Articles

All photos from the article

The term wood brushing, unknown until recently, is becoming increasingly popular today. A variety of people are interested in this method of processing wooden surfaces, from specialists in the production of luxury furniture to summer residents who decide to decorate certain wooden products in the surroundings of a country house.

So, what is brushing and what are the features of its implementation? In addition, what equipment is used for such processing of wooden surfaces and what are the characteristics of the finished result?

Microrelief of “aged” wood after coating with stain

Belt Sanding Machine Manufacturers

Buying a good tool is not easy, since the market is filled with models from different companies. In order for the device to last a long time, when choosing, you need to take into account the quality of materials and workmanship. Reliability and ease of use of the unit can be determined by the reputation of the manufacturer. The best belt sanding machines are produced by the following companies:

- Bort Global Ltd. _ is an international company producing construction equipment and power tools. Products are assembled in factories in China. The quality of the models is confirmed by a three-year warranty. Users appreciate them for their ergonomics, modern design, and innovative developments. The products are chosen not only by ordinary users, but also by professionals in the field of construction and repair.

- Hammer Werkzeug GmbH is a German company that produces electric tools, gardening and measuring equipment. Quality control is carried out in 2 directions - manual checking together with automatic testing, feedback from the consumer. Only those models that meet ISO standards are put into mass production.

- Hyundai is a South Korean holding company operating in the automotive, metallurgy, and chemical industries. It also produces consumer electronics, power, garden equipment, and power tools. The peculiarity of the latter is the use of the company’s original engines, which ensures reliable, stable operation. They are designed for the middle price segment.

- Bosch - a German group of companies is a reliable supplier of stationary and electrical tools, household appliances, and auto parts. The company has always been famous for the quality of its products, which allowed it to occupy top positions in the ratings of manufacturers of functional, reliable devices.

- Caliber is a Russian company that produces gardening and construction tools, welding and compression equipment. The low price of the product is due to the absence of additional frills and bells and whistles. The manufacturer places the main emphasis on a wide range of proven models that are designed for regular use in everyday life.

- Makita Corporation is a Japanese company that supplies the market with professional construction tools. The range includes over 1000 types of models for efficient processing of any materials. Users appreciate the quality, reliability of the engines, the strength of the housings, and the ability to work under extreme loads.

- Interskol is a Russian company engaged in the production, sale and service of power tools and small-scale mechanization equipment. The success of the company is due to the large assortment, affordable prices of products, and a wide network of service centers. Products have a low warranty return rate in their class.

- Black +Decker is an American manufacturer of construction and garden tools. The assortment includes models that will help in solving any issues regarding the arrangement of a home or cottage.

- Sturm is a Russian group of companies producing petrol, electric and hand tools. The product catalog includes all types of equipment that the consumer needs to work in the house, garden or country house. The models are assembled at the best factories in China. The development of devices is carried out jointly with Japanese and European specialists. In this case, the operating conditions of Russia are taken into account.

The best surface grinders

Skil 1215 LA

For home work, this 650 W tape machine with a sufficient tape width of 76 mm is also quite suitable. With the correct size of abrasive belt, it can provide both rough abrasion and cleaner grinding. The relatively light weight of 2.9 kg allows you to operate it even while suspended, controlling it with only one hand.

Let's briefly list the advantages:

- automatic alignment of the belt: one of the rollers along which it runs has a special shape that prevents it from moving;

- ease of assembly and disassembly;

- since the machine is quite reliable, it is necessary to stop it only when the sole becomes very hot;

- collapsible dust collector in the form of a box.

Price 4500-5200 rub. The disadvantage is the lack of a clamp for stationary fastening of the grinder and processing of workpieces. But Russian craftsmen have found a way out here too and attach a homemade platform to it using holes for screws.

Rating of belt sanders

The working tool of the unit is an sanding tape glued together in the shape of a ring. It is placed on rotating rollers that provide movement. Due to the high power of the engine, the device quickly removes a layer of wood with large irregularities. They can also be used for processing metal, plastic, and glass. When analyzing the top nominees, specialists from the Vyborexperta.ru website took into account the following characteristics of grinders:

- Belt speed;

- Power;

- The size of the treated area is determined by the length and width of the tape;

- Weight;

- The presence of a dust collector that ensures the cleanliness of the workplace;

- Speed controller type;

- Functional;

- Energy consumption level;

- Cord length;

- Equipment;

- Price.

The rating of belt sanders for wood contains a description of 10 models. Based on user reviews, pros and cons are highlighted for each device.

The best chain sharpening machines

Basic information

Antique decorated chest

Brushing wood with your own hands or using special mechanized equipment is a process during which soft fibers are partially removed from the surface of lumber, while harder fibers remain unchanged. As a result of this processing, the impression of old wood is created.

