A drill is a popular tool in the home. With the help of such a device, you can tidy up furniture and hang a picture in a short time. A universal tool can be of varying power. In order to understand how to choose a drill, you need to study the basic criteria and popular models.

Drill - a universal device for the home

The purpose of the drill, the difference from a hammer drill and a screwdriver

When choosing a device, you must first consider the scope of use. The tool can be used both in the apartment and in the country. The device will also be indispensable in the garage and small workshop. The drill can be used for the following purposes:

- drilling holes in concrete and brick walls;

- drilling in wooden surfaces;

- screwing in and removing bolts;

- metal drilling.

Depending on the power of the device, you can drill any surface. Therefore, such equipment will become indispensable during repairs.

Important! For universal use of the tool, users often purchase additional attachments.

The tool is used for drilling hard materials.

A screwdriver, unlike a drill, can unscrew bolts at different speeds, and can even cope with stuck specimens.

Some models come with an impact function, so they are often used instead of a hammer drill. However, it must be taken into account that a drill is not used for long-term drilling of concrete. For such purposes, it is necessary to purchase a hammer drill. The difference between the devices is that a drill drills, and a hammer hammer chisels and allows you to get large holes.

TOP hammerless drills

1

Metabo BE 850-2 BZP 850 W

Rating:5.0

- Power: 850 W

- Revolutions (rotation speed): 3100 rpm

- Weight: 2.6 kg

- Drilling diameter: 13-40mm

Average price: RUB 13,859

The tool is made of a lightweight and durable aluminum alloy body, which allows for optimal heat dissipation conditions, which increases the durability of the device. Equipped with a two-stage gearbox, the drill can provide both high torque and high rotation speed. The design of the spindle, made with a groove in the form of an internal hexagon, allows you to work with bits without a chuck. The cable entry is equipped with a hinge that reliably protects the wire from kinking and failure.

- The drill can operate in reverse mode;

- Reliable Metabo Marathon engine with dust protection;

- Safety coupling;

- Smooth rotation speed control is available using the wheel on the start button;

- There is an anti-slip Softgrip pad on the handle.

2

DP4010 720 W

Rating:4.9

- Power: 720 W

- Revolutions (rotation speed): 2900 rpm

- Weight: 2.3 kg

- Drilling diameter: 13-40mm

Average price: 9,200 rub.

The tool has expanded functionality due to the use of a two-speed planetary gearbox, which allows you to select the ratio of speed and torque that is optimal for the current job. There is a special mode switch for this. There is also a speed control located on the start button. Used for drilling plastic, wood and metal. The set includes an additional handle, a depth stop, and a jaw chuck.

- Durable housing;

- Conveniently located locking button in operating mode;

- No large vibrations during operation;

- Key chuck designed for drill shanks from 1.5 to 13 mm;

- The design uses a release clutch.

3

BOSCH GBM 10 RE 2009 600 W

Rating:4.8

- Power: 600 W

- Revolutions (rotation speed): 2600 rpm

- Weight: 1.7 kg

- Drilling diameter: 10-25mm

Average price: RUB 2,820

A compact and lightweight drill (1.7 kg with cord) that is great for working around the house. Designed for carpentry work, also suitable for drilling holes in steel, aluminum, and drywall. The shanks of the drills used are limited in size to 1-10 mm. The tool is distinguished by well-thought-out ergonomics of the body - there is a convenient protrusion above the start button for the placement of the middle finger, a soft rubber pad on the handle prevents the palm from slipping during operation.

- Smooth speed control with high discreteness;

- The reverse function allows you to use the drill as a screwdriver;

- High accuracy due to reliable fixation of the spindle in the bearing;

- Keyless chuck;

- Extended warranty – 3 years;

- No battery, works from mains.

