Many owners independently replace outdated taps in the kitchen and bathroom, taking into account the fact that the services of plumbers are expensive, and this operation is technically simple and does not require any skills. When installing a new plumbing fixture, you usually have to throw away the old hose for the kitchen faucet, which often loses its seal over time or after dismantling.

When choosing a new flexible eyeliner, several types of products on the market are considered, each of them has its own advantages and disadvantages. To make the optimal decision, it is necessary to study the features of each type of hose for water supply, read consumer reviews and products of well-established manufacturers on the market, and take into account the ease of installation.

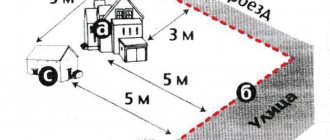

Examples of connecting reinforced connections

Where is the hot and cold water located on the tap?

On which side should the hot and cold water tap be? There are Russian and foreign standards. Their requirements for the location of taps differ.

According to Russian standards

SNiP from 1976 clearly states that in a water supply system, a faucet with warm water should be installed on the left side, and a tap with cold water on the right.

You can read about this in regulation III-28-75.

Warm water supply pipes are located in the system to the right of the cold risers . However, the outdated SNiP rules are no longer valid. But plumbers continue to model the water supply system according to the old standards.

That is why mixers are produced with the following indication:

- warm water - on the left side;

- cold - on the right side.

Sanitary requirements also regulate:

- Required pressure in water collection areas.

- The desired ambient air temperature in the heated room.

- Water consumption.

- Drinking water safety.

- Design of engineering systems in high-rise buildings.

- Fire safety system.

- Safety of hot water supply systems.

According to foreign standards

In European countries, the warm flow valve is located on the left side of the mixer. The current norms are simple and understandable to every person. In some countries, the mixer flow arrangement may be different.

Selection of material for installation

The choice of material is influenced by how the installation will take place, how the pipes will be laid - closed or hidden, ease of installation, i.e. the ability to do all the work yourself. Price is also an important factor.

Many sources still indicate that water pipes can be made with metal, but needless to say, this is already a thing of the past. And that there are a lot of good durable materials on the plumbing market that are quite easy to install, have a long service life, are reliable, harmless, i.e. They are perfect for drinking water supply and have a very nice appearance.

Below is a table with comparative characteristics of pipes used in the installation of water supply.

| Pipe material | price of pipes (rub) | fittings price | additional tool | difficulty of installation |

| skill required | ||||

| Stainless steel | Requires skill | |||

| Metal-plastic | + / — | Easily | ||

| Polypropylene | Easily | |||

| Polyethylene | Easily |

Which GOST regulates this issue, what does it say?

There is GOST 25809-96, which regulates the very design of the water tap, hoses, and outlet pipes. However, it does not regulate the supply to the mixer valves. The location of the water supply tap is determined only by the working drawing.

GOST suggests choosing the position of the hot and cold tap depending on the existing drawing of the system being modeled.

According to the European standard and the Russian standard, warm water is supplied from the left side of the mixer. Unless the plumbing customer requests otherwise, the water supply is determined as such.

Connection accessories

Before starting work on connecting the hose, you will need to purchase all the necessary materials. Each type of connection has its own list of required goods.

To the barrel

In order to carry out the procedure for connecting the hose to the barrel without any hitches, you will need to prepare the following available tools in advance:

- fum tape or specialized cream;

- connectors;

- union;

- coupling;

- filter.

It is advisable to purchase all components in a double set, especially if you have no experience in connecting pipes and hoses. There is a possibility of incorrect connection with further reworking of the work. Reattachment requires the use of new materials.

To the tap

When it comes to connecting a hose to a home plumbing fixture, the following list of items is required to be purchased:

- fum tape or sealing cream;

- connectors;

- union;

- coupling;

- clamp;

- threaded fitting (they differ; a different fitting option is selected for each specific situation);

- diverter.

The final list of required materials is influenced by the chosen connection method.

What to look for when installing faucets yourself?

Many apartment and house owners install the faucet themselves. The old SNiP regulations clearly stated the rules for the location of valves on the mixer. Therefore, professional plumbers continue to adhere to traditional standards. They are comfortable for most people.

When arranging the water supply system, it is recommended to pay attention to the comfortable use of water, the location of all valves, taps, and mixers convenient for each family member.