The term “brushing”, less common “brushing”, is a transliteration of the English word “brush”, which means “brush”. In Russian there is a term of similar meaning, “structuring a wood surface.” In both cases, the natural structure of the wood remains intact while the soft fibers are cleaned out.

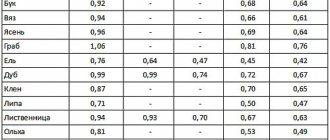

Important: The optimal structuring result is demonstrated by rocks with a pronounced structure. Species with an undefined structure, such as beech and maple, are not suitable for brushing.

The lumber processing technology includes the following stages:

- rough structuring, during which soft fibers are selected with a wire brush;

- polishing the resulting texture with a soft brush or polymer abrasive;

- final polishing of the texture using a sisal brush.

Structuring wood with your own hands or using mechanical devices provides the best result if the lumber used is harvested in the spring. It is in the spring, thanks to the growth of growth rings, that soft, loose fibers are formed, which can be easily cleaned by hand using a stiff brush.

Since wood structuring is based on the removal of soft fibers, it is advisable to use hard wood species such as oak, cherry and larch as the starting material.

Important: Most often, wood structuring is offered by companies engaged in the production of parquet and floorboards.

Brushing floor coverings, as is fashionable today, should not be done for two reasons:

- Firstly, dirt will accumulate in the relief texture, which will not be easy to wash out.

- Secondly, the grooves of the relief, unlike a flat surface, will wrinkle under the weight of the furniture.

Along with mechanical structuring, there is chemical brushing, during which certain chemical compounds are applied to the surface of lumber. As a result, loose fibers are etched away, while harder areas of the surface remain unchanged. (See also the article Leveling wooden floors: features.)

Artificial aging of wood is not difficult

Do you want to know how to paint brushed wood? Of course with acrylic paints

Brushing is one of the most accessible techniques that allows you to artificially age wood in such a way that it looks as natural and realistic as possible.

The maximum resemblance of the result obtained to a truly old tree is ensured by painting the brushed wood gray, followed by smearing the still wet paint from the relief surface. With the right approach to artificial aging, lumber products will look as if they had stood in the open air for at least 10 years.

In order for the wood to look naturally aged, in addition to structuring the fibers, the texture can be highlighted with color. To do this, the surface treated with a wire brush is cleaned and then unevenly painted.

We paint the depressions from which the soft fibers were selected with a darker color. We cover the surface of the texture with a light shade and thus make the relief more noticeable.

Applying stain along the grain

Tip: The simplest and at the same time effective way to highlight the texture of wood is to paint brushed wood with stain and then smear it with a foam swab.

As a result, the stain is quickly absorbed into the depressions, since the fibers there are loose. In the upper part of the relief, where the unselected fibers are hard, the stain does not have time to be absorbed, and light areas remain there. (See also the article Painting a wooden staircase with your own hands: features.)

Mechanical Tools Overview

This is what a brush attachment for brushing wood looks like

Structuring the surface of lumber with your own hands is a simple, but labor-intensive process that takes a lot of time. In order to save time and effort, a special tool for brushing wood is used.

Let's look at the main types of both hand and mechanical tools:

- Hand-held metal brushes with varying thickness and stiffness of bristles. The stiffness of the bristles depends on the length of the wire. The longer the wire, the softer the bristles, and the lower the price.

Wire hand brushes

Using a brush involves moving the bristles along the fibers in one direction. As a result, the hard fibers remain undamaged, while the soft fibers are carried out by the bristles.

Brushes are sold with different widths of the working part. As a result, you can choose the tool that will capture the required area of wood.

- Sandpaper with a coarse abrasive grain allows you to highlight the texture of the wood. The method of using sandpaper is generally similar to the process of using a brush. The sandpaper is applied along the grain with strong pressure. As a result, grooves remain on the surface, imitating the structure of fibers. By correctly selecting the grain size of the abrasive, it is possible to ensure that the grooves are deeper or, on the contrary, less pronounced.

- A hand chisel allows you to apply not even, but curved grooves of varying depths. With skillful use of this tool, the greatest realism of the artificial texture is achieved. However, there are also disadvantages. Firstly, applying relief is a labor-intensive process. Secondly, working with a chisel requires sufficient skill.

- An angle grinder (“grinder”) with special disc brushes is a device that allows you to speed up the aging process of wood without compromising the finished result.

In the photo there is a machine with a brush attachment based on a grinder

The optimal choice for mechanized brushing are angle grinders with the ability to regulate the speed. On such a tool, the minimum number of revolutions is set, as a result of which the texture looks realistic.

The realism of brushing is also influenced by the selection of brush heads. The thinner the stubble, the better.

