Gas holder - the name was borrowed from English. Gas – gas and holder – holder, owner. Under the loud name there is simply a storage tank for a gaseous substance. Most often, residents of private houses pump and store natural or liquefied gas into such containers. Heating systems that include solid fuel or diesel boilers may often not suit homeowners due to labor-intensive maintenance.

An alternative in this case is a high-tech gas boiler, but what to do when the main gas pipeline is too far from your home, or is completely absent? A gas tank comes to the rescue. The use of such a device is not at all uncommon in the modern world. A correctly selected gas tank, depending on the volume and corresponding gas consumption of the boiler equipment, is capable of providing a country house with fuel, requiring replenishment only twice a year.

What is a gas holder: general information

A gas holder is a container designed for long-term storage of natural gas or other gaseous substances (biogas, liquefied petroleum gas, air, etc.), but for heating purposes the tanks are filled with liquefied propane-butane. Gas holders are used both on an industrial scale and for private use.

This autonomous system is a large reservoir for storing gas reserves, which allows you to not depend on the state and independently regulate the amount of utility bills for gas supply. By refilling the container once or twice a year, depending on the volume of the tank, you can safely use a gas stove for cooking and heat the house.

Gas tanks vary in volume - from 2500 to 20,000 liters; small tanks are used for mobile gas tanks. Since these are devices that require increased attention, it is mandatory to install protective automation that monitors the gas pressure inside the tank, controls the distribution and amount of fuel, and is also responsible for the safety of the autonomous system. The gas holder, the photo of which is shown below, can provide gas to a large private house.

Horizontal gas tanks of large volumes Source rosavtonomgaz.ru

Where is mobile gas storage used?

Mobile gas tanks are used for a variety of purposes:

- on construction sites;

- for garden houses;

- at the dachas;

- for trailers and cabins;

- as a means of emergency gas supply, etc.

For example, on a plot of five to six acres, technical conditions do not allow installing a stationary model; all that remains is to either carry cylinders or use a mobile option, which is much more convenient. It needs to be refilled less often and is easier to use.

If extensive excavation work is required to install a stationary underground gas tank, then installation of a new mobile model will take a maximum of an hour

A mobile gas holder can power a boiler room; they are used for gas welding, for roofing work, such as drying surfaces, installing surface-surfaced materials: roofing felt, its bitumen-polymer analogues, etc.

In combination with a good gas convector designed for economical fuel consumption, a mobile gas holder will be an excellent choice for heating garages, utility rooms, change houses and other similar objects.

Types of gas tanks

Gas tanks have been used for private use for decades. Previously, they were very large, cylindrical structures with adjustable heights and were used to supply gas to entire areas in cities. Such systems are called gas holders of variable volume, and in some cities such buildings have been preserved to this day, albeit as museum exhibits.

What is a gas holder for a private home today? Modern versions of tanks are used mainly for gasification of private houses, summer houses, country cottages and have a more compact shape. They have a constant volume, are made of very durable metal and can be either vertical or horizontal. In addition, gas tanks are divided into above-ground and underground.

Installation of an underground gas tank Source rosavtonomgaz.ru

Ground. Installed on the surface of the land. A gas holder for a ground-based private house is advantageous in that the tank is easier to maintain and it is much easier to detect corrosion or other changes and breakdowns. But we should not forget that with such an installation in winter, the evaporation ability of the air-gas mixture drops sharply; in addition, the ground version of the tank requires additional safety measures.

Ground-based small gas holder Source rosavtonomgaz.ru

First of all, you need to make sure that the container is not exposed to direct sunlight. Despite the fact that the tank body is designed to withstand high temperatures, for additional safety it is better to install the gas holder in the shade.

In order to significantly save space on the site, when choosing a ground-based gas tank, preference is given to vertical type tanks with a small volume, which are connected into a single network. From the point of view of operation, a vertical gas tank is in no way inferior. The photo below shows horizontal and vertical containers of different volumes.

Vertical and horizontal gas tanks Source resant.ru

Underground. At first glance, the underground installation of a gas tank is associated with additional costs, which consist in the need to attract special equipment. But the underground location of the system provides protection from the cold, additional safety and constant, even gas pressure.

To prevent freezing of the tank and avoid mechanical damage, underground gas tanks are buried to a depth of at least 60 cm. As for the volume of the tank, on the site of a country house or private house you can easily place a tank with a volume of 2500 to 10000 liters, and the gas tank will not spoil its appearance landscape design.

