When starting a renovation, you want the updated interior to be beautiful and remain unchanged for as long as possible. Therefore, it is important to choose a practical, durable design, among the most popular finishing options: wallpaper or painting the walls, which is better - we’ll figure it out today. We’ll also tell you which rooms the decor is suitable for and where it’s best not to use it.

No time to read? Watch the video in which we compare the two types of finishes!

Fiberglass "gossamer": application

The modern market of finishing materials is characterized by regular updating of the product range. Recently it was replenished with another multifunctional product - fiberglass for painting. It is also called painting fiberglass or simply “cobweb”.

This material is obtained by pressing fiberglass threads. Using a similar technology, regular paper is produced. The process ends with the production of thin and perfectly smooth sheets of fiberglass “gossamer”, the density of which is 25–50 grams per 1 m². It is stacked in rolls: width - 1 m; length - up to 50 m.

Preparing the ceiling for gluing

In order for fiberglass to perform its functions, the working surface must be prepared accordingly. First, remove the remains of old finishing materials - wallpaper, paint. It is advisable to remove the lime with a spatula and then wash it off with a wet cloth.

Defects and seams between sheets of drywall are sealed with putty, and after drying, these places are sanded and re-treated with primer. The joints between the sheets are additionally covered with serpyanka or paper. If there are multiple depressions or cracks, the base base is leveled over the entire area. In general, craftsmen recommend updating the ceiling before installing the web not locally, but completely.

If cracks have formed on the new plaster after drying, then you cannot glue fiberglass in the hope that it will hide the defect. It is necessary to open up problem areas, re-prime them and seal them with fugenfüller or uniflot. If the defect occurs in a room where there is still a risk of cracking of the plaster, then you also need to use paper or sickle tape for strengthening.

At the next stage, a deep penetration primer is applied. For damp rooms, use antiseptic products that will protect the room from the appearance of fungus.

Differences between fiberglass and paper wallpaper

Despite the identical production, fiberglass in some of its properties is very different from paper. Its main technological parameters include:

- high water resistance;

- increased fire safety;

- resistance to chemical reagents;

- no static charges (dust is not attracted).

On the other hand, it has properties characteristic of paper:

- the “web” contains only natural ingredients;

- fiberglass canvas is transparent to air and steam;

- protects walls from fungus and mold;

- does not cause allergies.

At the same time, its qualities resemble glass wallpaper. Why do you need a fiberglass web? Firstly, the use of painting fiberglass “gossamer” can significantly reduce the time and effort for the next repair. And secondly, it serves as an excellent tool for leveling the surface of the ceiling or walls. Thanks to it, you can easily and quickly repair numerous small flaws.

Despite the fact that this is a very thin fabric, the glued “web” is a durable reinforcing layer. It is suitable not only for hiding small cracks, but is also capable of strengthening internal surfaces, preventing their growth and preventing the appearance of new ones.

The advantages of this material should also be added:

- no corrosion;

- strength and durability;

- absence of harmful components.

How necessary is fiberglass putty?

People who do not have special knowledge, and especially those who move into a new building where the interior decoration must be done on their own, often wonder whether it is necessary to putty the finished fiberglass or whether it is enough to simply paint it. After cracks appear on the surface of the recently finished walls and ceiling, and tears and bubbles appear on the wallpaper, it will become clear that this was necessary. Especially when, when you try to remove warped wallpaper, a cobweb trails behind it.

If painting or wallpapering was done directly on fiberglass, the texture of the fiberglass, seams, and joints will certainly be noticeable, which in this case will remain uncovered. This will give the freshly decorated room a not very neat look.

Fiberglass for putty should be purchased quite dense, this will simply further enhance its reinforcing properties. Such material is more expensive than thinner ones, but this is not an option on which you should look for a way to save money. Repeated repairs when the thin web fails to fulfill its purpose will cost much more than the small price difference between dense and denser pressed material.

Fiberglass "cobweb" for painting: how to glue?

Before gluing the fiberglass “cobweb”, it is necessary to carry out preparatory work. In practice, they coincide with the operations that are performed when working with ordinary wallpaper. However, if the surface of the walls is smooth and there are no visible damages, then you can do without puttying.

