Peculiarities

A window fan is a compact device that is light in weight. It is fixed in the window opening and serves as a means of improving air circulation. Depending on the power and other technical characteristics, with the help of this device it is possible to organize both full ventilation of the entire room and a ventilation system in individual stagnant zones.

The power of such fans is sufficient to ventilate rooms in an apartment or house, small offices, and retail premises. They are usually not suitable for ventilation of industrial facilities; more powerful supply systems are used there.

The fan can be mounted on top of the window or replace part of it, due to the low weight of the structure. As a rule, it is closed with blinds or curtains, which are raised (pulled apart) only when the device is operating. The rest of the time it is usually unnoticeable.

The presence of a fan allows you to quickly refresh the room without opening the window. This protects people from cold or hot (in the summer heat) air and street noise.

As with ventilation by opening a window, the fan allows fresh air to enter the room, but at the same time, heat loss is reduced by 50%. Using a fan is more hygienic compared to opening a window - owners are protected from dust, debris, and insects entering the room.

The fan operates almost silently, which is also an advantage. Finally, the device is universal and suitable for installation on metal profiles, plastic and wooden windows.

The service life of such products is 10-15 years. The variety of types and the ability to choose a fan of any size and power significantly expands the scope of application of the devices and determines their growing demand.

Among the advantages are:

- ensuring air exchange in the room, replacing a bulky ventilation system;

- compact size, inconspicuous on the window;

- economical energy consumption;

- possibility of adjusting work;

- high efficiency rate with correct calculation of the device’s power in accordance with the area of the room;

- affordability in comparison with the equipment of an efficient ventilation system or the use of air conditioners;

- the ability to operate in any weather conditions (unlike, for example, split systems, the operation of which in the winter cold is unacceptable);

- protection from dust and precipitation entering the room;

- ease of installation (even a non-professional can handle this) and operation.

Among the disadvantages are usually noted:

- the need to change the window design, which can negatively affect the strength of the profiles and the geometry of the glass unit;

- noise during operation (albeit small);

- the inability to completely avoid heat loss through the fan in the absence of additional insulation;

- risk of damage and leakage if installation rules are not followed or glass that is too thin is used.

Do your windows have them?

Boris Buttsev is a physicist by training (graduated from MEPhI), Ph.D. For many years I worked in the field of window production, promotion of modern ventilation systems, now I advise on any situations with condensation and mold, microclimate and comfort in inhabited premises.

What are these “holes”?

If you look closely, there are a lot of holes in the frame of a plastic window: not only in the lower, but also in the upper part of the window profile. Why do they all? For business! Holes in the frame of a plastic window remove moisture from the structure and provide window ventilation, compensate for wind pressure and reduce heating of colored profiles. We tell you which holes are needed for what purposes. Check if everything is in place at your window or the manufacturer “forgot” about them “as unnecessary”.

Drainage holes

There is a proverb: “water will find a hole.” It is also true for plastic windows. No matter how well PVC window blocks are made, there is a possibility that water will get inside the structure. Firstly, this can happen during rain or sleet. And secondly, with sudden temperature changes (condensation forms). And if the water cannot flow out, ice will form inside the window and the profile will simply collapse. To remove accumulated water, manufacturers make special drainage holes in plastic windows. They are found both in the moving part of the window (sash) and in the stationary part - the frame of the window block. The number and location of holes in a window structure are regulated in GOST standards and “processor folders” of a specific window system.

Holes in the sash

designed for draining the cavity between the edges of the glass unit and the folds of the profiles. According to »Window blocks made of polyvinyl chloride profiles. Technical conditions “GOST 30674-99”, they must be located in the deepest parts of the folds at a distance of no more than 600 mm from each other. There must be at least two drainage holes in the lower profile of the sash, measuring at least 5x10 mm (or with a diameter of at least 8 mm). The larger the window block, the more holes it should have. Two holes are made in the upper profile up to a meter long. If the profile length is more than a meter - three.

Holes in the window frame

serve to drain water. According to the same GOST, the lower profiles of boxes and horizontal imposts must have at least two drainage holes measuring at least 5x20 mm, located at a distance of no more than 600 mm from each other. Such holes can be located both on the inside of the window and on the outside. The latter should be protected by decorative visors.

