For more than two centuries, a system with natural coolant circulation has been used to heat a house. Despite the advent of circulation pumps, this system has not become less popular. And this is understandable, since power outages, especially in the private sector and cottage villages, are the main reason why most owners refuse to install a pump.

Few people know that a heating system with natural circulation (NC), convection and gravity systems are one and the same. When you come across all four names, keep in mind that this refers to a system where the movement of the coolant is achieved due to the force of gravity, and not due to the operation of the pump.

The principle of operation of the gravity heating system of a private house

The gravity heating system of a private house is based on two physical principles. The first is that substances have different densities at different temperatures. The second is that the pressure in the system is created due to the difference in the levels of liquid, and the greater the difference between the upper and lower points, the higher the pressure in the system.

The first principle of a gravitational heating system is that when the coolant liquid is heated, and it does not have to be water, it changes its density. Water in its normal state at a temperature of 20 degrees has a density greater than that heated to 45 degrees; when heated to 80 degrees, the difference will be such that additional volume for water will be required. In this case, the coolant of the same mass will occupy a different volume, which is why it begins to expand and is forced out of the heat exchanger. In a confined space, after the heated coolant begins to move, the cooled coolant takes its place. So, under the influence of heating, a flow arises, and the gravitational heating system begins to work.

The second operating principle of this circuit begins to work from the moment the coolant begins to move. As water or antifreeze heats up, the speed of movement increases, since the temperature rises quickly and the expansion of volume forces the liquid to be forced out of the water jacket of the boiler at a higher speed. Leaving the boiler volume, the liquid escapes through a vertical pipe to the expansion tank. Having reached the branch level, the liquid fills the volume of the pipe and rushes along the pressure loop to the pipelines leading to the heating radiators, creating the necessary pressure. Taking into account the difference in heights between the point at which the liquid enters the pressure loop and the lower drain point, the created pressure additionally affects the cold coolant.

Gradually warming up, the system reduces the temperature difference between cold and hot coolant, and thus the speed of fluid movement in the system increases to a maximum and can even reach 1 meter per second.

Boiler - which one to choose

Since the closed heating system of a private house can operate autonomously, it makes sense to install a heating boiler with automation. In this case, having configured the parameters, you do not need to return to this. All modes are supported without human intervention.

The most convenient gas boilers in this regard. They have the ability to connect a room thermostat. The temperature set on it is maintained with an accuracy of one degree. It dropped by a degree, the boiler turned on, heating the house. As soon as the thermostat is activated (the temperature is reached), the operation stops. Comfortable, convenient, economical.

Some models have the ability to connect weather-dependent automation - these are external sensors. Based on their readings, the boiler adjusts the power of the burners. Gas boilers in closed heating systems are good equipment that can provide comfort. The only pity is that gas is not available everywhere.

Two-pipe closed heating system in a house on two floors (diagram)

Electric boilers can provide a no less degree of automation. In addition to traditional units, induction and electrode units have recently appeared on heating elements. They are distinguished by their compact size and low inertia. Many believe that they are more economical than boilers using heating elements. But even this type of heating unit cannot be used everywhere, since power outages in winter are a common occurrence in many regions of our country. And provide the boiler with electricity. 8-12 kW from the generator is a very difficult matter.

Solid or liquid fuel boilers are more versatile and independent in this regard. An important point: to install a liquid fuel boiler, a separate room is required - this is a requirement of the fire service. Solid fuel boilers can be installed in the house, but this is inconvenient, since a lot of debris falls from the fuel during combustion.

Modern solid fuel boilers, although they remain periodic equipment (they warm up during combustion and cool down when the fuel burns out), but they also have automation that allows you to maintain a given temperature in the system, regulating the intensity of combustion. Although the degree of automation is not as high as that of gas or electric boilers, it is there.

Example of a closed heating system with an induction boiler

Pellet boilers are not very common in our country. In fact, this is also solid fuel, but boilers of this type operate in continuous mode. Pellets are automatically fed into the firebox (until the stock in the burner is finished). If the fuel quality is good, ash cleaning is required once every few weeks, and all operating parameters are controlled automatically. The only thing holding back the spread of this equipment is its high price: the manufacturers are mainly European, and their prices are corresponding.

A little about calculating boiler power for closed-type heating systems. It is determined according to the general principle: per 10 sq. meters of area with normal insulation take 1 kW of boiler power. It’s just not recommended to take it “back to back”. First, there are unusually cold periods during which you may not have enough rated power. Secondly, working at the power limit leads to rapid wear of the equipment. Therefore, it is advisable to take the boiler power for the system with a margin of 30-50%.