The sequence of actions is as follows: we start by removing dust and various debris from the surface, in particular, remnants of old wallpaper. Then you need to prime the wall or ceiling. The primer should be applied in such a way as to prevent it from drying out immediately.

It is advisable that the drying process lasts about 20–30 minutes. It should be taken into account that the working surface must be well saturated with the soil mixture. This will determine the strength of the adhesion between the fiberglass canvas for painting and the treated surface.

For this purpose, it is recommended to use a deep penetration acrylic primer. Such a solution, applied in 1 or sometimes 2 layers, penetrates to a considerable depth. This creates a surface film that provides high adhesion to the materials applied to it.

The chemical composition of acrylic primer is selected so that it can be used in combination with many other materials. As a result, we get something like a single whole. We also note its good hydrophobic properties and the possibility of uniform application over another coating.

Application of any primer material is carried out on the basis of appropriate technological instructions. No special skills are required to apply it. As working tools, you can use a brush, roller or spray.

The primer should be applied in an even layer. Product manufacturers indicate on the packaging the recommended material consumption value. On average, it is 120–150 g per liter. The undisputed leading manufacturers of acrylic primers are Knauf and Ceresit.

When caring about the quality of repairs using fiberglass, we must not forget about the choice of glue. Perhaps this is the most important point when sticking it and for all subsequent finishing of the room. Existing adhesive compositions have different purposes and have different characteristics.

What to do if a crack appears?

If a crack does appear, it can be easily fixed. A fiber patch is glued directly on top of the putty so that its width is at least 6 cm larger than the crack.

Then take a knife, apply good pressure and make a cut around the perimeter: through the patch, a layer of putty and the old canvas. Remove the layer of putty and glue the resulting patch to the exact size. Apply several layers of putty on top. If you want to extend the life of your finish, be sure to use such an inexpensive but very useful material as fiberglass. It is especially relevant for repairing cracks in plasterboard ceilings and boxes, which often crack at the seams. If you follow the technology for installing the structure and add to this the correct reinforcement of the joints, you will forever forget about microcracks.

Popular glue brands

The most popular of them include the following brands:

Oscar - available in dry or ready-made form. Features: high reliability; if necessary, you can make small movements of the canvas during the gluing process to adjust its direction; damp rooms and low temperatures do not affect the quality of the glue.

Bolars is a special adhesive for working with Fiberfix fiberglass from the company of the same name. It is intended not only for gluing the coating, but also for minor cosmetic repairs. Distinctive properties: quick drying; environmentally friendly composition.

KLEO - used not only for gluing fiberglass, but also non-woven and vinyl wallpaper. Characteristic features: the composition is transparent; correction of the canvas during operation is allowed; absence of harmful substances; the presence of an antifungal effect.

Bostik is a thick adhesive solution. Technological characteristics: increased elasticity; resistant to heavy loads; Composition options are provided for wet areas. Even suitable for gluing bathroom ceilings.

For a particular type of fiberglass, you should select the appropriate glue. Therefore, you need to follow the recommendations and use the composition intended for the material used. At the same time, universal adhesives are also produced, suitable for all types of “cobwebs”.

Types of adhesive mixtures

Not every adhesive can be used to glue fiberglass; the solution requires high strength and a high degree of adhesion. It is optimal to use adhesives designed for glass fabrics, glass wallpaper and fiberglass. The product is available in the form of a ready-made solution or dry powder. Both products serve their purpose by providing good grip on the surface.

There are fiberglass sheets with an adhesive base; they are moistened with water before gluing.

Not every adhesive can be used to glue fiberglass; the solution requires high strength and a high degree of adhesion.

Ready-made adhesives

Gluing fiberglass is very simple, because you do not need to prepare a solution. Most often, polyvinyl acetate or polyacrylic is used in the composition; drying occurs after the water evaporates. The popular glue for spider webs is acrylic, due to its low consumption; applying a thin layer is sufficient. The adhesion will be excellent.

Special adhesives in the composition are also supplemented with other elements: plasticizers, polyvinyl alcohol, colloidal additives, they allow you to obtain a more reliable bond without delamination. Antifungal elements can also be used.

