Door installation

A simple door closer can be easily made with your own hands from a piece of rubber.

The elastic material meets all the requirements for the product: it stretches and contracts with a force sufficient to return the door to its zero position. The rubber density must be selected depending on the weight of the door leaf: the heavier it is, the thicker the tape should be used for the door closer. When installing the device, the ends of the tape are secured as follows:

- the first - on the frame at a distance of 5-10 cm from the plane of the canvas adjacent to it;

- the second - on the panel itself.

Another option for making a closer - gravity - involves the use of a cable with a load. The end of the cord should be attached to the canvas at the top. For reliability, a metal plate with a hole can be used: it is easier to tie a cable to it.

To make a block mechanism, you need a bracket with an axle (for example, from a broken furniture roller or skateboard). If it is possible to use a ready-made block, the task becomes easier, but if it is not available, you can do it in 2 ways:

- the cable is simply thrown over the axle;

- make a wheel with a groove for the cord and install it in the bracket.

In the latter case, the cable will slide more easily. It will be possible to attach a weight to the free end of the cord that is sufficient to pull the door leaf to the frame.

Car enthusiasts have the opportunity to make a door closer with their own hands from the lifting mechanism of the luggage compartment of a sedan or hatchback car. This unit is distinguished by the presence of shock absorption and smooth opening functions. The device must first be modified by attaching plates with holes for attaching to the door frame and leaf.

It is easy to make a compact closer from a small holey rubber ball or a medical bulb:

- The round rubber product is attached to a wooden or metal plate using screws.

- The structure must be installed on the frame from the outside so that the edge of the ball is at the level of the junction of the box and the canvas on the hinge side.

- Place a metal corner on the door that opens outward, close to the ball, the length of one side of which is equal to the diameter of the ball.

When opened, the corner will compress the ball, squeezing the air out of it. By expanding, the ball will force the door to return to its original position.

A magnetic latch is more appropriate on an interior door. It does not perform a closing function, but reliably holds the door in the closed position in the event of a slight draft. To make the structure, you need a strong magnet and a small steel plate. The parts are attached to the frame and canvas so that when the door is closed they overlap each other. If the thickness of the elements is too large, then you can make recesses in the wooden door for them.

You can install a homemade or factory-made door closer according to the rules common to all options:

- find the maximum door opening angle;

- make markings for attaching the ends at the desired height or location;

- make holes for fasteners;

- strengthen the ends of the spring or other type of structural parts;

- If necessary, adjust the tightness of the sash.

Door hinges first appeared in human life a long time ago. The first of them are made from genuine animal leather. Some intertwined with each other using tree branches. Later they made special metal plates. Today there are a large number of different parts made from different materials. Each of them performs its own functions. They are comfortable and have decorative functions. Decorate the structure and interior. Loops are distinguished by several criteria:

- material of manufacture – brass, steel, bronze, etc.;

- installation method: cutting-in, by overlaying and screwing in;

- Features of the design of mechanisms: screw-in, mortise, overhead, angular, double-sided.

Door one-way spring hinges

Invoices are a classification of an element that is more common and popular than others. This is due to simple fasteners and an affordable price. Attaching them is not difficult, since it is enough to fix them with self-tapping screws to the surface of the door frame and leaf.

Mortise products are structures that are no different in manufacturing from overhead types. They differ in the installation method. Canopies of this type are cut directly into the surface of the door. In order to make the cut, use a chisel.

Hidden and screwed in at the same time. This is not a very common option for door hinges. This can be explained by the fact that they have a complicated installation, especially for beginners. They are placed inside the door frame and leaf. Hidden door hinges for opening in both directions cannot be removed or sawed after installation. To do this, complete dismantling is performed.

Corner products. From the usual loops, which differ in that the design of traditional cards does not contain. In their place are corners and hinges that are attached to each other. A positive characteristic of such elements is the possibility of equipping doors with a rebate.

Double-sided loops are parts that are similar to card loops, but have differences. Spring hinges have special springs inside.

