- Advantages of a ventilated roof

- Design

- Types of ventilated roofing

- Flat

- Sloping

- Installation technology

- Flat

- Sloping

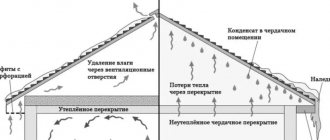

Constant daily temperature fluctuations cause condensation to form. It is the insulation that suffers the most from its negative impact. Having absorbed enough moisture, it practically ceases to perform its functions with all the ensuing consequences. Moreover, it should be noted that condensation is only one of the possible sources of moisture. But among the existing roofing structures there is one for which such problems simply do not exist. The design of a ventilated roof provides complete protection against swelling of the coating, penetration of moisture under it and the formation of mold. These are not the only advantages of this type of design.

Using a roof aerator on a soft roof

The use of aerators refers to point ventilation technology.

An aerator is a small device for ventilation, usually mushroom-shaped.

Height and diameter may vary. The quantity is also different:

- Small aerators are installed at the rate of one piece per 60 square meters;

- Large ones - 1 per 100-120 meters.

The devices are placed evenly over the roof area, preferably in its upper part. The distance between adjacent ones should not exceed 12 meters.

The aerator can be equipped with its own fan or built into the general house ventilation system.

How to choose

Since the basic principles of installation have already been discussed, you should familiarize yourself with the process of choosing a suitable aerator. They are selected according to several criteria.

The first is the device type. First, home owners must decide on the most effective type of system. It must function with maximum efficiency on a certain type of floor. On some it is better to use ridge plates, and on some roofs a few spot samples are needed. To avoid making mistakes, you should consult with roofing professionals. They will definitely tell you. Which option will be more effective and profitable.

The second criterion is cost. This indicator is considered critically important, since it must correspond to the average price segment. Most installers recommend purchasing products from popular companies at an average price. The quality of such aerators is high, and the price is relatively low.

The third criterion is the composition and reliability of the design. Any roofing product should be carefully examined before purchasing. There are several proven options with the most durable and durable design:

- A device consisting of three main parts. It is equipped with a clamping ring for reliable fastening to the surface of the soft roof. With a height of 26 cm and a weight of 330 grams, it demonstrates excellent insulating properties. Manufacturers indicate the optimal consumption - 1 device per 50 m².

- Identical 3-tier design for regions where there is increased snowfall. Its height is 36 cm.

- Aerator for 4 components. It is equipped with a durable cap that creates additional traction in the pipe. Thanks to this feature, the efficiency of the model increases almost 2 times. The height of the product is 47 cm, and the weight is 1.2 kg. It can ventilate an area of 100 m².

- A 4-part product for ventilation of the space under the vapor barrier layer and above the insulation material. With a height of 34 cm, it weighs only 780 grams.

- A common type of ridge aerator made of plastic. The design includes durable plates that can withstand any load during installation.

Ridge fans

Ridge (continuous) ventilation of the under-roof space of a soft roof is more effective than point ventilation. Local aerators are more often used for hard surfaces.

The ventilated ridge element is a rigid plastic structure consisting of a solid upper part in the form of a corner and perforated walls.

To install such an aerator in a ridge beam, grooves are selected along the entire length on both sides, which are then covered with a ridge element. Thus, the outflow of air from under the roof occurs along the entire length of the ridge.

Installation features:

- When laying the covering, the underlayment carpet near the ridge should protrude 15 centimeters from under the ordinary tiles;

- The protruding edge is folded onto the tile covering;

- A ridge is placed on the bent edges;

- The plastic parts are covered with tiled petals, the perforated walls are left open.

note

The advantage of a ventilated ridge: it can be installed not only during the construction of the roof, but also later, without dismantling the covering.

Lathing for soft tiles

You need to start by disassembling the sheathing. Since bitumen shingles are a flexible and thin material, when placed on any plane, it exactly repeats all its shapes. Therefore, installation of a flexible roof is carried out only on a continuous sheathing, assembled either from boards, or from sheet or slab materials, for example, from moisture-resistant plywood or OSB.

The plank sheathing is laid on the roof rafter system, leaving a gap of 1 cm between the boards. This is the so-called compensation gap in case of moisture and temperature expansion of the lumber.

Plywood and OSB boards are laid on a sparse sheathing of boards 20-25 mm thick and 100 mm wide. The installation step of the boards depends on the size of the sheets or slabs being laid. For example, if 125x125 mm plywood is chosen for a continuous sheathing, then the installation step of the sheathing elements should be within 70 cm. The edges of the sheet of plywood should lie on the two outer boards, and there should be another one between them. That is, the plywood sheet should lie on at least three boards.

