Some boiler malfunctions may be caused by incorrect parameters in the service menu settings. This can happen, for example, after unqualified intervention or... as once happened in my practice, after flooding the boiler board with water.

Of course, first of all, the service menu serves to configure, adjust and diagnose the operation of the boiler. In this article I will share how to enter the service menu of the Ariston Class 24 FF boiler and how to change the parameters, as well as give the values that were set in my boiler from the factory.

Before you begin any settings, it is important to carefully consider the menu structure, as well as understand whether you need to intervene and change any parameters. Incorrect intervention can lead to serious problems. For example, there is a parameter that is set depending on the boiler version and is used by specialists when replacing the board.

Considering all of the above, you should understand that some of the parameters I have given as “Factory settings” may differ from those you need specifically, and therefore you carry out all these movements and settings at your own peril and risk.

The most common error codes and troubleshooting methods

The most popular among Ariston boilers are wall-mounted 24 kW models. During the operation of the Ariston gas boiler, failures and malfunctions may occur, like with any other equipment. The list of error codes is given in the instructions in the form of a table. Some of them are a malfunction of the automation (cause a protective shutdown of the device) and can be eliminated by clicking on “Reset”, and some signal malfunctions and interference in the operation of the boiler and require intervention (block the operation of the system).

All codes are divided into six groups according to the number of boiler components. The first value indicates the node in which the failure occurred, the rest indicate the error code. But it should be noted that if the protective error is repeated frequently, this indicates a malfunction.

The most common of them:

Wall mount

Initially, I installed a coaxial angle on the boiler and measured the distance from the edge of the boiler to the center of the corner - it, as indicated in the instructions, was 105 mm.

The distance from the center of the corner to the top of the boiler is 105 mm

You can immediately fasten the narrow clamp, not forgetting to put the sealing gasket.

Before tightening the clamp, it is necessary to insert a sealing gasket

My house is sheathed on the outside with vinyl siding, so I immediately decided to mark it so that the hole for the pipe would fit entirely on one strip of siding.

Some sites suggest first making a hole for the chimney, and then screwing in the mounting strip. I decided to screw the bar first. As mentioned above, the kit includes two dowel nails. They are designed for mounting the boiler to a brick or concrete wall. Since the house was built from sandwich panels, I fastened the plank with roofing wood screws.

The bar is set horizontally and secured with five galvanized screws

Further in the wall, a through hole with a diameter of 10 mm was drilled. The center of the hole corresponded to the center of the coaxial pipe. I cut out the hole for the pipes on both sides using an electric jigsaw.

After cutting the hole and hanging the boiler, you can install a coaxial chimney

It is better to install the chimney together - one pushes the pipe from the outside, the other puts on the internal insulating gasket (made of hard plastic) and the clamp (it is more convenient to immediately screw the screws into the clamp).

The pipe is installed, the clamps are tightened

Due to the fact that the outer insulating gasket is quite elastic, it fits quite tightly to the siding.

Coaxial pipe after installation

I'll end this for now. Next comes the soldering of polypropylene pipes, the connection of polypropylene pipes with metal-plastic ones and the installation of additional taps on the heating system. Only after this can Ariston be launched.

To be continued…

- https://sovet-ingenera.com/gaz/equip/kak-podklyuchit-gazovyy-kotel-ariston.html

- https://starsb.ru/shop/folder/skhemi-podklyucheniya-kotlov-ariston

- https://xn--80ayehece2h.xn--p1ai/installation-of-boiler-ariston/

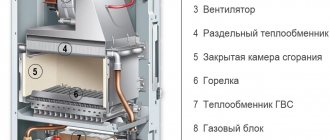

Ariston CLAS 24 CF

It is a double-circuit gas burner equipment equipped with an open combustion chamber. This boiler is wall mounted and is a universal solution for heating and domestic hot water in residential premises of any type. In addition, the model is designed to quickly heat water.

This design is a clear example of the fact that the Italian brand occupies its rightful place in the competitive niche of gas-burning heaters. The Ariston CLAS 24 CF model is a practical and reliable solution for heating a home, which will delight the buyer with its small dimensions.

The versatility of the product lies in the fact that it can be combined with new or outdated heating systems. Equipped with a convenient LCD display, the Ariston boiler can become an indispensable assistant in creating comfortable conditions in any home or apartment.

Among the advantages of the CLAS 24 CF model, the following undoubted advantages should be noted:

- Minimum fuel consumption, which makes it cost-effective and very practical.

- Maintaining the coolant temperature at the desired level for a long time.

- Flexibility and ease of reconfiguration in accordance with the user's wishes.

- The refined design of the unit allows it to be installed in a kitchen, plumbing unit or other utility room without compromising aesthetics.

- Light weight and compact dimensions.

- The presence of an automatic mode, which makes it possible to save energy and create the most comfortable conditions in a living space at any time of the year.

- The pipe fittings are well disguised, which is also an additional plus in the aesthetics column of the CLAS 24 CF boiler.

- Instant heating of water in the hot water supply system to the desired temperature.

- Quiet operation.

- Availability of a circulation pump adaptive to the temperature of the coolant.

- The presence of a system that prevents freezing of the coolant in the circuit during the cold season, which is important for the northern regions of our country.

- Boiler protection from scale formation and subsequent equipment failure.

In addition, the design provides for an automatic bypass, a pressure sensor, and a drain valve in the central heating circuit. The model also has a “Purge” option, which removes bubbles from the coolant to increase efficiency and stabilize the system. It is noteworthy that the Ariston CLAS 24 CF model has a built-in mode for evaluating combustion products in order to control their effective removal to the street.

