Among the wide range of building materials, geotextiles stand out. Literally a dozen or two years ago, among the owners of private houses, many did not even know about the existence of such a material, but it would have helped solve a lot of pressing problems that arose during the construction and arrangement of the site.

Geotextiles: what is it and how is it used?

And even today, it must be admitted, some inexperienced developers completely in vain ignore this specific material, perhaps simply due to the lack of information about its remarkable properties. We will try, as far as possible, to compensate for this gap with the publication we bring to the attention of readers - “Geotextiles, what is it and how is it used.”

Advantages of geotextiles:

- Versatility in use, high strength and resistance to chemicals;

- Geotextiles are durable and resistant to rotting, groundwater, microorganisms, and ultraviolet rays;

- Suppresses weed growth;

- Increases the service life of buildings, structures and other objects; geotextiles have a long service life and do not lose their properties;

- Prevents soil erosion, accelerates water drainage, acts as a filter, supports heat exchange, and allows air to pass through;

- It is characterized by high elasticity and resistance to tearing;

- Geotextiles are considered an environmentally friendly material, do not decompose and do not emit toxic substances;

- Quite inexpensive;

- Reduces the consumption of materials during the construction of buildings;

- Compact, easy to install.

Drainage system for garden plot

Too close a location of groundwater can have an extremely negative impact on the life of plants growing in the garden. However, a way to combat this phenomenon was invented long ago, and today it is quite easy to implement even with your own efforts.

In order to drain water from the site, it is necessary to dig narrow trenches in the form of a “herringbone” throughout its entire area. They will contain narrow pipes with a diameter of 6.3 cm. They are cut into pieces of the required length and connected at the turning points using special tees.

It is at this phase that it is necessary to pay attention to the role of geofabric. It is necessary to make a drainage pipe in the geotextile filter. Each section of pipe must be wrapped with geofabric at least three times, and the winding must be secured with wire.

After this, the layers are laid out in the following order: crushed stone, geotextiles, crushed stone, earth.

Drainage system laying diagram.

On a note! At this stage, the geotextiles must be overlapped to provide more reliable protection.

Functions of geotextiles:

- Reinforcement – geotextiles strengthen building structures, improve the stability of slopes, the bearing capacity of the foundation, and reduce the likelihood of settlement;

- Protection – preventing the interpenetration of soil and coarse materials, slowing down erosion, separating the soil. Better conditions are created for compacting layers, and better dynamic characteristics of the structure are achieved;

- Filtration – preventing the removal of soil particles as a result of water pressure, water flow, preventing drainage contamination;

- Drainage – acceleration of water removal in the desired direction. Geotextiles improve the performance of drainage layers, accelerate the consolidation of soils with high humidity;

- Waterproofing - impregnation creates a waterproof partition that prevents moisture from penetrating to the base of the building.

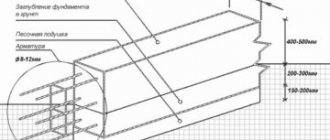

Drainage geofabric for arranging the foundation of a house

Its durability largely depends on how well the foundation of the house is laid. That is why it is worth paying special attention to the arrangement of the drainage system in order to avoid the house being washed away by groundwater. Before starting work, you need to understand exactly at what depth the waters lie, as well as what type of soil you are dealing with. This will help you navigate the choice of materials: pipes, geotextiles and crushed stone.

Based on production technology, a distinction is made between thermally bonded and needle-punched geotextiles.

First of all, you will need to dig a trench around the entire perimeter of the foundation. It should be dug with a slight slope towards the direction of water movement. In this case, the width of the recess is calculated based on the diameter of the pipes, as well as the required distance around the pipe. For example, if you are laying a pipe with a diameter of 11 cm, then the space allocated for crushed stone will be about 10 cm.

On a note! If there is a blind area, the trench must be located along it.

Then sand must be poured into the bottom of the trench. The thickness of the layer should not exceed 5 cm. Geotextiles are laid on top, which are immediately covered with crushed stone. Pipes are laid on top and crushed stone is poured back in.

The top and side layers of crushed stone must be at least 10 cm. All these components are covered with geotextiles, which are fastened with wire at intervals of about 30 cm. Then everything is covered with soil and the drainage system for the foundation can be considered ready.

Geotextiles in rolls.