The popular glue for spider webs is acrylic, due to its low consumption; applying a thin layer is sufficient.

Dry powder

Pasting walls with fiberglass can also be done with dry powders. Before use, they are diluted with water; the ratio is always written on the packaging.

Components of the powder:

- Modified starch;

- Methylcellulose;

- Dry PVA;

- Technological elements.

Re-wetting is unacceptable, so you should not choose to paint the surface with water-based paint products.

It is also undesirable to paste the material in rooms with high humidity. Although there are compositions with additives that improve moisture resistance.

Before use, they are diluted with water; the ratio is always written on the packaging.

Features of gluing glass wallpaper. What is the fiberglass “cobweb” glued to?

Gluing is done in the usual way. Apply glue with a roller to a section of the surface whose dimensions are slightly larger than the prepared canvas. We apply the sheet and use a spatula to ensure that it fits tightly. Then we soak it on top with a layer of glue.

Using a spatula, you need to go over the surface of the sheet again in order to rub in the glue and distribute it evenly. The entire surface without gaps should be covered with a layer of glue 1–2 mm thick. The sheet, once completely saturated, will darken slightly from moisture.

Preparing the next sheet. We apply glue to the surface with an overlap on the previous canvas. We glue it in the same way, then after saturating it, we begin to press it. To obtain an even and invisible seam at their junction, use a knife to cut a line through both layers (the strips are removed).

The resulting joint is additionally impregnated with glue. After about a day, you can move on to the next stage. To prepare fiberglass for painting, you need to apply at least two layers of putty. As a result, its texture is smoothed out, and paint consumption becomes minimal.

Important nuances

If the finishing is not done by hand, but by craftsmen interested in its speedy completion, they may insist that the surface can already be painted. If you do not putty the fiberglass, then you will have to apply 5-6 times more paint on it, because fiberglass has a high ability to absorb. To glue wallpaper, it is even more necessary to prime the fiberglass and apply a putty layer, because the entire texture of the glass fibers will be clearly visible, and a lot of wallpaper glue will also be used up.

In the future, a large amount of wallpaper glue can lead to damage to the wallpaper under the influence of external conditions. So the question of whether it is necessary to prime and putty is decided positively if the owner wants an excellent look and guaranteed durability of the result.

Even a non-specialist knows how to putty. The finished composition is applied with a spatula as the first layer, it is allowed to dry, then the second is applied, which is sanded after drying with a grinding machine, float or sandpaper. And only then can you paint or wallpaper.

How to putty on fiberglass (1 video)

Different types of putties for fiberglass (23 photos)

Types of fiberglass for painting

Manufacturers produce three main types of “webs”, differing in linear density. The density of the first option is 25 g/m2. As a rule, they are used to cover ceilings. Due to its lightness and transparency, it is easier to glue and absorbs paint the least.

The second variety with a density of 40 g/m2 is used most often. This type of “cobweb” is used to cover ordinary walls that are subject to stronger deformations than ceilings. It is also suitable for finishing the ceiling, as well as in rooms with high vibration.

The third option with a density of 50 g/m2 is the most durable material of this type. It is used to close large cracks and openings in walls. It is used to cover large premises (shops, showrooms, workshops) that are subject to significant damage.

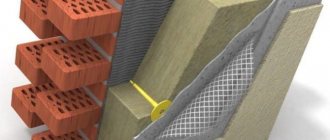

Construction sites where fiberglass is used: residential premises, hotels, offices, medical institutions. The basis for it can be various types of surfaces (concrete, brick, wood, metal), as well as plasterboard, chipboard and fiberboard.

Painting fiberglass is a multifunctional material designed to solve a number of problems:

- surface reinforcement;

- fixing plaster, putty

- preventing cracks.

The painting web, after completing the process of gluing it, is puttied and painted. The putty should be applied in several layers - at least 2, and preferably 3. The recommended thickness of one layer is no more than 1 mm. The main thing is that each layer should be applied evenly without differences.

To apply the top layer, a special finishing putty is used. It has a soft structure that can smooth out all unevenness. The third layer should have a minimum thickness. In practice, you don’t have to apply it; just use a spatula to smooth out any errors.