4

Interskol D-16/1050R2 1050 W

Rating:4.7

- Power: 1050 W

- Revolutions (rotation speed): 550 rpm

- Weight: 4 kg

- Drilling diameter: 16-35mm

Average price: RUB 5,590

An inexpensive but powerful hammerless drill that can easily be classified as a professional drill. Suitable for mounting drills with a shank up to 16 mm. Designed for long-term heavy work, for example, such as installing dowels when assembling a house from timber. It is successfully used as a mixer - the extended kit includes a special nozzle and a set of keys for its installation. Equipped with a reverse switch and a working mode lock - you don’t have to hold the button during the entire drilling time.

- Key cartridge 3-16 mm;

- A special insert that allows you to store the key on the cord;

- The set includes two handles: side and rear;

- Warranty period – 24 months;

- Metal gearbox;

- The weight is above average for drills - about 4 kg.

Selecting a drill class

When choosing a suitable device, you need to know what types of drills there are. The type of device depends on the purpose of use and the material to be processed.

Household

Household drills are suitable for home use. They can be rechargeable or powered by electricity. Household appliances have average power and are easy to operate. Even women can use the devices without damaging their manicure. Since the handles are comfortable, and the tool works at different speeds.

Professional

Professional devices are used in workshops or enterprises. They have high power and cope with materials of various densities. The advantage of the professional model is that you can use the drill for 8-9 hours without a break. Household devices are not intended for such purposes.

Professional models are often used in enterprises

Semi-professional

Ideal for home use. Suitable for cottages and garages. It has good engine power and is suitable for operating time up to 5-6 hours.

The best drill manufacturers

Nowadays there are a huge number of different models of drills on the market. All manufacturers are in a hurry to assure the buyer of the undoubted quality of their products.

- Makita . Japanese company with more than a century of experience. The tool is produced in large factories, three of which are located in Europe. High quality and constant improvement of technology.

- HILTI . European tool manufacturer, dating back to 1941. The company has a huge number of factories on different continents and several research centers where new devices are created.

- Bosch . A well-known German concern for which tools are only one of the areas of activity. The drills of this company are distinguished by their high durability and German build quality.

- DeWALT . An American company specializing mainly in impact drills. It is considered one of the most promising brands of electrical equipment.

- HITACHI . Another largest Japanese concern that creates reliable and durable tools. The main emphasis is on ease of use, lightness and resistance to falls.

- Bison is a proven manufacturer, creating a wide variety of construction tools. Including impact and non-impact drills. They are distinguished by high power, build quality and low price compared to other brands. Most models are made in a metal case, which is good news.

- Interskol . A Russian company that has been on the market relatively recently. And despite this, she managed to conquer a niche among the world's leading manufacturers. High-quality models for various purposes and in various price categories.

Types of drills by purpose

In order to understand how to choose a drill, you need to study all the types. Each type of device has its own distinctive points that must be taken into account.

Regular drill

A useful device that has universal application. Designed for drilling holes in materials such as wood, plastic, thin metal. They work both from the mains and from batteries.

Impact drill

The device is equipped with a striking element. Therefore, it easily copes with hard materials such as concrete and metal. It can perform some functions of a hammer drill, but is not used for a long time without stopping.

Drill/driver

If you need to choose a useful device for the garage or small workshops, you should pay attention to a similar product. Using the device, you can unscrew complex screws and bolts. However, such a device is not suitable for drilling hard materials.

Drill/driver suitable for auto repair shops

Drill mixer

The ideal solution for construction work. The device has medium power and can be used for drilling holes. The kit includes special nozzles for mixing the compositions. Therefore, using a drill, you can mix a solution or putty in a short time.

Angle drill

The tool is used most often during construction work. Allows you to reach the most difficult places. An electric angle drill has average power and is often purchased only when necessary.

What is better to choose

There is no such thing as a universal tool. For fast and high-quality work, you need to choose the right power tool, from a non-impact drill to a hammer drill. If drilling with infrequent impact work is necessary, we choose an impact device. For large volumes of work on brick and concrete, it is better to purchase a hammer drill.

The difference in power tools is not small. Of course, to perform quality work, it is advisable for a master to have all three types.

Subscribe to TechnoCouncil on social networks so you don’t miss anything:

Main characteristics

In order to understand how to choose a drill for home use, you need to take into account the criteria that make the process of use comfortable.