Types of geotextiles:

- Drainage – necessary for installing drainage or winding system pipes;

- Furniture – mainly used in the production of mattresses, for interior upholstery, and also during transportation;

- Garden - necessary for creating greenhouses, greenhouses, and also serves as protection from frost and ultraviolet rays. This material is often used to cover the soil around cultivated plants to reduce the number of weeds;

- Construction – used for waterproofing the basement or foundation of a structure, also used in road construction;

- Packaging – geotextiles used for packaging various materials.

The nuances of calculating the required quantity for installation

The main characteristics of the canvas are width, length and area. The width of the product ranges from 1 to 6 m. On average, winding 1 roll is 100 m. Depending on the manufacturer and the density of the fabric, this figure may vary. The area is indicated on the packaging (area, m² = length x width).

The consumption of the canvas is affected by the specifics of installation. When draining, the length and width of the pipe are taken into account. The required reserve is up to 15 cm on each circle. When fixing textiles to the base, you should always take a small margin, especially if the surface is uneven.

Classification by manufacturing method:

- Thermally bonded geotextiles are made by fixing fibers at high temperatures. This is a non-woven material, this fabric is highly durable, but it is not recommended for road construction or drainage, but it is quite suitable for laying paving slabs or protecting against weeds. Such textiles cannot efficiently filter water from soil with fine fractions;

- Needle-punched - it consists of polyester and polypropylene fibers, the fibers are pulled through the base layers using serrated needles. The product allows moisture to pass through well, but only up and down. This geotextile is very durable, does not deform, and is suitable for landscape design, road construction, and slope construction;

- Woven - in essence, the production method is no different from ordinary fabric. Propylene or polyester fibers are stitched with threads, additionally impregnated, and form a dense surface. This type of geotextile is also called knitting-stitching. The least resistant type of material, it is not very resistant to tearing and stretching.

Should I replace it with roofing felt?

Some builders use roofing felt and galvanized metal mesh for reinforcement instead of geotextiles. However, even taken together they cannot be compared with modern geotextiles in terms of durability. If roofing felt lasts only 20 years (and then in the best case), then geotextiles, which are entirely made on the basis of polypropylene fibers and processed by thermosetting, have a service life of 80-100 years!

So it is possible to replace geotextiles with roofing felt, but is it necessary?

Source

Geotextile manufacturers and selection criteria

The most well-known materials are Dornit, GronT, Avantex, Polyzon, Kanvalan, Geocom, Geotex, Montem, Nomotex, Stibitex - these are products of domestic manufacturers. Needle-punched materials are the most popular on the Russian market. Also known are such manufacturers as Aquaspan, SpunBel (Belarus), Geoyutex (Czech Republic), Terram (Great Britain), Secutex (Germany), Taypar (USA), Polifelt (Austria).

Dimensions

The width of such rolls is fixed and is usually 430 cm. However, modern developments on the sales market can already reach 5 m or more. The length is often used at 100 linear meters, so the weight of the purchase is significant.

Rolls of geotextile

The thickness of the raw material varies from 0.8 to 1.8 mm at minimum loading pressure and from 2.4 to 3.8 mm at 2 kPa. The steps of testing activities and their smallest details are very strictly regulated by state standards, so there is no need to fear any problems or incorrect technical indications.

Important! In this material, thickness and density are directly proportional - thick textiles will be many times more effective than thin ones.

Summary table of geotextile characteristics

When choosing geotextiles, first of all you need to pay attention to the density of the fabric.

- 100-150 g/sq.m - material of this density is used for arranging decorative ponds, lawns, embankments, and protection from roots. Geotextiles are mainly used in country houses and dachas;

- 180-200 g/sq.m – used for the construction of paths, as a basis for paving slabs, foundation, for separating layers of soil, protection from roots, and flooring in the house;

- 250 g/sq.m – for the construction of roads that are rarely used, as well as for dividing soil;

- 300 g/sq.m – for roads on which not only cars, but also trucks drive;

- 350 g/sq.m – for runways of small airports, busy roads, large bodies of water;

- 400-450 g/sq.m – for heavily loaded highways, strengthening embankments, runways.

- Density is the main criterion, but for a country pond there is little point in purchasing geotextiles with a density of more than 250 g/sq.m.