Pipe selection

The required profile size for the pipeline is called upon completion of the system design - this is the task of the master. The home owner, in turn, can choose pipes for installation. An option can always be recommended by a design specialist, but you need to understand what parameters a particular material has and how it will affect the operation of the heating. For gravity heating, the following options are used:

- stainless steel profile;

- polypropylene;

- copper.

Polypropylene pipe is considered the best choice. The material weighs little, is easy to install and does not corrode. The last property is especially important since the material will be in constant contact with the liquid. Polypropylene has excellent sound insulation. Typically, the flow of water is not accompanied by loud sounds, but due to the properties of the material, the operation of the system will be absolutely silent.

The main point when installing a polypropylene pipeline is the maximum temperature that the selected pipe can withstand. The reinforcing coating helps the polypropylene pipeline resist thermal deformation. This is a protective layer that neutralizes the effect of hot water on the material.

It is recommended to install the part of the pipeline through which water returns to the boiler from steel. This metal accelerates the cooling of the liquid and reduces hydraulic resistance during operation of the heating system.

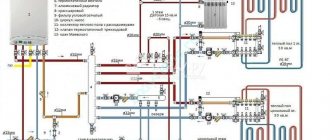

Connecting a heated floor to naturally circulating heating

- Installation of such a scheme requires additional costs in order to arrange the safe use of combined heating. In some cases, the water boils, pipes and boilers collapse, leading to explosions.

- The ideal solution for installing a heated floor in a house is to install a system that operates normally during a power outage.

- To operate radiator heating, a pipeline from the boiler is made with a slope so that water circulates, and for a water floor a pump is required to pump the coolant.

- A danger arises here: when the power is turned off, the water in the boiler heats up, but the pump does not circulate - an accident occurs. To prevent this situation from occurring, an additional check valve is installed that opens when the pump is turned off.

Manifold cabinet

- To reduce the water temperature, a thermostatic valve is installed on the heated floor circuit, which shuts off the flow of water when the set parameters increase. Deaeration valves are also installed. All this is mounted in a distribution cabinet.

- For coordinated simultaneous operation of heating systems (warm floors, radiators), two different subsystems are used with the installation of collectors. This makes it possible to more accurately regulate the flow in each circuit. Using a three-way mixing valve, the temperature in the radiators and underfloor heating is controlled separately. Thanks to the automatic valve, the water temperature corresponds to the needs of each system.

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is necessary to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the diameter of the pipe, etc. You may need professional help when performing the calculations.

Closed system with gravity circulation

In EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet received widespread use. The operating principles of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands and water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container consists of a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs and the gas squeezes water out of the tank.

Otherwise, closed-type systems work like other heating schemes with natural circulation. The disadvantages include the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a spacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantage of an open system is the ability to independently manufacture a container from scrap materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the entry of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing of the system is also a frequent “guest” in open-type circuits. Therefore, radiators are installed at an angle; Mayevsky valves must be provided to bleed air.

Calculation of gravity system

To calculate and design heating with natural circulation, proceed in this order:

- Find out the amount of heat needed to heat each room. Use our instructions for this.

- Choose a non-volatile boiler - gas or solid fuel.

- Develop a diagram based on one of the options proposed here. Divide the wiring into 2 branches - then the lines will not cross the front door of the house.

- Determine the coolant flow for each room and calculate the pipe diameters.

Note. There is no need to calculate slopes; take the standard value of 0.5 cm per meter of length. Deviations up or down in the range of 0.7…0.2 cm/1 m are allowed.

It will not be possible to split it into 2 branches right away. This means that the ring pipeline will definitely pass under the threshold of the front door. To withstand all the slopes, the boiler will have to be placed in a pit.

The calculation of the diameter of the pipes in all sections of the gravity two-pipe system is done as follows:

- We take the heat loss of the entire building (Q, W) and determine the mass flow rate of the coolant (G, kg/h) in the main line using the formula below. The temperature difference between supply and return Δt is taken equal to 25 °C. Then we convert kg/h to other units - tons per hour.

- Using the following formula, we find the cross-sectional area (F, m²) of the main riser, substituting the value of the natural circulation speed ʋ = 0.1 m/s. We recalculate the area of the circle into diameter, we get the size of the main pipe suitable for the boiler.

- We calculate the thermal load on each branch, repeat the calculations and find out the diameters of these lines.

- We move on to the next rooms and again determine the diameters of the sections based on heat costs.

- We select standard pipe sizes, rounding the resulting numbers up.

Let's give an example of calculating a gravity system in a one-story house of 100 square meters. The layout below already shows heating radiators and indicates heat losses. We start from the main boiler manifold and move towards the last rooms:

- The amount of heat loss at home is Q = 10.2 kW = 10200 W. Coolant flow in the main riser G = 0.86 x 10200 W / 25 °C = 350.88 kg/h or 0.351 t/h.

