Despite the fairly rapid development of construction technologies and the emergence of new types of building materials, brick, as before, remains the most popular and in demand. This is explained very simply: it has strength, durability and excellent performance characteristics. A brick wall, built according to all the rules and having a thickness calculated taking into account the purpose and type of construction, can last several decades.

Advantages of brick

Brick is a very reliable material. If the brickwork is laid according to technology and has the required thickness, it can easily withstand heavy loads from the roof structure, floors, and ceilings. In addition, this building material is endowed with such qualities as good sound insulation, fairly low thermal conductivity, high resistance to bending and deformation, frost resistance, and durability.

Brickwork, designed in accordance with established standards, does not require the construction of a bulky foundation, but at the same time it will have excellent load-bearing capacity. But all these qualities can be lost if the thickness of the walls of the house required for specific conditions is not taken into account.

The disadvantage of brick is that it is inferior to many wall building materials in terms of heat and sound protection characteristics. For example, when it is -30 °C outside (and this is not uncommon in Russia), the thickness of the external walls should be 64 cm. Whereas under the same climatic conditions, a wall thickness of 18 cm made of timber will be sufficient.

What to consider when choosing the type of brick wall

When choosing the thickness of brick walls, it is important to consider:

- Estimated load. After all, if the house is one-story, then the load, of course, will be completely different than in a multi-story house. In addition to the number of floors, the functional purpose of the masonry is of great importance.

- Climatic conditions. Any building must provide the required temperature inside the house. In other words, when building a brick wall, its thickness should be such that it retains heat in the room and does not freeze in the winter without heating.

- Compliance. When calculating the thickness of a brick wall, it is necessary to be guided by current GOSTs so that the structure being constructed is completely safe during operation.

- Aesthetic appearance. Different types of masonry look different. For example, masonry with one brick, as a rule, looks more elegant than a similar one with one and a half or two bricks.

Material advantages

The key positive properties of brick are:

- high strength;

- aesthetic appeal;

- good sound insulation properties;

- fire safety;

- resistance to negative temperatures;

- environmental safety;

- versatility;

- long service life.

It is possible to build both one-story private houses and high-rise buildings from brick, the main thing is to correctly calculate the thickness of the outer wall masonry. The material, without changing its own properties and characteristics, can withstand loads that are a thousand times greater than its own weight. Buildings made from it can last hundreds of years if all technological nuances of masonry are followed,

Brick sizes

The modern building materials market offers customers a variety of types of bricks:

- Single. The dimensions of such a brick are: height is 6.5 cm, length is 25 cm, width is 12 cm. The thermal conductivity of such a brick is 0.6-0.7 W/mS.

- One and a half. Its dimensions are as follows: length - 25 cm, height - 8.8 cm and width - 12 cm. From a financial point of view, it is much more efficient to use such bricks for the construction of external load-bearing walls.

- Double. Its parameters: length - 25 cm, width - 12 cm, height - 13.8 cm.

From a financial point of view, one-and-a-half and double bricks are the most effective. Their size allows the construction of load-bearing walls or the plinth of buildings of greater thickness, using less mortar than is necessary when building similar houses from a single brick.

Frame partitions:

With a wooden frame covered with boards and shingles

They are a prefabricated structure. The thickness of such a partition depends on the thickness of the frame and, taking into account the plaster layer, is 10-15 cm. As a rule, such partitions were made quite a long time ago in brick, block, stone and private adobe houses. Most often, such partitions are found in “Stalin” buildings and private houses.

Panel partitions made of boards

They are a prefabricated structure. Found only in wooden houses. If the boards are planed, they are not plastered.

With a wooden frame covered with plasterboard sheets

Oddly enough, plasterboard partitions were made by Soviet builders long before perestroika, although not very often. The thickness of such a partition depends on the thickness of the frame.

With a metal frame covered with plasterboard sheets

Modern partitions are not found in houses and apartments built before 1990. The thickness of such a partition, taking into account the thickness of the drywall, is 7.5, 10, 12.5 and 15 cm.