Equipment from the Italian brand can be easily installed in an apartment or house, and can be easily integrated with any systems, including multi-zone ones.

Settings and adjustments of Ariston boilers

An Ariston BS II 24 FF gas boiler has been installed, it has been in operation for about 3 years, recently a malfunction has been observed, after igniting the burner in the primary heat exchanger, a strong noise is heard for 10-20 seconds, like boiling water, then it subsides, but completely does not disappear, like a teapot. This is not observed when using DHW. The boiler starts and turns off normally. The radiators of the heating system are all warming up (no complaints here). I assumed that the filter in front of the pump was clogged and there was no water flow (and as a result, the water was boiling in the heat exchanger), I took out the filter - it was clean, the pressure in the system was maintained, replenishment was carried out extremely rarely, mainly before the heating season. What could it be? Scale in the heat exchanger? Or is the power set that is not suitable for my heating system? Ariston Uno wall-mounted gas boiler with chimney in operation. When trying to ignite after 1-4 seconds. turns off completely and then starts again. As if you could just turn the power off and on. What's wrong? Try to find the flame sensor in the combustion chamber and wipe it. Or wipe everything sticking out on the insulators there. The Ariston Uno boiler has been in use for 5 days, the heated area is 55 square meters, the air temperature outside is now +10, the boiler turns on every 2 minutes, heats the heating circuit for 10-15 seconds, then turns off. 1. Is it possible to increase the periods between switching on? Those. so that it turns on less often, but for longer. I heard that you can set a restart delay. I have an "ignition delay adjustment jumper" on the control board, is this what I need? Can you safely switch and enjoy? 2. 24 kW of power is, of course, a lot for my area. I read that some boilers can be switched to a lower power. I have an “ignition power adjustment jumper”, which means exactly the ignition power. There is also a jumper for “adjusting slow ignition/maximum heating temperature” and “switch-jumper for underfloor heating”, how do these jumpers work, i.e. how does the boiler behavior change? 3. What pump speed should I choose? The higher the pump speed, the louder it runs and consumes more energy (and this is important when running on backup batteries), and noise and consumption increase more significantly than the speed. I left it in 2nd gear for now. Another interesting point is the time I indicated during which the boiler is turned off/on. (2 minutes and 10-15 seconds, respectively) - this is exactly for the 2nd speed, and on the 3rd the boiler is turned off for the same 2 minutes, but it turns on for 20-30 seconds! Actually, why? After all, the heat loss in my house has not changed! I installed the boiler myself, the startup was carried out by a service representative, but he did not make any special adjustments. First, the pump must operate silently. If it makes noise, look for the reason. Air in the system and in the pump. Open the air vent behind the pump. Although this should have been done by your service master! And unscrew the large shiny washer on the pump in the middle. An Ariston Uno 24 gas boiler (double-circuit) is installed, but for some reason the DHW circuit does not heat up at all. What could be the reason? Check that all hydraulics are connected correctly to the boiler. Does the automation switch the boiler to DHW mode? If it does not switch, then the flow sensor is not working. If it switches, then see if the batteries continue to heat up. If they continue, the three-way valve drive does not operate. The gas boiler Ariston Uno 24 MFFI is in operation. It worked fine for two years. Suddenly a problem arose - the flame lights up, but then the ignition clicks are heard, the flame presence indicator starts flashing, and the boiler turns off. The “ignition failure” indicator lights up (gas supply stops) and the flame presence indicator flashes. I cleaned the ionization sensor, but to no avail. Sometimes the clicking stops, and the boiler works normally from a few seconds to 10 minutes, and then everything is as before. Most likely there is a fault in the electronic board. The heat exchanger is clogged, the pump is tired, the three-way valve is clogged/does not switch completely. Try checking the valve on the pump. This happened to us. It turned out that it was screwed all the way (it’s kind of gray). Apparently the “master” did not deign to bring it into working condition. I turned it two turns and heard air coming out. The pressure in the system has dropped slightly. I fed up to 1.5 units, turned on the power to the boiler, it started and worked silently. An Ariston bs II 24 ff double-circuit boiler was installed and connected. I just moved in, so I have no operating experience. It looks like there is a malfunction: When turning the heating temperature regulator to the left to “0”, the heating does not turn off - the boiler still operates at minimum. The feeling is that there is a bad contact somewhere, because when I pressed hard on the control panel, I managed to turn off the heating. Tell me what is the best thing to do: call a technician or open it and try to make the adjustment yourself? Call a specialist. One malfunction may lead to another. We completed the installation, installation and put into operation the Egis plus ff 24 boiler. I set the temperature to 82 degrees, but the boiler does not rise above 70, but is operating normally. DHW is not connected. Heating only. Tell me what's wrong. When the boiler was first started up, the gas valve service employees did not carry out the tincture at all. Just press the on button. and that's all. So it turns out that you have 12 kW of heating power. Change 231 to 70. Is it possible to reduce the boiler power in heating mode if the area of the house is 100 square meters and will this give any gas savings? Model Egis plus 24ff. Set the boiler power parameter in heating mode to 100, regardless of the area of the room, do I understand correctly? Each mode has its pros and cons; by lowering the heating power, we move away from clocking, thereby extending the life of the boiler, eliminating start-stop modes, but increasing gas consumption. Otherwise, we increase the number of cycles, reducing the boiler life, but reducing gas consumption. What is the minimum heating temperature for the Ariston Egis Plus 24 FF gas boiler? Everywhere they say it's 35 degrees. I installed such a new boiler before the heating season and the heating temperature cannot be set below 40 degrees. Is this how it should be? Or can the service organization set this up? The Egis Plus 24 wall-mounted boiler is in operation with an open combustion chamber. 