- The cross-sectional area of the supply pipe is F = 0.351 t/h / 3600 x 0.1 m/s = 0.00098 m², diameter d = 35 mm.

- The load on the right and left branches is 5480 and 4730 W, respectively. Amount of coolant: G1 = 0.86 x 5480 / 25 = 188.5 kg/h or 0.189 t/h, G2 = 0.86 x 4730 / 25 = 162.7 kg/h or 0.163 t/h.

- The cross section of the right branch is F1 = 0.189 / 3600 x 0.1 = 0.00053 m², the diameter will be 26 mm. Left branch: F2 = 0.163 / 3600 x 0.1 = 0.00045 m², d2 = 24 mm.

- Lines DN32 and DN25 mm (rounded up) will come to the nursery and kitchen. Now we calculate the sizes of collectors for the bedroom and living room + corridor with heat losses of 2.2 and 2.95 kW, respectively. We get both diameters DN20 mm.

To connect small batteries, you can use DN15 connections (outer d = 20 mm), the plan shows DN20 dimensions

Attention! The diameters obtained as a result of calculations indicate the size of the internal passage of pipelines (designation - DN or DN).

All that remains is to pick up the pipes. If you make heating from steel, the boiler riser will be Ø48 x 3.5, the branches will be Ø42 x 3 and 32 x 2.8 mm. The remaining wiring, including connections to the batteries, is done with a 26 x 2.5 mm pipeline. The first digit of the size indicates the outer diameter, the second - the wall thickness (range of water and gas steel pipes).

Wiring diagram

The figure shows a simplified installation diagram for a gravity heating system in a private home.

The main elements are:

- heating boiler;

- heating devices (radiators);

- pipes;

- compensation (expansion) tank.

In reality it should look something like this. The boiler is installed at the lowest point of the house in a pre-designed location. A riser is led from it to the highest point. It's better if it's in the attic. The accelerating riser must be connected to a compensation or expansion tank.

If the tank is open, then an overflow pipe is installed on it, which is installed as close as possible to the sewer system. When the tank is made closed, it can be located in the boiler room on the return line (In this design, a safety relief valve is installed). It is necessary to install an air vent on the open tank and release it from it. The filling of the system is welded to the tempering.

Everything, the skeleton, the backbone of the system, is ready. All that remains is to connect the pipes, heating radiators and you're done. We are warming up, but, as they say, “it was smooth on paper...”.

Open system configuration

Heating of the open type is carried out using the following components:

- boiler;

- expansion tank (atmospheric type);

- water pipes;

- heating radiators;

- return pipeline;

- circulation pump (if open-type water heating with a pump is used);

- primary fill valve;

- valve for draining water.

Let us consider in detail the features and characteristics of the main constituent elements.

Boiler

When using an open type heating device, the following types of boilers can be used:

- Units operating on gas fuel are used where a gas main can be laid to the house. This option is the most profitable due to the affordable price of energy resources. However, you will first have to make a project and coordinate it with the relevant services.

- Solid fuel boilers can be used in regions where it is easy to buy coal or prepare firewood. Modern devices are quite economical, have high efficiency and do not require constant monitoring.

- Electric boilers are used less frequently because they are less economical than other types.

- Combined multifunctional boilers are the optimal solution because they can operate in several modes using different energy sources.

Circulation pump

Although an open circuit can operate on natural circulation, if possible, it is better to install a pump. This will increase heating efficiency. Although the device consumes electricity, it provides significant savings on the main energy carrier that the boiler uses.

When choosing a suitable pump, take into account the diameter of the pipe where it will cut into, the performance of the unit and the liquid pressure. The choice of pump is made taking into account its technical characteristics for a specific heating system.

Expansion tank

You can make the tank yourself or buy a ready-made one. It is better to use stainless steel containers. The tank must have a removable or hinged lid to control the liquid level. A pipe is installed on top to drain excess water.

There are several options for installing an expansion tank:

- at the highest point;

- on the return;

- on the far riser;

- with a pump installed on the supply.

Heating radiators

You can use the following types of radiators:

- Cast iron radiators are ideal for open heating. Due to the high inertia of cast iron radiators, impressive savings on energy are achieved.

- Steel batteries are lightweight and inexpensive. If they have an anti-corrosion coating, they will last quite a long time. However, it is better not to use them in open circuits due to rapid cooling, which will lead to frequent operation of the boiler and significant energy consumption.

- Aluminum radiators are easy and quick to install and are durable. They have high heat transfer and good thermal capacity. However, aluminum is susceptible to oxygen corrosion, so choose devices with an anti-corrosion coating.