Wind pressure compensation holes

As a rule, they are made in window systems intended for installation at a height of more than 20 m. When there is a large wind load, increased pressure occurs inside the window, due to which water cannot escape through the drainage hole. Special holes in the upper horizontal profile of the window frame, located in the cavity between the frame and the sash, help compensate for wind pressure.

Important

: The holes must be offset in the profile walls by at least 50 mm relative to each other. Otherwise, the windows may begin to “whistle.” The size of the holes to compensate for wind pressure is regulated by GOST and must be at least 5x10 mm or 6 mm in diameter. Box profiles no longer than one meter must have two holes, and longer ones - three. In this case, the location of the holes should not coincide with the installation locations for the linings under the double-glazed windows.

Ventilation holes in plastic windows

They are made from the outside in colored window profiles. The fact is that under the influence of sunlight such profiles can overheat and then become deformed. Ventilation of external chambers helps to reduce the impact of the sun on the profile and avoid negative consequences. To do this, at least one through hole is made on each side of the window profile (through the walls of the outer chambers of the sash and frame profiles), with a diameter of 5–6 mm.

Important:

Any technological openings in plastic windows (for ventilation, water drainage, wind pressure compensation) should not pass through the walls of the main chambers of window profiles.

The edges of the holes must be smooth, without burrs that impede water drainage. How to clean openings in windows

Drainage holes in PVC windows periodically become clogged, preventing the effective removal of water. To avoid ice forming inside the window unit, the holes must be cleaned periodically. This is quite easy to do using a regular household vacuum cleaner.

- We wipe the window from dust and wash it thoroughly.

- We take a vacuum cleaner and try to pull out all the dirt from the drainage holes.

- Using a cotton swab or toothpick, remove everything that the vacuum cleaner could not remove.

By the way:

The same operation must be done with the holes in the upper chamber of a two-chamber refrigerator.

Supply and exhaust fans: with us it’s clean and fresh

The store's catalog contains models for ensuring normal ventilation in different rooms: kitchen fans from the world's leading manufacturers of various power and sizes, Russian and foreign roof-mounted supply and exhaust fans protected from negative external influences by a special galvanized housing, as well as fireplace and window fans, centrifugal and multi-zone fans .

Based on their main technological characteristics, ventilation devices are divided into supply and exhaust fans used in industry and in everyday life.

The household supply and exhaust fan is designed to provide a comfortable environment in apartments, private houses and cottages. The distinctive characteristics of household ventilation devices are their relatively low air output, noiselessness, low energy consumption and attractive design. The price of the models presented in the RoomKlimat store catalog makes them accessible to a wide range of customers.

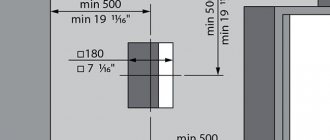

Methods for making holes in double-glazed windows and requirements for them

The work of cutting holes of the required size and shape is done manually, taking into account the requirements of the customer and the device for which it must fit. In this case, it is necessary to take into account the requirement of tightness of the hole, otherwise the effect of the installed household appliance will be reduced to a minimum.

When planning activities for cutting a hole, it is necessary to take into account that this cannot be done in a finished assembled double-glazed window, because the glass itself can be damaged from the lateral load during cutting. In addition, it is very difficult to accurately make holes in three glasses at the same time and exactly opposite each other.

That is why, especially in the case of double or triple glass, the work is carried out by qualified specialists, dismantling and cutting holes in each glass separately using glass cutters.

In this case, the inlets and outlets must absolutely coincide with each other, since after cutting and installing the glass, it is necessary to seal them and ensure a tight fit of the household device or air duct.

And also one of the methods for producing holes, often used in such cases, is cutting using a sandblasting machine. It makes it possible to cut a passage of absolutely any shape and size, which is inaccessible to conventional glass cutters.

This method is used in difficult cases by a qualified specialist and only with the appropriate equipment.

In addition, a household appliance, for example a fan, can be removed and the hole can be closed with a special plug to prevent precipitation from entering the room.