9 operating heating points, 1 outlet is plugged and 1 heating outlet to the attic is closed with taps. Cast iron radiators of the new type M-140, only 62 sections and PPR 25 mm. The radiators are new and cleaned before installation. The water in the system is filled by gravity through a hose made from melted snow. They also added from the city system for pressure. The filter is installed on the return side with an oblique 100. At the inlet there is a filter for cold water, a softener in front of the boiler for cold water. water. Heating system 2 pipes. The boiler was installed and connected - it started up normally. We made an adjustment immediately to 60 degrees. I worked for a day without problems, it became very hot in the house and the temperature was lowered to 53 degrees. But the next day the pressure began to drop by 4 divisions, from 1.2 to 0.8. They added it 2-3 times a day. There are no leaks - we checked everything, everywhere. We bled the air through the Mayevsky valve from all radiators. The radiators heat up perfectly - evenly. They called a technician, he pumped up the expansion tank through the top to 1.8 with a pump, without turning off the taps or draining the water. I checked the return filter - clean. After which the pressure stopped falling. But a day later, noise appeared in the boiler. The noise is very loud, which does not depend on turning the boiler on or off. Appeared for 10 seconds, disappeared for 2 minutes, appeared again for 10-15 seconds and disappeared for 5 minutes - everything was chaotic. The noise sounds like boiling and air bubbles or pieces of metal knocking. What could it be? The service technicians said that this is normal and will pass. And yet, we don’t turn on the hot water supply because the house is in the process of being renovated and there aren’t even taps yet. In the passport for the boiler, we read the filling of the heating circuit, the first commissioning, especially pay attention to the point where the air removal cycle is described. And it is advisable to install an automatic air vent at the highest point on the heating. In operation Ariston class 24 FF. It worked for 3 seasons, turned on the heating for a test, the temperature rises very quickly (5-15 seconds) and turns off the burner. The batteries are hot, there are no errors, I cleaned both return filters (washed out a couple of grams of rust), and cleaned the mesh on the flow meter. There’s a computer 7 programmer, like (I took it because the clocking was annoying), a system of 3 batteries and a heated towel rail, it was venting the air, but it doesn’t seem to be there. In chimney sweep mode, after a minute you can hear the primary boiling and the burner going out. Ariston Klass Evo 24 ff boiler installed. In heating mode, even if you turn the temperature regulator to maximum, it does not accelerate, the burner modulation above stage 3 (indicator on the display) does not occur, it is always lower. What's wrong? When DHW modulates to maximum, parameter 230-62/231-74. We recently had the filter cleaned and the Ariston BS 24 boiler blown out. Today I looked, but there was no circulation again, I drained the water from the boiler once, but I couldn’t remove the mud trap. I put everything back in place, filled the boiler with water, started it up, it started working, the circulation began, an hour later it disappeared again, I took it all apart again (drained the water). I took out the mud collector, it was clean. I started everything again - it works, but I hear air leaking in the heating system (by the way, this didn’t happen after the first cleaning 2 days ago) I checked there is no air in the batteries. What could be the reason for this behavior of the boiler? Problem with DHW on class b 24 ff. After a long period of inactivity (about 3 months), I started the boiler. The heating works normally, but when you open the hot water tap, after 20 seconds you hear an increasing hum (like the sound of a water hammer) and the burner goes out (no error is displayed on the indicator). After restarting the boiler, everything repeats. The heating works, but the hot water does not work either in comfort mode or in auto mode, i.e. the burner starts, after 20 seconds the noise increases, the burner goes out. The flow sensor was cleaned, the impeller rotated, and the secondary circuit was washed. Flush the secondary heat exchanger with coolant. Faulty wall-mounted boiler Ariston clas 24 ff. Heating problem, house 100 sq. 69 sections of steel radiators, two-pipe system, radiators connected bottom-to-bottom, floor. sushi The temperature in the radiators does not rise above 43-45 degrees. The boiler, adjusted to 45, works normally: it heats up to 48-50, the burner turns off, the pump turns on, the temperature drops to 40, the burner turns on again. But if you set the temperature to 70g, then the burner works and does not turn off, the supply temperature is also 70, because you can’t hold your hand, but the return temperature is warm, I assume 40-45g. The same goes for radiators (barely warm). I thought it was air and bleed it from both the radiators and the boiler. I thought about weak circulation when soldering the heating, checked by shutting off all the radiators, and opened each one individually, they were boiling, about 70g. Just balance the system, since they work one at a time. Although, in any case, the first ones should work. But still. Let's start with a banal CO filter. Then we cover the radiators. The closer to the boiler, the more covered. We don’t cover the latter at all. Sometimes the first 80 percent needs to be pressed. This is if it really is a two-pipe. The boiler begins to rise from 1.3 bar at a set temperature of 70 degrees to 3 bar, until the valve is activated. And all this winter I have observed many times a drop below 0.8 bar followed by a shutdown with error 108. I manually raise the pressure, and then it works again. The expansion tank must be inflated with air, so the pressure will not