07/27/2014 Category Sandwich panels

The term “sandwich panels” refers to multilayer frameless building structures. Their layered structure is indicated by the word “sandwich” itself, which comes from the English sandwich (translated as “layer, insert between something”). The characteristics of the products in question allow us to classify them as lightweight enclosing structures.

The panels are equipped with special locking connections, with the help of which they are connected into wall blocks.

- In most cases, a kind of “sandwich”, which is a panel, includes three elements:

- core made of foam plastics (polyisocyanurate foam, polyurethane foam, polystyrene foam) or mineral wool. Plays the role of a heat-insulating element;

- two metal sheets forming the skin. They are located on both sides of the core. Designed to protect products from mechanical damage, moisture and other negative factors, ensuring the external attractiveness of building structures. In addition to metal sheets, other materials can be used to make cladding.

Main characteristics

Sandwich panels are mainly used for the construction of low-rise buildings for commercial, industrial or other purposes. Due to its “official” appearance, it is rarely used in the construction of residential buildings. Most often this finishing material is intended for walls. Installation is carried out by attaching it to a metal frame with self-tapping screws.

One of the areas of application of sandwich panels is the construction of industrial buildings Source 2gis.ru

There are several types of sandwich panels.

- External wall sandwich panels . Made from metal sheets and insulation. They are mainly used for the construction of partitions, cladding the walls of a building, and for insulation purposes.

- Roofing sandwich panels . Used to cover roofs. Long-term use. They are made of fireproof materials, retain heat for a long time and isolate loud street sounds. Fastening is carried out using a unique technology that protects against deformation in the warm season.

- Three-layer sandwich panels . Convenient to use. Installation of such plates occurs quickly, without any difficulties. There is no need to strengthen the supporting structures of the building. Manufactured from galvanized steel and can be coated with polymer compounds. Currently, this type of sandwich panels is used most often. This is the most modern building material. Moreover, the use of three-layer sandwich panels significantly reduces financial costs.

- Corner sandwich panels . Used to create a complete image of a building. Can be semicircular or angular. Made from heat-resistant, fireproof material.

Corner sandwich panels reduce labor costs during the construction and finishing of buildings Source kingspan.com

Sandwich panels are varied in color, which is determined by international color standards. Colors must be chosen in accordance with climatic conditions. It is necessary to take into account the light reflection and light absorption properties of the material. The service life of the building directly depends on this.

See also: Catalog of companies that specialize in insulating country houses.

Specific installation nuances

It should be remembered that to form a connection that provides strength and insulation along the joint line, you need to use only the methods specified by the manufacturer.

Most panels are latched or doweled together. The junction points with the metal frame are covered with damper tape.

For fastening to the rafter system, self-tapping screws are produced, the selection of which for construction and cladding takes into account the base material. The roof of the panels is fixed to the frame of the building through a mauerlat installed around the perimeter or a wooden block replacing it along a metal frame.

Fastening elements are selected not only taking into account the upcoming application and the type of base to which they are to be attached. The thickness of the panel must be taken into account, which is also taken into account when choosing shaped parts and additional elements for arranging wall cladding and constructing insulated attic roofs.

Types of insulation for exterior sandwich wall panels

First of all, external wall sandwich panels are usually distinguished by the internal composition of the insulation:

- Polyurethane foam . The material is practically not subject to corrosion and deformation. Resistant to thermal and mechanical influences. It is a clean environmental product. Quite durable. The cost of such sandwich panels is quite high. However, the material is not safe in case of fire.

- Expanded polystyrene . Has high heat and sound insulation. Not exposed to thermal influences. Environmentally friendly and lightweight material. Retains its shape during prolonged contact with water. An advantage is the possibility of installing sandwich panels in the cold season. The main disadvantage of the filler was such characteristics as fire hazard, color change when exposed to sunlight, changes shape at temperatures above 1000⁰C, and causes various allergic reactions.

Sandwich panels with polystyrene foam insulation Source proroofer.ru

- Polyisocyanurate foam filler . The leading material among sandwich panels. Environmentally friendly, not subject to corrosion and deformation. Has minimal thermal conductivity and elasticity. Durable, fire resistant and durable. Among the disadvantages of the building material, one can highlight only its high cost.