Wood brushing attachment mounted in an electric drill chuck

Important: Polymer and metal brushes that are similar in appearance to attachments intended for use with angle grinders can be used in combination with an electric drill. Such nozzles, instead of a mounting hole in the center, are equipped with a shank that is tightly clamped in the chuck.

- A brush machine for brushing wood (stripping milling machine) is equipment designed for structuring fibers on large surfaces.

Wood brushing machine Makita 9741 with one brush

To obtain high-quality results, this equipment provides several replaceable brushes. By replacing the brushes according to the number of passes, you can gradually clean out the soft fibers, achieving maximum realism of the resulting texture.

- A wood brushing machine is the most productive industrial equipment used for preparing production materials and subsequent furniture assembly.

Machine in action

The device allows you to lay a wooden product on the frame and fix it there. As a result, vibrations are eliminated when brushes pass over the surface of lumber.

The use of machines allows you to simultaneously process wood with 2-3 brushes, one of which selects the fibers, and the other smoothes the texture. The rotation speed of the brushes is manually adjustable, so you can work with hard and soft wood.

Chemical structuring of wood

Microrelief of an “aged” board

Chemical brushing is used less often than mechanical treatment. This is explained by the fact that the use of chemical compounds requires additional qualifications from the master. In addition, the ingredients for preparing structuring compositions are not easy to obtain.

Important: Sulfuric and hydrochloric acids can be used to prepare wood before subsequent mechanical removal of soft fibers.

When carrying out chemical brushing, aggressive substances such as sulfuric and hydrochloric acid, ammonia, alkalis, etc. are used.

The instructions for aging the surface of lumber are as follows:

- the surface is sanded and cleaned of dust and dirt;

- a chemical compound is applied to the surface to be treated in a thin layer;

- as the chemicals evaporate, they must be reapplied;

- Residues of chemicals are washed off from the surface under running water with a soft brush;

- The wood is dried, after which you can begin painting.

Which belt sander is better?

Before purchasing, experts recommend trying to see if the instrument fits securely in your hand. If the weight of the machine exceeds 3.5 kg and the handle is uncomfortable, then when working, a person will think not about the quality of grinding, but about the possibility of intercepting the unit. This often leads to errors. An important selection criterion is the presence of speed control, which provides the ability to process different types of surfaces. The higher the power of the device and the speed of the belt, the longer it works without overheating. The following recommendations from the VyborExpert project specialists will help determine which belt sanding machine to choose:

- The most inexpensive model in the rating is Military BS600;

- Unit with minimal weight – Black+Decker KA88;

- The device with the best speed range is Hyundai BS 900;

- The device with the most powerful engine – Sturm! BS8511U;

- Users' choice – Hammer LSM 810;

- Best build quality – Bosch PBS 75 A;

- The most convenient to use is Bort BBS-801N.

Not everyone knows how to choose a belt sander from the existing variety of models. Before purchasing, it is recommended to study the influence of the device’s characteristics on the quality of work and ease of use. It would also be a good idea to read reviews that indicate the pros and cons of the selected model.

Makita 9910

A slightly less powerful (650 W), but also less expensive unit of Austro-German production with a belt width of 76 mm, designed for processing all types of materials from wood and plastic to metal. You can also clean vertical surfaces with it - the weight of 2.6 kg is quite sufficient.

When working with such a reliable workhorse, no problems arise - you just need to timely empty the debris from the dust collector and periodically change the worn abrasive. When using a coarse-grained tape, it easily removes up to 1.5 mm of the surface, so it can even replace an electric planer. Finer sandpaper provides more gentle sanding.

Other advantages of the Makita 9910 model:

- shockproof housing;

- double protective insulation;

- automatic centering of the belt: during operation it does not constantly slide to the side, and there is no need to manually correct it.

The only drawback is the lack of speed control. However, this disadvantage is compensated by the price - for a belt unit the cost is 6500-7200 rubles. is more than acceptable.

Metabo BAE 75

This good-quality model weighing 4.7 kg was also appreciated by professionals - for such a powerful unit of 1010 W, the average cost is 13,000-14,800 rubles. very acceptable. The 533 mm wide belt allows you to cover a large processing surface at once.

Pros of the sander:

- high-quality assembly;

- bed for processing workpieces and securing in an inverted position;

- hex key to change the position of the protective casing;

- speed adjustment: ability to remove different surface thicknesses;

- start button lock;

- additional handle;

- the presence of a frame limiter to control the thickness of the removed layer;

- dust bag;

- suction adapter for connecting a construction vacuum cleaner;

- longitudinal stop for fixing workpieces with the possibility of setting them at different angles.

Malfunctions from this no less eminent German company are rare, and if they do occur, the service centers eliminate them in a matter of days.