With a wooden frame covered with chipboard or plywood

Homemade partitions. Found in apartments and houses that have undergone redevelopment.

With a wooden or metal frame covered with plastic or MDF wall panels

Modern homemade partitions.

What should the wall thickness be?

Let's consider the parameters that depend on the thickness of the brick wall.

- Stability, strength and reliability of the structure. It is important to consider that when a load-bearing internal or external brick wall is built, it must be of sufficient thickness to ensure the stability of the building and be able to withstand not only the weight of the floors and all floors, but also the negative external influences of natural phenomena such as wind, snow and rain.

- Durability of the building being constructed. This parameter is ensured by many factors, including compliance with construction technologies, taking into account the characteristics of the climate and soil, the correct choice of materials, etc. However, the strength and thickness of the wall come first on this list.

- Sound and thermal insulation. When constructing a brick wall, its width must be calculated in such a way that it can optimally provide insulation from cold and external sounds. Thus, the thicker the brick wall, the more effectively it protects against these factors. However, here you need to take into account the cost of building materials. It is simply irrational to build walls thicker than those required by standards for certain climatic zones.

DIY device

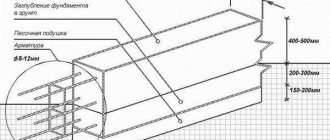

To install concrete products of this type with your own hands, you need to carefully study all the technology.

The main stages of constructing a monolithic reinforced concrete wall:

- Performing calculations

- Site preparation – removing dust and dirt, clearing the site

- Pouring the foundation, waiting for the due date to continue work

- Installation of removable/fixed formwork along the general perimeter of the building and all internal walls

- Mounting a reinforcing frame to strengthen the structure

- Pouring concrete formwork

- Proper care of concrete during its hardening and hardening process

Standard dimensions of brickwork

One of the main characteristics of a brick structure is the thickness of the wall. It is not at all difficult to define it. According to established norms and standards, this value should be a multiple of half the length of the brick, i.e. 12 cm.

But today factories produce brick blocks of various sizes. In addition, when working with this material, builders use different masonry schemes. This means that the walls will ultimately be different in width.

Wall thickness, according to SNIP, depending on the type of masonry and the number of bricks used:

- half a brick – wall thickness 12 cm;

- one brick is 25 cm;

- one and a half bricks – walls 38 cm;

- two bricks - 51 cm;

- two and a half bricks - 64 cm.

The goals are clear, the decision has been made

Scrolling through numerous Internet sites, you have probably repeatedly come across a variety of videos and photographs that show how easily part of a wall, or a fragment of it, can be removed in order to at least visually expand Khrushchev’s little rooms and give them a more or less bearable appearance in spatial terms. And if you add modern decoration to this, then the desire flares up on its own.

We also prepared materials on redevelopment, but in each material we referred to the fact that the load-bearing wall is inviolable. Now it is time to determine the degree of this immunity and the procedure for determining the load-bearing capacity.

So, you can determine a load-bearing wall:

- According to the thickness of the brickwork;

- According to the technical documentation of BTI;

- With permission from the architecture department of the locality in which you live;

- According to the consequences of rash actions.

A few words about thickness

- The thickness of any wall is calculated in brick parts from half a brick to three bricks . In the language of numbers, half a brick is 120 mm, and a full brick is 250 mm. When constructing buildings, calculations are also made for connecting seams, which according to standards are 10 mm. If you come across a 120 or 250 mm brick wall, then these are usually partition walls or partitions made from bricks. They do not carry a significant load, but one should not rush to conclusions. Load-bearing brick walls were usually built from 380 to 640 mm, depending on the climatic region in which the structure was erected. Thus, the minimum thickness of a load-bearing brick wall will be 380 mm, or one and a half bricks. Do you remember? Not a fact.

One and a half bricks, and even with reinforcement, probably load-bearing.