In the bathroom, it is important to consider the location and height of the shower hose holder.

Installation of water supply pipes

Although there are two different wiring schemes, in practice they usually use either a series circuit or a combined one - series-collector. The simplest materials in terms of installing water supply wiring are considered to be polypropylene, metal-plastic, cross-linked polyethylene pipes and copper.

Outdoor installation of water supply

– pipes run along the walls. For open installation, polypropylene pipes are most often used.

Hidden installation

water supply - pipes are laid in grooves and hidden with plaster, in a concrete screed, in the underground.

- The routing of water supply pipes starts from the entry point, i.e. source of water supply - pumping station, hydraulic accumulator, pressure tank, central water supply pipe entry.

The common supply pipe must have a diameter of at least an inch to ensure minimal pressure loss.

It is mandatory to install a coarse water filter and a shut-off valve.

Next, the installation of pipe routing begins according to the selected scheme, i.e. Pipes are installed in the bathroom, kitchen, and laundry room. If the pipework begins in the basement and the heating boiler is located there, then a separate exit to the boiler is made.

For sequential wiring, if you do not plan to hide it with decorative panels and a box, it is recommended to install the pipes 15–30 cm above the baseboard. Thus, the pipes will be inconspicuous and in some places hidden by plumbing fixtures.

When laying through walls and ceilings, pipes should be protected from damage. To do this, a casing pipe or a special collar is placed in the hole.

The pipes are fixed using special clips, plastic and metal clamps.

What to do if the sides are mixed up?

Incorrect placement of water supply hoses to the mixer causes great discomfort to many people. A hose with blue spots is used only for installing cold water supply. With red ones - for hot.

To resolve incorrect installation, it is recommended:

- Close the riser valve.

- Remove the nut from the distribution socket.

- Change hoses.

- Reinstall the hoses.

- Install new gaskets under the nuts.

- Check connections for leaks.

- Open the tap and check the flow.

The tubes must be swapped under the sink. The hot water supply is connected to the left socket. To the right - cold. The system can install universal hoses with blue and red shades. They are suitable for supplying both warm and cold flow.

Everything you need to know about hot water is presented in this section of the site.

Design and types of hoses for the mixer

The overwhelming majority of kitchen faucets on the market have standard inlets for supplying cold and hot water with a cut internal thread with a diameter of 10 mm. To connect to the mixer, the liner is equipped on one side with a fitting with an M10 thread (the height of the threaded ridge is 10 mm), and on its opposite end there is an American type fitting.

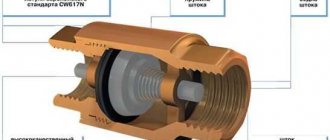

The American one includes a union nut placed on the widened (flared) end of the sleeve and a sealing gasket. When the nut is screwed onto the threads of the supply pipes, the ring seal is compressed and ensures the tightness of the connection.

The standard internal diameter of the union nut for connecting a kitchen faucet to water supply pipes is 1/2 inch (15 mm), and there are other less popular nut sizes - 3/4, 1, 1 1/2, 1 1/4, 2, 2 1 /2 inches.

Not every kitchen faucet hose has a threaded nipple for connection to the plumbing fixture. Some expensive models from the world's leading manufacturers with high spouts and internal shower heads (German companies Grohe, Hansgrohe, Blanco, Czech Lemark) are connected without threads by snapping.

Braided sleeves - device

Flexible braided hoses

The most popular and budget type of eyeliner. It is an elastic rubber tube placed on both sides in herringbone bushings and protected on top by a metal braid. The rubber casing (internal diameter 8.5 mm) is securely pressed against the fittings using pressed ferrules, ensuring a strong, tight and permanent connection.

In addition to ordinary rubber, high-quality hoses use tubes made of modern elastic material EPDM - a chemically produced elastomer, which is a peroxide cross-linked ethylene-propylene-diene rubber. Due to its high physical and chemical parameters (resistance to a wide range of temperatures and neutrality to most aggressive chemicals), the EPDM tube ensures a long service life of the entire product.

The outer shell of the sleeve consists of thin woven threads, the main material of which is aluminum or more expensive stainless steel; cheap galvanized steel is much less common.