jump. Well, there is also a possibility that the membrane inside the tank is unusable. On the DHW circuit it shows error 112, I restart it (off-on, reset does not reset), again the same error, after the 20th time the boiler lights up, runs for 5 minutes and again the same error. What could be wrong? In the display window, enter the error number (112) and find out that it is “Open or short circuit of the heating return temperature sensor (NTC2).” An Ariston gas wall-mounted boiler has been installed and connected, which does not hold pressure at all: while cooling the heated water, the pressure drops to zero, although water is regularly filled. What about the pressure? The boiler clearly lacks the capabilities of its own built-in expansion tank. Apparently, the volume of the heating system exceeds the service life of the standard equipment of the device. The Ariston Egis boiler is in operation. From the bottom of the boiler (inside) water is dripping from a plastic tube sticking out vertically. And precisely when I increase the pressure to normal (1.5 bar). The pressure drops after about 4-5 days of intermittent operation. Previously, the pressure lasted a month, or even more. Tell me, is it normal for water to drip? And what is the reason for the rapid drop in pressure? It is necessary to stabilize the pressure in the heating circuit; this is done using an expansion tank located behind the boiler or installed additionally. We installed and put into operation a double-circuit boiler clas 24 FF. The heating works fine until you start taking a bath in the bathroom. The water in the bath is hot, but in the radiators it cools. It’s dual-circuit, I don’t understand why yet. All double-circuit boilers have hot water (DHW) priority - when you use DHW, the boiler is disconnected from the heating system and switches to the DHW heat exchanger to prepare hot water. To eliminate this problem, it is necessary to additionally install a boiler, either storage or indirect heating, into the system. We launched the Ariston EGIS 24 FF boiler. It worked perfectly for a year, gas savings were half as much as with other simple floor-standing stoves. The other day there was a power failure, they turned off the power, then turned it on an hour later. The device was turned on through a stabilizer. I noticed a problem, the R101 lamp was blinking - overheating, I looked in the manual, what should I do? If it overheats, you need to wait until it cools down and reset the error. And if it doesn’t help, then replace the sensor or control board. I connected the wall-mounted boiler BS II 24 FF via INELT Inteligent 500LT2. Gel battery 100A. The boiler works perfectly from the mains, but when switching to a battery, after three unsuccessful starts it is blocked. UPS output voltage: from the mains 210-225 volts, and from the battery 234-235 volts. The sine wave is good. The UPS does not show an overload. What is the reason? The boiler does not see the flame, it needs zero for normal operation, an uninterruptible power supply operating from a battery does not give zero, it is necessary to connect the wires in the plug together, zero and ground, yellow and blue wires, naturally plug it in such a way that after turning on the light, the phase gets per phase, and zero to zero!!!! The gas boiler Clas 24 FF worked for 2 years without failures, now a problem has arisen: at T = 45 degrees D = 1.2, when heating the water in the heating circuit to 60 degrees D = 2.3 at this time, just turn on the hot water, the pressure jumps beyond 3 and the safety valve is triggered, and therefore the pressure in the heating circuit often drops. What settings need to be made? You have no pressure in the expansion tank. You need to relieve the pressure from the system, check the spool on the expansion tank and pump (without pressure in the heating system) 1 bar. Ariston Egis Plus was washed last winter, but after working for DHW for a month and a half, it started to malfunction again. The heat exchanger was leaking, but the owners waited until summer and turned it off. The entire warm season was unplugged. On the eve of the new heating season, I changed the heat exchanger, no problem, but the turbine fan starts and does not turn off. Naturally, because of this, the boiler does not start on its own. Disconnecting the wire from the pressure switch helps; when you connect it again, the boiler starts and works as it should before the shutdown, further in a circle. The board outwardly shows no traces of moisture or any other problems, there is a suspicion of the turbine switch relay, what is the probability that it is simply stuck? Replace the fan relay and everything will work. On the board this relay is marked as RL01. I use ALD124. We installed an Ariston Egis Plus 24 FF gas boiler. When trying to use hot water supply with low water pressure, we get boiling water. Can this model work with low water pressure without burning your hands? The indicator shows the set water temperature, but is it possible to see the real temperature? There is not enough water pressure, you need to install a pump. There is a problem with the Egis wall-mounted boiler. A week ago, after the rains, the house warmed up. Started and warmed up normally. A day later, a problem appeared. The yellow LED began to blink and the fan did not turn off. The fan relay is stuck. Located on the control board. Needs to be replaced with a new one. You are unlikely to find a native one, use ALD-124. A problem has arisen - the wall-mounted boiler Ariston BS 24 FF starts, the burner lights up, but after 5 seconds. Quite strong knocks appear and the LED lights up - an error. The boiler rises. According to the instructions, the yellow LEDs should light up indicating the error code, but this does not happen. The pump doesn't seem to be working, check. Or there is no contact in the combustion control wire connector. A bs II 24 ff gas boiler has been installed, the heating is working fine, the hot water supply is somehow unclear, the hot water pressure in the kitchen is excellent, but in the bathroom it barely flows, what could be the problem? Check the faucet in the bathroom, especially the aerator on the faucet (divider). The gas boiler BS II 15 FF is connected, when turned on, it shows an error - the low pressure in the system, however, on the pressure sensor, it matters 2 atmosphere before turning on, after dropping and repeated attempts to turn on the pressure