- And now a few words about the features of counting and buildings . Brick houses have always been considered a costly construction; the price of such a house has always been higher than a panel one. Brick solved problems of heat preservation worse, and it had to be laid in a large layer. In addition, the building brick did not have such a neat appearance, and the double sand-lime brick M 150, and even other sand-lime bricks of a higher grade, absorbed moisture well. In this case, additional cladding and new costs were required. In cases of housing construction, an attempt to save material was made already in those days. If load-bearing walls in a brick Khrushchev house were built with two bricks, then full masonry was carried out only on the first two floors. Next, well brickwork was made, and the voids were filled with expanded clay or other foamed material. By disassembling the panel limiting the expanded clay, you will get a whole bath of expanded clay. This is good for flower growers, but the rest of the residents obviously won’t thank you.

Internal wall thickness

Internal partitions of the structure are designed to divide the entire area of the house into separate rooms, as well as to sound and heat insulate rooms. The optimal thickness of brick walls located inside the building is 12 cm (built in half a brick). This size is quite sufficient for a comfortable stay.

Often during construction, brick blocks are laid “on edge”. This allows you to get thinner partitions - only 6.5 cm. This can significantly save on consumables. True, the heat and sound insulation qualities of the rooms will leave much to be desired.

Load-bearing brick walls and their thickness

External load-bearing walls are designed to bear the entire weight of the upper floors, roof and partitions. Naturally, they should be much stronger than others.

When choosing the thickness of load-bearing walls, the following factors are taken into account:

- climatic features;

- location of the future building;

- dimensions and layout of the building;

- estimated construction budget.

At the same time, you need to understand that the thickness of the load-bearing walls should be at least 38 cm (which corresponds to a masonry of 1.5 bricks), and in cold regions - 51-64 cm.

In a residential building, some internal brick partitions are also load-bearing. Here it will be enough to make a masonry of 1 brick, while the thickness of the walls of the house will be 25 cm. Such a structure will withstand any load without cracking or deforming.

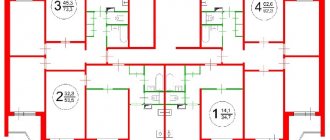

Designations on the house plan

One way to find out which walls in a panel house are load-bearing is to familiarize yourself with its structural plan. You can obtain it from the technical inventory bureau, the Management Company, or from the Capital Construction Department. The document can be shown by the chairman of the board of the house, who probably has all the necessary copies with him. Another option is to find a plan online. To do this, you need to know the design of the house and the year it was built. The easiest way to determine the location of load-bearing surfaces is to study the technical passport of the apartment, if it is not lost or has not become unusable during storage. The disadvantage of this solution is that a decryption is not attached to the passport. You may need to contact a construction specialist.

In the diagram, the walls are indicated by double lines with breaks at the places of window and door openings. There are several options for making projects when designers use colors or limit themselves to black and white. Carriers can be drawn in solid gray with an oblique stroke, red or black stripe. Non-load-bearing partitions are indicated by a thinner line in green, black or blue. To make the drawing easier to read, a table is made with a transcript of its contents.

How to reduce the thickness of brickwork by improving thermal insulation

Every developer, naturally, is concerned about the price of the issue, and, of course, there is a desire to reduce the cost of this process as much as possible. But at the same time, make sure that the savings do not affect the reliability, durability and thermal insulation qualities of the building.

There is a technology of well-shaped masonry, the principle of which is to erect load-bearing external walls in 2 rows. The empty space that remains between them is filled with porous material:

- light concrete mixture;

- slag;

- organic insulation;

- expanded clay;

- polystyrene foam.

This design of external load-bearing walls can significantly reduce the amount of brick, reduce the weight of the building, and increase noise and heat insulation. Such walls are strong, thick and reliable.

As additional thermal insulation, you can make a ventilated façade using special thermal insulation panels, various facing materials or plaster.

When finishing external walls with bricks, they need to be insulated from the inside. This operation is performed as follows:

- The internal surface of the external walls is sheathed with insulation.

- A vapor barrier film is mounted on the insulation.

- The resulting structure is covered with reinforcing metal mesh and plastered.

- Decorative finishing of the walls is being carried out. Finishing materials are selected depending on the taste of the home owners.

The use of this technology provides the building with high performance characteristics, while reducing construction costs.