The corrugated pipe from the floor air conditioner must match the diameter of the outlet in the device itself, otherwise the air output will be insufficient and the device will overheat.

Taking into account all the requirements for cutting holes for the use of various household appliances will ensure their efficient and long-term operation, as well as a comfortable stay in the house.

Domestic duct fans

Duct fans for round air ducts are designed for installation directly into a ventilation system with a round cross-section. The line of household fans is represented by several manufacturers. Models are presented in plastic and metal cases with bushings and bearings, with or without fastening... The choice is yours.

One of the most popular methods of room ventilation at the moment is the installation of duct fans. They work on the principle of moving air masses through ventilation pipes.

In our company Vent-Style you can always buy a powerful duct fan from various leading manufacturers, both Russian and imported. The cost of duct fans is indicated in our catalog for each model; all their characteristics are also described in detail, power and other necessary data that may be needed when ordering are indicated.

Duct fans are widely used due to their simple design, almost complete absence of noise during operation and a fairly long service life. They can be installed in apartment buildings, office premises, factories and large-scale production - the duct fan will find its place everywhere.

The duct fan has a simple operating principle: the air in the ventilation pipe is driven through the action of the duct fans operating inside them. This is where the name of this technique comes from.

The structure of a duct fan is very simple: a small electric motor, a wheel with blades and the housing itself. Such fans operate at temperatures from -15 °C to +30 °C. This allows them to be used as widely as possible. From us you can buy a separate duct fan for hot air, which has a larger range of positive temperatures.

Each fan model has a built-in thermal protection, which is triggered when the device overheats and turns it off, preventing it from malfunctioning.

The duct fan is highly resistant to rust, as its body is made of galvanized steel. The protective coating of the case prevents moisture from harming the mechanism. This makes it possible to withstand increased loads during equipment operation.

The sale of duct fans in our online store in Moscow occupies an important niche. We can always help you choose the right type of duct fan to complete your tasks.

Advantages of a duct fan:

- has high efficiency;

- suitable for all types of premises;

- easy to install;

- completely silent;

- has a reliable design and long service life;

- thermal protection with auto-on functions.

You can buy a Vents duct fan from us - this is a well-known brand that has long gained popularity in Russia for its high-quality ventilation equipment.

The round duct fan is perfect for installation in any round ducts of ventilation systems. They have all the advantages of duct fans listed above.

You can buy round duct fans in our store at any time, the product is always in stock. It is worth noting that this type of fans can be used during the distillation of non-explosive gaseous mixtures with a temperature of no more than +50 °C and no less than -40 °C through ventilation channels. Also, this type of equipment is resistant to aggressive environments.

In addition to the duct fans themselves of any type and purpose, in our store you can buy a regulator for a duct fan.

Specifications

The power of a household fan installed on a window is 15-20 W. These indicators are sufficient for high-quality air exchange and air purification. At the same time, low power ensures a reduced noise factor during device operation.

The operating speed of the blades of such units is on average 3,000 rpm. The body of the product is made of durable types of plastic that are resistant to atmospheric influences and temperature differences outside the window and in the room. The temperature range of fan operation is from -50° C to +50° C.

The use of fans with blinds or a cover allows you to avoid heat loss. They are used when the device’s engine is turned off. To increase the thermal insulation properties of the blind strips, they are equipped with special rubber seals that prevent the formation of gaps. When the lid is lowered, the fans turn off automatically.

Such devices do not have reverse draft and are recommended for installation on a window or instead of it.

How and where to drill PVC windows correctly?

Plastic windows can be drilled if this is unavoidable. This must be done very carefully. The most important thing is that the holes do not deteriorate the thermal insulation properties or the rigidity of the window structure, and that the fasteners do not interfere with the smooth opening/closing of the sashes. When drilling, it is very important not to touch the glass unit or fittings with the drill. As a rule, plastic window structures are drilled around the perimeter of the profile. To be sure that you won’t hit the double-glazed window with the drill, and also won’t damage the bead lock, it’s best to play it safe (especially if you don’t know how deep the double-glazed window is into the profile) and make a two-centimeter indentation from the bead.

You need to drill a PVC window with a metal drill.