on the sensor sharply go to the red zone, then the boiler shows the error Low pressure in the system and turns off. Tell me, what could it be? Perhaps some filter needs to be cleaned? Where is he and how to clean him, in fact? This is a malfunction of one of the NTC sensors. It is better to replace both NTC sensors at once. They made an installation and connection of a double-circuit boiler Ariston BS 24 without additional sensors, an apartment of 58 square meters, two radiators 1-10 sections, 2-8 sections, a heated towel rail, a collector for a warm floor of squares 10 probably. Last year, when turned on, the radiators were heated first, then gradually and the floors were all normal, and when turned on, only the floor or (if you turn off the floors is turned off) radiators, regardless of the set temperature (at the beginning this year, was, if less than 60 The degrees are cold radiators are cold, more hot), I also noticed that the boiler is often turned on, the system heats up in the maximum mode of 87 degrees. About 1-1.5 minutes and turns off, then after 1-2 minutes by 37-50 degrees (I did not understand the laws of power) is turned on again. What could be the cause of the breakdown? Is it possible to make an adjustment so that it warms the system longer in the minimum burner mode and, accordingly, turns on less? I read the instructions, I did not understand anything. What kind of parameter is an absolute maximum power, what does it affect? It is immediately clear that the poor circulation! If everything was fine after installation and launch, i.e. It warmed well, first try to clean the rude cleaning filter on the return. He stands in the boiler, or maybe another installers in front of the boiler was mounted! Try to check the heating NTC sensor. This is a heating temperature sensor that controls the boiler turning on and off. It's OK. It is checked by the usual tester for the dependence of "temperature - resistance". There are two questions for the work of the BS 24 FF boiler: is it possible to somehow set a delay in switching the boiler from the heating mode at at least a few seconds in case of short-term opening of the crane with hot water (the instructions have the “Lencing Delay” and “POSTICTION OF THE INSTALLY. After working in the DHW mode ” - what are they responsible for?). I see on the “PUMP Speed” circuit - the question is the following, what speed of the circulation is set according to factory settings, whether it can increase and whether this will give an effect if the last battery in the circuit warms up worse than the previous ones. Installed wall boiler class 24 FF. I turn on hot water, on the D50 monitor, the boiler turns on, there is hot water of 15-20 seconds. The boiler turns off, on the H50 monitor, 5-10 seconds, the water in the tap cools. Then the boiler will turn on on the D50 monitor, again 15-20 seconds and everything is repeated again. According to the description, H50 means that the temperature is achieved. The “glitch” of the NTC sensor is quite possible. Also watch the settings of the gas valve - the maximum / minimum. Maybe the boiler really heats the water to 50. It is necessary to watch and check the gas valve setting up. During the removal of the heat exchanger for washing, water hit the gas valve, after drying for about a day the boiler turns on, the pump begins to work, but neither spark nor ignition occurs, after a few seconds it gives out an error 502 (the flame is found with the gas valve closed). What could be the reason? By all grounds, the moisture fell not only on the gas valve, but also on the control board. The flame identification is carried out precisely by the control board. It is necessary to invite a heat exchanger to be a washer - let it now heal the control board. Last fall, the Ariston Clas Evo 24 FF boiler was installed. I put it, and until recently, everything worked fine. There was a problem-when opening a hot water crane, the boiler begins to click quite loudly and stops 5-10 minutes after the crane closed. How to solve this problem yourself? This model has a weak link. The caliper (three -legged rod) - lets the water, and spoils the mechanics of the servo drive. Less commonly, this phenomenon was observed on the UNO model (the valve and the servo are located horizontally), but in this case the motor was burning, and the front spring flies in the classroom. The wall gas -water -circuit boiler Ariston Class 24 FF is installed, the DHW mode, the water mode begins, begins to heat the water and the rivet appears in the boiler, an error 1P2 insufficient circulation occurs, this error of the heating contour, and the heating is turned off. What could be the reason? The reason is definitely in the incorrect survey of NTC sensors of the heating system. One of them behaves incorrectly. Another thing is that these devices were produced with three NTC sensors (two by heating and one according to the hot water) and with two NTC sensors - both in the primary circuit of the boiler. Understand the modification of the device and replace one of the sensors. In 2011, the Clas Evo System 28 FF boiler was connected. The boiler lay in the garage until now, it was not possible to install by coincidence. A month ago, he mounted the heating system, hung the boiler, launched CO, adjusted the radiators - all the same hot (well, as you put it yourself). But with hot water the problem. First there is a cold one (well, it is clear so far warmly), after 10 seconds it gradually heats up to a given one (though the temperature at the exit of the tap is not measured), it is normal for a few minutes, then hot and hot but not to boiling but still, then again cold and all the cold and all The cycle is repeated again. There is no hotel sensor in the boiler (I looked, they say that since 2009 they have not been put). The boiler at launch about this and says (ERR 201). The water in the house from the well + the deep pump and the accumulator, respectively, the CVS pressure ranges from 2 to 4.5 atm. (set on the pump automation unit). Tell me how to solve this problem with DHW. Put the DHW sensor - is it possible and will this help? Put a pressure gear at the input of the CVS boiler by 2 atm so that it no longer rises. To begin with, adjust the pressure relay to the difference “Turning on - Turning” in 1 AT. You have too much scatter. Automation of the boiler does not have time to respond. Perhaps you need to configure the gas valve.