- Bimetallic radiators, although expensive, combine the advantages of all of the above batteries. They are suitable for high pressure heating systems. However, it is impractical to install them in private houses with an open circuit in which atmospheric pressure is maintained.

Pipes of an open heating system

To install a heating circuit, it is important to choose pipes from a suitable material, as well as determine their diameter. For an open heating device, you can choose the following options:

For an open heating device, you can choose the following options:

- steel and metal pipes are almost never used today because they are very heavy and difficult to install;

- copper pipelines are high-quality, reliable, but expensive;

- metal-plastic pipes are of quite high quality, but the reliability of fitting connections leaves much to be desired and requires constant monitoring of leaks;

- the best option is considered to be pipelines made of cross-linked polyethylene with reinforcement and protection against oxygen oxidation (they are very reliable and easy to install);

- the most inexpensive option is to use polypropylene pipes with fiberglass reinforcement (for installation you will need a welding machine, which can be rented).

Installation

To enlarge, click

When choosing a gravity heating system, the first thing you need to do is design it. Perhaps this is the only moment when it is impossible to do anything with your own hands.

This part of the work must be entrusted to heating engineers. In order for the system to have an aesthetic appearance, it is advisable to involve a designer in the design. When their work is completed, calculations are made, diagrams are drawn, you can proceed directly to installation.

First you need to select the heating pipes. The diameters and lengths are already known from the project, all that remains is to choose the material. It is better to give preference to polypropylene pipes . They have a lot of positive aspects. These include low weight, ease of connection, high anti-corrosion resistance, high noise insulation, and resistance to defrosting.

All of the above parameters are ideal for GSO.

The remaining heating devices are purchased based on capabilities and preferences, according to indicators, without going beyond the scope of the project. When installing the system, preference is given to two-pipe heating systems. This means that during installation it is necessary to make two pipelines - supply and return.

In this case, the supply line (with hot water) is located under the ceiling, and the return line on the floor or in the basement.

If you need to make a warm floor, you will have to make a collector insert. In this case, each circuit of the system can be powered through its own temperature controller, which will create additional convenience, but will also somewhat complicate the system as a whole. The supply manifold is located at the highest point, preferably in the attic. At the same time, you must not forget about its insulation, by the way, like the entire attic.

Now you can begin installing the system. You need to start with a water heating boiler. Maintaining verticality as accurately as possible, a pipe is led from it to the top, which connects to the compensation tank. Immediately it needs to be well insulated. A hot circuit pipe is inserted into the lower third of the tank. It is connected to the wiring.

At the very top of the tank it is necessary to install an overflow pipe connected to the sewer. It will drain excess water in the system.

Next, you need to lay the pipeline to the heating devices (radiators). After completing these works, you can start laying the return line - a line through which cold water will return to the boiler. When all connections are completed, water can be poured into the system. If there is no water leakage from the connection points, the system starts up.

Such a heating system can easily cope with heating a small two-story cottage with all household premises. Thus, of all types of systems, it is advisable to give preference to a two-pipe system.

Options for piping in the system

The efficiency, economy and aesthetics of the heat supply system depend on the layout of heating devices and connecting pipes. The choice of wiring is determined based on the design features and area of the house.

Specifics of one-pipe and two-pipe schemes

Heated water flows to the radiators and back to the boiler in different ways. In a single-circuit system, the coolant is supplied through one large-diameter pipeline. The pipeline runs through all radiators.

Advantages of a single-pipe self-circulation system:

- minimal consumption of materials;

- ease of installation;

- limited number of pipes inside the living space.

The main disadvantage of a scheme with one pipe performing supply and return duties is the uneven heating of the heating radiators. The heating intensity and heat transfer of the batteries decreases as they move away from the boiler.

With a long wiring chain and a large number of radiators, the last battery may turn out to be completely ineffective. “Hot” heating devices are recommended to be installed in north-facing rooms, children’s rooms and bedrooms

The two-pipe heating scheme is confidently gaining ground. Radiators connect the return and supply pipelines. Local rings form between the batteries and the heat source.

- all heating devices heat up evenly;

- the ability to adjust the heating of each radiator separately;

- reliability of operation of the circuit.

A dual-circuit system requires large investments and labor costs. It will be more difficult to install two lines of communications along building structures.

The two-pipe system is easily balanced, ensuring the supply of coolant at the same temperature to all heating devices. Rooms are heated evenly

Upper and lower coolant supply

Depending on the location of the main line supplying hot coolant, a distinction is made between upper and lower connections.

In open heating systems with overhead wiring, there is no need to use air exhaust devices. Its excess is discharged through the surface of the expansion tank communicating with the atmosphere

With overhead distribution, warm water rises through the main riser and is transferred through distribution pipelines to the radiators. The installation of such a heating system is advisable in one- and two-story cottages and private houses.