The tank is buried in the ground so that only the neck remains on the surface, to which the filling unit is connected. Gas enters the house through pipes running from the unit to the building.

Vertical underground gas tank at the installation stage Source teplowood.ru

See also: Contacts of construction companies that offer house insulation services.

Vertical. They are very similar to huge cans, and differ from horizontal ones in that they take up relatively little space on the site. But with high gas consumption, such tanks are additionally equipped with evaporators, which help provide the consumer with the required gas pressure. This makes installation noticeably more expensive and increases operating costs.

Thus, a vertical tank is only beneficial if the gas is used for cooking and providing the home with hot water in the summer, when relatively little is required. It should also be taken into account that vertical gas tanks are most often designed for underground installation, which means that high installation costs are added to low efficiency.

Installation of a vertical gas tank Source magniteknn.ru

Horizontal. They are considered the most common in our regions due to the fact that they have a large area for the evaporation of the so-called “liquid phase”. In the horizontal version of the gas tank there is always a sufficient amount of air-gas mixture, which is enough to ensure normal pressure at increased consumption. Therefore, to ensure proper evaporation, natural conditions are sufficient and no additional devices are required, and this is a big cost savings. Horizontal gas tanks are capable of providing sufficient pressure even in severe frosts. Only one drawback was found - installing such a tank will require a lot of space.

Installation of a horizontal gas tank Source rosavtonomgaz.ru

Mobile gas tanks

If the housing is not used constantly or there is not enough free territory to place a stationary device, it is reasonable to use a mobile gas holder. What are they and how are they used: this is also a gas supply device, only in small sizes, they are used as needed, for example during the summer season, and when it is not needed, it is simply stored.

Advantages:

- Such devices can provide gas to the premises during the summer season, and you can take them with you for the winter;

- It is possible to provide gas to several objects in turn;

- No special equipment or free territory on site is required for installation and assembly;

- Since the volume of a mobile gas storage is small (approximately 500-600 liters), its cost is correspondingly low.

All gas holders require registration with the relevant authorities and the mobile version is no exception.

Mobile gas tank or mini gas tank Source resant.ru

Autonomous gas supply AvtonomGaz

Autonomous gas supply to private houses, carried out by AvtonomGaz, is a full range of equipment, works and services, including the following operations:

- Supply of an underground gas tank for storing liquefied gas with a volume of 2.7-20 m 3, manufactured and tested at the Chemet plant (Poland), audited by Rostechnadzor. The numbered gas holder of an autonomous gas supply system has a passport reflecting all stages of its production, a GOST-R certificate and permission from Rostechnadzor for use;

- Inspection by a specialist of the site for the possibility of placing an underground gas tank and carrying out work on autonomous gas supply;

- A specialist’s assessment of geodetic and hydrogeological information about the gasified area where it is planned to install an autonomous gas supply system;

- Development of the section “Autonomous gas supply” in the general design of the house (if the gasified house has no more than 3 floors and is intended for one family, then according to Article 48, Part 3 of the Town Planning Code of the Russian Federation, a general design for such a house is not developed);

- Digging a pit for a gas tank and trenches for a gas pipeline to the depth of soil freezing, removal of excavated soil, backfilling of a sand cushion (carried out by the customer or partner AvtonomGaz);

- Installation of the gas tank base plate;

- Installation of the gas holder and fastening of the gas holder legs to the plate using fasteners made of austenitic steel;

- Installation of a gas tank protective and grounding system;

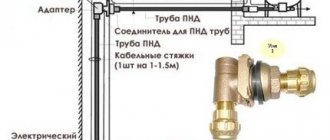

- Installation of an underground polymer gas pipeline with the installation of a warning tape, a butane evaporator collector and an all-welded steel base inlet with a bellows compensator;

- Testing the autonomous gas supply pipeline under pressure, monitoring the correct installation of the autonomous gas supply system and the integrity of the gas tank coating;

- Backfilling of the installed gas tank, gas pipeline and electrochemical protection system with sand (carried out by the customer);

- Connecting the gas pipeline of the autonomous gas supply system, purging it with inert gas and setting up the gas equipment of the gas tank using inert gas;

- Regular inspections of the autonomous gas supply system during maintenance;

- Refilling the gas tank with liquefied gas, launching an autonomous gas supply system;

- Regular monitoring of the performance of the filled gas tank and fittings of the autonomous gas supply system by a specialist;

- Regular routine technical diagnostics of the gas tank and other equipment of the autonomous gas supply system, pumping out unevaporated residues from the gas tank;

- Regular refilling of the gas tank with liquefied gas according to consumption.