Very often, holes are drilled in plastic window structures for cables (Internet, telephone, alarm). One or two holes reaching 1 centimeter in diameter will not damage the window in any way if everything is done correctly. In addition to the above drilling rules, you also need to take into account the diameter of the cable and select a drill so that the cable fits into the hole as tightly as possible. This way, you won't have to use sealant to seal extra millimeters.

Types of Window Fans

The main types of fans are: axial, which is divided into three more subtypes - supply, exhaust, supply and exhaust, and also household and industrial.

Each of them has its own properties and differences: appearance, power, functionality. So, for example, axial ones have a simple design, but a fairly high efficiency output. Household ones cannot boast of power, but they have a neat appearance and do not spoil the design solutions in the living space. At the same time, industrial ones are quite powerful, but their appearance does not carry much weight when choosing.

Window fan is applicable to any type of window

Axial window fans

As already mentioned, they have a simple design. In fact, they consist of a propeller (otherwise known as a blade), the housing itself and the engine, thanks to which the propeller rotates. This device has an axis of rotation; air is forced along it with the help of blades, creating a powerful flow.

Axial fans are not manufactured according to the standard, and depending on the purpose of use they differ in the diameter of the propeller (the blades can be from several meters to a couple of tens of centimeters). The number of propeller blades varies depending on the purpose, and the engine power may also vary.

Simple design - but maximum benefit

Exhaust window fans

The exhaust fan acts as an aid to the kitchen hood, or works independently, eliminating extraneous “odors”. Its work is aimed at removing polluted air. Thanks to the rotation of the blades at a speed of about 4 thousand revolutions per minute, with low power consumption, it eliminates excess moisture or excess heat, and produces some kind of one-sided air conditioning.

With the purchase of this type of hood with blinds, you will not have to think about the reverse draft that exists in conventional hoods, since the blinds prevent this.

Blinds prevent backdraft

Supply window fans

The supply air exchanger works opposite to the exhaust air exchanger. With its help, air flow is supplied, but does not decrease. This type is used for a room where there is no need to purify the air, but only to fill it with oxygen. Used in residential and guest rooms, offices.

As is known, the air exchange rate in residential areas should be at least 30 m3 per hour per person. It is important to consider that those rooms where additional enclosing structures are located (for example, a plasterboard wall) require additional ventilation. The inflow rate also varies depending on the “population” of a residential or office space.

It is important to maintain the required air exchange rate

Supply and exhaust window fans

This is already an entire ventilation system that works in both directions, performing complete ventilation, both to remove stagnant air and to introduce oxygen from the street.

A reversible (that is, supply and exhaust) fan operates in the following order: outdoor oxygen is taken and at the same time oxygen is taken inside the room, then the flow from both directions is cleaned by filters, the street (often cool) is supplied to the heating element (heater), in addition the street warms up, because it intersects in the system with the one that is output. Such functions are inherent in this type due to its distinctive structure.

Reverse type is ideal for cafes and restaurants

Household window fans

These have a number of advantages that are worth paying attention to: they are small-sized, inexpensive, consume little energy, have a low noise level, and are easier to install than any other modern technology.

Using a window household fan, you can ventilate your home without losing heat and without getting dirt and dust into the room. Oxygen in a living room should be completely renewed every 2 hours, but few people follow this rule and ventilate so often. Therefore, a household window fan, or a similar vent fan, will ensure regular maintenance of a good microclimate.

The characteristics of the device are specified in the passport

Industrial window fans

The peculiarity of these is their large size and use exclusively for warehouses, workshops of small and large industries. In such places there is no point in installing air conditioners, but a good old fan will do its job. In many factories, for a long time and to this day, the main “savior” is the fan, which supplies oxygen and “takes away” pungent odors from the work shops.

Usually their installation is provided for during construction, and window openings are already made taking into account their installation. Such units boast great power, meter-long blades, but also considerable noise output.

The sizes of industrial fans are much larger than domestic ones

Selection rules

If you need to choose a household fan, you need to pay attention to:

- Installation method. The most important point, if you already have windows, is to first find out whether it is possible to install a fan in them at all, and whether anyone will undertake this.