A heat supply system with bottom wiring is quite practical. The supply pipe is located at the bottom, next to the return pipe. Coolant movement in the direction from bottom to top. The water, having passed through the radiators, is directed through the return pipeline to the heating boiler. The batteries are equipped with Mayevsky valves to remove air from the line.

In heating systems with bottom wiring, it becomes necessary to use air exhaust devices, the simplest of which is the Mayevsky tap

Vertical and horizontal risers

Based on the type of position of the main risers, a distinction is made between vertical and horizontal pipeline routing methods. In the first option, radiators on all floors are connected to vertical risers.

Vertical wiring is used when arranging houses of two, three or more floors with an attic space, within which a pipeline can be laid and insulated

Features of “vertical” systems:

- no air pockets;

- suitable for heating high-rise buildings;

- floor connection to the riser;

- difficulties in installing apartment heat meters in multi-storey buildings.

Horizontal wiring involves connecting radiators on one floor to a single riser. The advantage of the scheme is that the device uses fewer pipes and installation costs are lower.

Horizontal risers are usually used in one- and two-story premises. The arrangement of the system is relevant in panel-frame houses and residential buildings without walls

Add-ons to improve system efficiency

The heating installation can perform better if improvements are made to the design. These measures optimize the system, increase efficiency and smooth out deficiencies that may affect the quality of operation. The following additions can be suggested:

- Installation of a reverse trap that blocks accidental movement of liquid in the wrong direction.

- Mounting the circulation pump. Installing this add-on reduces the inertia of the gravitational system. If the heating time is exceeded, this improvement increases the speed of water flow. As a result, the liquid is heated to the required level.

- Highway slope. Allows you to obtain the optimal pressure level during system operation.

Gravity heating in the basic configuration will work without additional measures, but installing auxiliary elements will significantly increase efficiency and reduce the likelihood of breakdowns. To make changes, they are discussed in advance with the heating engineer responsible for the project.

Installation recommendations

Pipe slope in a gravity heating system

Having completed the calculation for a gravity heating system made of polypropylene or steel pipes, you can begin installing it. To achieve optimal efficiency, experts recommend making small but important changes to the standard circuit:

- Highway slope . The optimal gravitational pressure for the heating system can be achieved by sloping the pipes after the air vent and on the return line behind the last heating device;

- Installing a circulation pump on the bypass . It will help reduce the inertia of the system. The heating time of the coolant can be very long, so the pump can increase the speed of its movement along the line until the desired temperature is reached;

- Minimum of turning units in the pipeline . They create excess hydraulic resistance, which reduces the speed of water movement;

- Installation of protective elements . By installing a check valve for gravity heating, you can prevent water from circulating in the wrong direction. This is especially necessary for a system with overhead wiring and multiple circuits.

The main components of a properly made pressure gravity heating system are a professionally made preliminary calculation, selection of the right materials and adherence to installation technology. This will make it possible to create an effective system for maintaining a comfortable temperature in the house.

Tips on arranging and using a gravity valve for heating when installing heated floors and additional elements can be seen in the video:

Standards and requirements for autonomous heating

Before designing a heating structure, you need to look into SNiP 2.04.05-91, which sets out the basic requirements for pipes, heating devices and shut-off valves.

General standards boil down to ensuring a comfortable microclimate in the house for the people living in it, properly equipping the heating system, having previously drawn up and approved the project.

Many requirements are formulated in the form of recommendations in SNiP 31-02, which regulates the rules for the construction of single-family houses and their provision with communications.

Temperature-related provisions are specified separately:

- the parameters of the coolant in the pipes should not exceed +90ºС;

- optimal indicators are within +60-80ºС;

- the temperature of the outer surface of heating devices located in the direct access zone should not exceed 70ºС.

It is recommended to make pipelines for heating systems from brass, copper, and steel pipes. In the private sector, polymer and metal-plastic pipe products approved for use in construction are predominantly used.

Pipelines for water heating circuits are most often laid in an open way. Hidden installation is allowed when installing “warm floors”

The method of laying the heating pipeline can be:

- Open. Involves laying on building structures with fastening with clips and clamps. Allowed when constructing circuits made of metal pipes. The use of polymer analogues is permitted if their damage from thermal or mechanical influence is excluded.

- Hidden. It involves laying pipelines in grooves or channels selected in building structures, in baseboards or behind protective and decorative screens. Embedding of the circuit is allowed in buildings designed for at least 20 years of operation and with a pipe service life of at least 40 years.

The open method of laying is a priority, because the design of the pipeline route must provide for free access to any element of the system for repair or replacement.