Power

One of the main characteristics that must be taken into account when choosing a drill is power. At home, models with a power of 1000 W can be used. Using such a device, you can drill holes even in hard places. For professional use, you need to choose tools with a power of 1500 W.

Power type

When choosing a device, you need to consider the conditions under which the drill will be used. Portable and networked devices can be found on sale.

Network

Drills that operate on mains power have high power and are most often used in workshops and in the country. The advantage of such a device is the ability to work for a long period and cope with hard materials.

Rechargeable

Battery models are most often chosen if it is necessary to carry out work in places where it is not possible to connect to the network. The devices are small in size and have average power. They are powered by high-capacity batteries, which are enough for several hours of continuous drilling.

Battery-powered models allow you to work away from home

Shaft rotation speed

In order to purchase a quality device, you need to know how many revolutions the drill has. The speed of revolutions can be adjusted. Semi-professional models most often have a shaft rotation speed of up to 3500 rpm. This indicator allows you to process all types of materials.

Shaft speed switch

High-quality models have a speed control function and allow you to make the drill a universal tool.

Drilling diameter

Each model has specific recommendations for the diameter of the drills used. If you use more drills than specified in the instructions, the device may become unusable. Most often, the kit includes drills with a diameter from 0.3 mm to 30 mm.

Chuck type

There are several types of chucks: key chucks and quick-release chucks. In the first case, to change the drill, you need to unscrew the chuck with a wrench. In the second case, the drill is fixed with a chuck on a latch.

Important! Experts say that models with a key cartridge last longer and are suitable for hard materials.

Ergonomics

In order to select the right drill, you need to hold the device in your hand. The device should fit comfortably in the palm of your hand and should not strain your hand when working. Thus, the user will be able to work for a long period in the desired position without load.

No. 6. Shaft rotation speed and its adjustment

The rotation speed of the drill shaft at idle speed can reach 3500 rpm , but such a frequency is not always necessary. The higher this parameter, the faster you can drill a hole and the smoother its walls will be. High speeds are more necessary for grinding and polishing the surface, but they will also come in handy for impact work. In order to tighten the screw, 400-500 revolutions per minute will be enough.

The versatility of using the tool is ensured by the rotation speed switch. The simplest models use a step switch, while more advanced ones use an electronic switch that clearly responds to pressing force. If you press hard, you get maximum speed.

A speed limiter and soft start will also be useful . The latter allows you to smoothly accelerate the engine and ensures a gradual increase in speed from the minimum to the required one. This allows you to get rid of jerks at the start, overloads and drilling errors.

What else to consider when choosing a drill

When choosing a device, in addition to the basic characteristics, it is necessary to take into account additional ones. These include:

- fixing the power button. This characteristic allows you to ensure safe operation of the device;

- Auto shut-off function. The presence of this function prevents the drill from burning out during prolonged use. If the device gets hot, it automatically turns off;

- backlight Allows you to make a hole accurately, even in a dark room;

- dust collector Makes it easier to clean the room later.

Also, additional criteria include the presence of attachments. A second handle will not be superfluous, with the help of which it will be convenient to work in hard-to-reach places.

Additional features make the tool convenient to use

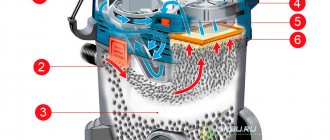

How does a drill work?

Briefly the design can be represented:

- housing made of durable dielectric plastic;

- an electric motor consisting of a stator and a rotor with windings;

- collector unit with brushes;

- buttons and a switch with thyristor regulation of the voltage supplied to the engine;

- worm mechanism for transmitting rotation from the engine to the working element;

- chuck for holding drills;

- air cooling system;

- handles;

- additional devices.

The layout of the parts of one type of impact drill is shown in the explanatory figure. It is clickable: when you click on the image, it increases in size for easy viewing.