Private houses in the suburbs of large cities cope with the heating issue without any problems, because in most cases gas pipes are installed in the suburbs, to which you can connect a private house, providing yourself and your household with heating, hot water and gas on the burners. But what to do if your home is built where there is no way to connect to the central gas distribution pipes. Sadly, there are still areas and districts on the territory of our large country where gas has never been supplied. In this case, people begin to wonder how to heat their home? Solid fuels are used, such as wood, coal, peat, some decide to purchase electric boilers, knowing full well that gas heating would solve the problems. And where can we get gas where it has not been supplied? An excellent solution is to purchase and install a gas tank on your site.

Principle of operation

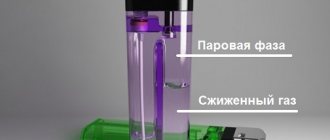

The principle of operation of a gas tank is quite simple: gas is pumped into a tank, and due to the fact that the tank is not completely filled, an air-gas mixture (propane-butane) is formed in the empty space of the storage. In order for the natural evaporation process to take place effectively, several rules should be followed:

- Do not fill the container with liquefied gas more than 85%.

- When installing a tank, it is necessary to strictly take into account that it should not be cooled below 0°, therefore, if a ground-based gas tank is installed, it will need to be insulated.

- If it is assumed that the evaporation area will be small (for example, in vertical containers), then it is necessary to consider an additional system of evaporators.

The gas mixture enters the house through a pipeline, just like through a regular pipeline. The gas tank is filled by specialists working on a machine with a filling tank. The procedure itself is reminiscent of refueling a car at a gas station.

Safety

Despite the advantages of an independent gas supply, owners of private houses are worried about the idea that a flammable fuel storage facility will be located next to their home. It is not enough just to observe the required distances during installation - you must adhere to the rules for refueling and servicing gas tank equipment.

Mandatory safety rules:

- Maintaining a constant supply of gas - approximately 25% of the volume. When the fuel is completely exhausted, a vacuum is formed inside the storage facility; during the next refueling, its technology is disrupted, which can lead to an explosion.

- Filling the gas tank should only be carried out by a specialized company. Small savings due to inviting unqualified gas workers privately will not cover the costs of eliminating the consequences of the fire.

- Safety valve control. Periodic inspections and troubleshooting help prevent emergency situations.

- Preventing leaks. The leaking propane-butane mixture weighs more than air, so it spreads over the surface of the earth.

The risk of fuel leakage is high due to physical damage to the walls, faulty shut-off valves, unqualified repairs or refueling, or leaking joints between parts of the gas distribution system.

Mandatory safety measures include the installation of grounding and lightning rod systems. It is prohibited to make fires or perform welding work in the immediate vicinity.

Video description

For more information about the gas tank and its installation, watch the video:

To control and regulate the process, the system has special automation; if you need to shut off the supply, you just need to turn a special tap. Excess pressure is removed using a special valve. The remaining gas is recorded thanks to a warning system that will warn the owner about the need to refill the tank.

Gas tank automation Source m.mitex-shop.ru

How many gas cylinders can a private owner carry in a car?

This is perhaps one of the main questions when it comes to homemade products from gas cylinders. Let's turn to the laws.

The transportation of dangerous goods in the Russian Federation is regulated by the following documents:

- “Rules for the transportation of dangerous goods by road”

- "European Agreement concerning the International Carriage of Dangerous Goods by Road"

- "Traffic Laws"

- “Code of the Russian Federation on Administrative Offenses”, Article 12.21 Part 2 of which provides for liability for violation of the rules for transporting dangerous goods in the form of “an administrative fine for drivers in the amount of one to three times the minimum wage or deprivation of the right to drive vehicles for a period of one to three times the minimum wage.” three months; for officials responsible for transportation - from ten to twenty minimum wages.”

But “The Rules do not apply to the transportation of a limited amount of dangerous substances in one vehicle, the transportation of which can be considered as the transportation of non-dangerous cargo.”

From here, we look in the table to see how many gas cylinders are not dangerous for transportation by private individuals and intended for personal use .

It turns out that 15 pieces are allowed to be transported without permission. gas cylinders of 50 l.