Applying putty to the ceiling requires special attention. Defects in operation can most clearly be detected through side lighting. And here, the main goal is the most uniform layer thickness. Sanding can begin after the putty has dried.

As a rule, it takes at least a day for the fiberglass to dry completely. As a result, the wall color becomes white and the surface becomes smooth. It is recommended to apply the paint after priming, since the material is characterized by high porosity.

Fiberglass: coating features

Fiberglass wallpaper is a decorative covering that feels like thick fabric. The basis of the material is a special type of fiber (analogue of fiberglass), but they are not only used to make pressed fabric, but also form decorative weaving of various types. This is both a reinforcing and decorative material that will last for several decades, and the paint can be renewed 6-7 times.

The stores offer glass wallpaper of various thicknesses and textures: from primitive zigzags and stripes to floral ornaments and complex patterns. You can apply this wallpaper to any surface: cleaned brickwork, metal, wood, concrete, plastic, chipboard, drywall.

Painting the "cobweb"

You can begin painting the fiberglass after sanding it with fine sandpaper. To improve paint adhesion and reduce its consumption, it is recommended to treat the surface with a primer. The algorithm for applying the paint coating is as follows:

- mix the paint thoroughly;

- pour paint into the tray and dip the roller into it;

- release the tool and start painting from top to bottom;

- let the first layer dry and apply the second layer;

- Touch up hard-to-reach places with a brush.

Why do we need personal protective equipment?

Fiberglass adhesive contains complex chemical compounds similar to PVA. Toxic fumes from covering walls with canvas can cause poisoning in workers and even cause hallucinations.

Since the work is carried out indoors, and there is no way to ventilate the room, you must wear a respirator.

Harmful fumes can negatively affect the outer shell of the eyes, in this regard, glasses are a necessary element of protection.

Fiberglass particles are hard, sharp “needles.” When cutting rolls and seams of fiberglass coating, there is a danger of sharp particles getting into the lungs. The respirator will not allow fiberglass needles to pass through.

If glass dust comes into contact with exposed areas of the body, it can cause irritation and burning on the skin. The work uniform must be such that harmful dust does not penetrate under it. At the end of work, work clothes should be washed thoroughly.

Conditions for storing and using fiberglass

Fiberglass is a reinforcing material characterized by such qualities as high mechanical strength and lack of susceptibility to rotting. Storage conditions: closed dry rooms; relative humidity not higher than 80%; temperature - not lower than 0 °C.

Racks or pallets can be used for storage. Rolls are stored on the end. At the same time, no more than 6 can be stacked in height when they are packed on a pallet, and no more than 8 - without a pallet. Warranty - 12 months from the date of manufacture.

Painting of fiberglass must be done in 2 layers. As already noted, the first layer is applied after its surface has dried. As a rule, not earlier than a day after pasting. The interval between the first and second layer is 12 hours.

When performing various works with fiberglass, it is necessary to observe certain precautions aimed at preventing small particles from getting on the skin, mucous membranes, and into the respiratory tract. It is necessary to use a respirator, goggles and special clothing.

Preparing fiberglass for painting can be done in the following way. The main thing that needs to be achieved is to reduce excessive water absorption. For this purpose, you can use a deep penetration acrylic primer or primer-paint.

Gluing fiberglass can only be done under certain conditions in the room being renovated. The air temperature should be in the range from + 18 to + 25 ° C, and the air humidity should not exceed 60%. Drafts and direct sunlight should also not be allowed.

The following indoor air parameters are suitable for painting fiberglass: temperature from +5 oC to +30 oC; humidity - no higher than 75%.

To paint fiberglass, you can limit yourself to the following set of tools:

- roller with tray or spray bottle;

- brush;

- masking tape and oilcloth.

The final coating of fiberglass is done using water-dispersed paints: acrylic, latex and silicone. They do not affect their properties and also have good performance. In particular, they are environmentally friendly and odorless.

Advantages of fiberglass:

- This is one of the most durable wall coverings: it does not scratch, does not tear, is resistant to moisture, their strength qualities are 2-3 times higher than those of vinyl;

- Wallpaper does not attract dust and does not accumulate static electricity;

- Mold or mildew does not grow under them;

- Non-flammable, do not emit toxic substances;

- The gluing technology differs little from the traditional one.

