No construction work is carried out without a hammer drill. The quality of the grooves created is influenced by an element that is unremarkable at first glance - the drill. Therefore, attention is paid to his choice.

The editors of the YaNashla website have prepared for you a rating of the best hammer drills for 2021.

Bur: purpose

Drills and drills are consumables, but their importance in the design is high. The element is a impact-cutting element. Novice builders sometimes confuse this product with a drill, but there is a big difference between the two.

The drill is made from alloy steel, but also has diamond brazing. This solution will increase service life and wear resistance. It has a tail part where special grooves are located, a spiral rod and a cutting part. Just like a drill, it is installed in a hammer drill chuck. We must not forget that the drill is a consumable item and is often used to create holes in a concrete or stone wall. The product should not be used on metals or wood as it is not intended for this purpose. For such purposes, it is worth purchasing the appropriate tools.

Drills are sold in different lengths and diameters. If a person is looking for an option for use at home, then a good solution is 6-10 mm. In this case, it is necessary to select a dowel that is suitable for these sizes. The maximum diameter is 5 cm. In the professional sphere, builders use material with a length of from 10 to 100 cm. It is important to understand that when making technical holes, compliance with the diameter and length is a mandatory requirement. This is the only way a person will ensure the greatest efficiency and durability of the nozzle.

A drill is not a drill

In terms of external signs, these elements have a minimum of differences, which is why an ignorant person may get confused and buy the wrong option. In addition, their purpose is also the same - creating holes. The only difference is that the drill is designed to work with plastic, wood and metal, but the drill is used only for concrete or brick surfaces. Often, because of this ignorance, people buy a standard drill, and when they get home they immediately break it.

The drill is many times stronger than a conventional element, and also has a larger size and diameter. The maximum cross-sectional value of the drill is 14 mm; for impact-cutting products this figure reaches 55 mm. In addition, the design of the shank differs. So the drill has special grooves, while the drill does not.

The product is used in every hammer drill, even hammerless ones, but it is not intended for use in a drill. Some drill models are manufactured with multiple cutting inserts and may also have a special geometry that holds it securely in the center of the hole. Also, impact cutting tools are durable, but the price of this product is several times higher.

Drill SDS plus-5X, 10x50x110 mm Bosch 2608833797 – a combination of quality and performance

The excellent quality of cutting tools equipped with carbide brazing will allow you to drill out concrete and brick walls and ceilings. Speed of passage and accuracy are ensured by a tip with four-way directionality. Drilling dust is discharged along spiral grooves along the main axis of the drill.

Pros:

- Excellent quality from a German brand.

- High performance.

Types of drills

Like most similar tools, the drill is not available in only one form; there are hundreds of variations in the store. Some are designed for concrete, while others are for dismantling. Depending on the design, the scope of application is determined.

Screw

This is a self-sharpening element that is used only when drilling deep holes. It is able to work for a long period and not break, while the quality of the grooves made is at a high level, no defects or cracks are formed. The durability of an auger drill is tens of months.

Often this element is used to create cylindrical holes. To create a groove of a larger diameter, it is necessary to use a pick, which functions on the principle of an electric hammer.

For dismantling and installation

Such models are designed for dismantling and work with many materials. To install electrical sockets, you need to use a part in the form of a crown. Using such a drill, a person will receive a high-quality hole of the correct shape, which will make it easy to place the necessary elements. This type is used for organizing water supply, as it is able to create the required diameter for laying pipes

For wood and earth

For wood, you can use not only a special drill, but also a drill, the latter will be many times superior to the element in terms of technical indicators and processing quality. Using such a tool, the working force will be reduced, and the chips will be separated quickly.

An earth drill is used to create round and neat holes. Thanks to the special structure of this device, a person will be able to create a hole of the required depth with minimal effort.

Chisels and chisels for rotary hammer

Such nozzles are used for breaking through concrete walls, as well as when dismantling a plaster layer or breaking off ceramic tiles. Certain models are used for drilling channels for electrical cables or when installing doors. Due to the different shapes, the equipment is selected for a specific job.

Without taking into account highly specialized nozzles, they can be divided according to their purpose into the following groups:

- for knocking down tiles, plaster, and similar materials - flat chisels;

- for making grooves, punching holes (for example, for small diameter pipes) - peaks;

- for small channels on the surface for cable routing - channel semicircular chisels.