- Mineral wool filler . The advantages of insulation are non-flammability and good sound insulation. The material is environmentally friendly. Does not undergo deformation when exposed to heat. When in contact with metal, the possibility of corrosion is reduced to zero. It is easy to use and install. Sandwich panels filled with mineral wool also have a number of negative characteristics. First of all, it is harmful. When installing such sandwich panels, you must use a respirator. Over time, the material loses its heat-insulating properties. Working with sandwich panels is only possible in good weather, since mineral wool is a non-moisture resistant material. In contact with water, the sandwich panel may delaminate. A fairly large weight requires additional strengthening of the supporting structures.

Mineral wool is an environmentally friendly material, but over time it loses its properties Source s-paneli.ru

- Fiberglass insulation . The composition of the filler is similar to mineral wool, but differs significantly in properties. The advantages of this material are non-flammability, fairly high heat and sound insulation. The product is light, elastic, durable and environmentally friendly. The disadvantages include high absorption of liquids, inability to use at high temperatures, and deformation due to sudden changes in temperature. If inhaled, it can cause severe allergic reactions.

- Combined type fillers . The filler contains a mixture of various building materials. Basically, these are mineral wool and polystyrene foam.

The properties of mineral wool and durability will be supported by polystyrene foam in sandwich panels with combined insulation Source samara-paneli.ru

House projects

If you decide to build buildings from panels, the first step is to make a project. A similar project is being created for other houses. It contains:

- foundation;

- number of storeys of the building;

- building perimeter;

- the number and size of all internal premises;

- location of electrical wiring;

- placement of heating devices;

- finishing method and many other nuances.

Creating a project is a very complex process, so you won’t be able to do everything yourself without certain skills and knowledge. This means it’s better to immediately turn to professionals so as not to forget anything.

In this case, the designer will be able to calculate how strong a foundation needs to be made for a particular house, as well as select the interior.

Types of external cladding of sandwich panels

Just like the internal filler of sandwich panels, their outer layers are made of various materials.

- Paper . Aluminum foil or polyethylene becomes an addition to paper. You can find panels in which the paper is impregnated with bitumen. Sandwich panels with such cladding have a relatively low price and are economical to use.

- Metal . Mostly thin stainless or galvanized steel is used. The metal is covered with aluminum foil, cloth or paper. This serves as a protective function for the upper layers of the sandwich panel.

- PVC . There is a layer of insulation between the PVC sheets. Such sandwich panels are used for the construction of partitions, finishing of door and window openings.

- Drywall, fiberboard, plywood . The product is sheathed on both sides with different materials. Used in the construction of office partitions. Convenient to hide wiring if necessary.

This is what office premises look like when equipped with sandwich panels Source stroi-innovatsii.ru

How to properly build houses from SIP panels with your own hands?

When you have a detailed project in hand, it is much easier to decide whether you can do everything yourself or whether you will still have to hire workers. In any case, you need to understand what is done and when when erecting a structure from SIP.

Foundation

As stated above, they are quite lightweight. 1 m2 it weighs no more than 20 kg, so there is no need to equip a very large and durable base.

If we compare the amount that needs to be spent on building a basement for a brick house and for them, then for the second option you need to use 3 times less money.

Most often chosen:

- pile foundation;

- shallowly recessed;

- monolithic concrete.

Any type of foundation must be waterproofed. This will help extend the life of the entire structure.

Laying the strapping beam

After the base is ready, they begin to set the “zero level”, which is also called laying the strapping beam. This stage is important, because the quality of the work determines how easy and reliable the installation will be in the future. Of course, the duration of operation also depends on the laying of the timber.

The beams are attached directly to the foundation. Anchor bolts are used for this. The beam is drilled through, so that the bolt goes deeper into the foundation by at least 10 cm.

After installation, the timber must be covered with bitumen or another mixture that can protect the wood from moisture.

Arrangement of floors and ceilings

Floors are created from horizontally laid sandwich panels and beams. Work according to the following plan:

- The filler is selected at their ends so that the panel can be secured in the corner of the trim beam cut during installation.