Double-sided spring hinges

Double-sided loops with springs differ from the usual card design in that they contain two cards located on pins. There is a spring inside this element. It helps return the door leaf to its original position.

Spring hinges with closer

- right-hand opening,

- left-hand opening.

Left- and right-hand ones can only open in a certain direction, while universal ones swing open in both directions. Bar hinges have features, pros and cons.

Bar hinges

The installation of spring structure parts is no different from the fastening of conventional mortise or overlay type elements. To complete the process, follow the correct sequence:

- first measure and make a mark with a marker for the hinges on the door frame, on the canvas;

- to release the spring, remove the stopper from the two cards;

- Insert a special pin into the hole located on the bushing and turn clockwise;

- attach the released plates to the intended marks and fix them with self-tapping screws, it is important to adhere to the dimensions to the nearest millimeter;

- before the loop is installed, it is unclenched, and after installation is completed, it is compressed;

- compress the springs, but to do this, close the doors;

- turn the pins on a separate card and insert the stopper;

- Initially screw the springs to the canvas, and then to the box.

Installation of spring hinges

If you are planning to install spring hinges on interior or entrance doors, you need to familiarize yourself with some of the features of this type of product. This will help you better understand the principle of operation of the mechanism and prevent installation errors.

The specifics of installing spring hinges differ from conventional models

First of all, you should find out what the distinctive features of spring hinges are. This type of door hardware may not be any different in appearance from conventional card models, which are often installed in residential buildings.

Very often, spring hinges are installed on the entrance doors of shops, offices, cafes and similar establishments, as well as utility rooms.

The main difference from conventional models lies inside the structure; the fact is that the loop cavity on the pin contains an additional element - a spring, which returns the blade to its original position. Thanks to this detail, this fitting has received special recognition. There is also a more advanced model - a universal pendulum hinge, it is designed to ensure two-way swinging of the door and bringing it to its original position, this is an ideal option if your hands are busy.

- What is a door closer?

- Door closer options

- How to install a door closer: instructions

- Non-standard solutions

A loudly slamming door or a door that won’t close – what could be worse? Installing a door closer yourself will correct the situation. Such a mechanism will provide soft, strong closure, while it will be compact and with a high level of reliability.

A closer is necessary to close the door softly and tightly.

Traditional springs and bulky counterweights no longer provide adequate comfort and convenience when closing/opening a door. Installation of the door closer is quick and you can handle the work yourself.

Door closer installation diagram.

- First, a design is selected that is most suitable for a particular situation. For a door with a weight of up to 20 kg and a width of up to 750 mm, an EN1 type door closer is suitable, and for a door leaf with a width of 850 mm and a weight of up to 40 - EN2. If the door is heavy, reinforced or armored, then it is best to use 2 door closers at once to be able to evenly distribute the load.

- Next, you need to select the location where the structure will be located. The direction of opening of the door leaf must be taken into account. If the canvas opens towards itself, then you need to place the product on the side of the hinges in the upper part. If the door opens “pull”, then a lever is fixed to the door leaf, and the device itself is mounted directly on the door frame. All closers are mounted in the same way.

- The installation diagram is applied to the canvas and the jamb, after which the holes for fastening are marked. The diagram is supplied with the design.

- You must drill holes for fasteners yourself; the diameter must match the fasteners. If the door leaf is made of metal, then it is necessary to use so-called bonks, which prevent the structure from deforming at the installation site.

- Self-tapping screws are used to strengthen the body of the product, the rack plate, and the lever shoe. Next, the mating part is fixed to the door closer body, and the lever is connected at the knee.

- The lever must be adjusted; it should be at an angle of 90 degrees relative to the door. If the design is with a clap, then the lever will move towards the closer, if without a clap, then in the opposite direction.

- After installation, you need to adjust the force. The door should be opened and assessed at what speed it closes. If necessary, the speed is changed using special adjusting screws.

- During installation, please note that some models may have additional functions. These include special braking for an open door. These options also require adjustment.