Pipes are hidden in rare cases, only when such a decision is dictated by technological, hygienic or structural necessity, for example, when installing “warm floors” in a concrete screed.

When laying pipelines for systems with natural coolant movement, it is necessary to maintain a slope of 0.002 - 0.003. Pipelines of pumping systems, inside which the coolant moves at a speed of at least 0.25 m/s, do not need to provide slopes

When laying an open highway, areas crossing unheated premises must be provided with thermal insulation that corresponds to the climatic data of the construction region.

Autonomous heating pipelines with a natural type of circulation must be installed in the direction of the coolant flow, so that the heated water reaches the radiators by gravity, and after cooling in the same way, moves along the return line to the boiler. The mains of pumping systems are constructed without a slope, because there is no need for it.

The use of different types of expansion tanks is stipulated:

- open, used for both pumping and natural forced systems, should be installed above the main riser;

- closed membrane devices, used exclusively in forced systems, are installed on the return line in front of the boiler.

Expansion tanks are designed to compensate for the thermal expansion of the liquid when heated. They are needed to dump excess into the sewer or simply onto the street, as is the case with the simplest open options. Closed capsules are more practical because they do not require human participation in adjusting the pressure of the system, but they are more expensive.

An open type expansion tank is installed at the highest point of the system. In addition to providing a reserve for liquid expansion, it is also entrusted with the task of removing air. Closed tanks are placed in front of the boiler; air vents and separators are used to remove air

When choosing shut-off valves, preference is given to ball valves; when choosing a pumping unit, preference is given to equipment with a pressure of up to 30 kPa and a capacity of up to 3.0 m3/h.

The budget opening variety needs to be refilled periodically due to normal liquid evaporation. For their installation, it is necessary to significantly strengthen the attic floor and insulate the attic.

It is recommended to install radiators and convectors under windows, in places convenient for maintenance. The role of heating elements in bathrooms or toilets can be played by heated towel rails connected to heating communicationsDifferences in the operation of a solid fuel boiler

The heart of any heating system is the boiler. Although the same models can be installed, operation with different types of heating will differ. For normal operation of the boiler, the temperature of the water jacket must be at least 55 °C. If the temperature is lower, then the inside of the boiler will be covered with tar and soot, as a result of which its efficiency will decrease. It will need to be constantly cleaned.

To prevent this from happening, a three-way valve is installed in a closed system at the boiler outlet, which circulates the coolant in a small circle, bypassing the heating devices, until the boiler heats up. If the temperature begins to exceed 55 °C, then the valve opens and water begins to flow into the large circle.

A three-way valve is not required for a gravity heating system. The fact is that here the circulation occurs not due to the pump, but due to the heating of the water, and until it heats up to a high temperature, movement does not begin. In this case, the boiler furnace remains constantly clean. A three-way valve is not required, which reduces the cost and simplicity of the system and adds to its advantages.

An alternative heating method

All of the above features do not mean at all that natural and forced circulation systems cannot function together.

So, the following installation option would be a very correct solution:

- A project is being created for a heating system operating according to the gravity type.

- A valve is installed in the circuit in front of the boiler, but this must be done so as not to reduce the cross-section of the pipe.

- The valve circuit is cut into a smaller pipe diameter, and after that a circulation pump is installed on the circuit (read: “Calculating the power of a heating pump”). If necessary, it can be completely separated from the main system using two valves. Next, in the space in front of the pump, you need to mount a mud trap.

Such an option for arranging a heat supply system will have undeniable advantages, namely:

- heating of all heating devices will be carried out much more evenly;

- the time required to heat the rooms after turning on the boiler will be much less compared to the standard operating principle of the equipment.

At the same time, there is no need to equip this heating option in a closed type, since the pump power is quite enough to function without high pressure.

If there is a power outage, you just need to turn off the pump and open the special valve on the bypass. In this case, the operation of the system will continue according to the gravitational principle.

Heating safety

As mentioned above, the pressure in a closed system is greater than in a gravitational one. Therefore, they take a different approach to security. In closed heating, the expansion of the coolant is compensated in an expansion tank with a membrane.

It is completely sealed and adjustable. After the maximum permissible pressure in the system is exceeded, the excess coolant, overcoming the resistance of the membrane, goes into the tank.

Gravity heating is called open due to a leaky expansion tank. You can install a membrane-type tank and make a closed gravity heating system, but its efficiency will be much lower because the hydraulic resistance will increase.

The volume of the expansion tank depends on the amount of water. To calculate, its volume is taken and multiplied by the expansion coefficient, which depends on temperature. Add 30% to the result obtained.

The coefficient is selected according to the maximum temperature that the water reaches.

What it is?