Chisels and chisels have different shanks, as do drills and bits. Now let's look at this issue.

What to pay attention to

There are hundreds of attachments in the store, and it can be difficult to determine exactly which one is suitable for a particular situation. Sometimes it takes several minutes to find a drill, especially if there is no consultant on the sales floor. To quickly identify a tool, just look at the shape of the edge that is fixed in the chuck.

The product has a cross-section with a complex configuration, so it can be with a small groove, convexity, SDS, etc. Unlike a drill, a drill has a standard round shape.

A complex cross-section is necessary for this tool, as it guarantees a tighter connection with the chuck of the electric tool. All attachments are classified into different categories to make it easier for a person to find a specific model. However, despite all this diversity, two types are considered popular:

- Plus for 4 slots, this option is used for electrical appliances with low power, which are most often used in the domestic sphere.

- Max - intended only for professional use, as they have higher power.

Tail

You need to pay attention not only to the shape of the drill itself and the material it is made of, but you should also take a close look at the shape of the tail. They lend themselves to fairly accurate classification, and correct selection according to it is extremely important for working with a specific type of tool.

Let us identify the following types by their tails:

- SDS - ranks first in popularity, has a diameter of 10 mm and 2 grooves.

- SDS-plus is the second most popular, the tail is 10 mm in diameter with 4 grooves.

- SDS-max - popular, designed for heavy hammer drills and heavy work; they make such a connector on equipment from 20 mm to 80 mm.

- SDS-top is a less common type, has a diameter of 14 mm and 4 grooves.

- SDS-quick - instead of grooves there are protrusions, this is rare.

If necessary, you can resort to using special adapters for drills, for convenience, or combination with your specific device. Drills with the ability to strike for making medium and large holes are highly undesirable. The drill cannot be used as a drill in this case, and will only make the situation worse. This leads to frequent breakdowns.

General recommendations

In order for the part to serve the maximum period and not break at the wrong time, it is recommended to frequently lubricate moving parts. To accomplish this, gel substances (for example, products from ARSENAL) or in the form of a spray (for example, WD40) are suitable. In addition, the protective layer that is applied to the outer surface will prevent the corrosion process.

If a person plans to use a drill when carrying out home repairs, then it is not advisable to buy expensive equipment, since its potential will never be revealed.

Products from the domestic segment will become affordable elements with high reliability. If you treat such drills with care (lubricate, do not overload, clean), then their service life will double.

Cheap companies are good, but it is better to avoid such products, since the quality of the material used will be at a low level. Only if a person needs drills for one-time use, then it is worth buying them. In other cases, they are useless. It is better to purchase a product from a well-known brand that values its reputation.

When performing a large volume of work and frequently using a hammer drill, it is better for the user to buy professional copies, as they are more resistant to mechanical wear and will not break due to frequent use. In addition, the accuracy of such drills remains at a high level.

If the buyer does not know which option to choose, then it is best to choose a well-known manufacturer about whom he knows a lot of positive things. It is not recommended to trust fly-by-night companies or unknown Chinese companies.

By applying the described recommendations, the user will avoid common mistakes when purchasing and will carry out high-quality installation at home. It is important to understand that productivity is affected not only by the cost of the tool, but also by the equipment used. The latter plays a much more important role than the electrical appliance.

Correct sharpening

It is impossible to sharpen diamond drills, but some coated with pobedite can be sharpened, and this is done as follows. On a special circle, observing safety precautions. It must be remembered that the sharpening process is just giving the edge a ragged angle. An ordinary stone wheel is not suitable for sharpening knives and other products, and you should purchase a special diamond sharpening wheel. The drill is set at an angle of 180 degrees, then we proceed to turning. After the procedure, we move on to sharpening the second side.

Important information: Under no circumstances should you use a grinder as a sharpening device, it is dangerous to life! A disk designed for cutting metal is not intended for sharpening drills, and if it comes into contact with its hard coating (winter), the rotating disk can break in half; getting such a splinter in the face guarantees death. Observe safety precautions when working with power tools.

We told you what kind of equipment there is for a rotary hammer and what it is called. But its functionality does not end there. There are also many narrow-profile attachments, for example, for removing paint and varnish compounds or for making holes in the ground (hole drill). It should also be noted that the capabilities of the tool also depend on the power, so the higher it is, the more varied the work it can perform. If the equipment was only used for drilling concrete, now you know what other jobs it can do.