- Will your glass hold up? If the fan is installed in standing plastic windows, this also needs to be clarified. You need to ask either the seller in the store (this is not a very good option, since you need to look at it live), or, ideally, call a specialist at home.

- Ability to control rotation speed. It is not necessary, but it is advisable for the fan to have several speeds. For example, you can keep it on at minimum speed all the time, and turn it on at maximum speed when smoking/cooking.

- Reverse. Of course, most often they are installed in kitchens, and only exhaust fans, but a reversible fan will not cost much more than a “one-way” fan. Therefore, it is better to take one just in case.

- Control method. The cheapest models with 1 speed can only be turned on and off, for which they usually have simple cord switches (pull the cord - the device turns on, pull again - it turns off). More expensive models have a remote control.

- The presence of blinds (check valve). A very useful option: if there are blinds, in cold weather, when the fan is not working, they will not allow cold air to flow inside. Of course, instead of blinds there can be a manual shutter, but you will have to open and close it yourself.

- The presence of a damper (lid). A mandatory item is to block the hole when the device is turned off.

- Performance. The only “quality” characteristic. Selected based on the volume of the room: the fan must remove 1 volume of air per hour. That is, if your kitchen has an area of 9 square meters and a ceiling height of 2.5 meters, its volume is 22.5 m³.

Model with lid

A small clarification about performance. According to SNiP 2.08.01-89, at least:

- 60 m³/h if there is a 2-burner stove;

- 75 m³/h if there is a 3-burner stove;

- 90 m³/h if there is a 4-burner stove.

Therefore, if you do not have a “regular” kitchen hood, and a window fan will replace it, focus on these indicators.

This advice is rather theoretical - in practice, even cheap models with a price of 1000 rubles will have a productivity of 100 m³/h+.

Advantages and disadvantages of use

The advantages include the following factors:

- no need to make a hole in the wall (as would be required to install an air supply unit/valve);

- low noise level (a kitchen hood can make noise about 50-60 dB or louder, a fan - on average about 30 dB);

- low power consumption (on average the hood power is from 0.3 kW, the power of a simple window fan is about 15-25 W);

- there is no need to lay an air duct (as for a kitchen hood).

Now about the cons:

- The fan will reduce visibility from the window and natural light.

- The passing air flow (if it comes from the outside inside) cannot be heated, filtered or cooled (unlike wall units and recuperators).

- In winter, cold air can enter the room through a non-working fan (even if the model with a cover is not a guarantee that this will help much).

- If there is no hole/block for the fan in the window, installing it will be very difficult (and essentially impractical).

- Not every glass can withstand a fan. If you place it in plain glass, it may crack (due to vibration of the motor, especially if it operates at high speed).

Is it worth installing such a fan?

Worth it if:

- Are you planning to replace the windows in your kitchen?

- There is no way to install a “regular” hood in the kitchen (for example, the ventilation shaft is damaged/clogged, or it doesn’t exist at all). In this case, a fan placed in the window will become its replacement. Although you can do it easier and install a fan in the wall.

Similar Soviet models were installed in old windows

In other cases, it’s easier to choose another option. This solution is specific, and simply choosing it is not very convenient.

Approximate cost and short list of models

For your reference, here are the prices for several different models:

- Era, size (diameter) 178 mm, with lid on the outside. Productivity - up to 280 m³/h, power - 16 W, for glass with a thickness of 3-6 mm. The cost is about 1000 rubles.

- Aeromat 100, type A (rectangular block, mounted in the sash). Productivity - up to 75 m³/h, power - 17 W. The approximate cost is from 16,500 rubles.

- Soler&Palau, simple model. Diameter - 174 mm, with blinds (check valve) and protective mesh. Power - 25 W, productivity - up to 400 m³/h. Costs about 2700 rubles.

- Soler&Palau HV, reversible model, with remote control. Diameter - 260 mm, power - 34 W, productivity - 600 m³/h. Costs about 16,000 rubles.

- Domovent. OK 150 Diameter - 150 mm, productivity - about 280 m³/h, power - 16 W. The cost is about 1000 rubles.