When choosing geotextiles, you need to pay attention to the manufacturing method (it is worth remembering that needle-punched fabrics are stronger than woven ones, and impregnated geotextiles have practically no filtering function). Pay attention to the purpose of geotextiles, the price category, and the reputation of the manufacturer. This is a fairly affordable and easy-to-use material that will last for many years!

Laying rules

In order for geotextiles to fulfill their functions, they must be laid correctly. First, let's tell you what shouldn't happen. First of all, you should not lay geotextiles with holes (mechanical damage). If it is not possible to replace the entire piece, lay a patch that is 50 cm larger than the size of the hole. Secondly, it cannot be dragged around. Thirdly, cars cannot be driven on the dispersed road surface.

Below are the general rules for laying geotextiles:

- Place it on an area that has been previously cleared of stones, roots, and construction debris. It is advisable to level the soil and, if necessary, compact it. The presence of sharp protrusions or depressions is an additional risk of getting a rupture in this place.

Even if there is no load, the overlap of the two canvases is necessary - If several strips are laid, an “overlap” is required. The minimum - 30 cm - is used when laying lawns and pedestrian paths. When laying under roads, platforms for vehicles, etc., the minimum overlap is 50 cm.

- It is better to fasten the edges of adjacent strips. You can sew it, you can use tape. This will ensure that the edges do not curl.

As we said earlier, the width of the canvas should be larger so that it can be wrapped on a layer of crushed stone, earth, sand. And so that the “turn” is at least 30-50 cm.

Application of geotextiles

There is one more question: which side should the geotextiles be laid on? There is no definite answer, as it depends on the material. Some types can be laid with either side, others - only with the smooth or only the fleecy side up. Specifically, which side to lay the geotextile is stated in the instructions for the material. If you do not buy a whole roll, but only a part, check the rules for laying it with the seller.

Needle-punched geotextiles are an indispensable solution for private construction

To produce needle-punched geofabric, both short and continuous polymer fibers are used. The mechanical method of fastening fibers simultaneously gives the fabric both strength and a high filtration coefficient. This significantly expands the scope of its application. Considering that modern technologies make it possible to produce material with specified density parameters, it is difficult to find a more suitable synthetic fabric for private construction than needle-punched polyester geotextiles.

Secrets of application

Even the best material must be used for its intended purpose and in accordance with the manufacturer's instructions. Geofabric is no exception. Failure to comply with installation and application technology can not only deteriorate the quality of the layer, but also lead to serious problems and even emergency situations. Any type of base must be clean; the presence of debris, roots and other inclusions is unacceptable. Laying of textile fabrics is carried out according to the manufacturer's instructions and, as a rule, overlaps. Another method is permissible only at the discretion of qualified civil engineers.

Application of material for laying roads

According to generally accepted standards, on flat areas the overlap of the layers relative to each other is 30 cm, on uneven surfaces this value is usually increased to 50 cm. Welded fastening is considered the most economical - it holds the canvas well even with a fly fishing of 10 cm. It is recommended to invite professionals for such events their own business, who have already had experience in laying similar products more than once. It is advisable to fill large areas with crawler-type excavators, performing delicate manipulations.

Important! If you decide to carry out the work yourself, remember that even small mistakes can result in big problems - the most durable material can break through and then a complete rework cannot be avoided.

Adviсe

Geotextiles are innovative products, the name of which indirectly reflects its characteristics. So, for reinforcing and hardening soils, geofabric is ideally suited; for underlying embankment levels, it is advisable to use geofabric. Drainage work does not allow any use of such products on a natural basis. Organic threads, even in minimal quantities, will quickly succumb to the process of rotting and will reduce the entire installation to nothing. Also unsuitable for drainage is fabric connected by thermal method. Experts for such events recommend a textile layer of medium thickness.

Arrangement of slopes

Important! Using geotextiles as a weed killer, the latter need to be cut off at the root, and only then the sheets should be laid.

In order to prepare the garden plot, 150 mm of sand or half as much crushed stone is poured over the textile lining. It is advisable to carry out similar procedures where planting is not planned in the near future. The ideal solution would be a combination of natural rest of the land with technological weed control. The latter, in the process of decomposition of the root system and shoots of weeds, will be saturated with organic matter and its fertile layer will increase. The first planting of plants on the renewed soil can be done within a year.

Preparing the garden plot

Under sidewalks, geological fabric sheets should have a density of 150 g/m2. It is with these indicators that they will be able to withstand all operational loads. Non-woven products cannot be used for this type of work.