If you have any questions or have not found the information you are interested in, write to us in the comments and our specialists will prepare an article on the relevant topic.

Tags:

- Home renovation

Rate the material:

Rating of the best drills for home use

BOSCH 3.5x50/110 mm; SDS+

High quality product made of hard alloy. The unique shape and durability (with proper maintenance) will help complete construction operations faster. The cutting edges are made to 5 points, so the drill can easily enter stone or brick, leaving behind an even mark. To obtain a better result, the element has a reinforced surface seal.

The average price is 591 rubles.

BOSCH 3.5x50/110 mm; SDS+

Advantages:

- German quality;

- Hard material was used;

- Length 110 mm;

- Dust is quickly removed.

Flaws:

- Price.

ATTACK SDS+ (4x110 mm)

Cheap product intended for infrequent use. It is impossible to compare with the previous one, since they are made of different materials and are not suitable for all purposes. For example, if in the previous version, a person could not worry when working with hard rocks, then here preference should be given to looser and softer materials.

The average cost is 90 rubles.

ATTACK SDS+ (4x110 mm)

Advantages:

- Good edge;

- Optimal length;

- Price;

- Effective dust removal.

Flaws:

- For infrequent use.

Encore SDS-plus reinforced (4 mm; 50 mm; 110 mm;)

A domestic drill, which is made from cheap alloy steel. Therefore, if used frequently, it will quickly fail. But this is not such a significant disadvantage, since the cost of the product is only 50 rubles, so it’s easy to buy 10 pieces or more in reserve. Suitable for drilling holes in every type of concrete, it is also possible to work with some types of stone.

The average price is 50 rubles.

Encore SDS-plus reinforced (4 mm; 50 mm; 110 mm;)

Advantages:

- Good strength for a low price;

- High quality edges;

- Small price.

Flaws:

- It bursts quickly.

Metabo Pro4 (4x110 mm; SDS-PLUS)

A reliable drill, which is designed for carrying out household work at the highest level. It has distinctive accuracy, which eliminates distortions, even on the tenth or twentieth hole. Made from wear-resistant materials, with active maintenance the product will last for several years, which is also a big advantage.

Sold at a price of 200 rubles.

Metabo Pro4 (4x110 mm; SDS-PLUS)

Advantages:

- Efficiency;

- Performance;

- Long service life;

- Value for money.

Flaws:

- Not detected.

Bosch SDS plus-1 (4x50x110 mm; SDS-Plus)

A cheaper product from a German manufacturer, designed for making simple holes in concrete or some types of stone. The resulting grooves are distinguished by good accuracy and “cleanliness” of execution. The product is made of high-quality stainless steel, which maintains its nominal technical characteristics for a long period. The total length is 110 mm, the working value is half that and is 50 mm.

Sold at a price of 100 rubles.

Bosch SDS plus-1 (4x50x110 mm; SDS-Plus)

Advantages:

- Price;

- Good cutting edges;

- Durability;

- Strength characteristics.

Flaws:

- Not detected.

Heller Bionic Pro (4x50x110 mm; SDS-plus)

If a person is looking for a product made of durable steel that will last for several years and is distinguished by performance, this is the right option. Thanks to the tight double seal, the service life increases significantly. To quickly remove dust from the spiral, special three-dimensional technology is used.

Sold at a price of 250 rubles.

Heller Bionic Pro (4x50x110 mm; SDS-plus)

Advantages:

- Strength;

- Durability;

- Price;

- Dust removal speed;

- Performance.

Flaws:

- Not detected.

Drill bit for rotary hammers (6x50/110 mm) P4Plus Metabo 626204000 – versatility

The drill belongs to the universal class - in addition to concrete, brick and rocks, the tool goes through a certain thickness of metal. This is facilitated by the main and side cutting edges. Compliance with technological rules during assembly made it possible to increase the accuracy of passage and reduce friction. The drilling flour is effectively removed by the special geometry of the spiral groove.

Pros:

- Excellent workmanship.

- Withstands contact with metal parts.

- Strengthening the rod.

Minuses:

- Perhaps the price. But it is justified by technical capabilities and long-term operation.