Decoding

Group 6 codes are caused by problems with the duct system. With error 607, peripheral devices have nothing to do with it: it is a consequence of problems with the equipment. In boilers of the Clas 24 FF series, it manifests itself in the form of ignition failure when Ariston is turned on, with the 607 symbols simultaneously displayed (accompanied by rotation of the fan shaft). The EGIS PLUS 24 FF models are different: the blades do not rotate.

Error 607 on the Ariston boiler display

The instructions say that the pneumatic relay contacts are closed even before the boiler is turned on. But the electronic board (“the brain” of Ariston) cannot be excluded from the list of “suspects”. Equipment diagnostics is carried out in stages, starting with the simplest actions.

How to work with the menu

By pressing the “OK” button once, the number 2 will blink on the digital indicator - this will be the first digit of the future three-digit code (Menu Group Number)

Using the plus and minus buttons you can change this value from group number 2 to any other group. To fix the selected group for further entering the code number, you need to press “OK” again - after this the second digit of the future three-digit code begins to blink (Submenu)

Having selected a submenu, fix it by pressing the “OK” button again and similarly select and fix the third digit (Parameter)

All! Now the screen will no longer display the three-digit code itself, but the set value of this parameter, which can be changed by pressing “plus” or “minus”. Having made the necessary changes, do not forget to commit them by clicking “Ok”.

Please note that after selecting the desired menu, after a few seconds of inactivity, a three-digit code will begin to be alternately displayed (to remind you where you are) and the parameter corresponding to this menu.

The ESC button is used to exit the settings menu and return to the previous step. The exit is carried out step by step, one press is equal to one step back.

Let's practice

Now, if you want, practice to better understand the switching order. For example, enter menu code 701; this will turn on the forced air removal mode, essentially turning on the pump in the boiler for 6 minutes.

When this mode is turned on, the “P I -” symbol will light up on the display. You can exit the “Anti-Air” mode without waiting 6 minutes by pressing ESC.

Then, using ESC, try to go back and switch to mode 300, which means (Set water temperature in the boiler) in the values you can see the temperature that is currently set by your DHW regulator.

Ariston CLAS 24 FF

The second variation of the popular boiler, the main difference of which is the presence of a closed combustion chamber. This equipment will delight you with the same advantages that are inherent in CF class equipment. The presence of a closed combustion chamber allows you to install the boiler anywhere. The forced smoke removal system makes this design the most acceptable engineering solution for small apartments and private houses that do not have a special room for installing gas boilers.

The Ariston CLAS 24 FF model will delight the user with high efficiency and amazing endurance when used in Russian conditions. The equipment is designed to work in aggressive climatic conditions, which makes it very popular in the northern regions of Russia.

Ariston provides high-quality service for gas burner equipment. This ensures that if any malfunction occurs, you will not have to wait long for the problem to be fixed. Any problem will be solved as quickly as possible and for relatively little money.

Self-installation of wall-mounted gas heating boilers

Installing a gas boiler with your own hands - we do it right However, not all manufacturers of gas heating equipment allow the installation of their heating units independently:

- Ariston, Viessmann, Bosch and a number of others oblige buyers to install a wall-mounted gas boiler exclusively by employees of certified centers;

- Some manufacturers, such as BAXI, Ferroli, Electrolux, are more loyal to this issue and do not prohibit unauthorized installation of wall-mounted devices. But in any case, for commissioning activities when arranging a heating structure, services will be needed from specialists who have permission to connect gas and electrical equipment.

Check what

Gas supply

Causes

- Ice blockage in the pipe.

- Freezing of the gearbox, “garbage” in the internal channel of the device.

- Fuel production - when gas supply to the facility from a cylinder group, gas holder.

- The main filter mesh is dirty.

- Meter failure.

- Road blocking. If a shut-off valve is installed on the pipe, it needs to be brought into working condition after each short-term power outage. A common cause of the sp1 gas boiler error.

Pipe pressure

The measurement is made with a pressure gauge, but not all users have this device. A gas stove will help you roughly estimate the main pressure. Light up the burners: by the flames and intensity of combustion it is easy to understand whether something has changed or not. Error sp1 of the Ariston boiler is associated with a drop in gas pressure.

Causes

- When transferring the Ariston boiler from main fuel to liquefied gas (LPG) or vice versa, the parameters in the menu were not reconfigured.

- A significant decrease in the volume of LPG in the tank (gas holder, cylinders) becomes the cause of error sp1.

- Incorrect operation of the gearbox. Clean it, warm it up, the fault code will clear.

Connecting the reducer to the gas cylinder

Ionization sensor

Controls the burner flame. If the electronic board does not receive a signal from the measuring device, the Ariston boiler is blocked with error sp1.

Causes

- Damage to the electrical circuit: break, unreliable contact, short circuit to the housing.

- Defective sensor holder. In most Ariston boilers it is located on the same assembly as the ignition electrodes. A crack or chip of ceramics causes error sp1.

- Wire contamination. Dust, soot, oxides accumulate on it, and sensitivity decreases. As a result, the sensor does not detect the flame after ignition, and error sp1 appears. Can be removed by cleaning the electrode.

Correct placement of ignition electrodes in an Ariston boiler

Ignition system

- Electrodes. The reasons causing the sp1 error are similar for the ionization sensor. Cleaning the wires clears the code. If the gap is increased, the spark does not jump or is weak, so there is no ignition. Check, fix.

- Ariston boiler ignition generator. The cause of error sp1 is damage to the electrical circuit: break, lack of contact. This resolves itself. Checking the unit for functionality is the prerogative of a professional.

Ariston boiler ignition generator

Gas block

The unit regulates the supply of “blue fuel” to the burner. If it does not work, ignition is impossible, error sp1 appears.

The reason is the gas valve

Electrical diagram of the gas valve

Cause

"Garbage" deposited from the highway. Obstructs or blocks the free movement of valve controls. If the channel does not open, error sp1 is displayed. For gas boilers, it is not uncommon for the smallest fractions to accumulate in the tube suitable for the unit. Disconnect, clean the cavity, the code will disappear. It is not recommended to disassemble the unit yourself; contact a service center for diagnostics.