Types of door hinges

The first door hinges in human history were made from animal skin, tree branches tightly woven together, and only much later - from a rough metal plate. Today, door canopies perform not only a practical function, but also a decorative one, decorating the door and the interior as a whole. Types of canopies differ according to several criteria:

- the material from which they are made (steel, brass, bronze, etc.);

- installation method (overlay, screw-in, insertion);

- design features of the mechanism (overhead, mortise, hidden, corner, double-sided).

Let's look at the last classification in more detail:

- Invoices. Hinges of this type are the most popular, due to their ease of installation and low cost.

To install overhead hinges, it is enough to secure them with self-tapping screws on the surface of the door frame and the door itself.

- Mortise. The design of these hinges is almost identical to overhead hinges; the only difference is in the installation method: hinges of this type are cut into the surface of the door.

Installation of mortise hinges requires experience with a chisel

- Screw-in, hidden. These are not the most popular hinges, which is explained by the fact that they are quite difficult to install (inside the frame and door leaf), and after installation, the door leaf cannot be removed without completely dismantling the hinges.

If it becomes necessary to remove the door, you will first have to remove the hinges

- Angular. They differ from all others by the absence of classic cards. Instead, corners are fitted to the central hinge. The advantage of such hinges is the possibility of installing hinge doors on doors with a rebate.

The advantage of corner hinges is that they can be installed on rebated doors

- Double sided. Outwardly, these canopies are similar to ordinary card canopies, but they have their own fundamental differences.

Spring hinges differ from simple double-sided hinges by the presence of a spring

How does the closer work?

A standard door closer is divided into three components:

- main fastening body;

- barbell;

- fastening element.

There is a spring inside the device body, which compresses when the door is opened. As soon as the canvas is released, it will begin to return to its original state. A special composition helps slow down this process and make it smooth - due to its viscosity, it prevents the door from abruptly slamming.

One of the internal mechanism options

The case has two compartments, in one of which the composition remains as long as the door is closed. When the composition changes, the oil flows into the second compartment, where the spring movement is inhibited.

The spring is closely connected to the rod - a movable element of the mechanism that connects the main body and an additional one - attached to the wall or door (depending on the model).

The device and functions of a door closer for closing doors

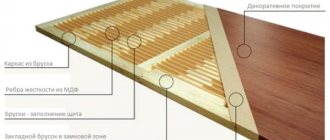

A gear and rack based closer consists of the following elements:

- Lever rod . Provides coupling between the mechanism drive and the door.

- Spring block . It contains a spring that serves as the main “engine”.

- Hydraulic cylinder . A sealed cavity filled with working fluid. Responsible for the speed and force of closing the door.

- Gear drive . Charges the spring through a system of gears and moves the linkage in the opposite direction.

- Adjustment screws . Necessary for adjusting device function parameters.

Spring models do not have a hydraulic cylinder. This is outdated technology. The cam mechanisms are complemented by a shaft with a heart-shaped cam, which acts as a closing speed regulator.

In addition to products with the main function of smoothly closing doors, there are accessories that can solve auxiliary tasks:

- Damping . Balancing the door opening speed if it is affected by a sharp gust of wind or human muscle force.

- Fixing the open position . Secures an open door to allow cargo to be carried through the entrance area.

- Closing delay . Allows the closer to operate only after some time, usually 30 seconds.

- Dokhlop . Acceleration or deceleration of the door movement approximately 15 ° before “meeting” the lock in the box.

There are mechanisms on the market without linkage . For them, the role of a connector is performed by a bar sliding in a profiled channel. The modification is more aesthetically pleasing and resistant to vandals: it is difficult to break.

Using a weight as a slamming mechanism

Before you make an automatic door closer with your own hands, you need to have an idea of what it should ultimately provide. The main function is shock absorption - preventing the door leaf from hitting the frame. Along with this, the following functionality is highlighted:

- adjustment - the ability to set the closing speed;

- attraction - if the closure is not tight, the mechanism will close the door itself;

- fixation - the ability to fix the closer in one position.

Its closing mechanism must attract and smoothly close the door. For these purposes, ready-made parts from cars or improvised means are used.