Top best drills for the professional field

Expert PRACTICE QUADRO (25x1360/1500 mm; SDS-MAX)

A reliable and expensive drill designed for professionals. Using this tool, a person will be able to work with stone and brick surfaces, not to mention concrete and reinforced concrete. The product is made from the best metal alloy, plus it has a special coating that increases performance significantly.

Sold at a price of 3,700 rubles.

Expert PRACTICE QUADRO (25x1360/1500 mm; SDS-MAX)

Advantages:

- Service life over 3 years;

- For professionals;

- Durable metal.

Flaws:

- Not detected.

DeWALT (12x400/540 mm; SDS-max)

One of the best products that will suit every professional. Used in standard rotary hammers, but it can also be used in jackhammers. Thanks to the unusual shape of the spiral, waste products are removed instantly, freeing the hole from excess dust. Using this tool you can work with concrete, brick, etc.

Sold at a price of 1,990 rubles.

DeWALT (12x400/540 mm; SDS-max)

Advantages:

- Efficiency;

- Price;

- Works with many materials;

- Strength.

Flaws:

- Not detected.

Inforce (18x540 mm; SDS-MAX)

An excellent product designed for work with reinforced concrete and granite. It has a durable body, which is made from the best materials. Thanks to the self-centering effect, the resulting holes are precise, which is why the fasteners are tightly fixed in the grooves. In addition, this equipment shows good drilling speed and has little vibration.

Sold at a price of 2,970 rubles.

Inforce (18x540 mm; SDS-MAX)

Advantages:

- Strength;

- Performance;

- Value for money;

- One year warranty.

Flaws:

- Not found.

Gigant GRD (25x540 mm; SDS-Max)

A productive device made of steel and with a special coating that increases durability. The product is designed to work with many materials, including brick and soil. It is used by professionals for frequent drilling, as it has good operating speed and can withstand intense loads.

Sold at a price of 550 rubles.

Gigant GRD (25x540 mm; SDS-Max)

Advantages:

- Cheap model;

- Suitable for soil;

- Withstands high loads;

- Life time.

Flaws:

- Not found.

Kango (22x520 mm; SDS Max)

Option with a centering tip, which is designed for creating holes in concrete, brick and granite walls. Made from hardened steel that can withstand high loads and does not burst due to frequent use. The cutting edge is made with high quality and sharpened to 5 points, which allows you to easily penetrate hard materials.

The average cost is 2,150 rubles.

Kango (22x520 mm; SDS Max)

Advantages:

- Reliability;

- Life time;

- Strength;

- Designed for many materials;

- Good cutting edge.

Flaws:

- Not found.

Design features of a drill bit, what they look like

Before starting the work, the master determines which drill to use to drill the concrete. If used with a drill, the base will be round or hexagonal. No side grooves are made here due to the fact that this is not necessary. They are required when the master will work with a hammer drill, and are designed for stronger fastening of the part.

For drilling in monolithic slabs, a pobedit tip is used. It retains its sharpness for a long time even with intensive use. Pobedit is an alloy of tungsten and cobalt, with very high strength.

Note! Drilling with diamond bits is used to create recesses. They are cylindrical in shape and made of hardened steel, mounted on a rod to be secured in a chuck. The working edge can be smooth or serrated. To increase its strength, diamond coating is applied to it.

Using diamond drills is more expensive than conventional tools, but provides better results. When using such a tool, even the most durable types of concrete will be drilled quickly. The resulting holes will have smooth edges. When the master works in this way, the formation of dust and debris is almost completely absent.

Device

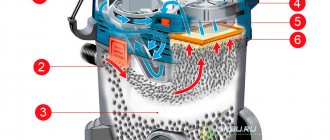

Regardless of the above-mentioned type, material and design features, drills for concrete hammer drills are built according to a standard principle. They are actually built from two parts: the shank and the working part. The latter, in turn, consists of 4 more zones:

- Spirals - spiral-shaped turns that help remove dust generated during the drilling process.

- The core is the main rod on which spiral-shaped turns and cavities are organized that remove dust.

- Channels for dust removal - peculiar cavities obtained due to the ribs of the spiral.

- The carbide cutting edge is the tip of the drill, which bears the main load during drilling. The effectiveness of work and the durability of the equipment depend on its quality characteristics.

How a drill for a hammer drill works Source redteh.ru

Important! When choosing a good concrete drill, pay attention to the location of the cutting plate. It should “sit” firmly in the saddle and be located strictly in the center.