- Vents 125 MAO1T, with shutdown timer and blinds. Diameter - 125 mm. Can be mounted in glass with a thickness of 4 to 17 mm. Productivity - 185 m³/h, power - 22 W. Costs about 2500 rubles.

- Ventilor, with blinds. Diameter - 200 mm, productivity - up to 450 m³/h, power - 50 W. Costs about 7,000 rubles.

To summarize : a simple model with a mechanical switch and blinds will cost about 1,500 rubles.

Review of the Domovent OK model (video)

Where can you not drill PVC windows?

The glass unit and latches (places for attaching glazing beads) are the most vulnerable areas of a plastic window. It is strongly not recommended to make holes around the perimeter of the bead connection to avoid damage. The most unacceptable area for drilling holes is considered to be the distance from the place where the bead seal begins and to its lower border, but not less than 20 millimeters. To avoid the risk of damage to the glass unit, be sure to take this distance into account. Also, you cannot drill moving parts of a plastic window structure. Holes can only be made in the frame and blind sashes.

ERA HPS 15 – inexpensive

An axial type fan built directly into the window opening - a window transom. A check valve is provided, controlled by a cord switch. Opening the protective device - towards the street, outwards.

Durable ABS plastic is used for the housing and impeller, resistant to moisture, ultraviolet radiation and temperature changes. Optimal for work in small rooms, kitchens, change houses.

Pros:

- Lightweight, quite economical, simple operation.

- The price is just right for installation in the kitchen.

- Easy installation, especially on wooden windows.

Minuses:

- I had to work on a collective farm to make a transition trim for the window. There are no ready-made ones for sale.

BPP 15 BVN (Bahcivan) – reverse

Household series window fan. The power housing and impeller are made of durable, weather-resistant plastic. The built-in reverse function allows the design to operate in two modes, supply or exhaust.

This allows you to remove stagnant dirty air from the room, followed by renewal of the air mass due to the forced pumping of a fresh portion. The process speeds up the restoration of a comfortable environment in a residential or commercial premises.

Pros:

- Performance, reverse function.

- Cord operating mode switch.

- He works in a small bakery and does his job well.

Minuses:

- Mechanical switching.

Hole in glass unit

Unfortunately, at home, making a hole in a double-glazed window with your own hands is an almost impossible job for many home craftsmen. This is due, first of all, to the complex design of the window profile, and even the double-glazed window itself, in which you need to make a hole for an air conditioner or fan.

A glass-cutting compass will not help with this problem either, since it will not be enough to simply remove the double-glazed window; you also need to be able to cut it. Fortunately for many people, there are various other alternative options for how to make a hole in a double-glazed window, or rather, replace it using any of the methods described below.

These methods will be discussed next, since in most cases many people choose them because of the simplicity of the actions.

Wind-K 125 ST – low noise

Exhaust fan installed in a window. It features controlled blinds and a timer. The latter function allows you to automate the operation of the device by setting a program for turning on or off the electric motor at certain intervals.

The design includes a protective cap that completely blocks the air flow when stopping. The quality of workmanship and proper balancing allowed the fan to achieve low noise during operation.

Pros:

- Quiet during operation, does not whistle like a jet plane.

- Price, cap - it doesn't show through the window.

- Timer: programmed, turned on and forgotten.

Minuses:

- Pull cord switch, it can be more expensive, but to work from the remote control.

Is it worth doing it yourself?

When drilling windows, care and accurate calculations are needed, since this activity is not only important, but also dangerous. If you do not have skills in this area, you need to carefully study the technical material or ask for advice from professionals.

Specialists know about the structure of structures and the nuances of various models, the location of air chambers in which holes need to be drilled.

There are also vulnerable points in the design of windows, in case of accidental damage the window must be quickly sealed.

The conclusion is simple: if you are confident in your knowledge and skills, you can make the holes yourself. If you don’t want to take risks, you can call professionals.

O'Erre Smart 15/6 M – five modes

Reversible window fan with the ability to set one of five rotation speeds. A reverse option is provided. The principle of operation of the device is supply and exhaust. Control is via a remote electronic remote control.

The curtains are opened or closed manually, using a telescopic insert that is adjusted to the actual thickness of the window. The plastic of the grille and body are made in a splash-proof design. The structure is fully prepared for installation in a window opening.