One of the simple and affordable ways is to install a spring as a closer. The advantages of this method include:

- ease of installation;

- availability;

- possibility of exposure regulation;

- relative aesthetics.

Springs have a number of characteristics, due to which the optimal option is selected. There is no clear formula for which spring to use for a door of a certain weight. Therefore, you will have to choose empirically.

Simple spring mechanism

This method is becoming one of the oldest and is rarely used today. With this method, a cable or rope is attached to the door leaf, the second end of which is passed through a wheel attached to the wall or frame. A weight is attached to the end, which closes the door. Its weight has to be selected manually, since there is no exact formula for calculating it.

The advantages of this method include its low cost, simplicity and efficiency. If necessary, you can even lock the door.

The obvious disadvantage is that while moving, the load swings and hits the door or frame. In order not to spoil the surface, it is placed in a pipe with the appropriate diameter. This approach will preserve the door and give the composition a more attractive and neat look.

After the fastening is completed, you should check how smooth the movement is; if something is wrong, make adjustments.

When making adjustments, it is important not to overdo it in tightening, as the spring can be torn off. When this process is completed, the installation part can be considered complete.

The most common type of closers are springs. It is not difficult to install a spring closer with your own hands, and the durability of the device is superior to other homemade designs. There are 2 options for installing the closer:

- in the middle of the box;

- on the top.

The last option is used if you want to hide a spring that is not decorative.

The spring stiffness must be selected depending on the weight of the door. To prevent the sash from slamming when the spring contracts, it is worth installing a shock absorber. The material for it can be a thin rubber hose: it will not prevent the door from closing smoothly when the door is close to the zero position.

The ends of the spring closer are attached to the frame and canvas with special plates with hooks. When installed on the side of the box, fastening to the frame is done from the hinge side. Depending on the distance from this point to the fastening on the leaf, you can adjust the force of slamming the sash.

The top installation option can be different, and the door closer can be fixed with your own hands in any convenient place on the upper side of the frame and near the edge of the door leaf.

It is convenient to install the shock absorber at the junction of the canvas and the frame on the side of the hinges. You can secure the hose with glue (liquid nails) or self-tapping screws. When the spring is activated to close, the edge of the canvas will rest against the rubber product, and then will be gently pulled towards the frame.

DOORS - AUTOMATIC | MODEL CONSTRUCTION

There are so many devices that can be invented to make the front door close on its own. These include special spring loops, cargo devices with counterweights and a block system, and all kinds of springs or rubber strips. There are also those produced by industry, however, unfortunately, they are not without drawbacks: some are too complex and quite expensive, others are inconvenient to use or unreliable, and quickly fail. Therefore, home designers continue to solve these problems on their own, as evidenced by the proposed selection of materials sent by readers. In winter, the entrance doors of our houses are often left open. This leads to excessive consumption of energy required for heating staircases. To preserve precious heat, simple automation is needed.

However, you can do without mechanical devices by ensuring a slight tilt of the entire door frame. The main drawback - the door hitting the frame - can be easily eliminated by laying strips of thick rubber along the vertical part of the door frame.

Rice. 1. Spring door closing mechanism:

1 — rubber shock absorber, 2 — door, 3 — spring.

To ensure tight closure, use a device with a weight connected to the door using a cable passed through a block. Depending on the installation location of the latter, the returning moment will either increase or decrease. To limit the angular velocity of the door when closing, the load is placed in a vertical cylinder filled with some liquid, preferably mineral oil. Under the influence of weight, the load will fall in a viscous medium, which will limit its speed and, accordingly, the angular speed of the door. The gap between the pipe wall and the cylindrical surface of the load should be no more than 1 mm.

Self-installation method

Let's look at how to properly install spring hinges. In general, their installation is not much different from conventional overhead models. The work is carried out in the following sequence:

- Mark the position of each half of the hinge at the end of the door and on the frame.

- Remove the stopper from both cards to release the spring. To do this, insert the pin into the hole on the sleeve and turn clockwise.