Here you can see that the locking clamp is inserted between the stationary and rotating gears and rolls between them, thereby eliminating the possibility of their contact with the relief gear surfaces. This mode is created for normal drilling and taking the impact mechanism out of operation.

When it becomes necessary to knock out holes in stone or concrete structures, the “impact-drilling” switch removes the locking clamp from the gear engagement. The moving gear begins to press against the stationary one and, rotating under the force of the engine torque, rolls its relief along its figured surface, rises along its convexities and falls into the depressions.

In this case, the gear shaft, on the reverse side of which a chuck with a working element is mounted, performs not only rotation, but also a reciprocating motion, creating drill impacts on the concrete being processed.

For these blows to be effective, it is necessary to press the drill firmly and with good force through the drill body into the hole being drilled. This feature of the operation of this impact mechanism significantly reduces the engine power to overcome friction forces.

The simplest drills do not have this function.

Features of choosing a tool for working on concrete

To understand what a concrete drill is and which one to choose, you need to consider the following expert advice:

- the instrument must be of the impact type;

- to obtain a neat hole, it is necessary to have a function for adjusting the speed of operation;

- presence of two handles. During operation, the tool must be held firmly; this is difficult to do with just one handle.

It is necessary to select devices with high power. Since the concrete coating is dense and cannot be drilled with ordinary drills.

Which impact drill is better to choose?

To choose a good drill for your home or work, you should decide what kind of construction and repair tasks need to be performed. For household needs, as a rule, the resource of a household model is more than enough. Such devices are cheaper both to purchase and to repair - users do not need to overpay for unused functionality.

Professional equipment, despite the increased cost, is in demand both in the commercial sphere and for domestic purposes. Drills of this class are indispensable for private construction and production. High service life, unpretentiousness and endurance allow you to operate impact drills for a long time, without interruptions.

When purchasing, you should also refer to the recommendations of experts:

- A tool with a power in the range of 550-750 W is most optimal for home use. With its small dimensions and weight, it is able to cope with most one-time jobs.

- Drills with a power of 750 W or more are less comfortable to use, but are preferable in construction conditions or frequent use under load. The power reserve extends the service life, since the tool is less often used at its maximum capacity.

- Heavy devices from 1 kW are not suitable for precision work. But in terms of performance they have no equal.

- It is advisable to make the choice between household and professional equipment taking into account individual technical tasks. For large-scale construction, it is worth choosing tools that are resistant to overloads. In everyday life, purchasing expensive equipment may turn out to be unreasonably expensive, since modern household tools are fully adequate for such tasks.

A review rating of the best impact drills in combination of price and quality will help you decide which one best suits your needs. According to reviews, each of the presented participants has the characteristics necessary for stable and comfortable work.

Rating of electric drills

Among the large assortment of electric drills, it is necessary to highlight models that have repeatedly proven their quality.

DIOLD MES-5-01 BZP 550 W

The model has an affordable price.

The inexpensive model is easy to use and has a power of 550 W. Ideal for home use. The chuck is key, allows you to firmly fix the drill. The user will be able to independently set the shaft rotation speed, depending on the material being processed.

The cost of the device is only 1600 rubles.

Makita HP1640 680 W

The impact model is equipped with two handles for comfortable work.

An impact tool with good power will be an ideal option for a small workshop or garage. Two comfortable handles make work easy. The power of the device is 680 W, the speed of rotation can be adjusted independently.

The model has a drilling depth limiter.

Cost 4000 rubles.

For reference! Makita offers a wide range of models, depending on user requirements.

BISON ZSSh-300-2, 300 W

The tool has compact dimensions.

The drill-screwdriver has compact dimensions and universal use. Despite the low power of only 300 W, it is very popular. The speed can be adjusted, the body does not heat up even during long-term operation.

Cost 3000 rubles.

Makita DA3010F 450 W

The tool is suitable for hard-to-reach places.

The device has compact dimensions and convenient backlighting. Using a drill you can get to the most difficult places. Power 450 W. Suitable for cutters of various diameters. It is also necessary to pay attention to the low weight, only 1.4 kg, so the device can be operated with one hand.