Fiberglass wallpapers are more expensive than non-woven or vinyl counterparts. One of the significant drawbacks is the minimal amount of painting: after 3-4 layers of paint, the texture begins to blur. By the way, only latex or acrylic paint is suitable for this material - it is less dense. And one more thing: glass wallpaper will be difficult to remove from the wall, since they are glued “tightly” as they say.

Features of water-dispersed paints

Acrylic compositions have gained the most popularity. Main advantages:

- good adhesion and quick drying;

- affordable price;

- moisture resistance.

The price of latex paints is higher than acrylic paints. This also applies to their operational properties, expressed in:

- increased wear resistance;

- durability;

- formation of a glossy surface.

Silicone paints are the most expensive solutions. They are characterized by all the already listed positive qualities of the compositions discussed above. At the same time, they are devoid of their inherent disadvantages. In addition, they have dirt-repellent properties.

Fiberglass: what are they?

Broadly speaking, the product is called fiberglass wallpaper. This is a coating that has a structure similar to fiberglass fabric. The material used is special glass. So, at a special temperature, fibers are drawn out of it. Then specialists form the yarn, and after that the material is created. Beautiful patterns are woven to create products.

It is important to choose the right glue for glass wallpaper: there are several variations of the substance. The better the composition, the easier it will be to glue the material, and the longer it will last on the walls.

Advantages and disadvantages of the material

The very first thing that should be considered a plus is fireproof glass wallpaper. Many experts recommend finishing even fire escape routes with this coating. Due to the fact that glass wallpaper is resistant to fire, toxic substances cannot enter the air.

An important advantage of glass wallpaper is its high environmental friendliness. During manufacturing, specialists use only natural, environmentally friendly ingredients:

- limestone;

- clay;

- quartz sand;

- soda.

Impregnation of glass wallpaper is carried out using a special stabilizing composition made from modified starch. Let's consider the main properties and applications of products. Fiberglass wallpaper has increased strength. Fiberglass is also used in mechanical engineering; during pasting, a reinforcement effect can be achieved.

If you want to protect your walls from accidental damage, then this option is ideal. Many residents of new buildings make their choice in favor of this material.

Some more important advantages of the material:

- The service life of the products is 30 years. In other words, during this time you can simply forget about repairs.

- Glass wallpaper breathes, creating an optimal microclimate in the room.

- Very easy to care for. So, for cleaning you can use any means, except for too aggressive chemicals.

- The surface of the product prevents the formation of various microorganisms. This means that the walls will be reliably protected from fungus and mold.

Among the disadvantages are: the material is expensive and requires further processing - glass wallpaper needs to be painted. It is also important to choose the right adhesive mixture and apply it - if there is an excessive amount of solution, the wallpaper may lag behind the wall due to its heaviness.

Recommendations for selection

Proper implementation of pasting is half the battle. First of all, it is necessary to choose the right material itself, as well as the adhesive solution for it. If the glass wallpaper is of high quality, then it will serve for many years, maintaining a presentable appearance. Poor-quality glue and fiberglass will disappoint, even if the pasting is carried out by highly qualified specialists.

How to choose glass wallpaper so that the final purchase does not disappoint? When purchasing a product, the consumer must be as careful as possible. For example, some unscrupulous sellers may fluff the fibers so that the design appears embossed. As soon as you start gluing the product, it smoothes out, and at the same time all the fluffiness disappears.

In order to make the fabric denser, some people impregnate it with starch. The substance dissolves in the glue, and in front of you is a low-quality material without relief. To avoid such embarrassment, before purchasing, ask to glue a small piece of canvas to the wall. So, if there are any pitfalls, they can be detected immediately.

In addition, if the glass wallpaper is really high quality and certified, then the seller is obliged to issue a warranty card. Unfold the roll - small particles should not break off from it, and there should be no cracks.

Perhaps the best option is to buy adhesives and glass wallpaper only from trusted manufacturers, if finances allow. However, before making a purchase, we recommend reading reviews about the manufacturer and its product on the Internet.