- Attach the plates and secure them with self-tapping screws according to the diagram below.

- After this, it is necessary to compress the springs. To do this, in the closed position of the door, alternately on both cards, by turning the pin clockwise, compress the spring and insert the stopper.

- Check the operation of the system and adjust the spring if necessary.

This completes the installation. Periodically it will be necessary to check the operation of the hinges and adjust the compression, since the springs weaken during operation.

Installation diagram of spring hinges. 1) spring 2) hole in sleeve 3) stopper 4) screw 5) top nut

Adjusting the hinges must be done extremely carefully, otherwise you risk breaking the spring.

If you did everything correctly, the door will open freely and then attract itself to the frame. It may be necessary to add a couple of degrees of inclination to make the task easier.

- Instructions for installing double-sided spring hinges Download 636.89 KB

Let's look at how to properly install spring hinges. In general, their installation is not much different from conventional overhead models. The work is carried out in the following sequence:

- Mark the position of each half of the hinge at the end of the door and on the frame.

- Remove the stopper from both cards to release the spring. To do this, insert the pin into the hole on the sleeve and turn clockwise.

- Attach the plates and secure them with self-tapping screws according to the diagram below.

- After this, it is necessary to compress the springs. To do this, in the closed position of the door, alternately on both cards, by turning the pin clockwise, compress the spring and insert the stopper.

- Check the operation of the system and adjust the spring if necessary.

If you did everything correctly, the door will open freely and then attract itself to the frame. It may be necessary to add a couple of degrees of inclination to make the task easier.

Open position

In some cases, it may be necessary to hold the door open for quite a long time. Let's look at how to adjust the door closer so that the doors do not slam, but remain open.

Many door closer models have a special “hold open” function for this purpose. To set it to this mode, you need to open the door about 90 degrees and then tighten the special lock. After such simple manipulations, you will be able to leave the door open when swinging it open to the set degree. A special lock will work in the closer, which will hold it in this position for as long as necessary. When it is necessary to close the door, simply pull it towards you and the lock will be released. If the door is not fully opened, it will move as usual, without delay.

Additional functions of the closer are adjusted with screws specially designed for them.

Rubber door closers

To make such a door closer with your own hands, the thrifty owner will not have to spend money. They can act as an attracting and shock-absorbing device;

- pieces of rubber;

- pears;

- hoses or tubes.

Example of pipes suitable for use

Located on the door leaf, these elements are easily deformed when the door is opened, but just as easily restore their shape, ensuring the door closes.

The advantage of this type is its cost, ease of installation, and the ability to regulate mechanical force. Rubber has different densities, which allows you to select the best options for a particular door. The only drawback is that it is not aesthetically pleasing, since a piece of rubber or a pear as a closer does not look very attractive. However, for storage rooms and other non-public premises this is the best option.

Features of spring hinges

A double-sided spring hinge is fundamentally different from a classic card hinge and consists of two cards on pins, inside of which a spring is installed that returns the door leaves to their original position. Depending on the direction of opening of the door leaf, spring hinges can be: left-handed, right-handed or universal. Left-handed - opens only on the left side, right-handed - on the right, universal - in both directions. Bar canopies have their own characteristics, advantages and disadvantages.

Advantages

The main advantage of bar hinges is their ergonomics, as well as the high throughput of doors equipped with them. The double spring hinge has the following advantages:

- ease of opening the door (using the body) when your hands are busy;

- preventing heat loss in the room through the door;

- the possibility of unhindered passage of a large number of people;

- preventing the formation of drafts in the room;

- automatic door closing.

Flaws

Door spring hinges, well made and installed correctly, have only one drawback: cost. The price of such canopies is several times higher than the cost of classic card canopies.

Options for door closers that you can make yourself

This is a special design used for smooth movement of the door leaf. The door closes automatically; there is no need to pull or slam it. The closer performs several tasks:

- Fixes the blade in the open position.

- Provides smooth closing of the door, without the need to pull it towards you.

- Protecting the structure from damage when hitting an obstacle.

- Possibility of two-range adjustment at the moment of slamming.