Cost 16,000 rubles.

BOSCH GSB 13 RE

The tool is safe to use.

The impact model is semi-professional and is often used in workshops. The power of the device is 600 W, so the tool quickly copes with hard materials. The device is equipped with a power lock button and a drilling depth limiter.

Cost 4000 rubles.

When choosing an electric drill, you need to carefully study the popular models. In order for the tool to serve for a long period, important criteria and expert advice should be taken into account.

No. 8. Drill chuck type

Depending on how the drill is fixed, the drill chucks can be:

- key or serrated chuck fixes the drill with a key, clamps it with three symmetrical “petals”. It is believed that this fastening allows you to hold the drill more securely, therefore it is used in powerful and impact drills. The downside is the inconvenience when replacing the drill, since you need to use a special key. By the way, it can get lost, and then the time to replace it increases several times. Some craftsmen tie a key to a drill;

- quick release mechanism allows you to change drill bits very quickly using only a little manual effort. In terms of reliability, it is not inferior to the key chuck, but is still used only in drills with low power, designed to work with not very hard materials. In terms of durability, the mechanism is inferior to the key one.

Also, when choosing a drill, pay attention to the diameter of the chuck. The minimum value may be close to 0, but it is usually not necessary to use a grip less than 1.5 mm. The maximum value can be 10-13 mm and even 16 mm for powerful drills.

Determining the criteria for choosing an electric drill

But choosing a suitable drill is not at all difficult, you just need to formulate the selection criteria for yourself. The criteria for different people can differ radically (brand, price, power, design). However, it is more logical, starting with your own goals, to formulate the requirements that your future electric “assistant” must meet. What exactly are you going to do with it? “Repairs, of course,” my friend widens his eyes. “What else should we do with it?” But repair is a flexible concept. “Okay,” I suggest, “let’s make a list of the jobs that need to be done.” - “What’s there to put together, all sorts of little things: hang a cabinet in the kitchen, a picture in the room and a hanger in the corridor...”. He scratches the back of his head thoughtfully, looking somewhere inside himself. “No, by and large, we need to install three more additional sockets - in the kitchen, in the nursery and in the bedroom, rearrange the switch in the corridor, connect the wires...” The gaze gets out of the wilds of the soul and rushes past me, somewhere into the vast distances. “I also want to cover the balconies with clapboards, make bookcases and build a bunk bed for my sons: as they grew up, it became cramped. And a shoe locker wouldn’t hurt either, my wife has been asking for it for a long time...”

Well, now, at least, everything is clear: once a repair has begun, it cannot be finished, it can only be stopped. Nevertheless, the goals have been outlined; it remains to find the means to implement them. Correctly formulating a goal is half the battle done!

STERN Austria drills are a reliable tool for household use. This is the Hobby line - tools accessible to the general public

Design features of electric drills

Just as no two craftsmen are alike, no two power tools are alike. All manufacturers are improving their equipment, trying to increase its reliability, productivity, and ease of use. Therefore, when choosing a drill, be sure to pick it up, twist it, and ask to turn it on. The ideal option is to try to work a little. Leading manufacturing companies provide customers with this opportunity. For this purpose, large construction supermarkets hold presentations, master classes and other events where the capabilities of the tool are demonstrated. Don't miss the opportunity to try the tool in action! But let's return to the design features of drills. There are single-speed and two-speed drills.

Single-speed drills are lightweight and compact. They are ideal for working with wood, plastic, and tightening screws.

Two-speed impact drills are powerful, versatile tools that can be used for a variety of jobs. It is possible to obtain high torque at low rotation speed (for example, when drilling large diameter holes). Or high rotation speed with low torque (for example, during grinding work).

Reverse function . This is the ability to rotate the drill in both directions. This function is very convenient if you need to remove a screw or self-tapping screw. This function is also useful if the drill gets stuck in the material. If there is a reverse, it is much easier to release it.

Leading manufacturers are improving their equipment to make it reliable, productive and easy to use.