Thanks to artificial heating of premises for various purposes, it is possible to compensate for heat losses and maintain the specified temperature values. Thermal comfort conditions for living require the operation of an open or closed heating system. Any type of heat supply network has undeniable advantages and certain disadvantages that must be taken into account when choosing a scheme.

Advantages and disadvantages

An open system is based on thermodynamic laws. Its main advantages include:

- energy independence;

- natural circulation of coolant;

- ease of maintenance;

- silent operation;

- minimum equipment;

- high level of reliability;

- ease of self-installation.

Significant disadvantages include bulkiness, the risk of cavitation, which destroys system elements, and low efficiency. Among other things, the operation of an open heating network requires strict control of the coolant level, as well as the impossibility of using antifreeze.

Differences from a closed system

Autonomous heating systems have a number of significant differences from a closed heating network. Features and main differences must be taken into account when choosing the optimal heating option for a room.

| Options | Open | Closed |

| Connection with the atmosphere | Permanent | Absent |

| Storage tank | Spacious round or rectangular tank with drain pipe | Double-chamber with membrane, designed for maximum pressure |

| Installation location | At the highest point of the mounted system | Not of fundamental importance |

In conditions of centralized heating (apartments), an open system is based on supplying hot water directly to the taps. The heat carrier first undergoes additional deaeration and mandatory cleaning, and after use it is discharged into the sewer.

Air locks and how to deal with them

For normal heating operation, the system must be completely filled with coolant. The presence of air is strictly prohibited. It can create a plug that prevents water from passing through. In this case, the temperature of the boiler water jacket will differ greatly from the temperature of the heating devices. To remove air, air valves and Mayevsky taps are installed. They are installed at the top of heating devices, as well as in the upper sections of the system.

However, if gravity heating has the correct slopes for the supply and return pipes, then no valves are required. The air in the inclined pipeline will freely rise to the top point of the system, and there, as you know, there is an open expansion tank. This also adds to the benefit of open heating by reducing unnecessary elements.

Is it possible to install a system made of polypropylene pipes?

People who do their own heating often wonder whether it is possible to make a gravity heating system from polypropylene. After all, plastic pipes are easier to install. There is no expensive welding or steel pipes, and polypropylene can withstand high temperatures. You can answer that such heating will work. At least for a while. Then efficiency will begin to decline. What is the reason? The point is the slopes of the supply and discharge pipes, which ensure gravity flow of water.

Polypropylene has greater linear expansion than steel pipe. After repeated heating cycles with hot water, plastic pipes will begin to sag, disrupting the required slope. As a result, the flow rate, if it does not stop, will decrease significantly, and you will have to think about installing a circulation pump.

Difficulties in installing a gravity system in a two-story house

A gravity heating system for a two-story home can also work efficiently. But its installation is much more complicated than for a one-story one. This is due to the fact that attic-type roofs are not always made. If the second floor is an attic, then the question arises: where to put the expansion tank, because it should be at the very top?

The second problem that you will have to face is that the windows of the first and second floors are not always on the same axis, therefore, it is impossible to connect the upper batteries with the lower ones by laying pipes along the shortest route. This means that you will have to make additional turns and bends, which will increase the hydraulic resistance in the system.

The third problem is the curvature of the roof, which may make it difficult to maintain proper slopes.

Detailed analysis of gravity heating

During the analysis process, we propose to consider a single-pipe scheme, which can later help you when building your heating system.

Let's agree that in the diagram we will consider water as the coolant. For year-round use in heating systems, it is recommended to use compounds that do not freeze at temperatures below zero (antifreeze, etc.)

By using antifreeze, you will eliminate the possibility of your system defrosting.

Gravity heating systems by their name indicate their operating principle. In such a system, hot water moves without the use of a pump. This happens due to different temperatures of the coolant at the inlet and outlet of the boiler.

As mentioned above, such a system is outdated and rarely seen in operation.

This is explained by significant disadvantages:

- high cost;

- low efficiency;

- not economical.

But if you look from the other side, this is one system with which you can heat a country house or a small private house without electricity. There are practically no such houses, but anything can happen.

Selection of boiler, pipes and consideration of the diagram

Therefore, the best choice in our case would be iron pipes.

As a result, there are immediate disadvantages:

- low efficiency;

- expensive and complex installation of the system;

- the size of the pipes is not aesthetic;

- the price of pipes is high.

It is also necessary to take into account that when entering the first radiator, the water will have the highest temperature. Therefore, at the beginning you need to install fewer radiator sections than at the end. The large volume of radiator sections compensates for the low temperature of the water (coolant).

The expansion tank is an important element of the heating system. It must be taken into account that when heated, water, like any material, tends to expand. In order not to deform the system, an expansion tank is installed. The instructions will help you choose the right volume.