Air supply channel

Lack of oxygen initiates the sp1 error.

Causes

Ariston atmo

- Insufficient ventilation in the room. It is easy to determine by swinging open the door and window sashes - the sp1 error will be removed.

- Operation of a powerful exhaust device in an adjacent room. When you turn it off, the sp1 error will be cleared.

Ariston turbo

- Icing of the pipe head of a coaxial chimney.

- Dust and frost on the filter mesh impair air flow.

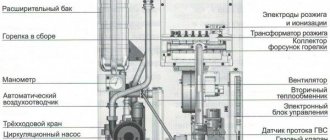

Electronic board

Errors are generated by the ECU of the Ariston boiler. Depending on the type of unit, the nodes differ in diagrams. The figures show two EPU options: CF – for naturally aspirated Ariston, FF – for supercharged models.

Electronic circuit of the Ariston CF boiler

Electronic circuit of the Ariston FF boiler

What to do

- Check the integrity of radio component housings and tracks. The detected gap is repaired with a wire shunt.

- Remove dust and condensation from the board. Dirt causes short circuits and errors in the Ariston boiler.

Useful tips

- In practice, there are frequent cases of “floating” error 108 of the Ariston boiler. Diagnostics of the circuit and equipment do not show any leaks, but the pressure in the system is slowly decreasing. The user has to recharge it periodically. The reason is in the expansion tank. Bringing the air in its chamber to normal eliminates the error.

- Ariston boilers, like all models of imported heating units, are sensitive to supply voltage. Jumps and deviations from the nominal value beyond the permissible value cause errors to appear and equipment to stop. This problem is completely mitigated by connecting Ariston to the network via a UPS. For objects located in rural areas, it is more than appropriate. Power supplies for boilers consist of a stabilizer, a group of batteries and an internal charger. No problems with industrial voltage or a backup electric generator will affect the operation of the heating equipment.

Heat exchanger clogged, reduced throughput

Often the fouling of the internal walls of the heat exchanger with scale or mud deposits is the cause of problems with hot water. If tap water does not undergo pre-filtration (rough cleaning) and the temperature of the hot water is too high, the walls of the heat exchanger become overgrown with scale and dirt over time, reducing their thermal conductivity and flow area. Each time the user increases the DHW temperature on the boiler more and more in order to obtain the desired result on the mixer. As the temperature rises, scale forms even faster and, as a result, the temperature of the boiler's hot water supply is at its maximum, and the water does not heat up enough. This process has a particularly negative effect on a boiler with a bithermic heat exchanger. Plate heat exchangers are easy to clean.

What to do

Checking that the parameters are set correctly

If the electronic board has been replaced, you need to make sure that it is “adapted” to this Ariston boiler model. Otherwise, errors cannot be avoided.

Checking connections

Code 105 is evidence of a lack of information exchange (or a failure in the GP-GIU chain). By inspecting the inside of the Ariston boiler, the signal lines are assessed. Breaks, short circuits (insulation melting) are the causes of error 105. The condition of the contact groups is checked for the absence of mechanical defects, oxides, contamination, and the quality of fixation.

Power check

- A low voltage value causes error 105, which is noted on thematic forums. Raise it and the fault code will disappear.

- Incorrect electrical connection. Error Ariston 105 is often displayed when a powerful consumer is turned on simultaneously with the boiler (with the “Comfort” mode set). By removing “COMFORT”, you can get rid of the 105th fault code by restarting the heating unit.

Grounding check

Illiterate organization, a violation of contact in the boiler-ground circuit initiates the appearance of error 105. It is also caused by interference, leading to malfunctions of the electronic board.

Advice

To eliminate the influence of stray currents on the operation of the Ariston boiler and the risk of errors, you need to install a dielectric coupling on the gas pipe. It's inexpensive and solves a lot of problems.

Connecting a dialectical coupling

Checking boards

- For dampness. Typical for Ariston boilers installed in rooms without heating. Condensation on the board causes various errors to appear. The problem is eliminated by blowing a stream of warm air.

- No damage. Panel curvature, breaks in conductive paths, burnt (melted) radio components are the probable causes of error 105.

- Diagnosis of nodes cannot be done at home - you need a special stand. But according to user experience, boiler error 105 can be removed by replacing the capacitors. They are located in the stabilizer circuit; loss of capacity leads to the appearance of a fault code (shown in the photo).

Display of capacitors on the Ariston boiler control board

If the operation of the boiler is not restored, you need to contact a service organization. And it must be certified by the manufacturer. Professionals interpret code 105 not as an error, but as information that the heating unit is in parameter setting mode. Their recommendations:

- install the display board on a working heating unit and check its operation;

- flash the electronic board.

It cannot be done at home, only in a hospital. The decision is justified - repairing the unit will cost several times less than purchasing a new one.

Installation Features

This device is quite quick and easy to install. Using the Ariston Egis 24 FF instructions, almost anyone who has ever dealt with gas burner equipment can do this. All electrical connections are accessible from the outside, which is very convenient.

If you are not confident in your strengths and skills, entrust the installation of the Ariston Egis 24 FF series to a professional who can not only install the unit efficiently, but also correctly configure its operation depending on your needs for heat and hot water.

Give preference to this particular technique when choosing the optimal heating unit, and you will never regret your decision.