Door closer device.

The main element of the mechanism is a spring; it accumulates energy, returning the door to the closed position. An oil shock absorber is used for smooth running of the blade. It is this that ensures the absence of such an unpleasant moment as a loud bang and too abrupt closing. Oil flows from one chamber of the device to another when the door opens/closes.

The installation of a door closer does not depend on its type, but in order to choose a reliable and durable option, you need to pay attention to the design features. Today, manufacturers offer different product models that differ in installation location and appearance.

Overhead closers are used most often. The housing is mounted in the upper part of the door leaf. Depending on the type of spring used, door mechanisms can be classified into models:

- with gear drive;

- with a sliding rod type.

Internal design of a toothed door closer.

In the first case, the design has a lever that is connected to a special gear. It drives a toothed piston or pin that has a spring. The circuit is reliable, simple and durable. It is used frequently and is a favorite option for many craftsmen. The second model has a heart-shaped cam shaft, which drives the spring.

Floor-mounted door closers can be seen in shopping and office centers; they are rarely used at home. This is a sliding rod design, but in this case there are no levers at all. During installation, the door is mounted on an axle; the weight of the door closer can be up to 300 kg.

The hidden type of door closer is used when the mechanism needs to be made almost invisible.

There are several options on sale:

- With a sliding rod they are more compact and are mounted in the door leaf itself.

- Closer hinges, which are the smallest today, are mounted in the door hinges. Additional installation work is not required, since the closer and the hinge are a single mechanism.

Due to the attraction of the closer, the door fits tightly to the jamb, which is very important when installing street structures. Most often, such mechanisms are mounted on the entrance doors of apartments, garages, utility rooms, as well as in public places. If necessary, they can also be installed on interior doors.

Consequences of improper use

Despite the fact that high-quality devices have fairly high durability, they also sometimes experience premature failure.

If used incorrectly, even high-quality door closers fail

- Mechanical breakdowns of the closer: deformation of the rods, disruption of the functionality of the piston. Such breakdowns appear as a result of improper use of doors and excessive physical effort on the door leaf.

- There are situations when mechanisms use oil that is not intended for operation at sub-zero temperatures. It sharply increases viscosity, doors open/close with difficulty, and great physical effort is required.

- Sealing failure and oil leakage. The seals cannot withstand the pressure and burst. When using the doors, oil gradually leaks and air takes its place. In addition to deteriorating the appearance of the doors, the performance of the door closer is impaired.

- Installation of a rigid closer on plastic doors. These structures cannot withstand significant forces, the elements of the door frame become loose over time, and the mechanism body falls with all the extremely negative consequences.

The type of closer must match the door design

We remind you once again that the duration of use of the door closer largely depends on the consumers. If they follow all the manufacturers' recommendations, then no unexpected problems will arise.

Prices for entrance doors

Entrance doors

Homemade or factory made?

Factory closers have an undeniable number of advantages:

- easy adjustment;

- aesthetics;

- increased reliability.

In fact, their only drawback is the price: it is unwise to spend a lot of money if you need to take care of closing the door leading to the cellar, pantry or garage. In such situations, homemade analogues come in handy. With proper installation and assembly, they regularly perform the functions of a door closer, and at the same time, the cost of creating such an analogue is often limited by the price of the part itself.

Non-standard solutions

Installation options for door closers.

- If the lever cannot be mounted on the box, you should first install a mounting bracket. It is fixed in a horizontal plane with self-tapping screws, and such a lever is placed on the inside.

- The body of the device can be placed on a corner; it is fixed on the slope, while the lever is attached to the canvas.

- First, a plate is placed on the door, the closer is already installed on it, and the lever is mounted to the door frame.

- The hanging mounting plate can be attached to the frame, the closer is placed on it, and the lever with this option is placed on the door.

- The door closer is attached in the usual way, but the lever is placed on the mounting plate to increase the slope area.

It is possible to supply a door closer with non-standard sizes and shapes. They are installed for wickets and gates, ensuring comfort and reliability of use. You need to choose closers based on ease of use; installation does not depend on the type; it is important to accurately determine the point for installation.