How to install a turnkey gas tank

You need to order a turnkey gas holder for a private home only from a specialized company that has the necessary license. You cannot install a gas tank with your own hands - it is illegal.

It is important! The supply of gas to the tank, refueling, connection of the gas holder to the gas boiler and all service work must be carried out only by certified workers from special companies. This is explosive equipment and requires proper maintenance by qualified technicians.

On a note! You can get professional advice on autonomous gasification of a private home directly from specialists

Various volumes of vertical and horizontal gas tanks Source brickandpress.com

Preparatory stage

To properly install the gas tank, you must first carry out preparatory work. All dimensions of the pit and its location relative to the building must comply with the standards and requirements for the installation of gas tanks.

- The pit should be 0.5 m larger than the size of the tank on all sides.

- A concrete slab with fastenings for the tank feet is placed at the bottom of the pit.

- The trench under the highway should not interfere with or intertwine with other communications.

- The depth of the pipeline trench must be at least 1.70 m, and the slope towards the house must be at least 5°.

- The distance to a residential building from the gas tank is at least 10 m.

Delivery of the gas tank to the site for installation Source rosavtonomgaz.ru

Device

Adjustment of gas consumption, the volume of its supply to a private house, and control of the remaining fuel in the storage facility is carried out automatically through distribution equipment. If necessary, the gas supply is also shut off manually.

Structurally, the gas tank is similar to a “barrel” made of sheet metal. The outer surface is painted in several layers of epoxy paint, which protects the structure from corrosion and gives additional strength.

Filling the container with fuel is carried out through the neck located in the upper part of the body. The higher the neck is, the less likely the gas tank is to flood during the season of heavy rainfall and active snow melting. This is especially important for private homes located in areas with harsh climates.

Gas tank installation

Equipment and work processes are controlled using shut-off and control valves. The composition of the kit for different models may vary, but even the simplest tanks are equipped with:

- valve for condensate drainage;

- a sensor indicating the filling level of the container;

- filling valve;

- reducer for setting operating pressure parameters;

- safety valve;

- pressure gauge.

Expensive models provide for the installation of automation with program control and high-precision electronic pressure gauges.

Shut-off and control valves

Video description

For more information about autonomous gasification, watch the video:

If you want to buy a mobile gas tank, its price will be much cheaper than usual, and it will not require installation on site.

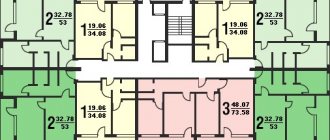

How to calculate the volume of a tank for a private house

Bigger does not mean better, so you need to calculate the volume of the gas tank correctly. This is done based on the technical characteristics of the heating boiler, the area of the house, and the number of cooking surfaces.

Horizontal gas tanks are selected with a margin of 15% of the calculated consumption indicators, and vertical ones with a margin of 10%.

Correct calculation of the tank volume allows you to choose a suitable gas tank for a private home; prices for them mainly depend on the volume, which means that you will not overpay for extra and unnecessary tank volume.

Installation diagram of a gas tank for heating a private house Source resant.ru

The cost of a gas tank and its installation

When choosing gas tanks for a private home, prices in the Moscow region can take a long time to review, since they depend both on the manufacturing company and on the volume of the tank itself. At first glance, everything is simple: the larger the tank, the higher the price, but the economic benefits of small storage facilities are sometimes deceptive. After all, a small tank needs to be refilled more often, which means additional costs for gas delivery. Therefore, you should choose a gas tank after first calculating the volume of the tank required for heating the house.

If you have already chosen and purchased a gas tank, the cost of installation will be calculated specifically for you by a specialist who comes to the work site. Typically, prices vary depending on the distance of the site from the city where the installation will take place, the size of the tank and its type, as well as the length of the gas pipeline. The cost of installation can vary from 40,000 to 100 thousand rubles. This includes everything (earth and installation work, reinforced concrete slab, set of materials, delivery), except the cost of the gas holder itself.

Installation of two gas tanks for heating a private house Source svoigaz.ru

What options are there for autonomous gas supply to a dacha?

There are radiator heating systems with diesel hot water boilers. In principle they work fine. There are no problems with purchasing diesel fuel - delivery announcements are common. Heating systems with autonomous gasification using a gas holder - a tank filled with propane-butane - are also common. There is a choice, but where to stop? We began studying these two alternative systems of thermal energy sources for a country house.