Pros:

- Five rotation speeds, remote control.

- Possibility of installing reverse.

- Rain, wind and sun resistant plastic.

Minuses:

- Consumers do not note any negative aspects.

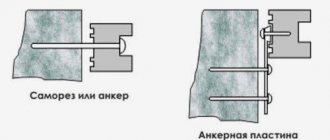

Self-tapping screws for PVC windows

An incorrectly selected screw, as well as an incorrectly selected drilling location, can severely damage a plastic window. To install various additional and decorative elements on plastic window structures, experienced installers, as a rule, use self-tapping screws 9.5 millimeters or 15-17 millimeters in length. At the same time, as mentioned above, they need to be screwed into potentially safe places. Self-tapping screws should have a thin base and be without a drill at the tip. The main mistakes that non-professionals make when drilling plastic windows:

- If you try to screw a self-tapping screw into the glazing bead or slightly below it, the glass unit will be damaged. The glass used in PVC window structures is very durable, but despite this, touching a self-tapping screw to a double-glazed window will cause cracks to appear on the glass. Repairs will not be possible; the glass unit will need to be replaced completely. It will cost at least a third of the entire cost of the window structure.

- A self-tapping screw of the wrong length (too long) will most likely break the tightness of the internal chambers of the PVC profile. As a result, the heat and sound insulation properties of the structure will be lost. Also, incorrectly selected screws can disrupt the operation of the fittings and cause the window to stop opening.

- It will not be possible to disguise a hole from an incorrectly screwed screw without compromising the aesthetic and performance qualities of the structure.

Based on all of the above, it becomes obvious that, if possible, it is worth choosing other methods of attaching additional elements to a plastic window. And if drilling cannot be avoided, it is better to trust the professionals.

Elicent VITRO 6/150 PA – automatic blinds

A device mounted on a window transom or directly on a double-glazed window. Designed to move air masses outside to update the air composition. The fan is equipped with an automatic system for opening and closing protective shutters.

The latter are made taking into account the effects of atmospheric moisture, solar radiation, and temperature changes. It is possible to work with a programmable timer to set the frequency and duration of fan operation.

Pros:

- Automatic operation mode, setting a timer simplifies control.

- It is quite compact and light weight, which allows it to be installed directly into a double-glazed window.

- Works in the kitchen, easily removes odor and smoke when something burns on the stove.

Minuses:

- A bit noisy, but not too much.

Manufacturing a double glazed window with a hole

It is important to understand that cutting or drilling a hole in a double-glazed window while preserving its functional features is impossible at home or in a DIY setting! Only a professional master, using professional equipment, will be able to perform high-quality work like this!

Production stages

- Preparation of glass sheets according to the dimensions of the future double-glazed window.

- Milling of holes in each glass according to precisely measured measurements.

- Processing cut edges, cutting spacer frames.

- Assembly and sealing of double-glazed windows (primary and butyl sealants). Filling with inert gases;

- Delivery of the finished product to the site and its installation.

Systemair BF-W 230A Window fan – installation on a window or wall

Window fan to create air flow to renew the air mass inside the room. Can be installed directly on a window or wall.

The design is equipped with a gravity check valve, which is opened by the pressure created when the device is turned on. Closing - when disconnected.

The fan is installed in residential, domestic and civil premises. Used in catering establishments. It features high performance with low power.

Pros:

- Performance with little power.

- Universal installation.

- Gravity check valve.

Minuses:

- Very noisy at full load.

Vortice Vario 230/9″ AR – full functionality

High quality product from an Italian manufacturer. The window fan can operate in supply and exhaust mode. Equipped with automatic blinds. High-quality materials and ball bearing supports significantly increased the overall service life of the assembled product.

Increased rotation speed and productivity. The outer grille is made in a weather-resistant design. The body and blades are made of impact-resistant polymer. Power supply: from a stationary power supply of 220 volts.

Pros:

- Supply and exhaust ventilation, automatic blinds.

- Reliability, durability, service life.

- Easy installation and operation.

Minuses:

- High noise at full load.

- The price is high.