Door closers are designed to smoothly close doors, preventing them from slamming and heat loss. It is not difficult to install the structure, but you need to choose the right place and determine whether there is a need for non-standard solutions.

Principle of operation

The most common are door closers in which the smooth movement of the door is ensured by gradual compression of the spring using a gear moving along a rack in an oil solution. Such devices can be equipped with rack tires (providing better traction) or sliding channels.

Opening a door with a cam shaft and a sliding channel requires virtually no effort, so such door closers are installed in high-traffic areas and in specialized institutions (kindergartens, places where people with disabilities live, hospitals, etc.). The smooth movement of the door in such designs is ensured by a cam pushing the piston, which, in turn, presses on the spring. When the door leaf is closed, the piston returns to its original position, and smooth movement is ensured by the second, brake piston.

The design of a factory-made device is quite complex. The spring mechanism works on compression when opening, and the smooth movement when closing is ensured by a piston system filled with oil. The mechanism housing must be sealed. Making such a device with your own hands is quite difficult.

A homemade door closer, created with your own hands, like a factory-made device, can be based on the elasticity of the material. But at home it is easier to make a lining that acts like a spring, stretching when the door is opened. Returning the closer to its original position attracts the door leaf to the frame, closing it.

The gravitational design is no less simple. The principle of operation of a weighted door closer is that the door returns to its place under the influence of gravity, which puts pressure on the weight, which pulls the door into the closed position.

Spring hinges: selection and installation

Spring hinges belong to the category of hidden double-sided awnings and have several names: bar, subway, western.

Their distinctive feature is the ability to open the door in any direction, which is why they are also called pendulum. The scope of application of such loops is in places with high traffic: bars, shops, medical institutions, industrial and retail premises. The installation of these elements has some features, which you can learn about by reading this article. Spring hinges are usually installed in high traffic areas

Choosing a closer

The more massive and heavier the door, the higher the parameters the closer should have. The selection of the mechanism is made according to a special table in exact accordance with the width of the door and its weight. According to the European standard, first class products (EN1) are mounted on lightweight doors with a width of no more than 0.75 m and a weight of up to 20 kg. Seventh class closers are respectively installed on doors with a width of 1.6 m and a weight of 160 kg.

Advice. You should not buy designs with a reserve of power, otherwise you will have to apply excessive force when opening.

Types of overhead closers

For standard street and interior doors, it is recommended to use products of classes 3-5. For entrance doors, it is better to select door closers designed for a wide range of temperatures. In this case, the oil inside the piston will not harden in the cold.

Door hinges that contain springs inside are easy to choose. When choosing, you should know what details to pay attention to. To determine what type of hinges to buy, you need to stand facing the door and pull the door towards you with your hand to determine what type of opening they have. Opening factor: if the door swings open with the right hand towards you, this is a right-hand opening. For this reason, we will consider the selection criteria one by one:

- The width of the loop plays a role and should be selected depending on the width of the fabric;

- weight of the canvas - this factor determines how many loops should be installed: from two to four;

- Now we can mention aesthetic qualities, because all the details can be different in length and color;

- common sizes are: 75, 100, 125 mm;

- colors that are often used are brass, chrome, bronze, matte or polished;

- adjusting the speed of opening and closing the doors:

- the contents of special bearings inside the part, which ensure ease and softness of movement, smoothness, and noiselessness;

- take a closer look at products that are known for quality.

Spring hinges for doors: advantages

Hinges of this type work due to the main component - the spring. When moving, it returns the door leaf to its original state, providing a slight movement in both working directions.

Spring hinges installed indoors provide the following advantages:

- Heat conservation and draft-free.

- Convenient use of doors even with busy hands by not using them, which serves as a useful function in restaurants, bars, subways, medical institutions and offices.

- Providing trouble-free passage in cases of mass gatherings and large numbers of people.

- There is no need to close the doors, since this process occurs independently.

- Possibility to install them yourself.