The diesel fuel heating system consists of the following equipment:

- containers for storing diesel fuel (from 1000 l), which can be installed in a separate boiler room or buried in the ground;

- fuel lines:

- hot water heating boiler with a burner for diesel fuel;

- heating systems directly (pipes, radiators, distribution and safety devices).

The liquefied gas heating system includes the following equipment:

- tank for storing liquefied gas - a gas holder with a set of equipment for refueling and safety system elements, a pressure regulator and a concrete base for securing the tank in the pit;

- gas pipeline: underground part, above ground, basement inlet;

- hot water heating boiler with gas burner;

- heating system (pipes, radiators, distribution and safety devices).

For both systems there are both domestic and imported certified equipment, installation and maintenance organizations. The choice of equipment is varied both in configuration and price.

Accessories

In this situation, it all depends on the price, type of model, and manufacturer. But even the purchase of expensive equipment does not guarantee that its components will include a complete set of all the necessary tools for comfortable work.

Here is a list of tools that you may need to comfortably use a laser machine.

- Case for transporting equipment.

- Protective glasses from laser light.

- Sighting targets.

- Laser receiver.

- Remote Control.

- Mount for the device.

- Tripod.

- Magnetic mounts for installing the device on a vertical plane.

- Additional battery.

Although a device such as a laser level is an expensive tool, its characteristics and capabilities easily pay for its cost, making work more comfortable, faster and more convenient.

Formulas for heat load and gas flow

Gas consumption is conventionally designated by the Latin letter V and is determined by the formula:

V = Q / (n/100 x q), where

Q – heating load (kW/h), q – gas calorific value (kW/m³), n – gas boiler efficiency, expressed as a percentage.

Main gas consumption is measured in cubic meters per hour (m³/h), liquefied gas - in liters or kilograms per hour (l/h, kg/h).

Gas consumption is calculated before designing the heating system, choosing a boiler, energy carrier, and then easily controlled using meters

Let us consider in detail what the variables in this formula mean and how to determine them.

The concept of “heat load” is given in the federal law “On Heat Supply”. Changing the official wording a little, let's just say that this is the amount of thermal energy transferred per unit of time to maintain a comfortable air temperature in the room.

In the future, we will also use the concept of “thermal power”, so at the same time we will give its definition in relation to our calculations. Thermal power is the amount of thermal energy that a gas boiler can produce per unit of time.

The heat load is determined in accordance with MDK 4-05.2004 by thermal engineering calculations.

Simplified formula:

Q = V x ΔT x K / 860.

Here V is the volume of the room, which is obtained by multiplying the height of the ceiling, the width and length of the floor.

ΔT is the difference between the air temperature outside the building and the required air temperature in the heated room. For calculations, the climatic parameters given in SP 131.13330.2012 are used.

To obtain the most accurate gas consumption indicators, formulas are used that even take into account the location of windows - the sun's rays warm the room, reducing heat loss

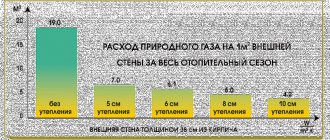

K is the heat loss coefficient, which is the most difficult to accurately determine due to the influence of many factors, including the number and position of external walls relative to the cardinal directions and wind conditions in winter; number, type and sizes of windows, entrance and balcony doors; the type of building and thermal insulation materials used, and so on.

On the building envelope there are areas with increased heat transfer - cold bridges, due to which fuel consumption can significantly increase

If it is necessary to perform a calculation with an error within 5%, it is better to conduct a thermal audit of the house.

If the calculation requirements are not so stringent, you can use average values of the heat loss coefficient:

- increased degree of thermal insulation – 0.6-0.9;

- medium degree of thermal insulation – 1-1.9;

- low thermal insulation – 2-2.9;

- lack of thermal insulation – 3-4.

Double brickwork, small windows with triple-glazed windows, an insulated roofing system, a strong foundation, thermal insulation using materials with low thermal conductivity - all this indicates a minimum coefficient of heat loss for your home.

With double brickwork, but a regular roof and windows with double frames, the coefficient rises to average values. The same parameters, but single brickwork and a simple roof are a sign of low thermal insulation. The lack of thermal insulation is typical for country houses.

You should take care of saving thermal energy already at the stage of building a house by insulating the walls, roof and foundation and installing multi-chamber windows

Having chosen the coefficient value that best matches the thermal insulation of your home, we substitute it into the formula for calculating the thermal load. Next, using the formula, we calculate the gas consumption to maintain a comfortable microclimate in a country house.