Continuous sheathing made of boards Source krysha-expert.ru

And two important points:

- a gap of 1 cm is left between the laid slabs or sheets;

- The panels are laid with an offset of half the element, thus achieving uniform distribution of loads on all sheets (slabs).

Ventilation devices for flat roll roofs

All of the above technologies are intended for pitched roofs. They are not effective for flat ones. On flat soft roofs, ventilation is carried out using special devices:

- Ventilation nozzles;

- Inertia turbines;

- Electric fans for roofs.

I have already written in detail about the construction of flat roofs. I also advise you to read about the features of waterproofing flat roofs.

Types of binder

The base of the rolled roofing material is coated on both sides with a binder protective composition. It could be:

- bitumen (Gidroizol based on asbestos paper, glass rubber);

- tar, bitumen-tar compositions;

- rubber-bitumen composition (Stekloizol)

- rubber-polymer;

- polymeric.

The best characteristics are found in rubber-bitumen and polymer-bitumen compounds. Some of them are designed for use in severe frosts - down to -40°C, while others tolerate high temperatures - up to +150°C.

Folgoizol - foil is glued to the bitumen-polymer binder on one side

For regions with high temperatures, there are roll roofing materials based on foil - Folgoizol. Bitumen-rubber or bitumen-polymer binder is applied to the foil from the bottom side. Due to the reflective properties of the foil, the roof temperature will be 20°C lower. The front surface can be painted with weather-resistant paints and varnishes. Folgoizol bends well, is cut, and nailed with roofing nails. There are roofing (FC) and waterproofing (FG).

Ventilation passage through a soft roof

Dormer windows are often used to pass ventilation through the roof. But there are also special systems, the so-called. passage nodes.

note

The unit is an opening in the ceiling and roof through which a metal pipe with a wall thickness of at least a millimeter passes.

Pipes are available in round, square and rectangular sections. Air exchange system – natural or forced (using a fan).

Ventilation for a soft roof is a very important point; under no circumstances should it be left to chance. This will lead to low functionality of the roof and its premature destruction.

If you contact us, we will help you choose the type of roof ventilation that is suitable for your home and install it inexpensively in the shortest possible time.

Installation

The ventilated roof is installed in the following order:

- Preparing the base for work, including eliminating cracks and potholes. This can be the usual laying of cement mortar, leveling the entire surface, or paving the slab. It must be remembered that the minimum slope of such a roof should be two to three degrees!

- Next comes the laying of a layer of vapor barrier film and insulation, in which stripes and cracks are unacceptable. Most often, mineral wool or glass wool is used for this, which guarantee excellent quality and low installation cost.

- Depending on the type of roof, further installation work may vary, but basically a waterproofing layer and cement screed are laid.

- Roll fused materials are used as roof coverings, which provide excellent quality. Laying is carried out using a gas burner, while the bitumen is melted, the material itself is firmly glued to the base. The lateral overlap should be from one millimeter to five.

When installing, do not forget to mark the exit points of the ventilation ducts and insulate them properly to ensure the normal functioning of the roof. Only in this case will it acquire its proper qualities.

Additional materials on the topic

CertainTeed Shingles

More details

Roofing units made of flexible tiles

More details

Flexible tiles ICOPAL

More details

Your feedback, comments, questions

Dear visitors! We will periodically answer your questions in the comments as we are busy. In order for us to respond to you promptly (within an hour), you can: call, write a personal message or leave a request for a free consultation by phone.

Comments

Vladimir 10.23.2016 19:23

0 Hello, please tell me if the roof is planned from HS. hip roof with an area of 185 square meters (13x11 m), cold attic, roof overhang 50 cm, perforated lining and soffits. Tell me if additional attic ventilation is needed at the ridge of the roof. Thank you.

Reply | Reply with quote | Quote Consultation by phone +7(495) 241-00-59 Answered by Mikhail moderator

Hello. I always do ventilation in the ridge. After all, the main thing is that there is a draft and the warm air does not stagnate, so it will only be better.

Update list of comments

Types of protective coating

Binders that are used in the production of rolled roofing materials require protection from weather conditions. Sprinkles of varying degrees of grinding are used as a protective layer:

- coarse-grained (K);

- fine-grained (M);

- dusty (P);

- scaly (H);

- special resistant to alkalis or acids.

Coarse-grained topping not only protects, but also gives a decorative appearance.

In the marking, the letter indicating the type of sprinkle is placed third. Rolled materials used for lining are sprinkled on both sides with fine-grained or dusty powder. Its task is to prevent the roll from sticking together.

Fine-grained or dust-like crumbs are also applied to the back side of the roofing roll material, and coarse-grained or scaly crumbs are applied to the front side, which not only protects the coating, but also gives it a more attractive appearance. To give it an even more aesthetic appearance, the sprinkles are painted in different colors. Typically the colors are red, grey, burgundy, brown, green and blue.