- Lay the first row.

- In the longitudinal parts, where there are already recesses, logs are installed from timber or two boards fastened together.

- All elements are secured to each other with self-tapping screws.

- Next, subsequent panels are laid in the same way.

- At the last stage, their ends are necessarily closed.

A floorboard or other flooring material can be laid on top of this structure.

Construction of walls, description of the process

Before you start building walls from sandwich panels, you need to make the bottom frame of the walls. For this, a wooden beam with a height of 50–60 cm and a width corresponding to the thickness of the insulation is used. If it is not on sale, you can use several boards that are fastened together.

The products are fixed with self-tapping screws in increments of no more than 40 cm. Such piping is made taking into account all the internal premises that are included in the house design. For the construction of walls, the frame method is most often used. They work like this:

- The first panel, which will be corner, needs to be cleared of a little insulation on both sides. Next, for installation, the following manipulations are performed in all panels. This is where the frame element will be placed. This design is aligned at an angle.

- On the other hand, the walls install a second slab perpendicular to the first.

- All elements are connected to each other with self-tapping screws.

- Next, proceed to install the second plate on the wall. The frame post should be placed clearly in the middle between the two elements.

The entire structure is assembled according to the plan proposed above.

Roof arrangement

To build a roof, first construct the following from the same SIP slabs:

- load-bearing elements;

- runs;

- skates.

They must rest on the frame posts. In the same places, the parts are fixed using self-tapping screws. Next, proceed to the rafters. It all starts from one of the gables and moves to the other. This is a rather important stage, so it’s better to hire workers to create the roof.

Polymer coating

Sandwich panels also differ in the type of polymer coating. Let's look at a few main types.

- Pural (pural) . The material is resistant to sudden temperature changes and does not react when exposed to ultraviolet rays. Mainly used for external cladding of buildings.

- PE (polyester).

- Polydifluorionad . The coating is resistant to aggressive chemical compounds, changes in air temperature and external mechanical influences.

- Plastisol . Sandwich panels with such a coating are used not only for exterior decoration of buildings, but also for interior decoration.

Sandwich panels coated with plastisol can be used both indoors and outdoors Source user.it

Construction cost

How much the owner will spend on building a house from SIP panels depends on several points:

- Socle type.

- Size of the house (number of square meters and floors).

- Who will do the work.

- You can buy a ready-made house kit or assemble all the elements yourself.

- Materials for external and internal finishing.

If you are interested in a specific price , then a two-story house with an area of 129 m2 and all the work done by professional craftsmen will cost about $32,000 .

Dimensions

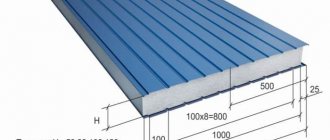

The sizes of sandwich panels that go on free sale have a certain value. Namely:

- Length from one to eight meters.

- Width 120 cm (installation width – 115 cm).

- Standard thickness varies from five to twenty-five millimeters.

It should be noted that roofing products are larger in size. The size of composite panels does not differ.

Sandwich panel sizes

On a note! During construction, when it is necessary to finish a large area, the size and characteristics of this material can be ordered individually.

Product composition

As already noted, this type of material has a multilayer structure. Therefore, sandwich panels mistakenly include anything that more or less resembles a sandwich. Which causes some confusion. More specifically, to decide, the following should be said about them:

- Indeed, this product has a multilayer structure; the simplest ones consist of three layers (see photo).

- The facing material on both sides is a hard material (aluminum and galvanized sheets, wood fiber boards), it can be quite different.

- There is filler inside. Most often this is a certain type of insulation that is glued to the outer sheets.

Multilayer sandwich panel composition

On a note! Often the filler can consist of several elements, each of which has its own purpose. And together they give better results.

Bottom line

The use of sandwich panels for the construction of prefabricated facilities can significantly reduce construction time. This is explained by the low final weight of the walls, which do not require an expensive foundation. However, with all their advantages, such buildings are inferior in durability to traditional houses made of brick, stone and blocks. They are designed to last approximately 50 years.

Sandwich panels: pros and cons, types, use, cost

Wall material construction sandwich panel