The expansion tank is installed at the highest point of the heating system.

Advantages and disadvantages of GSO

Gravity heating systems are becoming increasingly popular when heating small one- or two-story country houses.

It has become widespread due to a number of advantages unique to it.

First of all, these include:

- high efficiency;

- reliability;

- ease of maintenance and repair.

The savings from such a heating system are evident even at the preparatory stage. There are no booster pumps in the system. The savings on the purchase of pumps and the electricity they consume are obvious. The system itself is very simple in design, which means that expensive repairs will bypass it. These two aspects will already provide significant savings.

Conclusions and useful video on the topic

Organization of a single-pipe circuit based on an electric boiler for a small house:

Operation of a two-pipe system for a one-story wooden house based on a long-burning solid fuel boiler:

The use of natural circulation during the movement of water in the heating circuit requires accurate calculations and technically competent installation work. If these conditions are met, the heating system will efficiently heat the premises of a private house and relieve the owners from pump noise and dependence on electricity.

If you have any questions on the topic or would like to share your personal experience in organizing and operating a gravity-type heating system, please leave comments on this article. The feedback block is located below.

Movement of cooled coolant

One of the misconceptions is that in a system with natural circulation, the cooled coolant cannot move upward.

I don't agree with this either. For a circulation system, the concept of top and bottom is very arbitrary. In practice, if the return pipeline rises in some section, then somewhere it falls to the same height. In this case, gravitational forces are balanced.

The only difficulty is in overcoming local resistance at turns and linear sections of the pipeline. All this, as well as possible cooling of the coolant in the lifting sections, must be taken into account in the calculations. If the system is correctly calculated, then the diagram presented in the figure below has a right to exist. By the way, at the beginning of the last century such schemes were widely used, despite their weak hydraulic stability.

Radiator location

They say that with natural circulation of the coolant, radiators must be located above the boiler.

This statement is true only when the heating devices are located in one tier. If there are two or more tiers, the radiators of the lower tier can be located below the boiler, which must be checked by hydraulic calculations.

Specifically, for the example shown in the figure below, with H = 7 m, h1 = 3 m, h2 = 8 m, the effective circulation pressure will be:

g = 9.9 [ 7 (977 – 965) – 3 (973 – 965) – 6 (977 – 973)] = 352.8 Pa.

Here:

ρ1 = 965 kg/m3 – density of water at 90 °C;

ρ2 = 977 kg/m3 – density of water at 70 °C;

ρ3 = 973 kg/m3 – density of water at 80 °C.

The resulting circulation pressure is sufficient for the operation of the above system.

Gravity heating - replacing water with antifreeze

I read somewhere that gravity heating, designed for water, can be painlessly converted to antifreeze. I would like to warn you against such actions, since without proper calculation, such a replacement can lead to a complete failure of the heating system. The fact is that glycol-based solutions have a significantly higher viscosity than water. In addition, the specific heat capacity of these liquids is lower than that of water, which will require, other things being equal, an increase in the coolant circulation rate. These circumstances significantly increase the calculated hydraulic resistance of a system filled with coolants with a low freezing point.

Using an open expansion tank

Practice shows that coolant must be constantly added to an open expansion tank, as it evaporates.

I agree that this is a really big inconvenience, but it can be easily eliminated. To do this, you can use an air pipe and a hydraulic valve installed closer to the lowest point of the system, next to the boiler. This tube serves as an air damper between the hydraulic seal and the coolant level in the tank. Therefore, the larger its diameter, the less will be the level of level fluctuations in the water seal tank. Particularly advanced craftsmen manage to pump nitrogen or inert gases into the air tube, thereby protecting the system from air penetration.

Using a circulation pump in gravity heating

In a conversation with one installer, I heard that a pump installed on the bypass of the main riser cannot create a circulation effect, since the installation of shut-off valves on the main riser between the boiler and the expansion tank is prohibited.

Therefore, you can install the pump on the return line bypass, and install a ball valve between the pump taps. This solution is not very convenient, since each time before turning on the pump you must remember to turn off the tap, and after turning off the pump, open it. In this case, installing a check valve is impossible due to its significant hydraulic resistance. To get out of this situation, craftsmen are trying to convert the check valve into a normally open one.

Such “upgraded” valves will create sound effects in the system due to constant “squelching” with a period proportional to the speed of the coolant. I can offer another solution. A float check valve for gravity systems is installed on the main riser between the bypass taps. The valve float is open in natural circulation mode and does not interfere with the movement of the coolant. When the pump is turned on on the bypass, the valve closes the main riser, directing the entire flow through the bypass with the pump.

In this article, I have not considered all the misconceptions that exist among specialists who install gravity heating. If you liked the article, I’m ready to continue it with answers to your questions.