Crimping sleeves in high-quality connections are made of plastic and durable AISI 304 stainless steel, the fitting and union nut are made of nickel-plated brass (grades UNI EN 12165 CW614N, UNI EN 12165 CW617N), in cheaper types - of AISI 304 stainless steel, O-rings and gasket - made of EPDM.

A flexible braided hose can be designed to supply only cold or hot water (individual threads are blue or red, respectively), but in everyday life, universal hoses with red and blue markings are most often used.

Braided hose - materials of manufacture

There are a large number of braided hoses on the market of domestic, Chinese and European production, which have a significant difference in manufacturing quality, on which the service life and physical and chemical parameters of the products depend. Therefore, when considering the technical characteristics, these factors should be taken into account, the main features of the braided eyeliner:

- The working pressure for products made of high-quality rubber and a stainless steel shell is 10 bar, the maximum can reach 20 bar; for budget varieties, these figures are on average half as low - 5 and 10 bar, respectively.

- The operating temperature range of the products is from 1 to 90 °C with a maximum of up to 100 °C.

- The service life of the hose depends on the quality of the hose and, accordingly, its cost; for budget types, its average is 5 years, for expensive ones 10 or more.

High strength multi-layer hose design

- Thanks to the elastic inner tube and outer reinforcement, the liner can be bent with the smallest radius, while a more budget-friendly product in an aluminum shell is more ductile and softer than with stainless steel reinforcement.

- The liner is easily connected to the mixing device using a wrench; first, the fittings are screwed to the body (for ease of connection they come in different lengths), then it is attached to the pipeline using the union nut of an American fitting.

- On the market there are reinforced, expensive models from foreign manufacturers that have a polymer (nylon, polyethylene) braid or two layers of metal and synthetics. This hose can withstand a pressure of 20 bar (tensile strength 80 bar) and has an average service life of 15 years.

- The main advantage of flexible hoses with metal reinforcement is their affordability; they are classified as budget products.

- The disadvantages of braided liners include the satisfactory reliability of their internal rubber tube - over time, it loses its elasticity, becomes brittle, cracks appear on the shell and the sleeve begins to leak.

Rubber braided and polymer hoses

Polymer

Water connections made of polymeric materials (cross-linked polyethylene, silicone, polyvinyl chloride) are often used in shower systems to attach shower heads; unlike their analogues in metal corrugated pipes, they do not scratch the surface of plumbing equipment - shower cabins, bathtubs. To increase strength, a metal spiral or a rigid cord made of synthetic threads is often located inside the polymer tubes.

To connect mixing devices, polymer hoses are used much less frequently and usually in models for kitchens from foreign European manufacturers. Polymer liners have high temperature (up to 100 °C) and pressure (working pressure up to 20 bar) characteristics, a long service life of at least 15 years.

Bellows liner - physical characteristics of Laflex brand products

Bellows hoses

A bellows connection is a corrugated (compressed in the transverse direction) thin-walled 0.3 mm stainless steel pipe (AISI 304 grade) with connecting fittings at the edges. In appearance, the bellows corrugated pipe is similar to a hose for a kitchen faucet equipped with a retractable shower head. However, the latter has a completely different design - its outer shell is made of spiral-wound stainless steel (a similar design for shower heads), inside of which there is an elastic tube made of rubber or silicone.

To connect to the mixer, the corrugated pipe is equipped with a fitting with O-rings on one side and an American-type union nut on the other. The pressed fitting is made of stainless steel or brass, as is the American union nut, which is held on the flared pipe end.

Bellows hoses and examples of their application

The bellows corrugated pipe has the following features:

- The service life of high-quality stainless steel is quite long; for a bellows liner its average value is 25 years.

- It is clear that stainless steel can withstand significant temperatures; for thin-walled metal the working value is about 250 °C.

- The bellows tube is highly durable; it can be used to supply water with a working pressure of 16 atmospheres with a maximum of up to 50 atmospheres.

- Stainless steel is an environmentally friendly material, therefore it is safe for humans when used in drinking water supply lines.

- When bending, the corrugated surface of the sleeve prevents the cross-section of its shell from changing, that is, it cannot bend like a flexible polymer with complete blocking of the passage channel.

- The bellows corrugated tube dampens vibrations in the system and is resistant to water hammer and prevents salt deposition.