For high-quality heating of medium-sized private houses (250-300 m²), the Ariston BS24FF boiler, operating on natural gas, is perfect. This is a fairly reliable product from a well-known Italian brand, with an affordable price. Unfortunately, the instruction manual supplied with it describes the design and functions of the heating unit rather briefly, so it is worth considering them in more detail.

Restart the unit

Press and hold the Reset button for 5–6 seconds. If error 303 is caused by power instability, it will be removed.

Press the Reset button to reset error 303 on the Ariston boiler control panel

Check signal circuits

Inspection reveals defects: breaks, melted insulation, short circuits, unreliable contacts. Anyone causes an Ariston boiler error. There is no need to interfere with its design - you just need to fold back the front panel.

Check the integrity of the wires in the Ariston boiler

Assess the condition of the boards

In addition to the electronic (“brain”), a unit with navigation buttons and a display is subject to visual testing. The cause of malfunctions and errors 303 is dampness. Even if there are no visible droplets of moisture (condensation), dust settled on the boards, when wet, turns into a conductive layer. Hence the short circuit and the fault code. Typical for Ariston boilers installed in rooms with excess humidity (kitchens, cold utility rooms). Gently clean with a soft swab and code 303 will disappear.

Ariston boiler control board

On a note!

If the steps taken do not resolve the 303 error, contact service. But only certified by the boiler manufacturer Ariston. It’s not worth contacting a “general profile” workshop for repairing household appliances: the lack of diagrams, methodological documentation, equipment, spare parts, and trained specialists will take a long time to solve the problem, and will be expensive in terms of money.

- Error 303 does not indicate a specific system, an Ariston boiler unit, it is internal to the ECU. The probable cause is a discrepancy between the secondary voltages and the required values, which leads to malfunctions of the board. To understand it, you need a detailed diagram and tables.

- User tips found on forums are vague. In addition, different boards are installed in Ariston boilers: it depends on the model, series of the unit, and year of manufacture. Therefore, the reasons for the 303 error are different.

When contacting the service, you must indicate the designation of the ECU (in numbers, letters on the panel). The technician will replace it with a working unit from the repair stock, and take the problematic unit for testing in a hospital setting. It will cost no more than 1000 rubles, while a new EPU for an Ariston boiler costs from 7200 to 10800. This solution is the most rational.

Other breakdowns

In addition to those described above, the following codes may appear:

- 608 - the system generates this error when the fan starts, but the pressure switch does not work.

- H45 - the last two digits may change.

The reason lies in the NTSc sensor, there is no hot water at the outlet, the safety valve is leaking. If there is no hot water, but the heating system is working, most likely the water flow sensor is faulty or clogged with debris. Another reason may be that the turbine blades have worked too hard, stuck to the housing, this can interfere with rotation, replace the blades or the turbine itself.

The second reason in this situation may be the NTC sensor; to check its functionality, measure the resistance at its contacts with a multimeter; if it is unstable, replace the sensor with a new one. If the safety valve is leaking, the gaskets may be worn out, replace them.

NTC sensor

How to determine the error code if the device does not have a display or does not have a dial, such as on the Ariston BS II 24FF model? This device is equipped with indicator lights, thanks to which you can determine the breakdown. So, for example, if the 90 indicator and the crossed out water drop icon are on, this means that the boiler has overheated and is blocked. To eliminate this, you need to check the pressure switch and its connection to the board.

How to enter closed menu sections using an access code

So, if you understand how to work in the menu, then it’s time to move on to more serious things. The vast majority of all settings are protected from accidental intervention by an access code. Therefore, to begin setting up the boiler, we perform the following steps.

Press “Ok” several times until the indicator shows the value 222 - Then hold down “Plus” until the value becomes 234 - then “OK” again - Everything is ready!

Now we have one number 2 constantly glowing and another 2 blinking - Which, as you understand, means the following - Menu 2 is turned on and you can select a submenu, and then a parameter. Having set the required three-digit code and clicking “OK”, we will see the parameter value that can be changed.

Use the ESC button to go back and move on to select other menu items and submenus.

Check what

The traditionally practiced reset for error 607 of the Ariston boiler will not help. This is also stated in the fault table (User Manual).

Fan

- Performance is assessed in dynamics (~220 per terminal). Remove the casing of the Ariston boiler, unplug the wires, and apply voltage from the outlet. If the impeller rotates, there are no complaints about the device.

- The presence of U coming from the ED is checked. If error 607 of the Ariston EGIS PLUS model occurs, the multimeter will show zero - no fan control.

Boiler pressure switch

Controls the operation of the fan. If the device turns on, it sends a signal to the electronic board that the Ariston boiler is ready to ignite. There is a microswitch under the cover of the pneumatic relay; a movable membrane is responsible for its operation. It shifts with air pressure flowing through the capillary tubes from the fan. The pressure switch is checked by closing the contacts: if the Ariston boiler ignites, there is a malfunction in the sensor.

Pressostat and boiler fan Ariston clean

Causes

- Clogged tubes. A common problem. Blocking of the channel is caused by the ingress of condensate and tiny dust fractions. Blow and the 607 error will disappear.

- Membrane deformation. Over time, solid particles accumulate on rubber goods, elasticity is lost, and when pressing on the microswitch, the contact group does not work. The solution is simple: the sensor body is non-separable, you just need to shake it a little and tap on the cover. But the service life after such actions is low, and the risk of error 607 appearing again for the same reason remains - the pressure switch will have to be changed.

- Microswitch failure: contacts sticking. The processor regards this as normal fan operation and does not give a command to turn it on. Unrecoverable, the pneumatic relay is rejected.