situation with the disconnection process for the three-wire electrical wiring of a two-button shutdown device. You will need to lay a four-wire cable (ground+neutral+1 phase on+2 phase on) for a chandelier with double switching. In the two-wire version, three wires are sufficient, since there is no need for ground. Let's look at the diagram for the last case.

As you can see, the result is four twists. In this case, we do not take into account the connection point of the grounding conductors. Without exception, all blue zeros must be connected to each other.

The phases are also twisted together on the sockets, on the common terminal of the switch of a two-key design with two conductors going to the lamp bulbs independently of each other, and the power cable. You can consider this process in more detail in the article on connecting lighting fixtures.

Even without extensive experience in electrical work, wiring a box on your own is not that difficult. If any faults are found, carefully check the wiring diagram.

The main thing that is required of you is to strictly adhere to all the provisions of the instructions, to exercise caution and accuracy during the work. And also follow the golden rule of professional electricians - never show excessive haste in order to protect yourself from negative aspects during the operation of the wiring.

Installation of components

All devices mounted in the electrical panel have unified standard dimensions, which greatly facilitates their installation. The main fastening is a DIN rail made in the form of a metal profile. Seats are measured in modules. This unit corresponds to one space occupied by a single-pole circuit breaker.

When calculating the number of places that need to be provided in the panel, it is necessary to take into account that two modules correspond to a two-pole circuit breaker, and three modules correspond to a three-pole circuit breaker. A single-phase RCD requires two modules, a three-phase one requires four. One terminal block occupies one module, and an electric meter may require 6-8 modules, depending on its design.

It is recommended to assemble the shield in an apartment on a flat and level surface, for example, on a table. Performing this procedure on the wall is much more difficult and inconvenient. In any case, the mount for the shield is installed even before it is filled with equipment.

The input automatic protection device is always installed first. Further, the schematic diagram can be implemented in practice in two versions:

- The linear diagram assumes the location of all RCDs after the input circuit breaker, and behind them there are automatic circuit breakers. In this case, it is very difficult to detect a fault on the line.

- Group scheme. First, a common RCD is installed for the entire group, and then the machines are installed. In this case, in the event of an accident, only one group is switched off, while all the others continue to work.

The cable connection is

I was once asked to take photographs of how I disconnected distribution boxes so that this work could be visually represented. This is the first time someone has to do this and at first they don’t seem to understand how it all happens. In principle, there is nothing complicated here. Below you can see this. If you have the desire, then you will definitely cope with this work the first time)))

While doing work at one site, I had the opportunity to photograph the switching box connection step by step, which I did. Below there will be many photos and few words. Enjoy watching )))

At the first stage, all distribution boxes are attached and the necessary cables are inserted into them. They can be on the ceiling, in the wall, etc.

Stage 1. External insulation is removed from the cables and all cores are distributed into groups (connections). That is, those wires that need to be connected together are bent into a separate bundle and tilted to the side so that they do not mix with other wires.

Below is an example of how cables are connected to outlets in a distribution box. This is a simple diagram. Here all the wires are stupidly separated by color and connected in the same way. In light line boxes the situation is different. They can connect wires of different colors.

Stage 2. Next, GML sleeves of the required cross-section are selected and the cores are stripped to their length. The sleeves are placed on bundles of wires. If there is still free space in them, then you need to take the stripped section of the core and hammer it inside the sleeve. In other words, you need to make sure that the sleeve itself is completely filled.

Unplugging boxes

Disconnection of the distribution box (Wiring) is carried out by an experienced specialist.

According to the PEU, electrical connections of wires should be made only in junction boxes. By contacting Efas LLC, you can be confident in the reliability, quality, and durability of this work. We provide a 5-year warranty on the wiring of junction boxes . Very often you can find a poor-quality connection of wires, which can cause a fire, or simply a loss of voltage in an apartment, house or workplace. Remember that now there are a lot of “specialists”, but not many will perform high-quality wiring of the box .

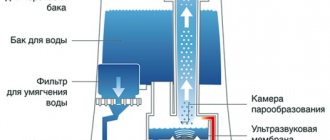

Electrical panel installation

There are many types of electrical panels with different sizes. The size of the panel is selected taking into account the number of electrical appliances that need to be placed in it. The electrical panel contains a zero bus, a protective grounding bus, a Din - rail for installing automatic machines, an RCD, and a voltage relay.

Separately, below the rows of machines there is a special cable duct with slots for the cable cores to exit. If the switchboard box is metal, then there should be a welded bolt with a nut inside it to connect the protective grounding. A grounding bolt is also installed on the switchboard door.

At the bottom of the box there are holes for cable entry. These holes are equipped with plastic bushings to protect the cable insulation from mechanical damage. The left hole is usually used for the input cable.

The din rail is cut to length depending on the number of installed machines and protective equipment. After installing the DIN rail, all the necessary machines and a meter are attached. Several machines are installed in the switchboard for different groups of lighting and sockets. If the load is light, you can combine rooms using a separate machine.

Busbar for circuit breakers

For powerful household appliances - an electric stove, a boiler, an air conditioner and others - separate machines are installed, and a separate cable is laid to the sockets of these appliances. One RCD is installed after the 300 mA input circuit breaker or for each group of loads, where a separate RCD is installed after the circuit breakers. Expensive, but reliable. The owner of the house decides which version of the electrical wiring diagram to choose.

What is an electrical panel for?

The distribution panel installed at the entrance of an apartment or in a private house primarily ensures electrical safety during the operation of devices and equipment. In new buildings, they are initially provided for by the design, and in old buildings, panels are gradually replacing meters with plugs. With the help of a switchboard, electricity is distributed between groups of consumers, and reliable protection against overloads and short circuits is created.

A metal or plastic box is used to place electrical appliances. It is mandatory to install an electric meter and a general switch to completely de-energize the apartment. Shutdown can be done manually or it will happen automatically when an emergency occurs. If the introductory machine is installed in front of the meter, then it is subject to mandatory sealing, just like the meter itself.

The most numerous group of devices are automatic switches. They protect not only the wiring, but also the household appliances themselves. Each machine corresponds to a specific group of consumers, and an individual machine is installed on each powerful device. Each of them can be forced to turn off or work automatically.

In addition to automatic machines, residual current devices are installed in the panel. They compare the incoming and outgoing currents, and if the established balance is violated, they are triggered. As a rule, this happens due to uncontrolled current leaks, and the shutdown itself occurs under the influence of a current that is safe for humans.

The electrical panel contains special busbars made in the form of copper strips. Machines and other devices are connected to them. The neutral wires are connected to a separate block with terminals - the neutral bus. To connect the grounding, a special grounding bus is used.