- The bellows is not very convenient when connecting in a confined space - it is less flexible than polymer hoses with or without braiding, and has a large radius of curvature.

- Also, the disadvantages of the bellows include its slightly higher price than its braided counterparts.

Hard eyeliners - varieties

Hard

Sometimes a kitchen sink is hung on the walls and does not have a cabinet underneath, in which case the usual eyeliner does not look very aesthetically pleasing. To give the appearance a style and increase its decorativeness, hard eyeliner is sometimes used, which has the following varieties.

Metal hoses

This type is usually used in expensive imported faucets; in them, the fitting for connecting to the tap does not have a thread, and the other end is connected to the pipes using an American one. The materials used to make the metal liner are corrosion-resistant compounds - chrome-plated or colored-coated brass, stainless steel, copper, bronze.

Fittings for connecting polymer pipes

Some plumbers prefer a reliable and rigid method of connecting a mixer using plastic pipes if they supplied water to the entire house or apartment. To implement this connection option, the retail chain sells special compression fittings with fittings for connecting to the mixer body - one of them is straight, and the second is curved at a certain angle. After screwing the adapters, a metal-plastic pipe is connected to them and clamped with a compression nut.

Examples of rigid connection of mixers

pros

The positive aspects of hard type eyeliner include:

- Looks quite stylish compared to flexible;

- Long service life, which is about 20 years;

- High quality materials that are not subject to corrosion;

- Installation is quite convenient (although it has its own nuances, so it cannot be called a purely plus);

- The product is reliable;

- Due to the smooth surface, keeping the eyeliner clean does not become a problem. Dirt does not accumulate on the tube;

- The device is not afraid of thermal and chemical influences and can withstand higher temperatures and changes than flexible analogues.

Installation with copper pipes

You will need - ¾ and ½ inch pipes (copper pipes have thin walls); gas-burner; a hacksaw and a metal brush for cleaning; flux paste; solder; fittings - adapters, elbows, crosses, tees, couplings, water sockets.

Installation of connections using soldering.

- The end of the pipe and the inside of the fitting are lubricated with a thin layer of flux

The fitting is put on the pipe until it stops

The connection is heated until the color of the pipe changes

Soldering copper pipes.

For open pipe laying, non-annealed pipes are used, for hidden pipes, annealed pipes are used (they bend easily).

Installation with metal-plastic pipes

Such pipes are used for both open and hidden installation.

When open, you can use press fittings (not dismountable) and clamp fittings (dismountable).

When hidden - only press fittings.

This is due to the fact that the clamp fittings weaken over time and require tightening with a wrench.

For installation you will need: 1 inch and ¾ pipes; fittings – elbows, couplings, adapters, tees, crosses; pipe cutter; calibrator; press tool for press fittings (can be rented); wrench for clamp fittings.

Metal-plastic pipes are sold in long-length coils, therefore, when laying pipes under screed or under plaster, it is advisable to use a solid pipe.

Metal-plastic pipes are sold in long-length coils, therefore, when laying pipes under screed or under plaster, it is advisable to use a solid pipe.

Installation of connections using threaded fittings.

Pipes and press fittings.

Minimum amount of authorized capital of LLC

It is known that in 2021 the minimum capital of an enterprise is 10,000 rubles. But here are some points to consider:

- Depositing funds into the LLC management company is not necessary at the registration stage. The company's participants have four months from the date of completion of registration to replenish the capital by 100%.

- Payment for the shares of the management company is made by each founder personally and in an amount that corresponds to his part.

- In the course of future activities, the enterprise has the right to increase its authorized capital. This procedure is possible through cash injections or other assets (property, securities and others).

- In the process of determining the share at the registration stage, participants should be aware that the nominal price of the share in the charter capital is displayed in rubles, but in the future it may increase along with the amount of capital.

- Measuring the value of an organization's capital can only be done if a notary body is involved.

As noted above, the lower limit of the authorized capital is 10,000 rubles. But there are a number of nuances here:

- In some types of activities, the lower level of the Criminal Code is higher. This applies to commercial banks, alcohol producers, insurers and other organizations.

- If there is any doubt whether it is better to choose an LLC or an individual entrepreneur, the entrepreneur must remember that in the second case there is no need for contributions. This is due to the fact that the entrepreneur’s area of responsibility is all of his property, and not just the management company.