Spring hinges for doors have a number of advantages

The choice of spring hinges does not seem difficult. When choosing, you should take into account some features and important details, such as the direction of movement, you need to take into account the desired side where the doors will move - right/left. It is also possible to purchase universal hinges.

The width of the parts is selected according to the dimensions of the door base, which should be given utmost emphasis. The weight the loop can support must be determined immediately, focusing on standard options (about 20-60 kg per loop). Knowing the required weight, it is possible to determine the required number of loops.

Considering all the positive properties and functions of spring hinges, they turn out to be more expensive compared to conventional mechanisms.

Species characteristics are important; loops can have significant differences in length and color. Common sizes are 7.5x10x12.5 cm, colors are bronze, brass, chrome, gold, nickel. It is also worth considering the ability to control the speed of closing doors and parts that provide smooth and silent movement.

Installation procedure

1. The installation technology for all types of door closers is similar. When opening the door inward (towards you), their body should be located in the upper part of the leaf. If it opens outward (away from itself), the closer, on the contrary, is installed on the jamb, and its lever is attached to the canvas.

2. For normal operation of the mechanism, the main thing is to determine its location on the door as accurately as possible and ensure its firm fit to the door leaf. To simplify installation, a mounting diagram (template) with a scale of 1:1 is attached to each closer. It is applied exactly to the door leaf, and then the locations of the holes for fastening are marked.

3. To install the mechanism in a metal steel or aluminum profile, special threaded steel cylinders (bonks) are used, which do not allow the metal to deform.

4. Closers on wooden doors are attached to sufficiently long self-tapping screws, which will ensure maximum reliability of the connection. On plastic structures, screws are used that pass through the canvas and are secured with nuts or washers on the reverse side.

Advice. To protect the mechanism from dust and moisture, closers on street doors should only be attached indoors.

Any of these mechanisms will work correctly only if the door is installed correctly and does not rub against the floor, and the hinges allow it to move without much effort. It is better to entrust the installation of floor-mounted and hidden mechanisms to specialists: the installation of these devices is more complex and requires special calculations.

Where to put

Most often, closers are installed on external and entrance doors, as well as on gates and entrance gates. They can be found in apartments and country houses, in office buildings and commercial facilities.

In some door models, the door closer is included in the basic package. The closer must be installed on fire and evacuation doors, entrance areas with an intense flow of visitors, and in access control systems.

On doors, the housing must be indoors. The external location causes corrosion and negatively affects the operation of the hydraulics. Only frost-resistant models, protected from external factors, can be used outdoors.

Adjusting the closer

A door equipped with such a mechanism should move as smoothly as possible, without jerking. The closing and opening speed is adjusted using two screws located in the housing. Most often they are covered with a decorative panel, but they can also be located at the end of the case on the side facing the hinges. It is not recommended to completely remove the screws.

Layout of the closer adjustment screws

The spring power cannot be changed. Only the speed of movement of the door when opening is regulated: in this case, it is necessary to ensure that the door and the lever form an angle of 90° between themselves. If the mechanism is additionally equipped with a door locking function. Then the fixation installation point is also adjusted by tightening the nut on the lever.

Adjustment of closing speed and closing speed

Connect the lever to the rod

When the rod and lever are fixed, it is important to give the desired position, which will determine the speed of movement of the door before closing. The position and length of the two-piece rod can be adjusted with a long grub screw. It rotates and changes size at the same time.

Installing the rod perpendicular to the door leaf will help to achieve smooth finishing. To do this, make a setting and reduce its size. If there is a door latch, the pull must be strengthened to overcome the resistance. The mechanism is untwisted and adjusted to make it longer.

Tips for use

To increase the service life of this mechanism, you should adhere to several simple rules: • since during operation the screws can become loose and the viscosity of the oil in the housing can change under the influence of temperature fluctuations, to ensure uninterrupted operation, adjustment of these mechanisms should be carried out at least 2 times a year;

If oil leaks appear or other irreparable defects occur, the closers are removed and replaced with new ones.

Related video: Installing a door closer